SMP000SS-654Installation, Operation, and Maintenance Manual

L6SMP000SS-654

18

11 of 44 © 2020 654_D - 02/20

Access Levels and Access Level Lock

The control is shipped pre-programmed with common settings.

The control has an

“

Installer

”

access level that allows full

access to all settings and a

“

User

”

access level that restricts

the number of settings available. The control defaults to the

“

User

”

access level after 12 hours of operation.

Notice: tekmarNet® system controls include a Global Lock that

locks all connected snow melting controls and thermostats. Set

the tekmarNet® system control to unlock to allow access level

adjustment on all connected devices.

To change to the

“

Installer

”

access level:

• In the Toolbox menu, locate Access

•

Adjust the access level to

“

Installer

”

by pressing the up or down

button. This will permit setting changes to the control.

Press and hold the Home button for 3 seconds to enter the programming menus. The control returns to the last programming

menu previously used.

Select a Programming Menu

--------------------

•

Touch “NEXT” to advance (clockwise in above illustration)

to the next menu.

•

Touch “BACK” to go backwards (counterclockwise in above

illustration) through the menus.

• Touch “ENTER” to enter a menu.

Setting Items

------------------------------------

------------------------------------

• Touch or arrow to adjust the setting if required.

• Touch “NEXT ITEM” to advance to the next item within the

menu.

•

Touch “BACK ITEM” to go backwards to the previous item

within the menu.

•

To return to the parent menu after changing a setting, press

and release the Home button.

• To return to the Home screen, press and release the Home

button twice or wait 30 seconds to automatically return to

the Home screen.

Press and

hold for 3

seconds to

access the

programming

menus.

Programming Menus

© 2020 654_D - 02/20 12 of 44

View Menu (1 of 2)

The View menu items display the current operating temperatures and status information of the system.

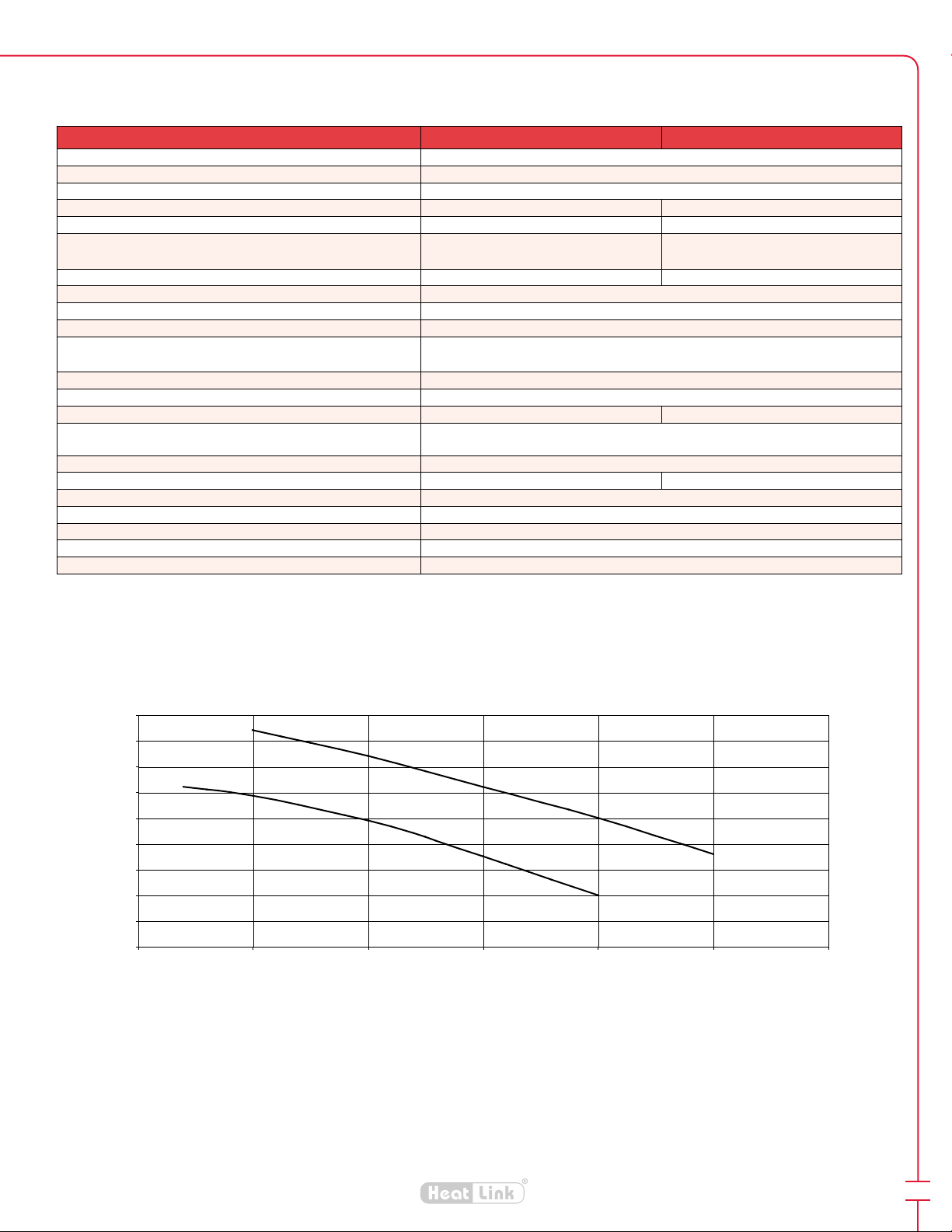

Item Field Range Access Description Set to

1 to 12 User

Installer

SNOW ZONE

The snow melt zone number on the tekmarNet®

system.

Conditions: tekmarNet® communication available.

– – –, -76 to

149°F

(-60 to 65°C)

User

Installer

OUTDOOR

Current outdoor air temperature as measured by the local

or remote outdoor sensor. The outdoor air temperature is

shared to all devices in the tekmarNet® system. “– – –” is

displayed when no outdoor sensor is available.

Conditions: Application Mode is set to PWM, Boil, Mix or

Elec.

– – –, -76 to

149°F

(-60 to 65°C)

Installer

SLAB TARGET

The calculated slab target of the snow melting system.

“– – –” is displayed when the snow melt control is off.

Conditions: Application Mode is set to PWM, Boil, Mix or Elec

and a snow/ice sensor or slab sensor is installed.

-76 to 149°F

(-60 to 65°C)

User

Installer

SLAB

Current slab temperature as measured by the control.

Conditions: Application Mode is set to PWM, Boil, Mix or Elec

and a snow/ice sensor or slab sensor is installed.

DRY or WET User

Installer

WATER SENSOR

Current status of the water detection sensor.

Conditions: A snow/ice sensor or snow sensor is installed.

---, 70 to 200°F

(21.0 to 93.5°C) Installer

BOILER TARGET

The calculated boiler target of the snow melt system.

“– – –” is displayed when the snow melt control is not operating

the boiler.

Conditions: Application Mode is set to Boil.

---, 70 to 200°F

(21.0 to 93.5°C) Installer

MIX TARGET

The calculated mix target of the snow melt system. “– – –”

is displayed when the snow melt control is not operating the

mixing valve or mixing injection pump.

Conditions: Application Mode is set to Mix.

-58 to 212°F

(50.0 to 100.5°C) Installer

SUPPLY

Current system supply temperature as measured by the

control.

Conditions: Application Mode is set to PWM, Boil or Mix.

-58 to 212°F

(50.0 to 100.5°C) Installer

BOILER RETURN

Current boiler return temperature as measured by the

control.

Conditions: Application Mode is set to PWM, Boil or Mix and

Out/Bret Sensor is set to Bret (boiler return sensor).

0 to 100% Installer

MIX RATE

Current position of the mixing valve or mixing injection

pump speed.

Conditions: Application Mode is set to Mix.

0 to 100% Installer

BOILER RATE

Current firing rate of the modulating boiler.

Conditions: Application Mode is set to Boil and Boiler Type

is set to Mod (modulating boiler).