@ n"r"u

CONT INUE

{...2

START

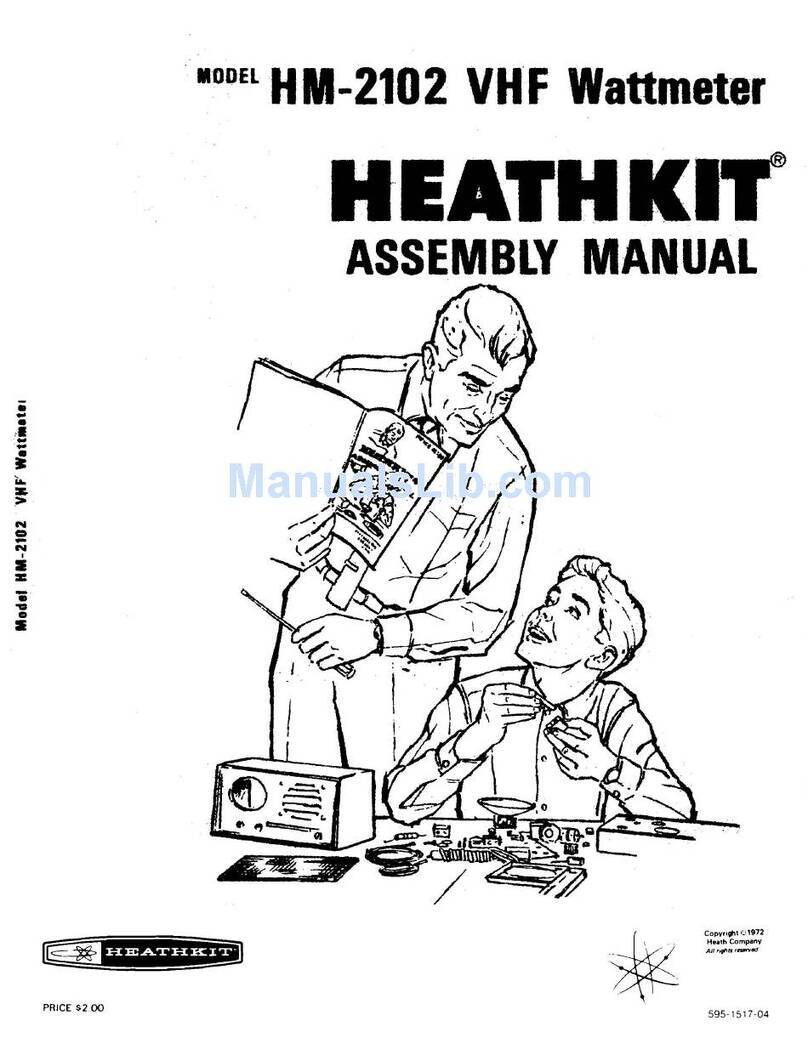

( ) Locate the circuit board (#85-

1?8-1) and position it lettered

side up as shown in Pictorial 1.

Then perform the following

steps. Do not solder or cut off

any leads until you are directed

to do so in a step.

( ) 100 KO (brown-black-yellow)

( ) 560Q (green-blue-brown).

( ) ZZOO Q (red-violet-red)"

NOTE: Precision resistors are

identiJied by resistance value.

MA = megohm = 1,000,000 ohm

KQ = kilohm = 1,000 ohm

Example: 2.162 Kf,) = 2162 n

NOTE: The Solid-State Voltmeter

can be wired for use with either a

120 volt AC power source or a 240

volt AC power source. Followeither

the 120 VOLT WIRING steps or the

240 VOLT WIRING step, whichever

applies to your needs. ( ) 6.838 MO 1% precision.

( ) 2.162lAlO L% precision.

I2O VOLT WIRING

( ) 1" bare wire. Use hookup wire

with insulation removed.

( ) 1" bare wire.

( ) 683.8 KO 1ft precision.

( ') 216.2 KQ 170 precision.

( ) 68.38 KO 1$ precision.

( ) ZL.AZ KQ 170 precision

240 VOLT WIRING

( ) 3/4" barewire.Usehookupwire

with insulation removed.

\_l u

,.+lr-J

I l. ,

( ) Solder all connections and cut

off the excess lead lengths.

( ) 6.838 KQ l/e precision.

( ) 2,162 KQ 170 precision.

( ) 10 KSl (brown-black-orange ( ) 900 Q lft precision.

( ) 10 KSl (brown-black-orange). ( ) 10 O 170 Precision.

( ) 90 f,) 170 precision.

( ) 3.3 MO (orange-orange-

( ) 22 Ka (red-red-orange).

( ) ss n (orange-orange-black).

( ) 4? KO (yellow-violet-orange

) 22 KA (red-red-orange). ( ) 270 KO (red-violet-yellow).

( ) 47 KO (yellow-violet-orange) ( ) Solder all connections and cut

off the excess lead lengths

PROCEED TO PICTORIAL 2

( ) Solder all connections and cut

off the excess lead lengths.

PICTORIAL I