Heater Sports HTR6000BBC User manual

IMPORTANT

DO NOT RETURN THIS PITCHING MACHINE TO THE RETAIL STORE WHERE PURCHASED.

CALL TOLL FREE: (800) 492-9334.

WARNING: THIS PRODUCT IS TO BE USED BY ADULTS ONLY. SERIOUS BODILY INJURY MAY OCCUR! MAKE

SURE MACHINE IS TURNED OFF BEFORE ASSEMBLY! KEEP HANDS AND ALL BODY PARTS AWAY FROM

BASEBALL ENTRY AND EXIT! SERIOUS HAND AND BODILY INJURY MAY OCCUR!

BASEBALL PITCHING MACHINE INSTRUCTIONS

BASEBALL PITCHING MACHINE LEG ASSEMBLY

STEP 1: Slide Sections A, B, C, and D together. Lock the sections together by making sure the push pins line-

up with each adjoining hole and lock into place.

Section A

Section B

Section C

Section D

Follow Step 1 to assemble all three legs for the

pitching machine. (There will be 16 leg sections)

®

PITCHING MACHINE AUTO-BALL FEEDER ASSEMBLY

STEP 1: Slide Sections A - B - C Together.

Section A

Section B

Section C

STEP 2: Insert 1/4” Short Bolt From Inside Of Feeder Through Hole In Feeder Bracket (4X).

1/4” Short Bolt

STEP 3: Place Washer Over Short Bolt. Screw on Nut And Tighten Nut (4X).

WARNING • WARNING

• Turn off pitching machine and

auto-ball feeder motor when

loading balls.

• Make sure batter is ready before

turning on auto-ball feeder and

machine.

• Make sure all persons stand clear

of pitching machine and ball path.

• Make sure all persons are aware

pitching machine is throwing balls

automatically.

• Make sure machine operator is

ready to turn off auto-ball feeder

power switch if necessary.

WARNING! WARNING! WARNING!

USE REAL BASEBALLS IN THIS MACHINE AT YOUR OWN RISK!

IT IS RECOMMENDED THAT YOU ONLY USE DIMPLED PITCHING MACHINE BASEBALLS TO PITCH

TO BATTERS. PITCHING MACHINES THAT USE A WHEEL TO THROW BASEBALLS WILL THROW REAL

BASEBALLS INACCURATELY BECAUSE OF THE SEAMS ON THE BASEBALL AND MAY HIT A BATTER

AND CAUSE PHYSICAL INJURY!

IMPORTANT: THIS PRODUCT IS TO BE USED BY ADULTS ONLY. SERIOUS BODILY DAMAGE MAY

OCCUR! MAKE SURE MACHINE IS TURNED OFF BEFORE ASSEMBLY! KEEP HANDS AND ALL BODY

PARTS AWAY FROM BASEBALL EXIT! SERIOUS HAND AND BODILY INJURY MAY RESULT!

Step 1: Slide galvanized steel legs into leg support tubes and tighten thumb screws.

Step 2: Insert auto-ball feeder tubes into auto-ball feeder bracket (2X) and plug in to housing.

Step 3: Place balls into auto-ball feeder. (Make sure the pitching machine is not plugged in.)

Step 4: Turn pitching machine variable speed control knob off (counter-clockwise until you hear a click).

Step 5: Plug pitching machine into 3 prong power outlet. (Make sure pitching machine wheel

is not spinning.)

Step 6: Aim pitching machine at desired target.

Step 7: Make sure every person and everything is clear of pitching machine ball path.

Step 8: Turn variable speed control knob on (clockwise to approximately #4 on speed control).

Step 8: Make sure batter is ready and turn on the auto-ball feeder.

Step 9: Adjust baseball pitch height by loosening the Pitch Height Adjustment Knob and rotating

the Baseball Housing to desired location. Re-tighten Pitch Height Adjustment Knob.

BASEBALL PITCHING MACHINE INSTRUCTIONS

95 West 650 South • St. George, Utah 84770 • PH: 800-492-9334 • PH: 435-656-1756 • Fax: 435-688-0741

Model# HTR6000BBC

®

Thank you for purchasing the Heater Pitching Machine. If you have any questions or comments

on how Trend Sports can improve the Heater Pitching Machine, please call our 24 hour custom-

er service hotline at (800) 492-9334.

WARNING!

• Do not put hands or

fingers in pitching machine.

• Make sure all persons are

clear of the baseball path and

away from pitching machine

before pitching any baseball.

• Make sure you pitch only one

baseball at a time.

• Make sure all baseballs are

out of machine before

turning the pitching machine on.

• Do not stand in front of

pitching machine.

• Do not operate in moisture.

• This machine may cause

serious bodily injury.

• For adult operation only.

• Batter must wear NOCSAE

Approved Batting Helmet.

• Pitching Machine Operator must

stand behind protective

safety screen.

WARNING!

• Only use dimpled pitching

machine baseballs to pitch

to batters. Pitching machines

that use a wheel to throw

baseballs will throw real

baseballs inaccurately

because of the seams on the

baseball and may hit a batter

and cause physical injury.

• Always have back legs

staked into the ground before

pitching to a batter or the Heater

Pitching Machine may move and

hit the batter and cause serious

physical injury.

• Make sure you pitch only

one baseball at a time.

• Batter must wear NOCSAE

Approved Batting Helmet.

• Pitching Machine Operator

must stand behind protective

safety screen.

95 West 650 South • St. George, Utah 84770 • PH: 800-492-9334 • PH: 435-656-1756 • Fax: 435-688-0741

Model# HTR6000BBC

WARNING • WARNING • WARNING

• Make sure pitching machine is aimed and throwing properly before allowing

batter to step up and hit balls pitched from the Heater Pitching Machine.

• Turn off pitching machine and auto-ball feeder motor when loading balls.

• Make sure batter is ready before turning on auto-ball feeder and machine.

• Make sure all persons stand clear of pitching machine and ball path.

• Make sure all persons are aware pitching machine is throwing balls automatically.

• Make sure machine operator is ready to turn off auto-ball power switch if necessary.

• Power Cords over 20 feet can lose energy and cause the Heater to pitch slower than normal.

HEATER SPEED CONTROL DIAL SPEEDS

Knob Setting = 10, Est. Speed = 50 MPH • Knob Setting = 9, Est. Speed = 46 MPH

Knob Setting = 8, Est. Speed = 42 MPH • Knob Setting = 7, Est. Speed = 38 MPH

Knob Setting = 6, Est. Speed = 34 MPH • Knob Setting = 5, Est. Speed = 30 MPH

Knob Setting = 4, Est. Speed = 26 MPH • Knob Setting = 3, Est. Speed = 22 MPH

Knob Setting = 2, Est. Speed = 18 MPH • Knob Setting = 0, Est. Speed = 0 MPH

Pre-Operating Instructions

Pre-Operation #1

Locate Allen Wrench (provided in package) and unscrew (3) three

wheel cover screws.

Pre-Operation #2

Tire pressure should be between 30 - 32 lbs. psi. If tire pressure reads

low, use an air pump to inflate the tire to 30 - 32 lbs. psi. If tire pressure

reads high, decrease the air pressure by pushing down the air stem

bubble located in the middle of the air stem. ••Inspect the air pressure

periodically to make sure air pressure is still within the 30 - 32 lbs. psi

range.••

Check The Air Pressure In The Heater Pitching Machine Tire.

Warning: Make sure Heater Pitching Machine is unplugged and the

tire is not spinning during these operations.

Pre-Operation #3

Locate Allen Wrench (provided in package) and secure Wheel Cover back

on machine by tightening (3) three Wheel Cover Screws.

Warning - Serious Bodily Injury: Never operate Heater Pitching

Machine until Wheel Cover is secured on the Heater Pitching Machine

with the (3) three Wheel Cover Screws.

Check Heater Fuse Reset Button

Fuse Re-Set Button

The Heater Pitching Machine has a fuse reset button which is designed

to protect the electronic circuit in the Heater Pitching Machine. If the

Heater will not turn on, check this button to make sure it is not popped

out. If it is popped out, press it back in to reset the fuse circuit breaker.

This should allow the Heater to operate safely again.

Important:

Make sure machine is unplugged and tire is not spinning during the

following operations.

••• Periodically inspect the tire to make sure it is not worn out or punc-

tured. Serious damage could result if operated in this condition •••

Read This Before Operating

IMPORTANT OPERATING INSTRUCTIONS

THE ACCURACY OF THE HEATER PITCHING MACHINE DEPENDS ON THE QUALITY, HARDNESS,

AND TYPE OF BASEBALLS USED WITH THIS PRODUCT!

TREND SPORTS HAS INCLUDED 1 BONUS HEATER PITCHING MACHINE BASEBALL (RECOMMENDED FOR

USE WITH THIS MACHINE) TO TEST THE HEATER’S ACCURACY AND PITCH SPEED. THIS BALL IS PRECISELY

CRAFTED TO PROVIDE YOU WITH HOURS OF ACCURATE, TROUBLE FREE BATTING AND FIELDING PRACTICE.

Heater Pitching Machine Baseballs

Heater Pitching Machine Baseballs are recommended for use with the Heater Pitching Machine. These base-

balls are the most accurate, longer lasting, and produce less wear and tear on the Heater Pitching Machine. •••

Please purchase at least one dozen of these baseballs. This will extend the life of the Heater Pitching Machine and

improve customer satisfaction. •••

IF BASEBALLS GET WET, THEY WILL NOT PITCH PROPERLY UNTIL THEY DRY.

KNOWN FACTS ABOUT DIFFERENT BASEBALLS:

The speed and accuracy of each pitch is dependent on the hardness, roundness, and type of each ball.

For example: If you have 12 baseballs and four are softer than the others (these balls will throw lower than the

other baseballs), if four are harder than the others (these balls will throw higher than the other baseballs), and if

four are not round (these balls will throw inside and outside). THIS LEAVES THE USER WITH THE IMPRESSION THAT

THE HEATER PITCHING MACHINE IS INACCURATE.

KNOWN PROBLEMS WITH THE FOLLOWING TYPES OF BALLS . . .

Simulated leather baseballs:

These balls are usually a cheap, inexpensive baseball and don’t pitch very fast with the Heater. Because of the

plastic simulated leather on these balls, consumers have thought the Heater was shooting out puffs of smoke.

This is incorrect. The puffs of smoke were coming from these baseballs because every time they run through

the machine, part of the cover gets turned into small dust particles and makes the consumer think these puffs of

smoke are coming from the Heater, wherein reality, the puffs of dust (or sometimes thought of as smoke) are actu-

ally coming from the simulated leather baseballs.

Real leather baseballs:

The Heater Pitching Machine should perform to your satisfaction as long as you purchase new, real leather base-

balls. However, the accuracy of these balls will vary more than with Heater Pitching Machine baseballs because of

the seams on real baseballs.

Table of contents

Other Heater Sports Accessories manuals

Popular Accessories manuals by other brands

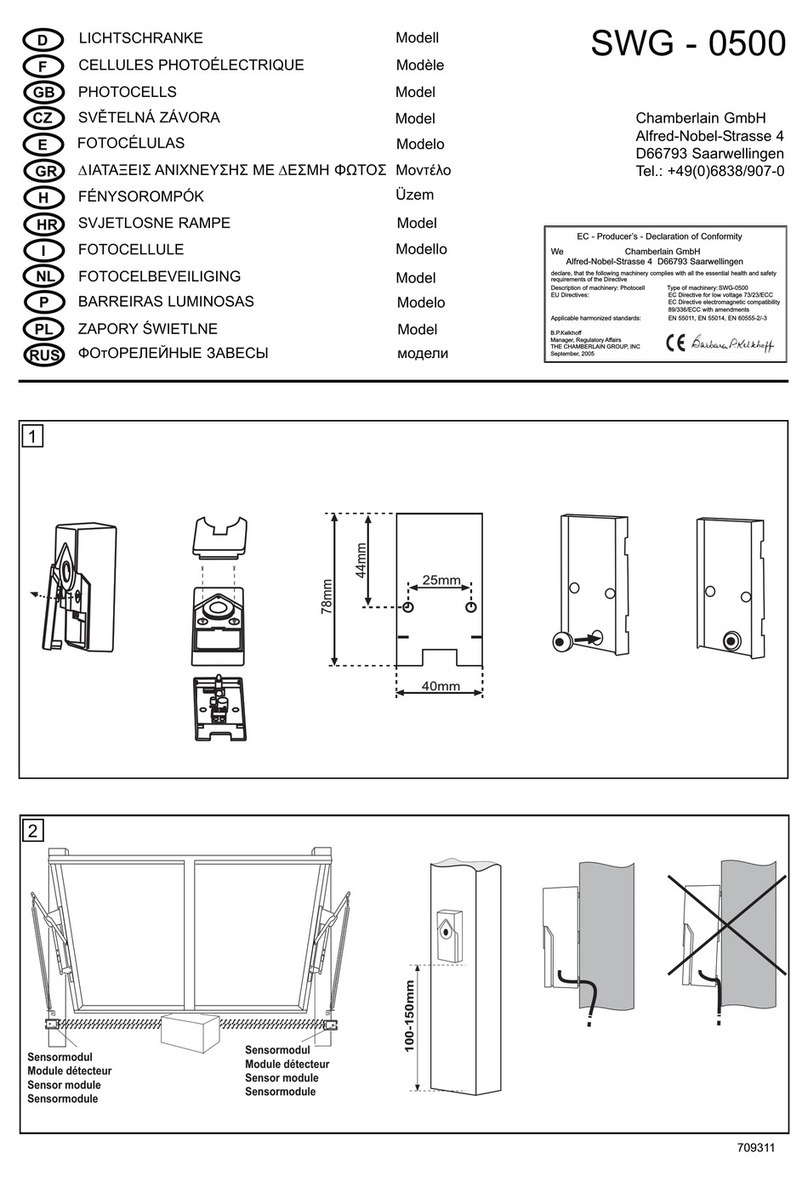

Chamberlain

Chamberlain SWG-0500 installation instructions

Newgy

Newgy Robo-Caddy Assembly instructions

Awaiba

Awaiba Dragster V3-8K-3.5 Calibration manual

Fisher Scientific

Fisher Scientific Isotemp 500 Series instruction manual

DURAVANT

DURAVANT QC Conveyors AS40 Installation operation & maintenance

Bogen

Bogen NR-100 Specifications