Heathkit IN-12 User manual

Other Heathkit Measuring Instrument manuals

Heathkit

Heathkit HD-1250 User manual

Heathkit

Heathkit im-5210 User manual

Heathkit

Heathkit IM-16 Installation instructions

Heathkit

Heathkit Heathkit HM-2102 User manual

Heathkit

Heathkit IM-48 User manual

Heathkit

Heathkit Heathkit HM-102 User manual

Heathkit

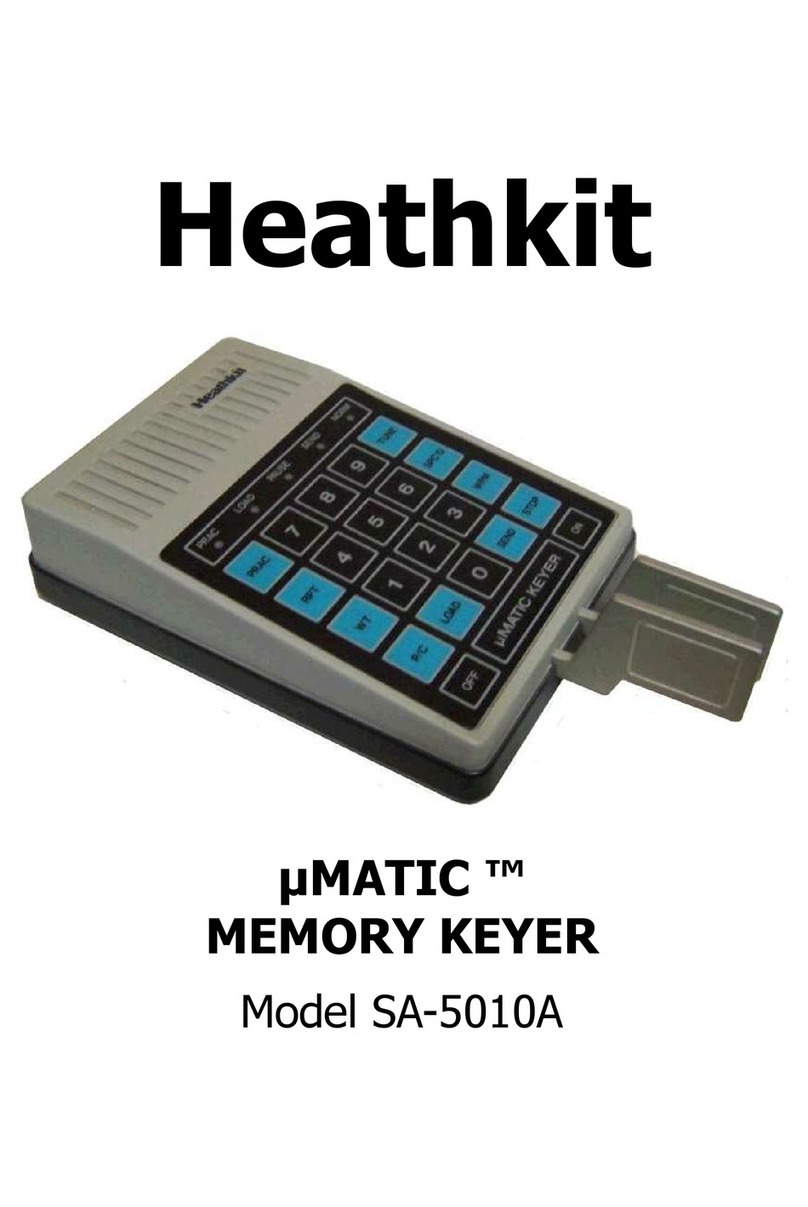

Heathkit mMATIC SA-5010A User manual

Heathkit

Heathkit SG-6 Guide

Heathkit

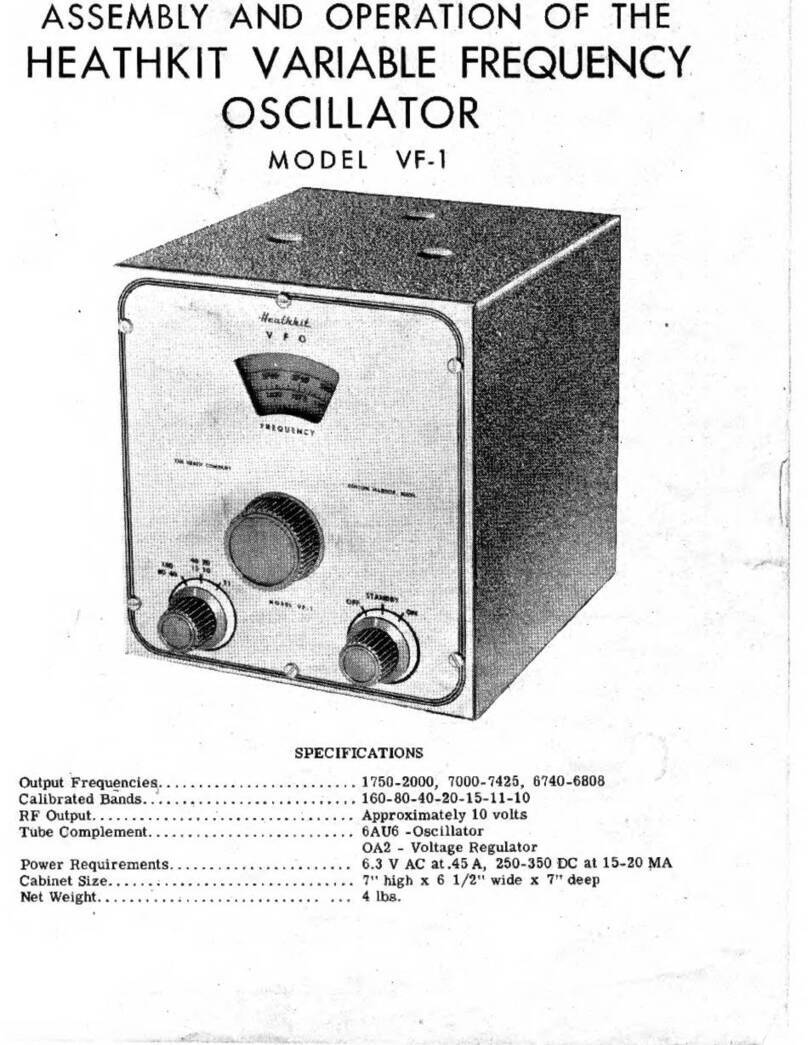

Heathkit VF-1 Installation instructions

Heathkit

Heathkit IM-5228 User manual