HEATEC VEGA PULS 63.UX User instructions

Figure 3. PLICSCOM indicating and adjustment module.

Figure 2. VEGA PULS 63.UX radar sensor.

Figure 1. Heatec vertical asphalt tanks.

Setting up Vega radar sensors

for Heatec vertical asphalt tanks

This document provides information for setting

up Vega radar sensors installed on Heatec tanks

that store liquid asphalt (Figure 1). It applies

to VEGA PULS 63.UX (Figure 2) and PULS

65.UX sensors with Indicating and Adjustment

Module PLICSCOM (Figure 3). It applies to

Heatec vertical tanks with capacities ranging from

10,000 to 35,000 gallons. The sensors are optional

equipment for Heatec tanks.

The sensors indicate levels of asphalt in the tanks.

Levels are shown in feet, measured from the

bottom of the tank.

This document is furnished with Heatec vertical

tanks equipped with the sensor. Applicable

operating instructions, published by Vega are also

furnished. Both documents are needed to set up the

radar sensors for Heatec tanks.

The sensors require a preliminary setup and a final

setup. The preliminary setup is normally done at

the Heatec factory. The final setup should be done

in the field after the tank is operational. If a new

sensor is installed in the field, and the preliminary

setup was not done at Heatec, it must be done

before final setup can be done.

Publication No. 5-04-116 Revised 6-17-10

HEATEC TEC-NOTE

Page 2

NOTICE

This document supplements the Vega manual

and should always be used along with the Vega

manual. Be sure to read all appropriate warnings

and precautions in the Vega manual before

doing any work on Vega sensors. The following

statement appears in the Vega manual and should

be followed:

Authorized personnel

All operations described in this operating

instructions manual must be carried out

only by trained and authorized specialist

personnel. For safety and warranty reasons,

any internal work on the instruments must

be carried out only by VEGA personnel.

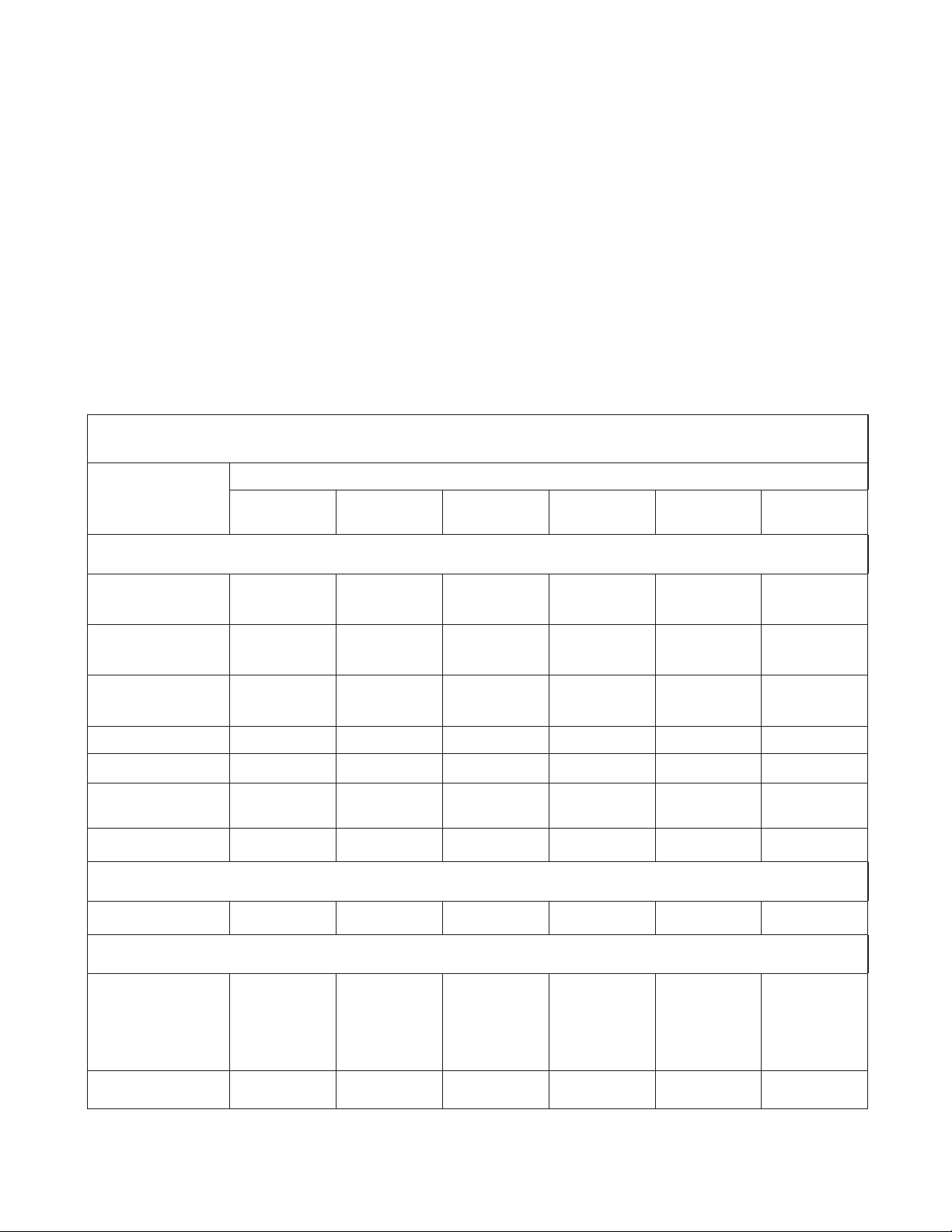

PRELIMINARY SETUP

The preliminary setup can be made either before

the sensor is installed on the tank or after it is

installed. Use the buttons on the PLICSCOM

module (Figure 3) to make the settings. Set the

sensor according to the settings shown in Figure

4. Do not change any settings other than the ones

shown in Figure 4. These are the settings we use

for preliminary setup of the sensors at the Heatec

factory. They are the only settings we change from

the original Vega factory settings.

HINT: Before trying to set the PLICSCOM

module, be sure to get familiar with its four

keys (refer to applicable instructions in the Vega

manual). When navigating the menu on the module

of the sensor, make sure the menu numbers

(which appear in the upper right-hand corner of

the display) match the menu numbers shown in

Figure 4. The menu terminology shown in Figure

4 should match the menu terminology that appears

on the PLICSCOM module.

NOTE: Please disregard any minor differences

in terminology shown in Vega manuals and the

terminology that appears in the display of the

PLICSCOM module. These differences should not

affect your setup procedure.

FINAL SETUP

Final setup of the sensor can only be done after the

sensor is installed in the tank. During final setup

the sensor creates an electronic profile of the inside

of the tank. It senses obstructions, such as ladders,

mixing blades, etc. It stores the profile in memory

and uses it to eliminate false echoes from those

components. This procedure is known as False

echo memory.

We normally run the false echo memory procedure

on empty tanks equipped with sensors at the

Heatec factory. At that time the tanks are new and

have never been filled with asphalt. The profile

we create should enable the sensor to provide

fairly stable and accurate indications of level.

However, the sensor will provide greater stability

and accuracy if the procedure is repeated after

the inside of the tank is coated with asphalt. The

sensor can be set to update the profile that was

originally made at Heatec.

We recommend that you update the profile after

the tank has been used for a while. Do this when

the asphalt level is barely above the heating coils

or at the lowest level before you would normally

refill the tank. If the tank has a mixer, make sure it

is running while performing this procedure.

Basic instructions for creating false echo profiles

are in the Vega manual.

Here’s how to build an accurate profile: Set the

sensor module to menu 4.1 False echo memory. You

will see the word: Change? Press the OK button

and you will be presented with three choices:

Delete, Update, Create new. Be sure to choose update.

Otherwise, you will delete the profile that was

created at Heatec.

NOTE: While you are running the false echo

memory procedure you will be prompted to

enter the distance from the sensor to the surface

of the asphalt. So, be prepared to make actual

measurements through the manway in the top

of the tank. You will need to measure from the

surface of the asphalt to the mounting flange of the

sensor.

TROUBLESHOOTING

The sensor may show erroneous readings if its

antenna becomes contaminated with asphalt

residues. If this happens you must remove the

sensor unit and clean the antenna using a solvent

Publication No. 5-04-116

Figure 4. Settings for VEGA PULS 63 and PULS 65

with Indicating and Adjustment Module PLICSCOM

SENSOR

MENU

HEATEC VERTICAL TANKS

TAV-10 TAV-15 TAV-20 TAV-25 TAV-30 TAV-35

1 Basic Adjustment

1.1 Min. adjustment 0.00%

16’ 06” 2/16

0.00%

24’ 06” 2/16

0.00%

30’ 06” 2/16

0.00%

38’ 06” 2/16

0.00%

44’ 06” 2/16

0.00%

50’ 06” 2/16

1.2 Max. adjustment 100.00%

2’ 00” 2/16

100.00%

2’ 00” 2/16

100.00%

2’ 00” 2/16

100.00%

2’ 00” 2/16

100.00%

2’ 00” 2/16

100.00%

2’ 00” 2/16

1.3 Medium Unknown Unknown Unknown Unknown Unknown Unknown

1.4 Vessel type Stirred Vessel Stirred Vessel Stirred Vessel Stirred Vessel Stirred Vessel Stirred Vessel

1.5 Damping 0 s 0 s 0 s 0 s 0 s 0 s

1.6 Linearization

curve Linear Linear Linear Linear Linear Linear

1.7 Sensor-tag Sensor Sensor Sensor Sensor Sensor Sensor

2 Display

2.1 Display value Height Height Height Height Height Height

4 Service

4.3 Current output

Output mode

Failure mode

Min. current

4-20 mA

< 3,6 mA

3,8 mA

4-20 mA

< 3,6 mA

3,8 mA

4-20 mA

< 3,6 mA

3,8 mA

4-20 mA

< 3,6 mA

3,8 mA

4-20 mA

< 3,6 mA

3,8 mA

4-20 mA

< 3,6 mA

3,8 mA

4.6 Select ft (d) ft (d) ft (d) ft (d) ft (d) ft (d)

Page 3

that will dissolve asphalt. Before removing the

sensor be absolutely sure to mark its position so it

can be reinstalled in the same position. Otherwise,

all of the false echo memory information will be

useless and the sensor will not function properly.

Note: The sensor has a small hole drilled in the

side of its stainless steel body. This hole should

always point towards the center of the tank.

REVISIONS TO SETTINGS IN FIGURE 4

Over the years we have revised the settings shown

in Figure 4 because we have found that some work

better than others for asphalt storage tanks. The

settings we now recommend are shown in Figure

4. If your unit is new, make sure its settings match

those shown in Figure 4. However, if you have an

older unit that has been in service for quite a while

and it is working well, there is no need to change

its settings.

EFFECT ON CONTROLLERS

The settings shown in Figure 4 are coordinated

with settings of the controller used with the radar

unit. Be sure to check controller settings to make

sure they agree with radar unit settings in Figure

4. Otherwise, level indications will be erroneous

and shutoff control will not work properly!

See Heatec Tec-Note 6-10-236 Setting Yokogawa

UT150 controller used with Heatec vertical

asphalt tanks or Tec-Note 5-04-120 Setting

Publication No. 5-04-116

Page 4

Figure 5. High-level proximity switch and float pipe protruding

through sleeve in top of tank.

Honeywell controller used with Heatec vertical

asphalt tanks.

SPECIAL SETTINGS

All of the current VEGA radar units used on

Heatec AC tanks have special factory settings.

These settings can only be made using a computer

loaded with special Vega software and a special

connect cable. These settings cannot be made

using the keys on the PLICSCOM module.

One of the special settings is known as SECURITY.

Prior to September 2004 it was set to ON. The

advantage of having this setting turned on, is that

the unit provides better control of tank overflow.

However, having this setting activated can

create a problem in an environment where

there is condensation of moisture and vapors. If

condensation accumulates on the radar antenna

it can keep the radar unit from working properly.

This may occur inside an asphalt tank.

Accordingly, radar units used on Heatec AC tanks

starting September 2004 have the SECURITY

setting set to OFF. This should eliminate possible

problems due to condensation.

If your Heatec tank uses a radar unit that has

settings made prior to September 2004 and you

think you may be experiencing problems due to

condensation, please contact the Heatec service

department.

NOTE: The Vega software is designed primarily

for use by original equipment manufacturers

(OEMs) such as Heatec. It is not recommended for

end users.

OVERFLOW PROTECTION

Turning off the SECURITY setting does not leave

the radar without overflow protection. However,

it could make the radar overflow control more

susceptible to problems if the radar antenna is

accidentally immersed in asphalt.

In any case, a backup system will prevent overflow

if the radar is not working properly. The backup

system consists of a proximity switch activated by

a float (Figure. 5 and 6). The proximity switch

will shut off the unloading pump when filling the

tank and the float activates the proximity switch.

An indicator light labeled HIGH ASPHALT FLOAT

LEVEL (at the unloading pump controls) comes

on when the proximity switch has been activated.

For more information on shutoff controls please

refer to Heatec Tec-Note 9-04-147 Heatec asphalt

tanks—maintenance.

In normal operation the radar shuts off the

unloading pump before the proximity switch is

activated. Thus, if the proximity switch shuts off

the unloading pump it means that the radar is not

working properly.

So every time you fill the tank pay special

attention to whether the indicator light for

high float level comes on. If it does come on,

this indicates that the radar failed to shutoff the

unloading pump and the shutoff was achieved only

by the backup system.

Publication No. 5-04-116

Page 5

Figure 6. Float for high-level proximity switch.

© 2010 Heatec, Inc.

Heatec, Inc. 5200 Wilson Road Chattanooga, Tennessee 37410 www.heatec.com (423) 821-5200 (800) 235-5200 Fax (423) 821-7673

If the radar fails to shut off the unloading pump

the most likely cause is that the radar antenna was

accidentally immersed in asphalt. This should not

happen in normal operation. Cleaning the radar

antenna should restore the radar unit to normal

operation.

In the unlikely event that both the radar and

proximity switch fails to shut off the unloading

pump, the asphalt level will reach the top of the

vent/overflow pipe inside the tank. It will then

spill into the pipe, which will carry it out of the

tank onto the ground at the bottom of the tank.

Moreover, if an overflow occurs, you can be sure

that the asphalt level was high enough to immerse

the radar antenna.

RESERVED SPACE

Some space in the top of the tank is reserved to

allow for expansion of asphalt and for overflow

control when filling the tank. So you should not

expect to fill the entire space inside a tank with

asphalt. Your volume of asphalt will always be

somewhat less than the volume of the tank.

The settings shown in Figure 4 cause the radar

to shut off the unloading pump when the liquid

reaches a level approximately 18-5/8 inches below

the bottom surface of the upper bulkhead inside

the tank. At this level the asphalt will be 38-1/8

inches from the bottom surface of the flange of the

radar unit. This is the surface from which all radar

measurements are made.

The proximity switch and float system is set up

to shut off the unloading pump when the level of

asphalt is approximately 7-1/8 inches from the

bottom surface of the upper bulkhead

OLDER TANKS

Certain dimensions on vertical tanks manufactured

prior to 2001 may differ from those on tanks

manufactured after that year. If a radar unit is

being retrofitted to a vertical tank manufactured

prior to 2001 you may need to use different radar

settings than those shown in Figure 4. Otherwise

the level indications may be incorrect. Please

contact Heatec service department for help.

TECHNICAL SUPPORT

For questions about sensor settings for Heatec

tanks, please contact the Heatec service dept,

phone 423-821-5200. Please have the model of

your sensor. If your sensor was installed at the

Heatec factory, please have the Heatec job number.

If you need a manual for the VEGA PLICSCOM

sensor you can download one from heatec.com/

literature/Tec-Notes/acTank_pubs.htm.

For problems with the sensor, please contact

Ohmart/Vega Customer Support at 1-800-367-

5383 or 1-800-543-8668. Please have sensor

model. Before calling, please verify that your

settings match those shown in Figure 4.

Publication No. 5-04-116

This manual suits for next models

1

Table of contents