Page 2

• Any machine can be dangerous to operators when improperly used or poorly maintained.

• All employees operang and maintaining Labelmate equipment should be instructed on correct use and

safety guidelines.

• Most accidents are preventable if adequate precauons are taken.

• Be aware of safety labels and instruconal decals that have been placed near any potenal hazards.

It is the responsibility of the customer to ensure that all personnel are instructed on proper operaon of

Labelmate equipment prior to use. All personnel operang, inspecng, servicing, or cleaning this equipment

must be properly trained in operaon and machine safety. Read all operang instrucons before using this

equipment.

• Ensure that all power sources are turned o when the machine is not in use.

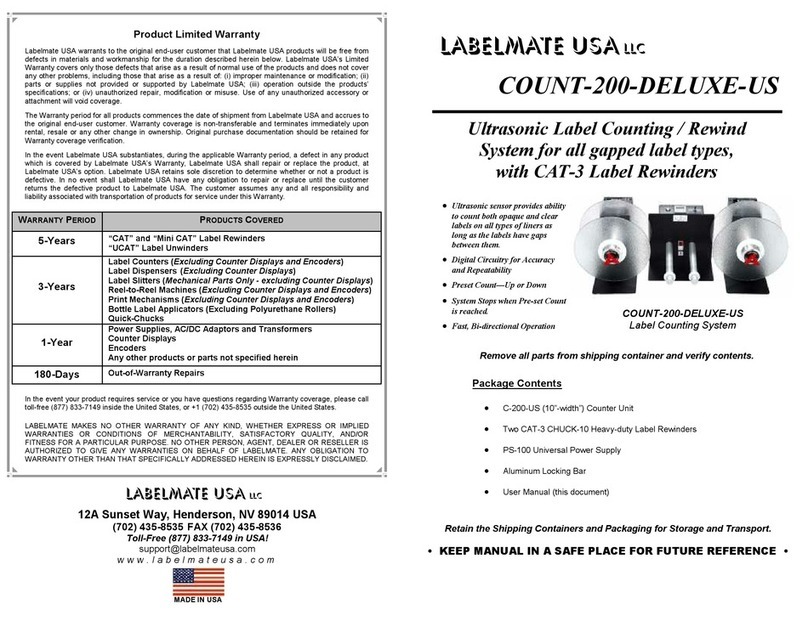

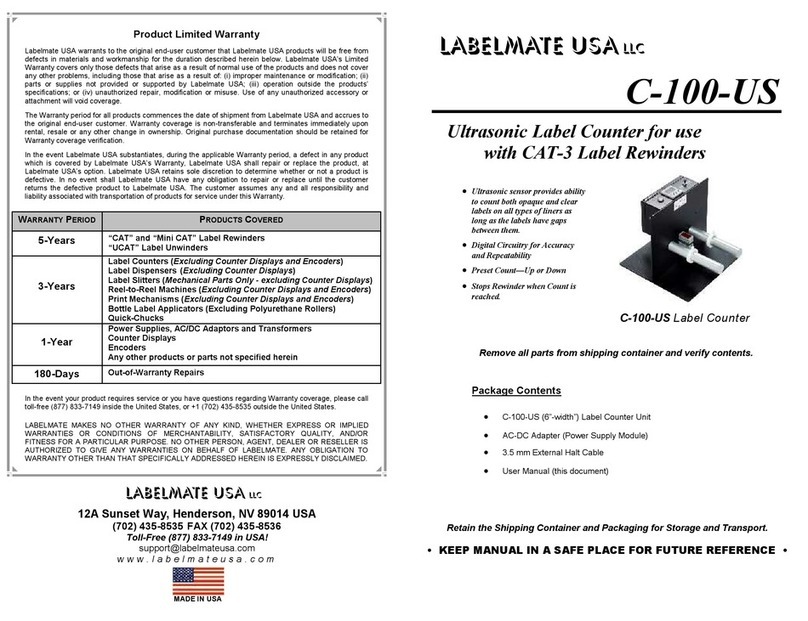

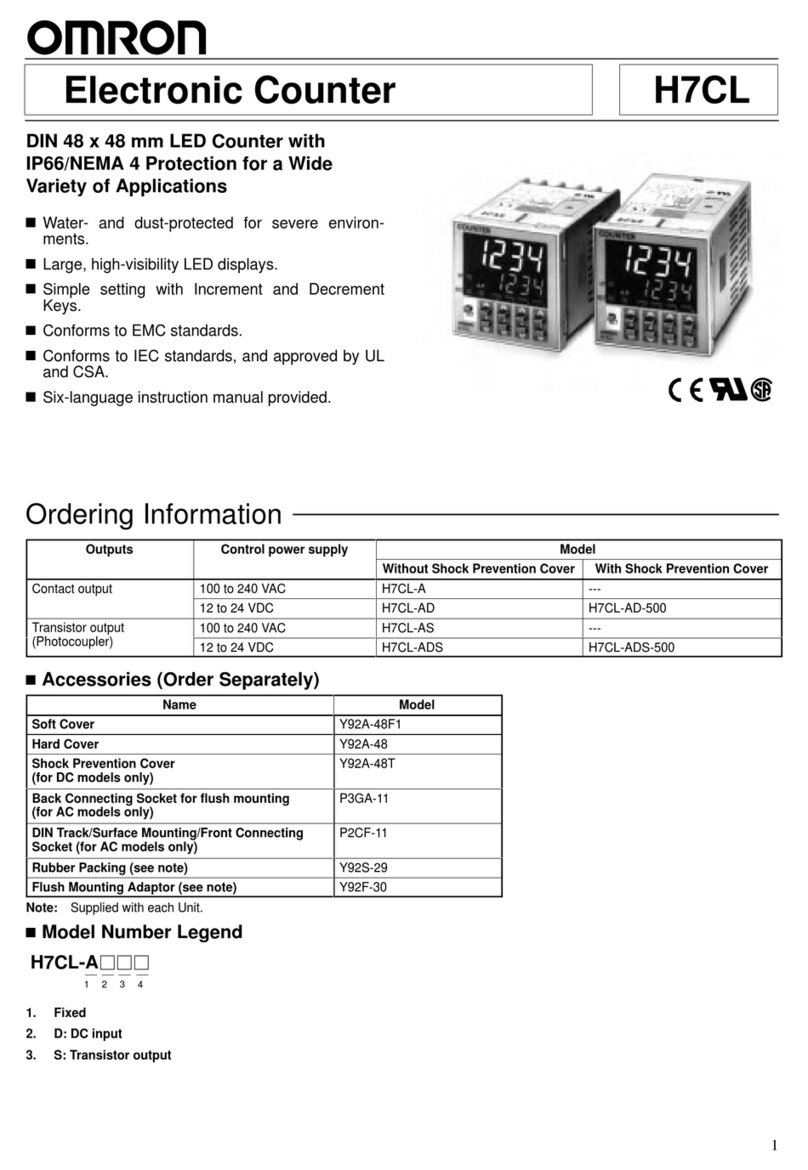

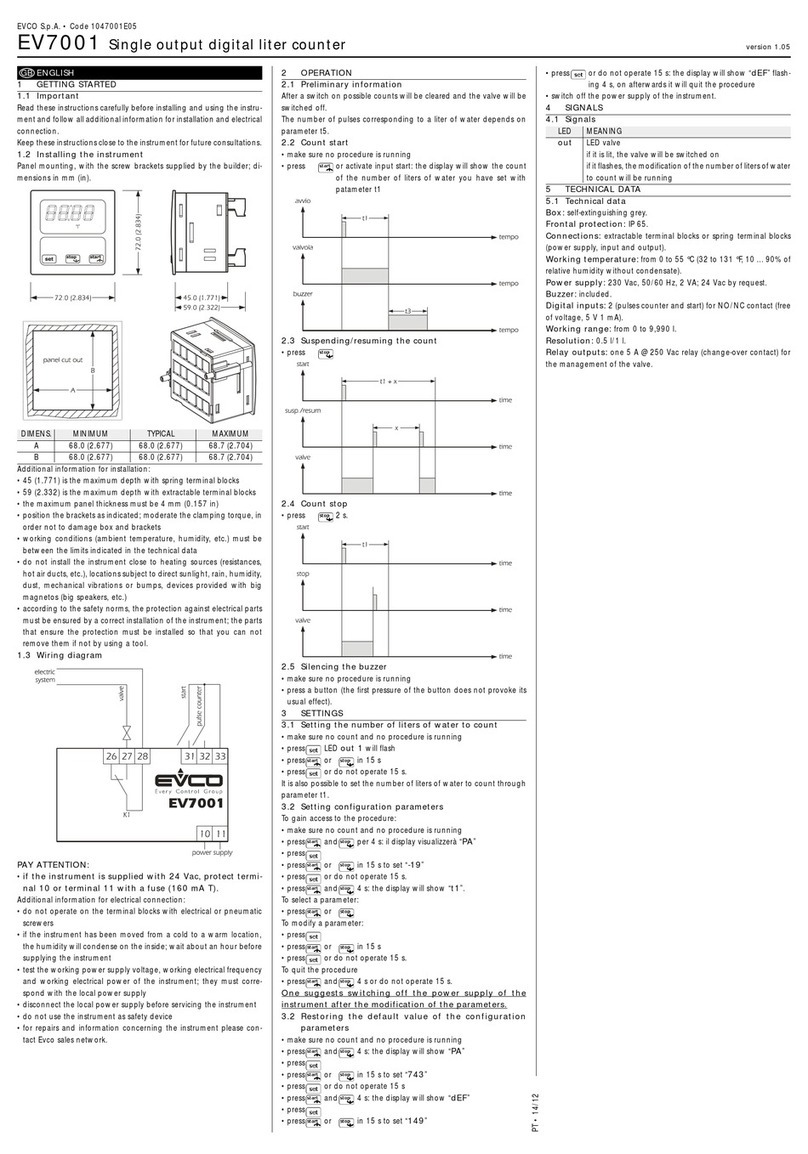

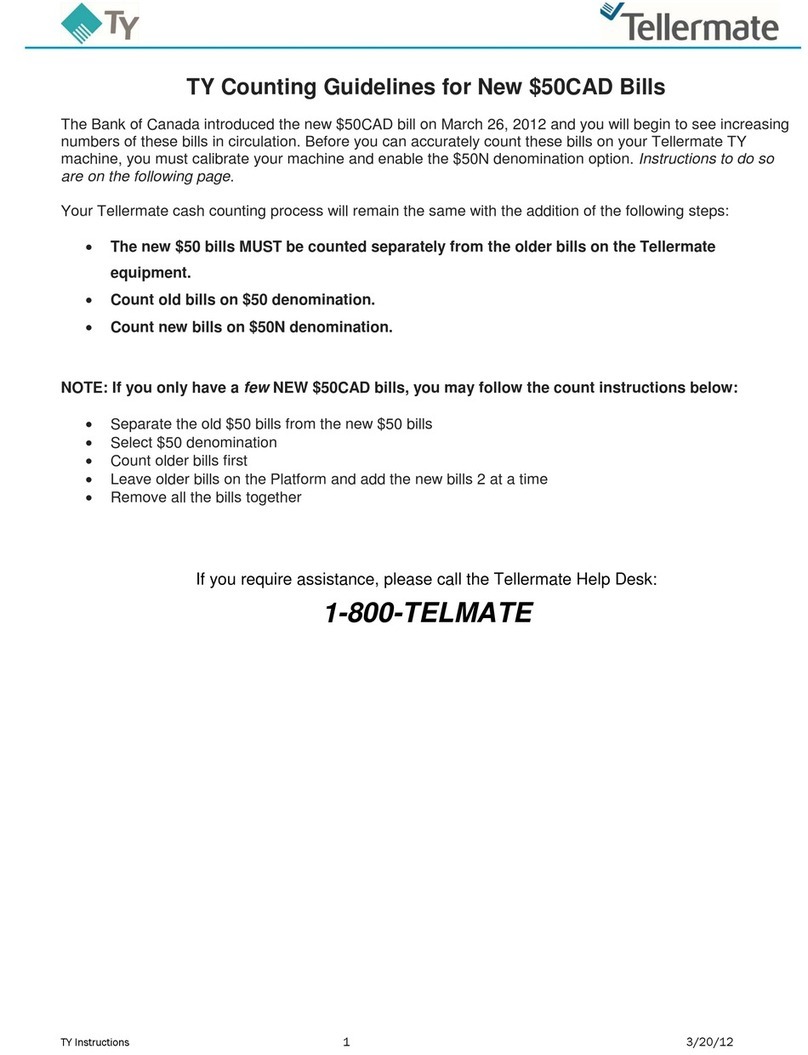

• Read the manual for any special operaonal instrucons for each piece of equipment; user manuals are

included in the product packaging and/or can be found on the website www.labelmateusa.com.

• Know how the equipment funcons and understand the operang processes.

• Know how to shut down the equipment.

• Understand the equipment safety labels.

• Wear the appropriate personal protecve equipment for the job to be performed (eg: eye protecon,

gloves, safety shoes, etc.).

• When working on or around all equipment, avoid wearing loose clothing, jewelry, unrestrained long hair,

or any loose es, belts, scarves, or arcles that may be caught in moving parts.

• Keep all extremies away from moving parts; entanglement could cause severe injury or death.

• For new equipment, check plant voltage with the voltage specied on the machine; electrical specica-

ons for this machine are printed on the power adaptor used with the machine.

• A properly grounded electrical receptacle is required for safe operaon regardless of voltage require-

ments.

• Use the equipment for its intended purpose only.

Safety First