PIPE +GF+ SIGNET

-

--

--

--

-

-

-

-

--

--

--

-

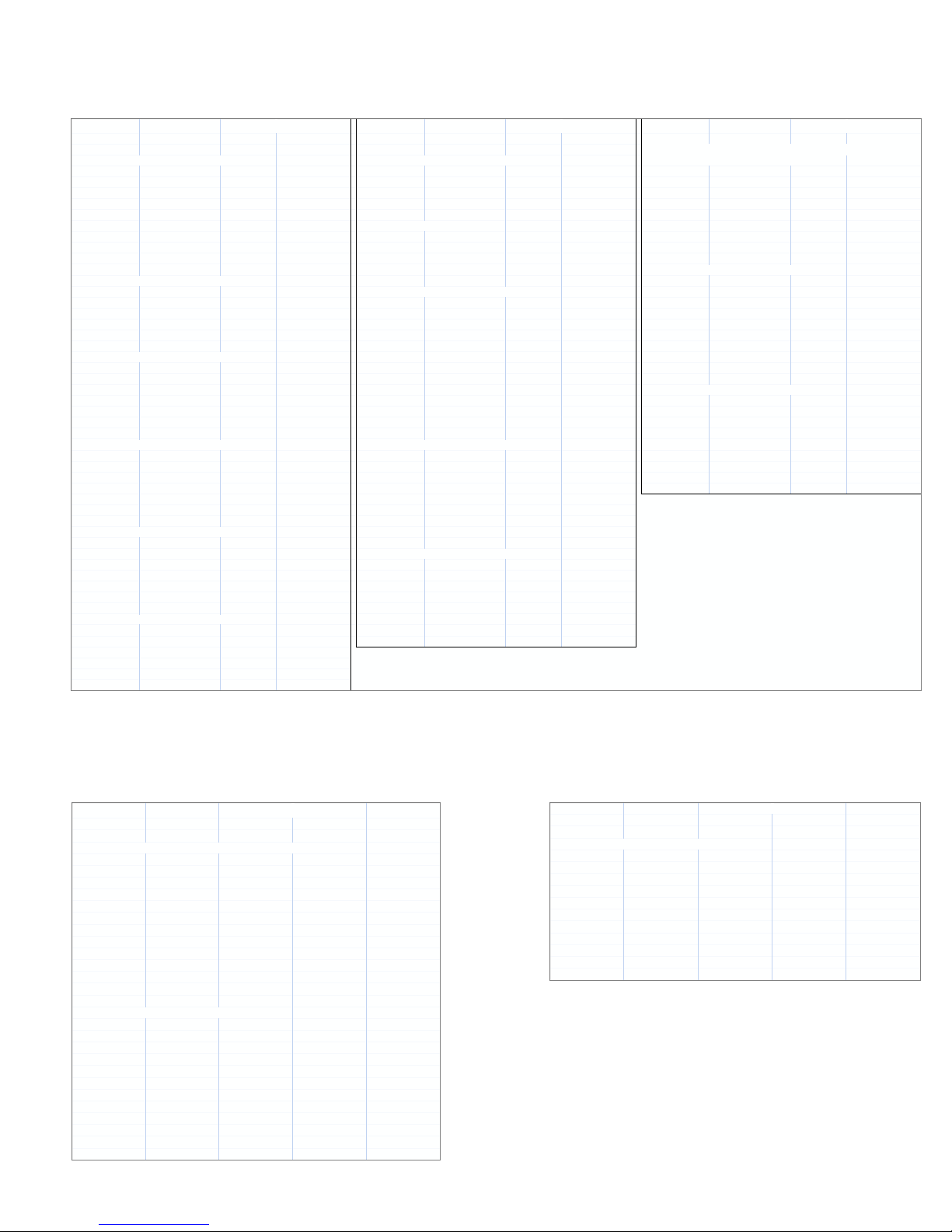

SIZE FITTING TYPE U.S. GAL LITERS

CODE

PVC FITTINGS (DIN/ISO) - EUROPE ONLY

DN 15 PVMT005 486.183 128.450 198.150.480

DN 20 PVMT007 242.846 64.160 198.150.481

DN 25 PVMT010 148.637 39.270 198.150.482

DN 32 PVMT012 85.125 22.490 198.150.483

DN 40 PVMT015 51.855 13.700 198.150.484

DN 50 PVMT020 29.750 7.860 198.150.485

DN 65 PVMT025 17.487 4.620 198.150.538

DN 80 PVMT030 12.491 3.300 198.150.539

DN 100 PVMT040 8.138 2.150 198.150.540

DN 150 PVMT060 4.088 1.080 198.150.543

DN 200 PVMT080 2.044 0.540 198.150.545

PIPE +GF+ SIGNET

-

--

--

--

-K

K-

-F

FA

AC

CT

TO

OR

R-

--

--

--

-

SIZE FITTING TYPE U.S. GAL LITERS

CODE

POLYPROPYLENE FITTINGS (DIN/ISO AND BS AND ANSI)

DN 15 PPMT005 481.553 127.227 198.150.522

DN 20 PPMT007 277.089 73.207 198.150.523

DN 25 PPMT010 141.181 37.300 198.150.524

DN 32 PPMT012 83.540 22.071 198.150.525

DN 40 PPMT015 51.265 13.544 198.150.526

DN 50 PPMT020 29.596 7.819 198.150.527

DN 65 PPMT025 20.658 5.458 198.150.560

DN 80 PPMT030 13.330 3.522 198.150.561

DN 100 PPMT040 8.708 2.301 198.150.562

DN 125 PPMT050 5.067 1.339 198.150.563

DN 150 PPMT060 3.689 0.975 198.150.564

DN 200 PPMT080 2.040 0.539 198.150.565

PVDF FITTINGS (DIN/ISO AND BS AND ANSI)

DN 15 SFMT005 420.868 111.194 198.150.529

DN 20 SFMT007 228.149 60.277 198.150.530

DN 25 SFMT010 136.697 36.116 198.150.531

DN 32 SFMT012 79.294 20.950 198.150.532

DN 40 SFMT015 43.490 11.490 198.150.533

DN 50 SFMT020 25.908 6.845 198.150.534

DN 65 SFMT025 18.067 4.773 198.150.571

DN 80 SFMT030 12.357 3.265 198.150.572

DN 100 SFMT040 8.060 2.129 198.150.573

DN 125 SFMT050 4.431 1.171 198.150.574

DN 150 SFMT060 3.227 0.853 198.150.575

DN 200 SFMT080 2.036 0.538 198.150.576

PIPE +GF+ SIGNET

-

--

--

--

-K

K-

-F

FA

AC

CT

TO

OR

R-

--

--

--

-

PIPE +GF+ SIGNET

-

--

--

--

-K

K-

-F

FA

AC

CT

TO

OR

R-

--

--

--

-

PIPE +GF+ SIGNET

-

--

--

--

-K

K-

-F

FA

AC

CT

TO

OR

R-

--

--

--

-

SIZE FITTING TYPE U.S. GAL LITERS SIZE FITTING TYPE U.S. GAL LITERS SIZE FITTING TYPE U.S. GAL LITERS

SCH 80 PVC TEES FOR SCH 80 PVC PIPE GALVANIZED IRON TEES ON SCH 40 PIPE COPPER/BRONZE BRAZOLETS ON SCH 40 PIPE

1/2 IN. PV8T005 480.190 126.867 1 IN. IR4T010 104.538 27.619 2 1/2 IN. BR4B025 18.800 4.967

3/4 IN. PV8T007 257.720 68.090 1 1/4 IN. IR4T012 62.979 16.639 3 IN. BR4B030 12.170 3.215

1 IN. PV8T010 174.670 46.148 1 1/2 IN. IR4T015 46.688 12.335 4 IN. BR4B040 6.960 1.839

1 1/4 IN. PV8T012 83.390 22.032 2 IN. IR4T020 29.459 7.783 5 IN. BR4B050 5.260 1.390

1 1/2 IN. PV8T015 58.580 15.477 6 IN. BR4B060 3.690 0.975

2 IN. PV8T020 32.480 8.581 BRONZE TEES ON SCH 40 PIPE 8 IN. BR4B080 2.130 0.563

2 1/2 IN. PV8T025 21.833 5.768 1 IN. BR4T010 104.538 27.619 10 IN. BR4B100 1.350 0.357

3 IN. PV8T030 13.541 3.578 1 1/4 IN. BR4T012 62.979 16.639 12 IN. BR4B120 0.960 0.254

4 IN. PV8T040 7.626 2.015 1 1/2 IN. BR4T015 46.688 12.335

2 IN. BR4T020 29.459 7.783 SCH 80 IRON SADDLES ON SCH 80 PIPE

SCH 80 CPVC TEES FOR SCH 80 CPVC PIPE 2 IN. IR8S020 32.360 8.550

1/2 IN. CPV8T005 480.190 126.867 COPPER TEE FITTINGS ON COPPER PIPE PIPE 2 1/2 IN. IR8S025 22.220 5.871

3/4 IN. CPV8T007 257.720 68.090 1/2 IN.SK K CUKT005 443.206 117.095 3 IN. IR8S030 13.420 3.546

1 IN. CPV8T010 174.670 46.148 1/2 IN. SK L 414.413 109.488 4 IN. IR8S040 7.660 2.024

1 1/4 IN. CPV8T012 83.390 22.032 3/4 IN.SK K CUKT007 212.156 56.052 5 IN. IR8S050 5.860 1.548

1 1/2 IN. CPV8T015 58.580 15.477 3/4 IN. SK L 191.086 50.485 6 IN. IR8S060 4.090 1.081

1 IN.SK K CUKT010 127.176 33.600 8 IN. IR8S080 2.330 0.616

SCH 80 PVC SADDLES FOR SCH 80 PVC PIPE 1 IN. SK L 119.840 31.662 10 IN. IR8S100 1.530 0.404

2 IN. PV8S020 32.480 8.581 1 1/4 IN.SK K CUKT012 88.218 23.307 12 IN. IR8S120 1.060 0.280

2 1/2 IN. PV8S025 21.833 5.768 1 1/4 IN. SK L 85.451 22.576

3 IN. PV8S030 13.541 3.578 1 1/2 IN.SK K CUKT015 56.962 15.049 SCH 80 IRON SADDLE ON SCH 40 PIPE

4 IN. PV8S040 7.626 2.015 1 1/2 IN. SK L 55.160 14.573 2 IN. IR8S020 26.820 7.086

6 IN. PV8S060 4.162 1.100 2 IN.SK K CUKT020 29.370 7.759 2 1/2 IN. IR8S025 18.800 4.967

8 IN. PV8S080 2.370 0.626 2 IN. SK L 28.605 7.558 3 IN. IR8S030 11.990 3.168

4 IN. IR8S040 6.850 1.810

SCH 80 PVC SADDLE ON SCH 40 PVC PIPE STAINLESS STEEL WELDOLETS ON SCH 40 PIPE 5 IN. IR8S050 5.330 1.408

2 IN. PV8S020 27.350 7.226 2 1/2 IN. CR4W025 18.800 4.967 6 IN. IR8S060 3.760 0.993

2 1/2 IN. PV8S025 18.874 4.987 3 IN. CR4W030 12.170 3.215 8 IN. IR8S080 2.130 0.563

3 IN. PV8S030 12.638 3.339 4 IN. CR4W040 6.960 1.839 10 IN. IR8S100 1.350 0.357

4 IN. PV8S040 6.728 1.778 5 IN. CR4W050 5.260 1.390 12 IN. IR8S120 0.960 0.254

6 IN. PV8S060 3.730 0.985 6 IN. CR4W060 3.690 0.975

8 IN. PV8S080 2.153 0.569 8 IN. CR4W080 2.130 0.563

10 IN. CR4W100 1.350 0.357

CARBON STEEL TEES ON SCH 40 PIPE 12 IN. CR4W120 0.960 0.254

1/2 IN. CS4T005 370.202 97.808

3/4 IN. CS4T007 212.063 56.027 CARBON STEEL WELDOLETS ON SCH 40 PIPE

1 IN. CS4T010 141.138 37.289 2 1/2 IN. CS4W025 18.800 4.967

1 1/4 IN. CS4T012 60.655 16.025 3 IN. CS4W030 12.170 3.215

1 1/2 IN. CS4T015 45.350 11.982 4 IN. CS4W040 6.960 1.839

2 IN. CS4T020 26.767 7.072 5 IN. CS4W050 5.260 1.390

6 IN. CS4W060 3.690 0.975

STAINLESS STEEL TEES ON SCH 40 PIPE 8 IN. CS4W080 2.130 0.563

1/2 IN. CR4T005 358.960 94.838 10 IN. CS4W100 1.350 0.357

3/4 IN. CR4T007 202.610 53.530 12 IN. CS4W120 0.960 0.254

1 IN. CR4T010 127.140 33.590

1 1/4 IN. CR4T012 61.910 16.357

1 1/2 IN. CR4T015 40.410 10.676

2 IN. CR4T020 22.300 5.892

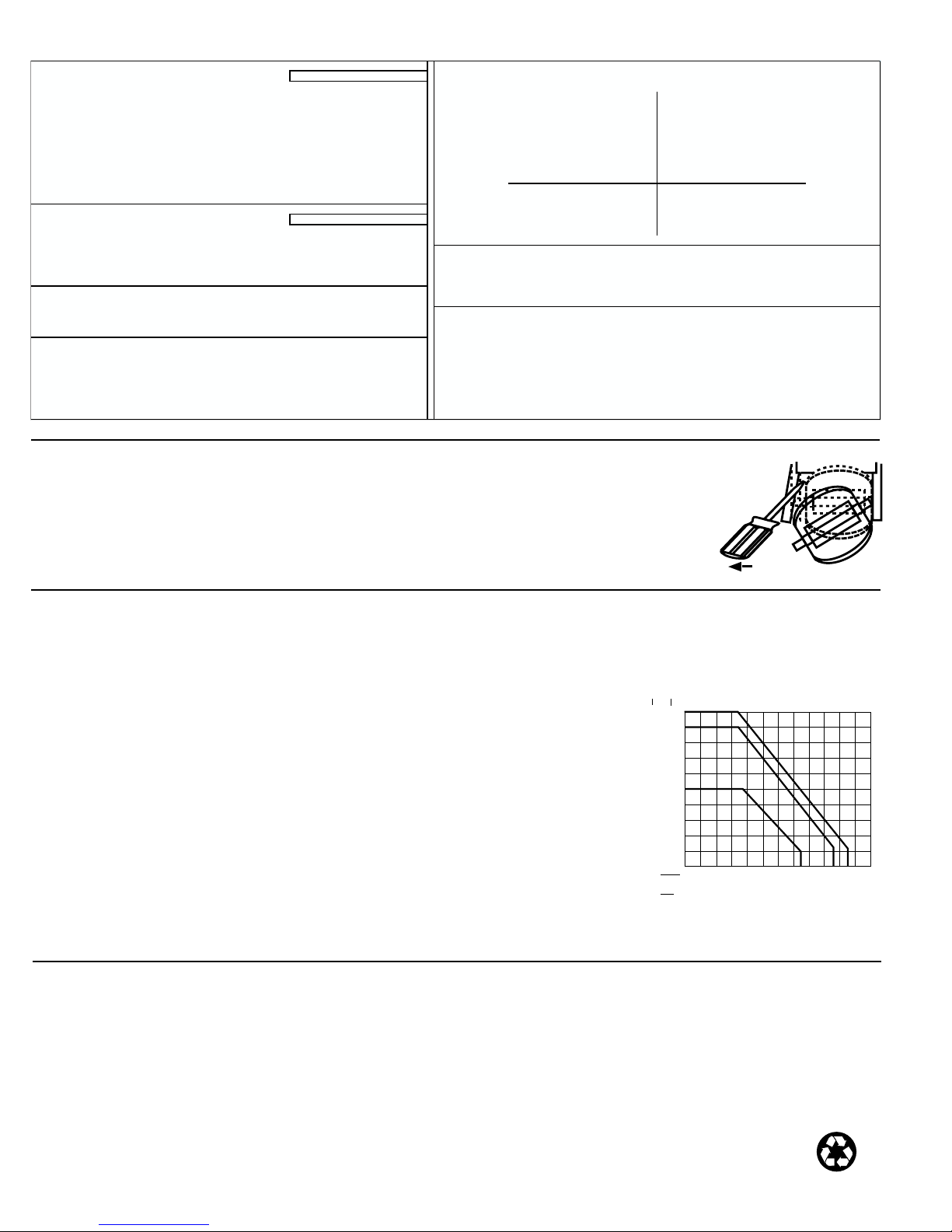

9. K-Factors

The K-Factor is the number of pulses the sensor will generate for each engineering unit of fluid which passes. They are listed in U.S. gallons and in liters. For

example, in a 1 inch PVC pipe, the paddlewheel generates 176.670 pulses per gallon of fluid passing the rotor. K-factors are listed for pipes up to 12 inch. For

pipes over 12 inch, consult your +GF+Signet distributor.

K-Factors DIN Pipes

Conversion Formulas

1 U.S. gallon = 0.003785 cubic meters

0.000003069 Acre feet

8.3454 pounds of water