ii installation & operation manual | ola heating system

IMPORTANT SAFETY

INFORMATION

!

Hazardous voltage: Before wiring, servicing or cleaning

the heating system, turn off the power and follow your

organization’s lockout and tagout procedure. Failure to do

so could allow others to turn on the power unexpectedly,

resulting in harmful or fatal electrical shock.

!

Electrical hazard: All electrical work must be done by

qualied personnel in accordance with national, state

and local codes.

Electro-static discharge: Wipe all operators and hoses

with damp cloth to reduce potential for electro-static

discharge.

CAUTION

!

Read instructions carefully: The safety of any system

incorporating this equipment is the responsibility

of the assembler. The safe and proper use of this

equipment is dependent upon the installer following

sound engineering practices. If the equipment is

used in a manner not specied by the manufacturer,

the protection provided by the equipment may be

impaired. All applicable electrical safety standards

dened by local jurisdictions must be followed.

(Reference EU directive 2014/34/EU in EU countries.)

• Read carefully: Installers and operators of this

equipment must be thoroughly familiar with the

instructions in this manual before commencing work.

• Hot surfaces: Avoid contact with the system while it

is in service. Some surfaces may remain hot even if

the system is not energized.

• Proper lifting: Use proper lifting equipment and

rigging to move this equipment. Create a plan

before attempting to move. Proper lifting locations

are identied with labels on each system; use these

locations when lifting and mounting the system.

• Rotating equipment: The heating system can start

automatically and without warning. Avoid contact

unless a lockout at the service panel has been

installed.

• Grounding: The heating system must be connected

to a suitable ground (protective earthing conductor).

• Overcurrent limiting: The power supply must be

protected by a suitable overcurrent limiting device.

• Power disconnection: A means to disconnect the

heating system from the power supply is required.

HOTSTART recommends that a power switch or

circuit breaker be located near the heating system

for safety and ease of use.

• Flameproof joints: Flameproof joints are not

intended to be repaired in the eld. Do not attempt

to repair any ameproof joints that become

damaged.

• Bend radius: Do not adjust cable bend radius in the

eld. Cables are pre-wired to meet the minimum

requirements for bend radius. If a cable is moved

from factory positioning, adjust cable to ensure

minimum bend radius is 7 × (Ø) outer diameter of

the cable.

• Enclosure yield strength: The enclosures utilize

metric bolts that are Class 8.8 minimum and Class

A4-70 with a minimum yield strength of 600 MPa.

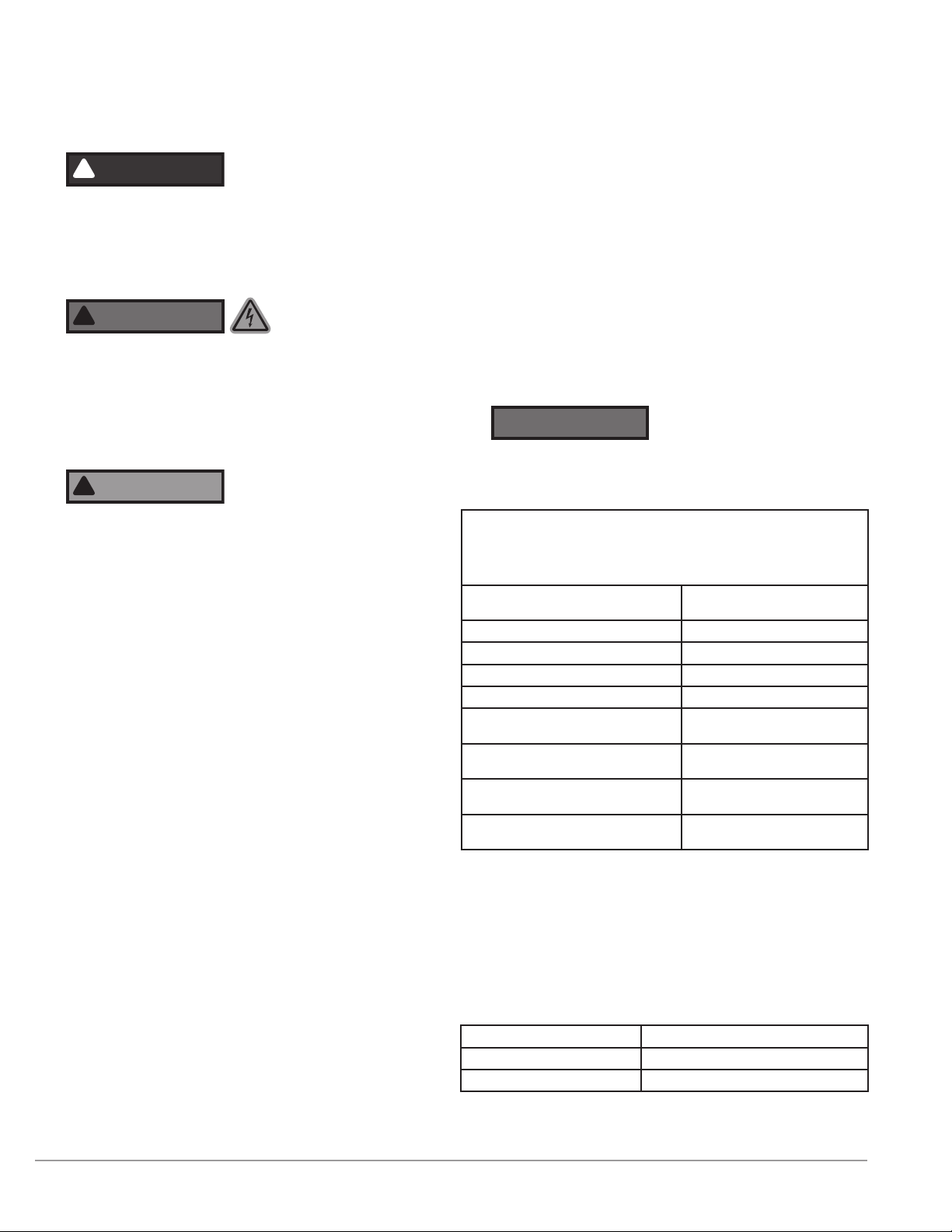

NOTICE

EU Countries only: Equipment rated for the conditions

listed in EN 601010-1 1.4.1 Ingress protection rating IP54.

(Special conditions for specic applications may apply.)

CERTIFICATIONS

Certications:

IECEx UL 18.0106X

Ex db IIA T3 Gb

DEMKO 18 ATEX

2107X

C0539 ` II 2 G Ex

db IIA T3 Gb

Standards used for

certications:

• IEC 60079-0:2011

and Corr. 1:2012

and Corr. 2:2013

• IEC 60079-1:2014

• EN 60079-0:2012

and A11:2013

• EN 60079-1:2014

• IEC TS 60079-46

Max/ Min. process uid temp. 0 °C to 80 °C

Ambient temp. -20 °C to 40 °C

Voltages 120 to 575 V AC, 50/60 Hz,1/3 phase

The following additional previous editions of Standards noted under the

“Standards” section of the Certicate were applied to integral Components

as itemized below. There are no signicant safety related changes between

these previous editions and the editions noted under the “Standards”

section.

Weg Induction Motors of Frame Size

90 to 132 IEC 60079-1 Edition 2007

Siemens Motors IEC 60079-0 Edition 2009

Siemens Motors IEC 60079-1 Edition 2007

ABB M3JP Motors IEC 60079-0 Edition 2009

ABB M3JP Motors IEC 60079-1 Edition 2007

CMP Products Limited TMC2X

Range of Cable Glands IEC 60079-1 Edition 2007

CMP Products Limited Cable Gland

Types PX** IEC 60079-1 Edition 2007

Adalet/Scott Fetzer Co. XCEX

Series Enclosures IEC 60079-0 Edition 2009

Adalet/Scott Fetzer Co. XCEX

Series Enclosures IEC 60079-1 Edition 2007