Heath Company RC-1 Installation instructions

SPECIFICATIONS

Time Constant:. ..................................................... 0.5, 1, 5 and 10 seconds

Ranges: .................................................................. 0-100, 600, 6000 and 60,000 counts per minute

0-.02, .1, 1 and 10 milliroentgens per hour

Meter: ..................................................................... Calibrated 4 1/2" 200 uampere movement

Probe: ...................................................................... Satin aluminum and chrome plated steel probe

contains extra sensitive type 6306 Bismuth Geiger

counter tube.

Speaker: ................................................................. Loudspeaker driven by transistor gives pleasant

tones on most sensitive range, no harsh clicks.

Muted by panel control.

Calibration: ........................................................... Calibrate control on panel, radioactive sample

furnished.

Batteries: ................................................................ 1 - 67 1/2 volt B battery (approximately 200

hours to 40 volt end point), intermittent

operation.

2 - 1 1/2 volt A batteries (approximately 20 hours

to 1 volt end point), intermittent operation.

Tube Complement: ................................................ 1 - 1U4 Amplification, pulse shaping and

1 - 3V4 counting tubes.

1 - 1U5J

1 - 5841 corona regulator tube

1 - 6306 bismuth counter tube

1 - 2N109 transistor (oscillator)

Provision for use of external meter (jack on panel).

Prewired high voltage power supply assembly.

Regulated 900 volt DC applied to 6306 tube in probe.

Coiled cord between probe and instrument, no tangling.

Cabinet: .................................................................. Aluminum, 9 1/2" high x 6 1/2" wide x 5" deep

Net Weight: ............................................................ 6 1/2 lbs.

Shipping Weight: ................................................... 8 lbs.

INSTRUMENT DESCRIPTION

The Heathkit Radiation Counter model RC-1 is a highly developed instrument, designed expressly for the serious

prospector. A prewired power supply delivering the required high voltage, coupled with a four tube amplifying and

pulse shaping circuit, gives extremely high sensitivity far in advance of most other counters now available,

regardless of cost. A large 4 1/2" meter calibrated in counts per minute gives f u ll scale readings from 100 cpm to

60,000 cpm. The meter is also calibrated in milliroentgens per hour (mR/hr) from .02 mR/hr to 10 mR/hr full scale.

An added feature is the use of a loudspeaker for aural monitoring, excited by a transistor oscillator, thus

allowing a more pleasing (to the ear) tone than the usual harsh clicks. To further increase its flexibility, the

circuit has been so designed to operate accurately and sensitively with the Heathkit Geiger Counter Probe

model GC-1, which uses a bismuth counter tube. Using the model GC-1 Geiger Counter Probe with the model

RC-1 Radiation Counber comprises an instrument more sensitive but otherwise equal to many now selling for

$250.00 or more. A calibrated, completely safe radiation source is provided with each model RC-1 for spot

calibration in the field.

THEORY OF OPERATION

Negative pulses generated in the probe are impressed across the input grid resistor through the .01 ufd

blocking capacitor and are amplified and inverted by V1, appearing across the 68 K plate load resistor. V2

further amplifies and reinverts the signal pulses and injects them into the grid of V3. The two stages of

amplification have been designed to have a sensitivity of approximately .1 volt and to limit at an input of .25

volts. This insures a pulse of the proper amplitude for triggering V3, even though the input pulses may vary

considerably in height.

V3 and V4 together constitute a mono-stable multivibrator, sometimes called a "one-shot," since it makes one

complete cycle for each pulse (trigger). Operation is as follows: The two tubes have a common cathode resistor

of 15K serving as one leg of the coupling impedance necessary for oscillation and also serving as a source of

cut-off bias for V4. The control grid of V3 is returned to a positive point on the voltage divider connected

between B+ and ground, causing it to conduct. This conduction causes current flow through the common

cathode resistor and the voltage drop across it is sufficient to cut V4 off, since the grid of V4 is returned to

ground. This enables the use of a tube with comparatively large emission capabilities as V4 without increasing

the B battery drain, since V4 is not allowed to draw current except during the short operating cycle following each

input trigger. The RANGE switch connects various precision capacitors between the plate of V3 and the grid of

V4 and, in conjunction with the common cathode resistor, provides the necessary cross-coupling to enable

multivibrator operation. The capacitors switched between the two tubes determine the period of time the

multivibrator will remain in its unstable state. This in turn determines the average current flowing through the

meter. The meter is calibrated in both COUNTS PER MINUTE and MILLIROENTGENS PER HOUR. The use

of precision capacitors to determine the range and therefore the current for full scale meter deflection enables

the use of a single calibration control. Calibration made at one point will hold to within 10% at all points. The

calibration control also enables the instrument to be calibrated even when the B battery is quite weak. The

overall circuit including the power supply sub-assembly has been designed to operate correctly until the B

battery voltage has dropped to 40 volts and/or the filament batteries have dropped to 1 volt or less. This has

been done to enable longest battery life commensurate with reliable operation and to preclude the necessity for

carrying an excessive number of spare batteries in the field.

An interesting departure from the usual method for aural monitoring has been incorporated in

this instrument. A transistor oscillator, using an output transformer as the oscillatory inductance, derives its

operating voltage from the voltage drop across a by-passed portion of the plate

load resistance for V4, voltage being present only during unstable state immediately following the

input trigger pulse. A small loudspeaker is connected directly across the output transformer and

reproduces the audio tone generated by the transistor oscillator. This tone may be varied by

adjustment of the 2K PITCH control to that most pleasing to the operator., Since it is an audio

tone and not a click, it can be recognized in even the noisiest locations and is invaluable when

prospecting in a moving vehicle or aircraft.

Page 3

Two filament batteries (ordinary flashlight cells) and a 67 1/2 volt B battery (such as is used in

most portable radios) supply all operating voltages for the instrument. The power supply sub-

assembly derives its operating voltage from the 67 1/2 volt B battery. Its output voltage is

sufficiently high (greater than 1200 volts) that it may be regulated at 900 volts for use with the

Geiger Counter Probe.

The meter used is a 4 1/2" 200 microampere movement for greatest sensitivity combined with

ruggedness. When the instrument is turned OFF, the RANGE switch puts a short across the meter

for added protection. A TIME CONSTANT circuit has been incorporated to give added flexibility

to the counter, allowing a meter time constant of 1/2 second to 10 seconds. The 1/2 second

position of the TIME CONSTANT switch is used when moving over the ground rapidly and the 10

second position is used when checking ore samples for the greatest accuracy.

OPERATION OF THE CORONA REGULATOR TUBE

(Courtesy of Victoreen Instrument Company)

The Corona Voltage Regulator tube exhibits many unique virtues when properly used to regulate

the output voltage of a high voltage, low current power supply. Like any other type of regulator, it

can be a tremendous source of annoyance when improperly used. Among its virtues are its

simplified circuits, low cost, good regulation, low power consumption, small spread between

starting and operating voltages, and its ability to regulate against variations both in load current

and input voltage. It is also mechanically rugged, supplies its own reference, has long operating

life and a relatively wide range of operating temperatures.

Since the operation of a corona tube is not widely

understood, a simplified discussion of its behavior

is appropriate.

In general, it may be stated that when two coax-

ially positioned cylindrical electrodes are

enclosed in a gas-filled envelope and a DC

potential is applied between them in such a

direction that the central electrode is positive

with respect to the outer, the unit may be

considered as a variable resistor which is very

current sensitive. The volt-ampere relations will

exhibit three distinctly different regions, as

illustrated in Figure 1.

The exact values of voltage and current for any one of these regions are determined by electrode

dimensions as well as gas nature and pressure, and other considerations. When these

parameters are selected to provide a useful corona region, the other two regions become limited.

Similarly, if the tube is designed for the glow region operation, the characteristic curve may

pass through the corona region so quickly as to be hard to identify.

Roughly speaking, these three areas of operation may be distinguished by the location of any

visible light. The corona will appear around the anode, while the glow appears adjacent to the

cathode. The arc is visible between the two.

Obviously corona tubes are useful for high voltage-low current application, glow tubes for medium

voltage-medium currents, while the arc involves higher orders of current and lower voltage drops.

As a voltage regulator, the corona tube is connected across the load whose voltage is to be

regulated, in series with the resistor, in the same manner as the more familiar glow tube regulator

would be used.

Page 4

The supply voltage is then divided between the series resistor and the parallel combination of

regulator and load, and the regulator tube tends to hold the voltage across the load constant.

For circuit analysis, the tube may be considered as a constant voltage source (whose value is

the nominal operating voltage of the regulator) in series with a resistance (computed from the

published regulation curve). For example, the type 5841, regulating at 900 volts with a regulation

of 1.5% between 5-50 ua may be considered as a 900 volt battery in series with a resistor.

From this equivalent circuit, other parameters may be established. In most cases, the

variations in load are predetermined by the application, and the variations in unregulated supply

are imposed by its nature, so the problem becomes one of evaluating the series resistor

necessary to produce the required degree of regulation. It should be pointed out that while high

values of series resistance tend to produce the best percent regulation, they also produce the

smaller values of regulator tube current and vice versa. The circuit used in the Heathkit

Radiation Counter tends to keep the operation of the tube as near the center of the corona region

as possible, since transients in the supply or load might cause the momentary operation of the

tube below the corona region (temporary extinction) or above the corona region (glow and arc).

In either case, serious instability would result.

When the supply voltage has appreciable ripple and/or large transients, such as are unavoidable

in the vibrator or fly-back type, considerable filtering is necessary between the supply and the

regulator. The positive peaks of the waveform of the voltage at the resistor in series with the

regulator must not be permitted to drive the corona into the glow or arc region nor must the

negative peaks be permitted to fall below the striking voltage of the regulator. Either condition

may introduce very objectionable AC components into the load.

The corona regulator greatly aids the filter in attenuating AC components. The AC components

ahead of the series resistor are attenuated at the load by the voltage divider action of the resistor

in series with the parallel combination of the load and the dynamic resistance of the corona. Since

the ratio of the series resistor to the parallel combination is usually high, the degree of attenuation

of ripple is also high.

Due to the relatively small spread between striking and operating voltage, its relatively low

dynamic resistance (300 K at 50 uamperes), its relatively short ionizing and deionizing time, etc.,

the corona regulator makes a very poor relaxation oscillator when confined to the corona region.

For this reason, small capacities may safely be placed across it to improve filtering. However,

care must be exercised, less a transient should inadvertently cause the tube to momentarily pass

sufficient current to swing it to the glow or arc region, which would dump the entire charge of the

shunt capacitor into the tube and permanently damage it, as well as temporarily impairing its

regulation.

Like the glow tube, there is a minimum

current required to sustain the corona in a

stable condition, but unlike the glow tube,

the corona tube may satisfactorily operate

in its unstable low current area if by-

passed with a capacitor to relieve the

transients produced in this region.

Adequate filtering ahead of the regulator is

required for this type of operation and the

degree of regulation may be slightly

impaired when operating below the

published minimum current. See Figure 2.

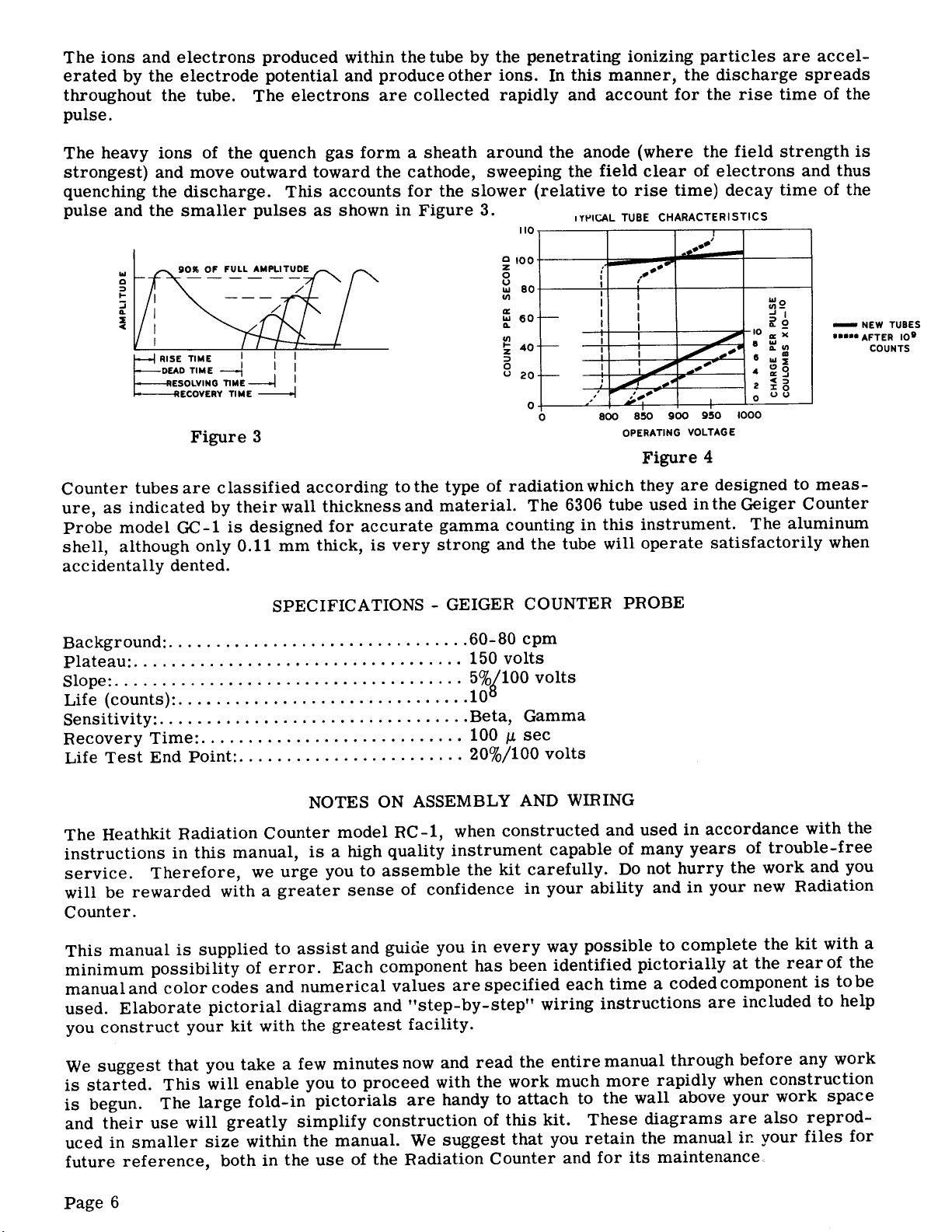

TYPE 6306 THYRODE TUBE

A thyrode counter tube is a gas diode designed to produce an electrical pulse when its sensitive

volume is penetrated by an ionizing particle.

Page 5

Read the notes on soldering below. Crimp all leads tightly to the terminal before soldering.

Be sure that both the lead and terminal are free of wax, corrosion or other foreign matter. Use

only the best rosin core solder, preferably a type containing the new activated fluxes such as

Kester "Resin-Five, " Ersin "Multicore" or similar types.

Resistors and controls generally have a tolerance of ±10% unless otherwise specified in the parts

list. Therefore, a 100 K control may test anywhere between 90 K and 110 K. (The letter K is

commonly used to designate a multiplier of 1000.) Tolerances on capacitors are generally even

greater. Limits of +100% and -50% are common for some types. The components furnished with

your Heathkit have been specified to enable you to obtain maximum performance, accuracy and

life from the completed instrument.

PROPER SOLDERING PROCEDURE

Only a small percentage of Heathkit purchasers find it necessary to return an instrument for fac-

tory service. Of these, by far the largest proportion function improperly due to poor or improper

soldering.

Correct soldering technique is extremely important. Good solder joints are essential if the

performance engineered into the kit is to be fully realized. If you are a beginner with no

experience in soldering, a half-hour's practice with odd lengths of wire and a tube socket will be

a worthwhile investment.

High quality solder of the proper grade is most important. There are several different brands

of solder on the market, each clearly marked "Rosin Core Radio Solder." Such solders consist

of an alloy of tin and lead, usually in the proportion of 50:50. Minor variations exist in the mixture

such as 40:60, 45:55, etc. with the first figure indicating the tin content. Radio solders are formed

with one or more tubular holes through the center. These holes are filled with a rosin compound

which acts as a flux or cleaning agent during the soldering operation.

NO SEPARATE FLUX OR PASTE OF ANY KIND SHOULD BE USED. We specifically caution

against the use of so-called "non-corrosive" pastes. Such compounds, although not corrosive

at room temperatures, will form residues when heated. The residue is deposited on surrounding

surfaces and attracts moisture. The resulting compound is not only corrosive but actually destroys

the insulation value of non-conductors. Dust and dirt will tend to accumulate on these "bridges"

and eventually will create erratic or degraded performance of the instrument.

NOTE: ALL GUARANTEES ARE VOIDED AND WE WILL NOT REPAIR OR SERVICE

INSTRUMENTS IN WHICH ACID CORE SOLDER OR PASTE FLUXES HAVE BEEN

USED. WHEN IN DOUBT ABOUT SOLDER, IT IS RECOMMENDED THAT A NEW

ROLL PLAINLY MARKED "ROSIN CORE RADIO SOLDER" BE PURCHASED.

If terminals are bright and clean and wires free of wax, frayed insulation and other foreign

substances, no difficulty will be experienced in soldering. Crimp or otherwise secure the wire (or

wires) to the terminal, so a good joint is made without relying on solder for physical strength.

To make a good solder joint, the clean tip of the soldering iron should be placed against the joint

to be soldered so that the terminal is heated sufficiently to melt solder. The solder is then

placed against both the terminal and the tip of the iron and will immediately flow out over the

joint. Refer to sketch on Page 8. Use only enough solder to cover wires at the junction; it is

not necessary to fill the entire hole in the terminal with solder. Excess solder may flow into

tube socket contacts, ruining the socket, or it may creep into switch contacts and destroy their

spring action. Position the work so that gravity tends to keep the solder where you want it.

Page 7

A poor solder joint will usually be indicated by its appearance.

The solder will stand up in a blob on top of the connection,

with no evidence of flowing out caused by actual "wetting" of

the contact. A crystalline or grainy texture on the solder

surface, caused by movement of the joint before it solidified

is another evidence of a "cold" connection. In either event,

reheat the joint until the solder flows smoothly over the entire

junction, cooling to a smooth, bright appearance. Photographs

in the adjoining picture clearly indicate these two

characteristics.

A good, clean, well-tinned soldering iron is also important to obtain consistently perfect connections. For most wiring, a

60 or 100 watt iron, or the equivalent in a soldering gun, is very satisfactory. Smaller irons generally will not heat the

connections enough to flow the solder smoothly over the joint and are recommended only for light work, such as on

etched circuit boards, etc. Keep the iron tip clean and bright. A pad of steel wool may be used to wipe the tip

occasionally during use.

Take these precautions and use reasonable care during assembly of the kit. This will insure the wonderful satisfaction of

having the instrument operate perfectly the first time it is turned on.

CHASSIS PARTS MOUNTING

() Lay the chassis upside down with the apron having the two large and one small hole toward you as shown In

Pictorial 1 on Paee 9.

( ) Mount a 5-pin sub-miniature socket from the

top of the chassis at A. Slip a mounting ring

(part #436-6) over the socket from the

bottom, forcing it against the chassis until

the socket is securely fastened. See

Figure 5.

( ) In a like manner, mount the other 5-pin sub-

miniature socket at B.

( ) Insert a 3/8" rubber grommet at C.

( ) Mount a 7-pin miniature socket at D, using 3-

48 screws and nuti as shown in Pictorial 1 . The wide space between pins 1 and 7 should be on your left, when the chassis

is oriented as described in Step 1 above. See Figure 6.

Page 8

( ) In a like manner, mount the other three 7-pin sockets at E, F and G. Note the position of the

wide space on these sockets. See Pictorial 1.

( ) Mount the filter capacitor mounting wafer at H as shown in Figure 7, placing it on top of the

chassis, using 6-32 x 3/8 screws and nuts. Use #6 solder lug on the inside screw, orienting as

shown in Pictorial 1. Mount 1-lug terminal strip TTon the other screw, using a #6 lock-washer and

nut.

( ) Install the output transformer at J, feeding the four wires through grommet C. Use 6-32

hardware and mount a 4-lug terminal strip P on the screw nearest the rear of the chassis,

orienting as shown.

( ) Install the 4-section electrolytic capacitor through the fiber mounting wafer H as shown in Pictorial

1. Twist each of the four short mounting tabs 1/8 turn. Do NOT twist the longer tabs.

( ) Mount a 5-lug terminal strip K, using 6-32 hardware and orienting as shown.

( ) Mount a cable clamp at M, using 6-32 hardware.

See Figure 8.

( ) Install the single wafer switch at S, using a control

lockwasher over the bushing and a flat washer and

control nut on the outside of the chassis apron. See

Figure 9 and Pictorial 4. Do not tighten securely

yet.

( ) In a like manner, mount the double wafer switch at Q orienting as shown. Do not tighten fully

as yet, since both switches must be loosened later to mount the panel.

PANEL PARTS MOUNTING

( ) Mount the speaker at AA, using 6-32 screws, nuts and #6 lockwashers. See Figure 10 on

Page 11. Screen wire is mounted with the speaker as shown. Trim the screen to approximately 1/16"

more than speaker size. '

( ) Mount the 2000 ft control at BB. See Figure 9 and Pictorial 2 for position.

( ) In a like manner, install the 100 K control at CC. This control has the slotted shaft.

Page 10

( ) Mount the meter jack at DD. Follow the procedure for mounting of controls as in Figure 9.

( ) Install the coaxial connector at EE, using 4-40 screws, nuts and #4 lockwashers. Install

a 2-lug terminal strip FF on the screw nearest the speaker.

( ) Mount the meter at GG, using hardware supplied. Be careful not to scratch the meter face.

Page 11

POWER SUPPLY AND BATTERY MOUNTING

( ) Assemble the A battery mounting brackets as shown in Pictorial 3 and fasten to the side of the

U-shaped bracket, using 6-32 hardware. Use flat head screws at X.

( ) Mount the rectangular bracket to the other side of the U-shaped bracket, using 6-32 hardware.

Use long 6-32 bolt on the open side. Do not tighten this bolt now.

( ) Slip the U-shaped bracket inside the Z-shaped bracket so the two holes in each are in line.

( ) Install the power supply assembly inside the U-shaped bracket as shown in Pictorial 3 . Insert

the mounting bolts through the holes in both brackets. Use #6 lockwashers and 6-32 nuts over the

mounting bolts and tighten securely.

CHASSIS WIRING

( ) Lay aside the short length of stranded teflon insulated wire. DO NOT USE THIS WIRE UNTIL

INSTRUCTED TO DO SO.

( ) Connect a wire from Dl (NS) to El (NS). See Pictorial 4 on Page 13.

( ) Connect a wire from D7 (S) to E7 (NS).

( ) Connect a wire from Dl (NS) to K4 (NS).

( ) Connect a wire from E7 (S) to QA12(S). Run this wire against the chassis between B and C.

( ) Connect a 4.7 K resistor (yellow-violet-red) from Dl (S) to D4 (NS).

( ) Connect a 68 K resistor (blue-grey-orange) from D2 (NS) to D3 (NS).

Page 12

( ) Connect a 680 K resistor (blue-gray-yellow) from D6 (NS) to D4 (NS).

( ) Run a wire from D4 (S) to E4 (NS).

( ) Connect one lead of the .01 ufd 1.6 kv large ceramic capacitor to D6(S). Lay this capacitor

against the chassis. Be certain neither lead is shorted to the chassis.

( ) Connect the other lead to TT (S).

( ) Connect a wire from E4 (NS) to SL1 (NS). Run this wire against the chassis.

( ) Cut the positive (+) lead of the 10 ufd 25 volt capacitor to 3/4". Connect to El (S). Place

this capacitor between H and E as shown. Connect the negative (-) lead to E4 (NS). Use

sleeving on both leads.

( ) Run a wire from D3 (NS) to E3 (NS).

( ) Run a wire from D3 (S) around socket D and along the edge of the chassis to SI (NS).

( ) Cut both leads of an 1000 uuf disc capacitor to 1". Slip short lengths of sleeving over both

leads. Connect one lead to D2 (S). Connect the other lead to E6 (NS).

( ) Connect a 270 K resistor (red-violet-yellow) between E2 (NS) and E3 (NS).

( ) Connect a 680 K resistor (blue-gray-yellow) between E6 (S) and E4 (S).

( ) Connect a wire from E3 (NS) to F3 (NS).

( ) Connect a wire from Kl (NS) to Fl (NS).

( ) Connect a wire from Fl (S) to G5 (NS).

( ) Connect a 15 K resistor (brown-green-orange) from G5 (S) to F4 (NS).

( ) Run a wire from F4 (NS) to P2 (NS).

( ) Strip 1" of insulation from the end of a wire. Feed this bare wire end through Gl (NS) to

G7 (S).

( ) Connect the other end of this wire to F7 (S).

( ) Connect a wire from Gl (S) to QA8 (S).

( ) Cut both leads of an .01 ufd disc capacitor to 1" and slip short lengths of sleeving over each

lead. Connect one lead to E2 (S). Connect the other lead to F6 (NS).

( ) Connect a 2.2 megohm resistor (red-red-green) between F6 (NS) and F3 (NS).

( ) Connect a 1 megohm resistor (brown-black-green) between F6 (S) and F4 (S).

( ) Connect a 68 K resistor (blue-gray-orange) between F2 (NS) and F3 (NS).

( ) Connect a wire from F2 (S) to QB12 (S). Route this wire under the wiring between F and G

and between B and P.

( ) Connect a 1 megohm resistor (brown-black-green) between G6 (NS) and P2(NS) (use sleev-

ing).

Page 14

( ) Connect a wire from G6 (S) to PI (NS).

( ) Run the red lead coming through grommet C along the inside edge of terminal strip P and

connect to G2 (NS).

( ) Connect a wire from G3 (NS) to QB6 (NS).

( ) Connect a 47 K resistor (yellow-violet-orange) between P4 (NS) and G3 (NS).

( ) Connect an 18 K resistor (brown-gray-orange) between G2 (NS) and P3 (NS).

( ) Connect a wire from G3 (S) to Hi (NS).

( ) Connect a .1 ufd capacitor between G2 (S) and HI (S) (use sleeving).

( ) Connect the green lead coming through grommet C to QB6 (S).

( ) Note the manner in which the pin connections to socket A and B appear. Carefully bend the

outside pins (Al, A5, Bl and B5) outward away from the socket. Use care to prevent breaking

these pins.

( ) Cut the blue wire extending through grommet C to length and connect to B5(S). Use extreme

care when soldering connections to sockets A and B to prevent shorting the connections

together with excess solder.

( ) Connect a wire from QA7 (S) along the edge of the chassis and through the cable clamp M to

K2 (NS).

( ) Connect a wire from QAll (S) routed as above to K5 (NS).

( ) Connect a wire from P2 (S) to QA1 (S).

( ) Connect a 100 uuf ±1% capacitor between QBl (S) and Pi (NS). Use sleeving on the lead

going to P1.

( ) Connect a 2000 uuf ±1% capacitor between QB2 (S) and PI (NS).

( ) Connect a .02 ufd ±2% capacitor (matched pair, each .01 ufd) between QB3 (S) and PI (NS).

( ) Connect a .1 ufd ±2% capacitor (matched pair, each .05 ufd) between QB4 (S) and pi (S).

Install as shown in Pictorial 4, making sure the leads do not short against the chassis.

( ) Run a wire from A5 (S) to SL1 (S). See Pictorial 4.

( ) Connect a wire from S2 (S) to H7 (S).

( ) Connect a wire from S3 (S) to H6 (S).

( ) Connect a wire from S4 (S) to H5 (S).

( ) Connect a wire from S5 (S) to H8 (S).

Page 15

PARTIAL ASSEMBLY AND WIRING

( ) Remove the nuts and flat washers from the two switches Q and S on the front chassis apron.

( ) Carefully mount the chassis to the panel as shown in Pictorial 5, inserting the switch shafts

through the matching holes in the panel. Install flat washers and nuts on both switches and

tighten securely.

( ) Place the small gray knob on the shaft of the PITCH control CC and tighten.

( ) Rotate the shafts of switches Q and S fully counterclockwise, using pliers. Place one of the

large skirted knobs on shaft Q with the index aligned with the OFF position and tighten.

( ) Similarly, place the other knob on shaft S with the index aligned with 10 SEC and tighten.

( ) For the following steps see Pictorials 4 and 5.

( ) Connect the black wire coming through grommet C to AA2 (NS).

( ) Connect a wire between Bl (S) and AA2 (S).

( ) Connect a wire between B2 (S) and BB2 (S).

( ) Connect a wire from BB1 (NS) to H3 (S).

( ) Connect a wire from BBl (S) to AAl (S).

( ) Connect a wire from BB3 (S) to P3 (S).

( ) Connect a wire from P4 (S) to CC2 (S).

( ) Connect a wire from CC1 (NS) to DD4 (S).

( ) Connect one end of an 8" wire to CC1 (S). Feed the other end of this wire up through

grommet C and connect to GG2 (S). See Pictorial 2.

( ) Run a wire from QB5 (NS) through grommet C to GG1 (S).

( ) The B battery connector has yellow and black wires attached. Shorten the yellow lead to

4 1/4" and the black lead to 2".

( ) Connect the yellow lead to F3 (S).

( ) Connect the black lead to QA2 (S).

( ) Connect a 5 1/4" wire to Kl (S). Leave the other end free.

( ) Connect a 3 1/4" wire to K2 (S). Leave the other end free.

( ) Connect a 4 1/4" wire to E3 (S). Leave the other end free.

( ) Connect a 4 1/2" wire to K3 (S). Leave the other end free.

( ) Connect a 6 1/2" wire to K4 (S). Leave the other end free.

( ) Connect a 3 1/2" wire to K5 (S). Leave the other end free.

( ) Connect a wire from QB5 (S) to DD1 (S).

Page 17

( ) Connect a wire from DD2 (S) (outside terminal) to SI (S).

( ) Connect a 1 megohm (brown-black-green) resistor between FFl (NS) and EE (NS).

( ) Connect a .02 ufd 1.6 kv capacitor from FFl (NS) to FF2 (S).

( ) Identify the short length of teflon insulated wire. This is the short length of stranded wire. The

insulation will have a soapy feel. DO NOT USE ORDINARY HOOKUP WIRE.

( ) Connect a 5" length of teflon wire between EE (S) and TT (S).

( ) Connect a 6" length of teflon wire between FFl (NS) and A3 (S).

( ) Connect a 7 3/4" length of teflon wire to FFl (S). Leave the other end free.

( ) Mount the handle on the front panel as shown in the photograph on Page 1. Insert a 10-24

screw through the 7/32" hole between Q and S from the inside of the chassis. Do not tighten

until the hole in the other end of the handle is aligned with the 7/32" hole below the speaker.

Do not insert the other screw yet.

( ) Now check your wiring and remove any wire ends or other foreign matter before proceeding.

( ) Mount the power supply and battery assembly in place as shown in Pictorial 6 on Page 19.

Use the other 10-24 screw and tighten securely.

( ) Connect the wire coming from E3 to ZZ INPUT (S).

( ) Connect the wire coming from K3 to ZZ GROUND (NS),

( ) Connect the lead coming from FFl to ZZ OUTPUT (NS).

( ) Connect a .02 ufd 1.6 kv capacitor between ZZ GROUND (S) and

ZZ OUTPUT (S).

( ) Connect the wire coming from Kl to YY1 (S). See Pictorial 6.

( ) Connect the wire coming from K2 to YY2 (S).

( ) Connect the wire coming from K4 to YY3 (S).

( ) Connect the wire coming from K5 to YY4 (S).

( ) Insert the two 1.5 volt batteries in the battery clip YY. Observe polarity as shown in

Pictorial 6.

( ) Snap the battery connector to the B battery and insert battery in the battery clamp. Tighten

the clamping bolt. Do not overtighten as this will damage the battery.

( ) Insert the 2N109 transistor in socket B, making certain the wide

space is to the rear on the side closest to the tubes. Be sure the

wire leads of the transistor mate with the proper pins of the socket.

If the transistor is plugged in wrong, it may well be damaged. See

Figure 11 A.

( ) Cut the leads of the 5841 corona regulator tube to 3/16" and insert

it into socket A allowing the wire leads to mate with proper socket

pins. See Figure 11B.

Page 18

( ) Plug the remaining miniature tubes in the proper sockets. Be sure the tubes are plugged

into the proper socket, otherwise the instrument will not operate properly and tubes or other

components may be damaged.

( ) Mount rubber feet in the four large holes near the corners of the bottom of the cabinet.

See Figure 11-C.

( ) Insert the instrument into the cabinet so the three small holes in the

cabinet bottom line up with matching holes in the chassis and Z

bracket. Be sure the edges of the panel are in place on the outside

of the cabinet.

( ) Fasten the instrument in the cabinet using three self-tapping screws

through the holes in the bottom of the cabinet.

This completes the construction of your model RC-1 Radiation

Counter.

CONSTRUCTION OF THE GEIGER COUNTER PROBE MODEL GC-1

Refer to Pictorial 7 on Page 21. This"exploded view" is designed to assist you to rapidly

complete construction of the kit.

( ) Prepare the cable ends as shown and attach the coaxial plug to the short end.

( ) Feed the long end of the cable through the handle as shown. If necessary,

lubricate with soap.

( ) Tie a knot very close to the prepared end.

( ) Solder the outer (shield) conductor to the retaining ring as shown and cut off any

excess.

( ) Insert the retaining ring into the handle and seat it in the groove provided, pulling

gently on the cord to seat the knot against the inner flange of the handle.

( ) Drop the socket over the center conductor and solder this center conductor. Push

the socket in against the retaining ring.

( ) Insert the thin plastic into the probe housing.

( ) Remove the 6306 tube from its carton and insert gently into the socket. DO NOT

HANDLE THIS TUBE WITH THE FINGERS EXCEPT ON THE BASE OR FLANGE OR

THE THIN WALL MAY BE CRUSHED.

( ) Slip the probe housing over the 6306 tube and screw carefully on the handle. Tighten

securely.

This completes construction of your Heathkit Geiger Counter Probe model GC-1.

TEST AND CALIBRATION

Check over your wiring for errors, poor or unsoldered joints and wire ends or other

foreign matter lodged in the wiring. Be sure all tubes and the transistor are plugged into

the proper sockets. See that the 1.5 volt batteries are held solidly in their clamp] and that

they are properly polarized. Make sure the B battery connector is in place.

Connect the probe to the probe socket. Advance the RANGE switch to the 600 CPM

range and the TIME CONST, switch to 5 SEC. A rapid, uniform clicking will be heard

coming from the

Page 20

Table of contents

Popular Cash Counter manuals by other brands

B+K precision

B+K precision 1803D instruction manual

Feig Electronic

Feig Electronic Sensors VEK CN1-1 operating instructions

Kübler

Kübler CODIX 54U operating instructions

SBM

SBM SB-7 Service manual

Labelmate

Labelmate RRC-400 user manual

ThermoFisher Scientific

ThermoFisher Scientific Invitrogen Countess II user guide