2Heatilator • ECO-ADV-WS22 • 7057-128D • September 15, 2011

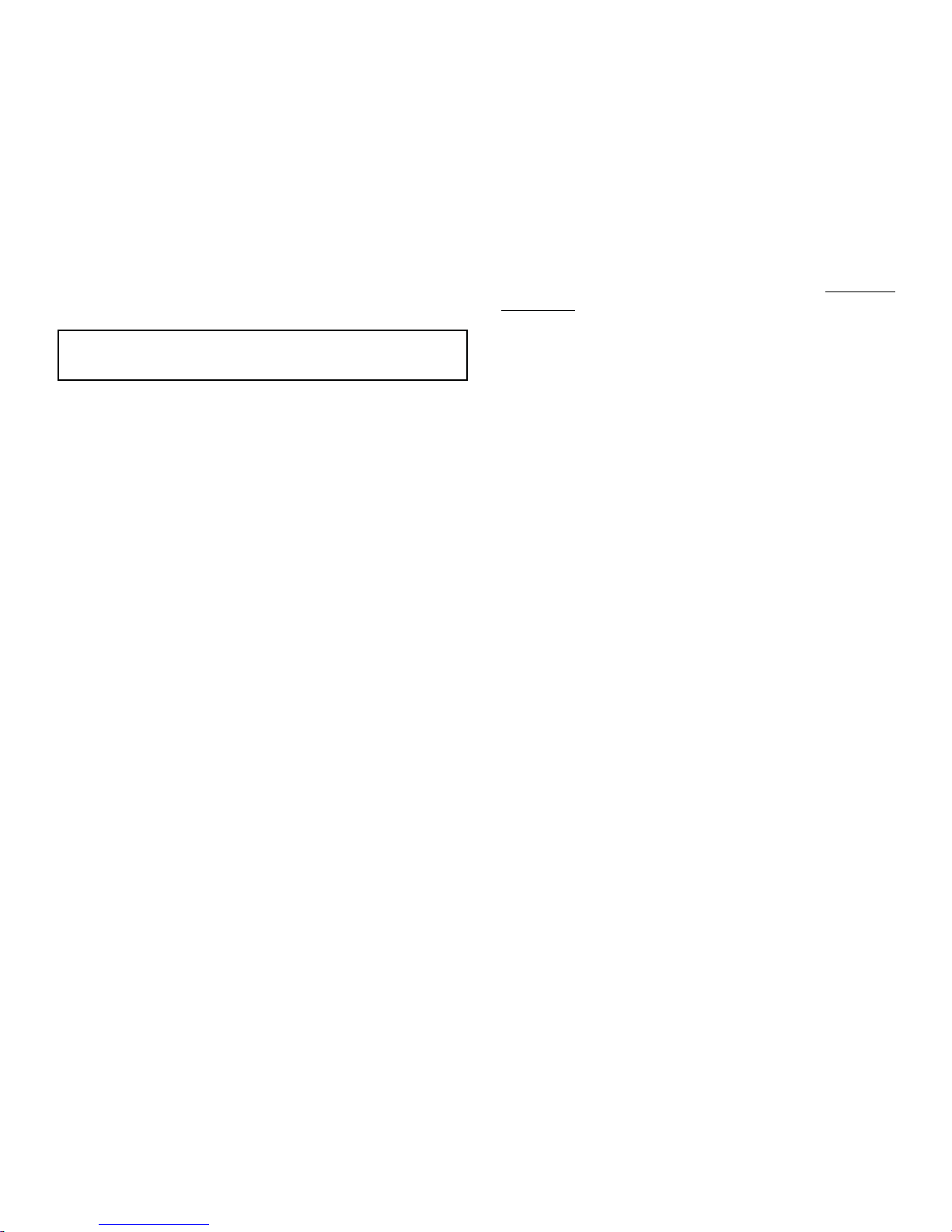

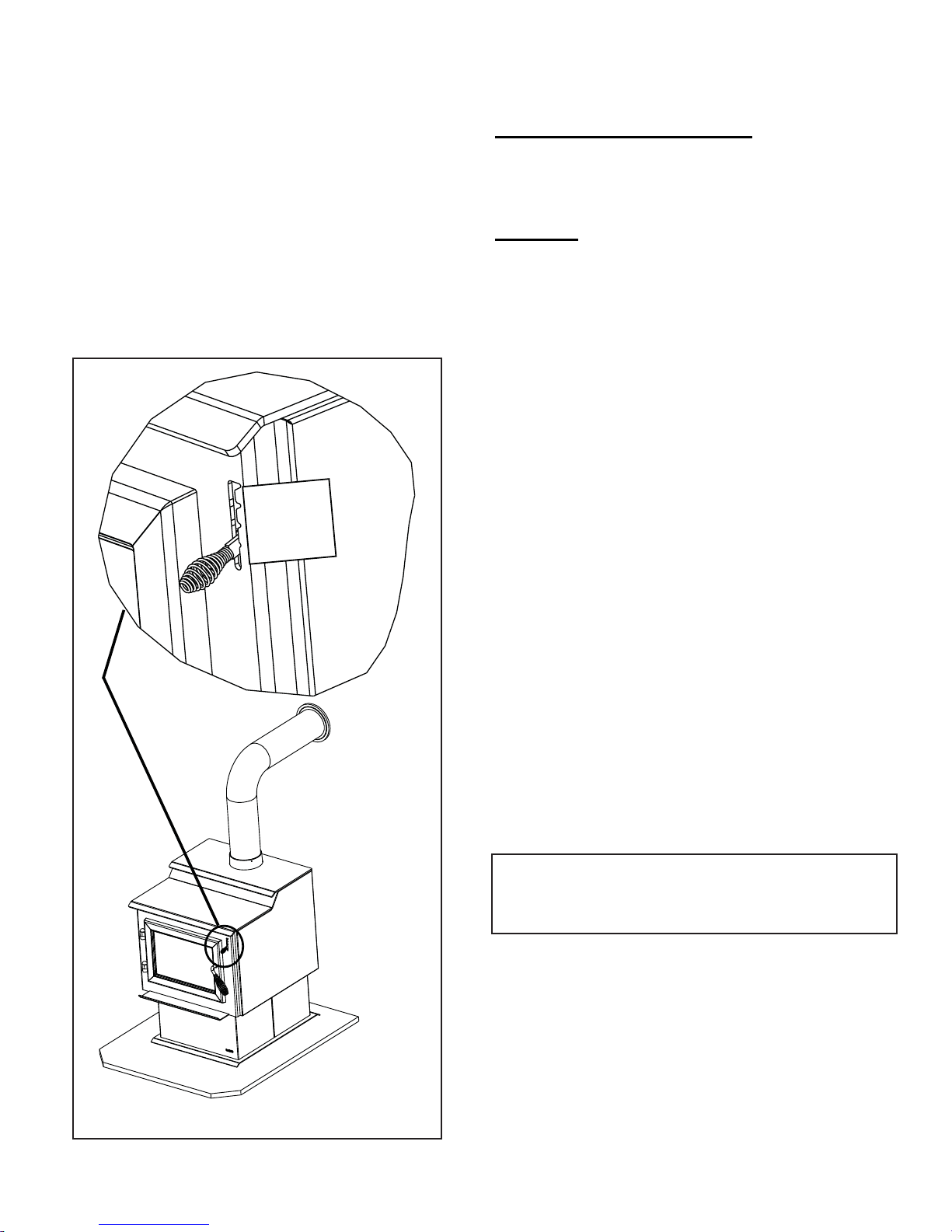

SAMPLE OF SERIAL NUMBER / SAFETY LABEL

LOCATION: Back of Appliance

Read this manual before installing or operating this fireplace.

Please retain this owner’s manual for future reference.

Congratulations!

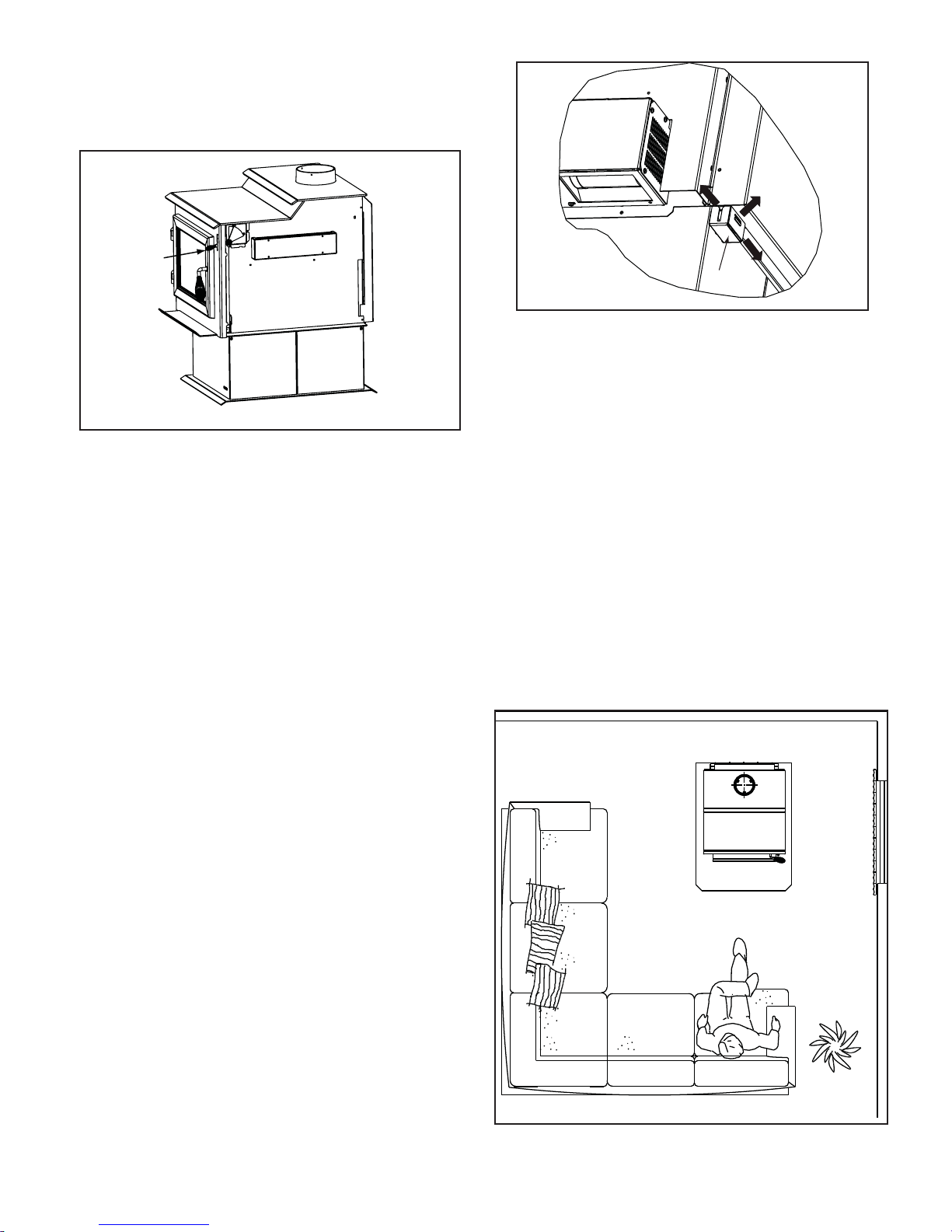

Congratulations on selecting a Heatilator wood burning

appliance. The wood burning appliance you have selected

is designed to provide the utmost in safety, reliability and

efficiency.

As the owner of a new wood burning appliance, you’ll want

to read and carefully follow all of the instructions contained

in this owner’s manual. Pay special attention to all cautions

and warnings.

This owner’s manual should be retained for future refer-

ence. We suggest you keep it with your other important

documents and product manuals.

Your new wood burning appliance will give you years of

durable use and trouble-free enjoyment. Welcome to the

Heatilator family of wood burning products!

NOTE: Clearances may only be reduced by means

approved by the regulatory authority having jurisdiction

SPÉCIFICATIONS DE LA VENTILATION:

MUR SIMPLE: De six (6 inches) (152mm) de diamètre le connecteur de

minimum d'acier noir ou bleu de minimum de 24MSG, avec une chemin

usine UL103HT* de Classe "A", adéquate pour usage avec les combustio

ou une cheminée de briques, avec espaces libres référés.

MUR DOUBLE: De six (6 inches) (152mm) de diamètre, le connecteur

d'air isolé pour mur double avec une cheminée bâtit en usine UL103HT*

"A, ou une cheminée de briques, avec espaces libres alloués.

MAISON MOBILE: Utiliser un conduit de mur double par Dura-Vent D

Metalbestos DS ou Security DL. Doit être équipé d'un arrêt d'étincelle.

espaces libres pour mur double comme mentionné ci-bas.

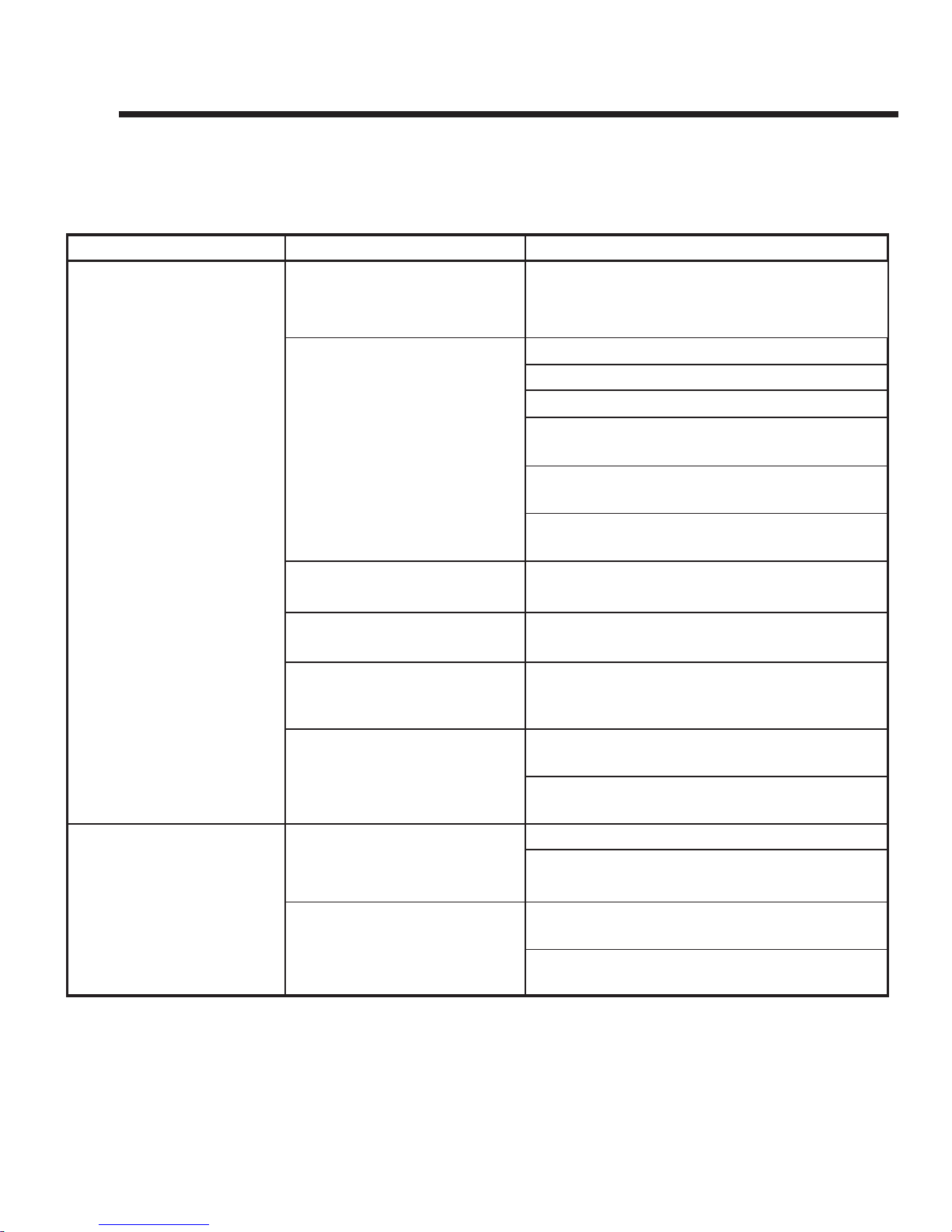

MINIMUM CLEARANCES TO COMBUSTIBLES In Inches & (Millimeters)

NOTE: All "A" , "C" and "F" Dimensions are to inside diameter of the flue collar.

LISTED ROOM HEATER, SOLID FUEL TYPE.

ALSO FOR USE IN MOBILE HOMES. (UM) 84 HUD .

"For Use with Solid Wood Fuel Only"

1445 N. Highway, Colville, WA 99114

www.heatilator.com

Install and use only in accordance with

manufacturer's installation and operating

instructions. Contact local building or fire officials

about restrictions and installation inspections in

your area. Do not obstruct the space beneath

heater.

WARNING - For Mobile Homes: Do not install in

a sleeping room. An outside combustion air inlet

must be provided and unrestricted while unit is in

use. The structural integrity of the mobile home

floor, ceiling and walls must be maintained. The

stove needs to be properly grounded to the frame

of the mobile home. Components required for

mobile home installation: Outside Air Kit, Part

Number OAK-ACC.

Refer to manufacturer's instructions and local

codes for precautions required for passing

chimney through a combustible wall or ceiling and

maximum offsets.

Inspect and clean chimney frequently - Under

Certain Conditions of Use, Creosote Buildup May

Occur Rapidly.

Do not connect this unit to a chimney serving

another appliance.

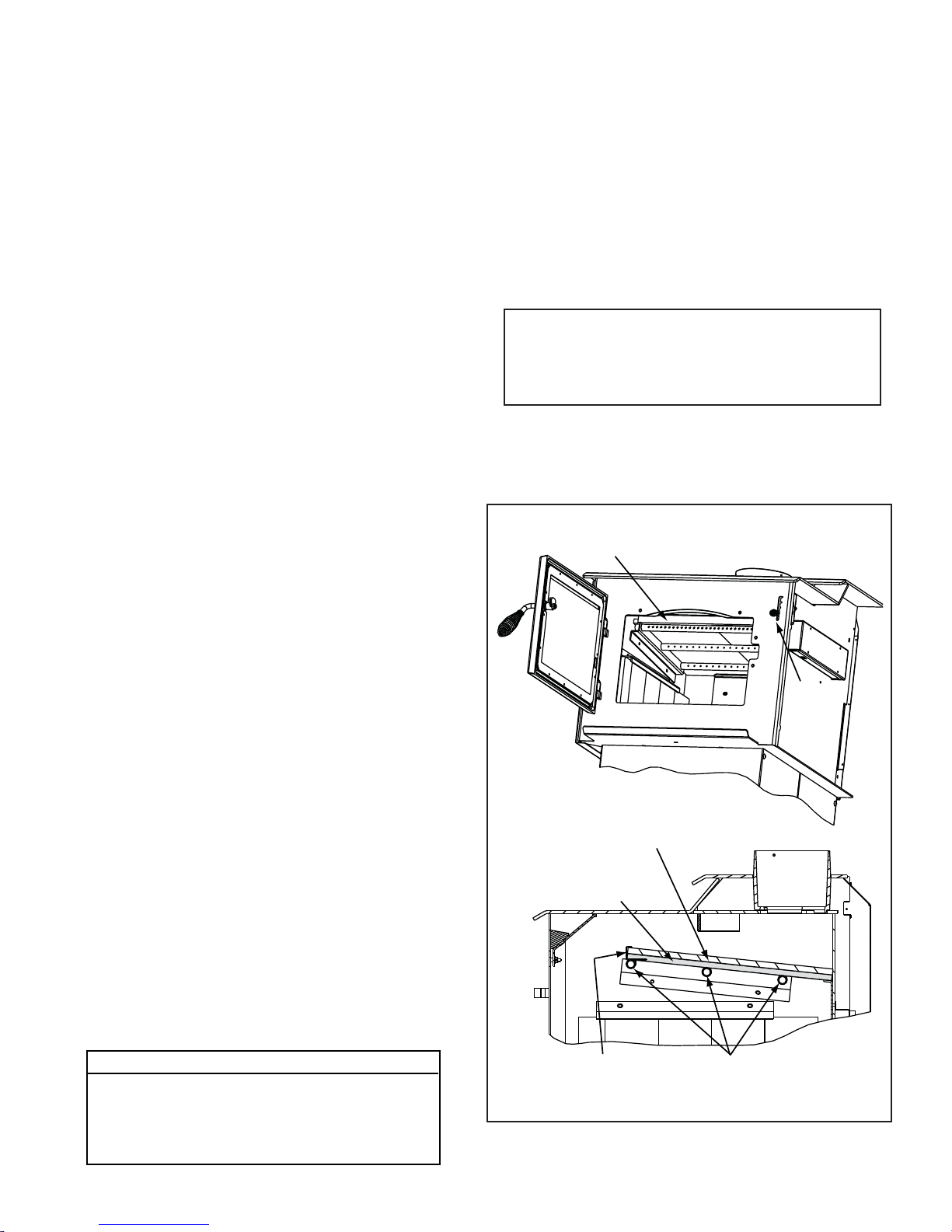

Optional Components: Optional Blower, Part

BK-ACC.

Electrical Rating: 115 VAC, 1.2 Amps, 60 Hz.

Route power cord away from unit. Do not route

cord under or in front of appliance.

DANGER: Risk of electrical shock. Disconnect

power supply before servicing.

Replace glass only with 5mm ceramic available

from your dealer.

Do not use grate or elevate fire. Build wood fire

directly on hearth.

Do not overfire - if heater or chimney connector

glows, you are overfiring.

CAUTION

:

U.S. ENVIRONMENTAL PROTECTION AGENCY - Certified to

comply with July 1990 particulate emission standards.

2010 2011 2012 Jan. Feb. Mar. Apr. May June July Aug. Sept. Oct. Nov. Dec.

PREVENT HOUSE FIRES

Report / Rapport: 3198460

Manufactured by:

HOT WHILE IN OPERATION DO NOT TOUCH, KEEP CHILDREN AND CLOTHING AWAY. CONTACT MAY CAUSE SKIN BURNS.

KEEP FURNISHINGS AND OTHER COMBUSTIBLE MATERIAL FAR AWAY FROM THE APPLIANCE. SEE NAMEPLATE AND INSTRUCTIO

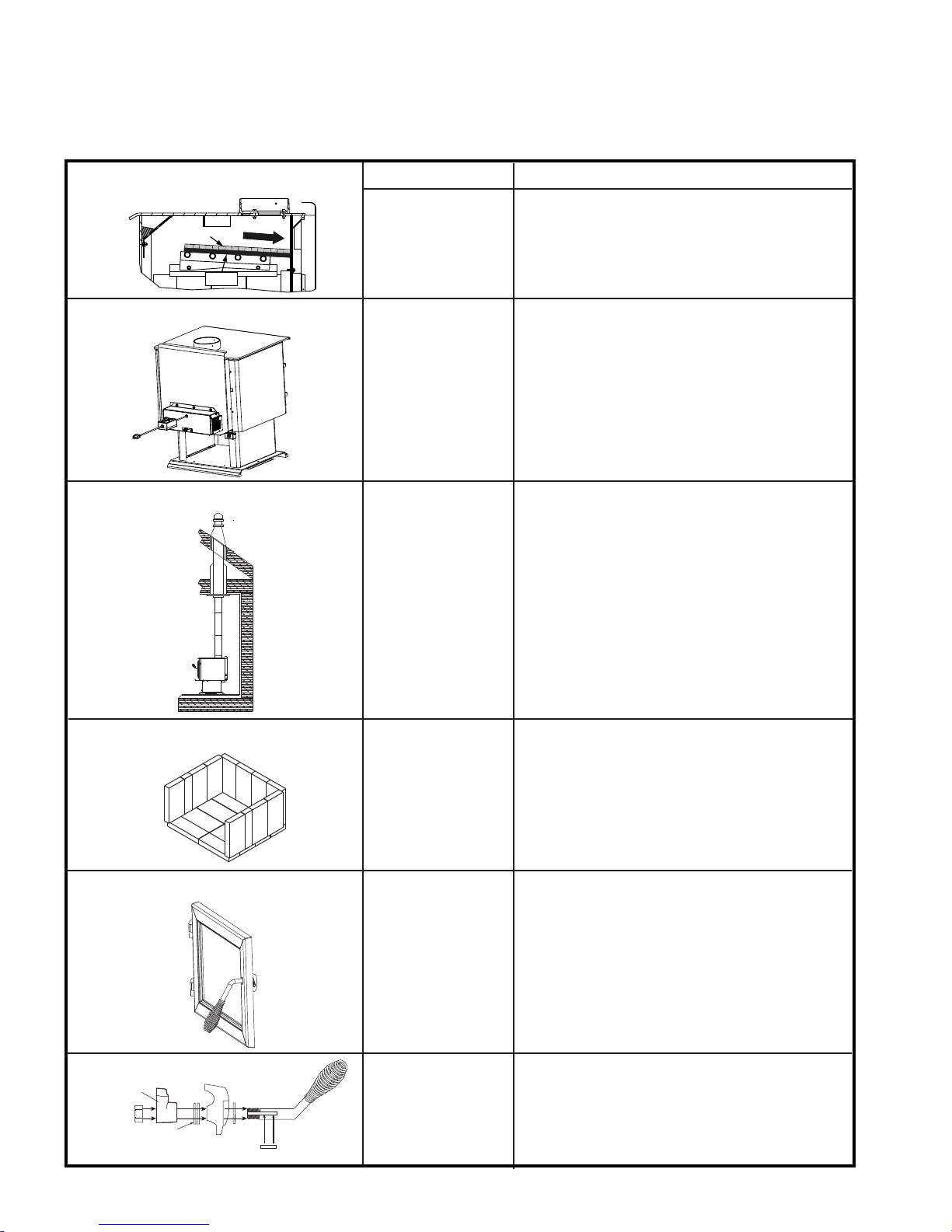

A B C D E F G H

SINGLE WALL PIPE 10 (254) 8.25 (210) 21 (533) 11 (279) 3.5 (89) 12.5 (318) 49 (1245) *

DOUBLE WALL PIPE 9 (229) 7 (178) 19.5 (495) 9 (229) 3 (76) 12 (305) 49 (1245) 10 (254)

SINGLE WALL PIPE 9.25 (235) 7.5 (191) 18 (457) 8 (203) 3.5 (89) 12.5 (318) 49 (1245) *

DOUBLE WALL PIPE 9.25 (235) 7.5 (191) 18 (457) 8 (203) 3 (76) 12 (305) 49 (1245) 10 (254)

VENT SPECIFICATIONS:

SINGLE WALL: Six inch (6 inches) (152mm) diameter, minimum 24 MSG black or

blued steel connector pipe, with a listed factory-built UL103HT* Class "A" chimney,

suitable for use with solid fuels, or a masonry chimney, and the referenced clearances.

DOUBLE WALL: Six inch (6 inches) (152mm) diameter, listed double wall air

insulated connector pipe with listed factory-built UL103HT* Class "A" chimney, or a

masonry chimney and the referenced clearances

*In Canada must comply with Standard CAN/ULC-S629-M87 for the 650 degree

Factory-built chimneys.

MOBILE HOME: Use double wall pipe by Dura-Vent DVL, Selkirk Metalbestos DS or

Security DL double wall connector pipe. Must be equipped with a spark arrestor.

Apply double wall clearances below when installing unit.

SERIAL NO.

/ NUMÉRO DE S

WS22 WOOD STOVE

7057-

CHAUD LORS DE L'OPÉRATION. NE PAS TOUCHER. GARDEZ LES ENFANTS ET LES VÊTEMENTS LOIN DE L'ESPACE DÉSIGNÉ DE L'INSTALLATION. LE CONTACT PEUT

DES BRÛLURES À LA PEAU. GARDEZ LES MEUBLES ET LES MATÉRIAUX COMBUSTIBLES LOIN DE L'ESPACE DÉSIGNÉ DE L'APPAREIL. VOIR L'ÉTIQUETTE ET LES INSTR

ATTENTION:

APPAREIL DE CHAUFFAGE DE PIÈCE, DE TYPE DE

COMBUSTIBLE SOLIDE, POUR USAGE DANS LES

MAISONS MOBILES. (UM) 84-64 HUD. "Pour Usage

Avec Bois Solide Seulement"

Installez et utilisez en accord avec les instructions

d'installation et d'opération du fabricant. Contactez le bureau

de la construction ou le bureau des incendies au sujet des

restrictions et des inspections d'installation dans votre

voisinage. Ne pas obstruez l'espace en dessous de l'appareil.

AVIS - Pour Les Maisons Mobiles: Ne pas installer dans une

chambre à coucher. Un tuyau extérieur de combustion d'air

doit être installé et ne doit pas être obstrué lorsque l'appareil

est en usage. La structure intégrale du plancher, du plafond et

des murs de la maison mobile doit être maintenue intacte.

L'appareil de chauffage doit être fixé à la charpente de la

maison mobile. Les composants requis pour l'installation des

maisons mobiles: Assemblage d'air extérieur, Numéro de

Pièce OAK-ACC.

Référez vous aux instructions du fabricant et des codes

locaux pour les précautions requises pour passer une

cheminée à travers un mur ou un plafond combustibles, et les

compensations maximums.

Inspectez et nettoyez la cheminée fréquemment. Sous

certaines conditions, il se peut que la créosote s'accumule

rapidement.

Ne pas connecter cet appareil à une cheminée servant un

autre appareil.

Composants Optionnels: Ventilateur Optionnel, Pièce

BK-ACC.

Puissance Électrique: 115 VAC, 1.2 Amps, 60 Hz.

Éloignez le fil électrique de l'appareil. Ne pas faire passer le fil

électrique au dessus ou en dessous de l'appareil.

DANGER: Il y a risque de décharge électrique. Déconnectez

le fil électrique de la prise de contact avant le service.

Remplacez la vitre seulement avec une vitre céramique de 5

mm disponible chez votre fournisseur.

N'élevez pas le feu. Bâtissez le feu de bois directement sur

l'âtre.

Ne pas surchauffer. Si l'appareil de chauffage ou le tuyau de

PRÉVENTION DES FEUX DE MAISON

ESPACES LIBRES MINIMUM DES MATÉRIAUX COMBUSTIBLES En P

(millimètres)

NOTE: Toutes les dimensions "A", "C", et "F" sont à partir du diamètre i

l'entrée du conduit.

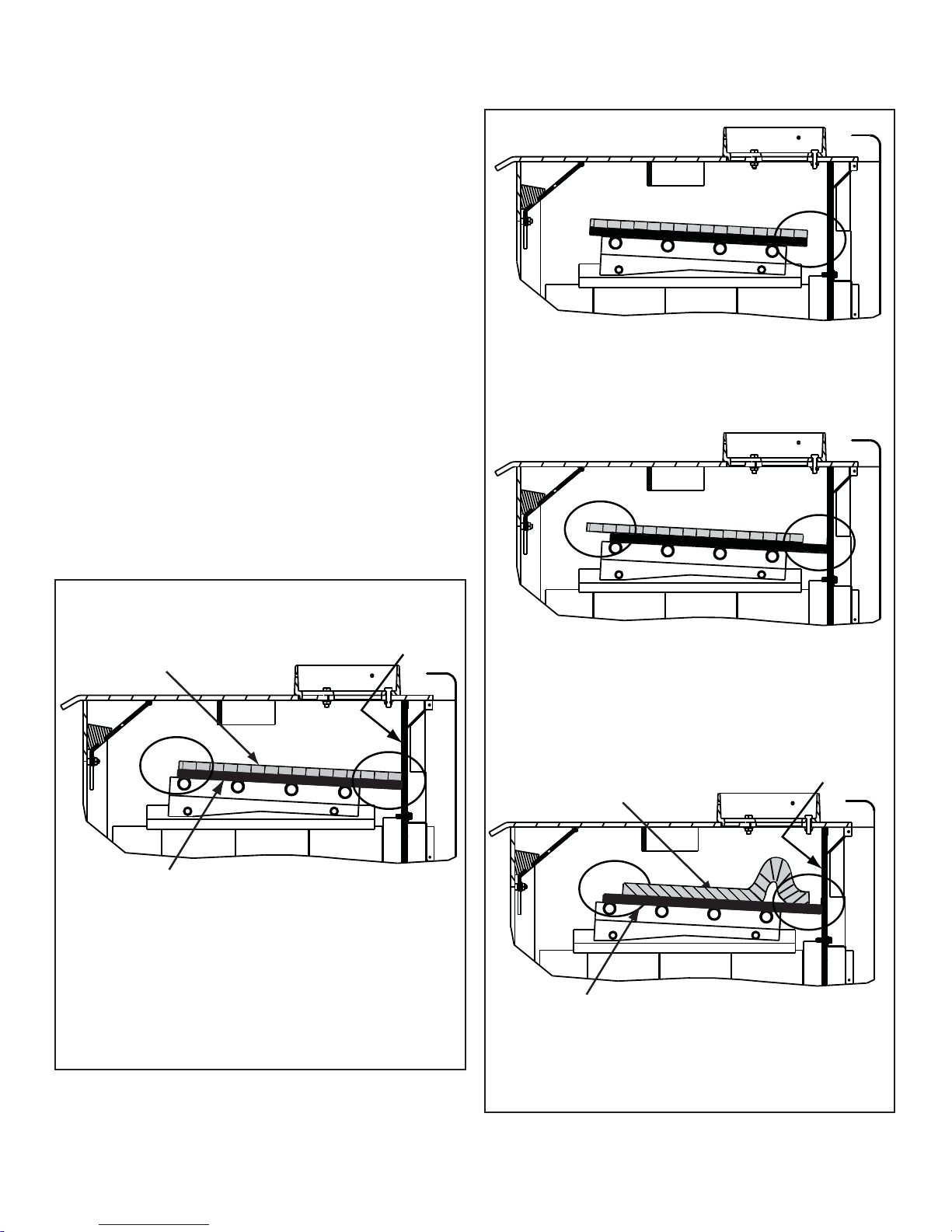

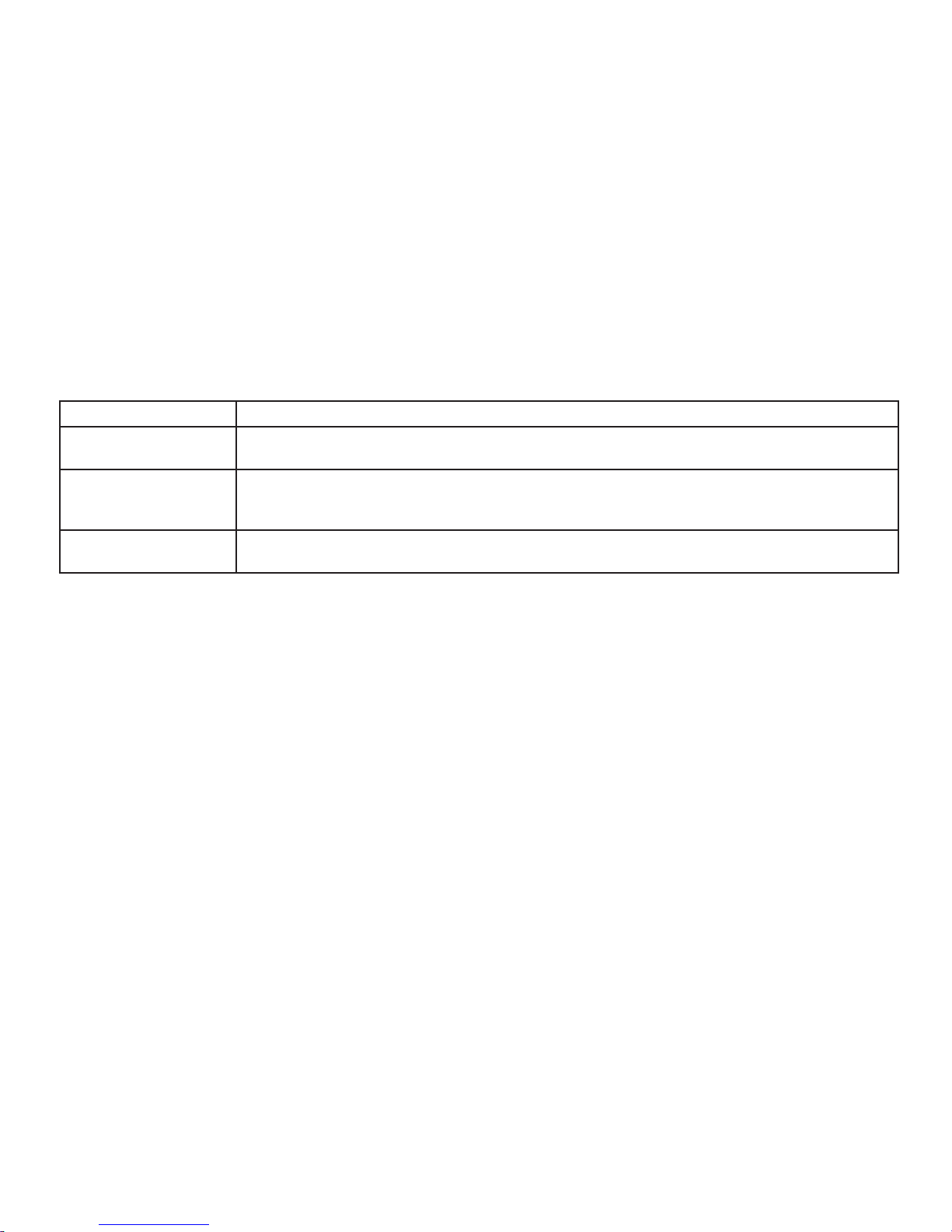

BACKWALL/SIDEW

MUR ARRIÈRE/MUR D

CORNER INSTALLATI

INSTALLATION DU CO

CONDUIT DU MUR SIMPLE

CONDUIT DU MUR SIMPLE

CONDUIT DU MUR DOUBLE

CONDUIT DU MUR DOUBLE

INSTALLATION: FULL VERTICAL / ENTIÈREMENT VERTICALE

INSTALLATION:

HORIZONTAL WITH MINIMUM 2 FT VERTICAL OFF STOVE TOP

INSTALLATION:

HORIZONTALE AVEC 609mm VERTICAL MINIMUM DU HAUT DU POÊLE

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER L'ÉTIQUETTE

Made in U.S.A./Fait Aux États-Unis

*Au Canada doit conformer a CAN/ULC-S629-M87 la norme pour 650 degré C

bâtit en usine.

Fabriqué par:

007017

TESTED TO:/ TESTÉ À:

UL 1482, ULC S627-00.

AB

C

D

INSTALLATION: 90

o

ELBOW OFF TOP OF STOVE THROUGH BACKWALL

INSTALLATION: 90

o

DU COURBURE AU DESSUS DE HAUT DU PO

Ê

LE A TRAVERS LE MUR ARRIERE

Test Lab and

Report Number Model Name Serial Number

Manufacturer Date

SAMPLE