Hedman DI-100 User manual

198552HF 4/00

HEDMAN

DI-100

Document Imprinter

Service Manual

DI-100 Document Imprinter

Service Manual

4/00 i

TABLE OF CONTENTS

1. INTRODUCTION ..............................................................................................1

1.1 WHAT’S EXPECTED OF THE TECHNICIAN .............................................................. 1

1.2 SERVICE LEVEL .................................................................................................1

1.3 ADDITIONAL SERVICE SUPPORT..........................................................................1

1.4 SAFETY TERMS .................................................................................................2

1.5 SAFETY PRECAUTIONS.......................................................................................3

1.6 FREQUENTLY-USED TERMS................................................................................4

1.7 REPACKING INSTRUCTIONS ................................................................................5

2. SPECIFICATIONS & REQUIREMENTS...........................................................6

2.1 PHYSICAL SPECIFICATIONS.................................................................................6

2.2 ELECTRICAL REQUIREMENTS..............................................................................6

2.3 OPERATING REQUIREMENTS...............................................................................7

2.4 NECESSARY TOOLS ...........................................................................................7

3. OPERATION.....................................................................................................8

3.1 DI-100 DESCRIPTION ........................................................................................8

3.2 SEQUENCE OF OPERATION.................................................................................8

3.3 OPERATING INSTRUCTION ................................................................................10

3.4 OPERATING TIPS .............................................................................................12

3.4.1 ENDORSING SMALL DOCUMENTS ...............................................................................12

3.4.2 CALCULATING PIECES FED PER MINUTE ...................................................................12

3.4.3 FINDING A NON-IMPRINTED DOCUMENT....................................................................12

3.4.4 FEEDING VARIOUS SIZED DOCUMENTS .....................................................................13

4. POWER CONNECTION .................................................................................14

4.1 SAFETY .......................................................................................................... 14

4.2 LINE VOLTAGE ................................................................................................14

4.3 LINE FUSES ....................................................................................................16

4.4 POWER CORD .................................................................................................17

5. MAINTENANCE .............................................................................................18

5.1 CLEANING....................................................................................................... 18

5.2 ADJUSTING BELT TENSION ...............................................................................19

5.3 REPLACING A FUSE......................................................................................... 20

6. TROUBLESHOOTING ...................................................................................22

6.1 OPERATION TROUBLESHOOTING .......................................................................22

6.2 MECHANICAL TROUBLESHOOTING .....................................................................23

6.3 ELECTRICAL TROUBLESHOOTING ......................................................................24

DI-100 Document Imprinter

Service Manual

ii 4/00

7. PROCEDURES............................................................................................... 25

7.1 BASE..............................................................................................................25

7.2 CIRCUIT CARD ................................................................................................28

7.3 CONTROL PANEL .............................................................................................29

7.4 COUNTER .......................................................................................................30

7.5 DOCUMENT DETECTOR .................................................................................... 31

7.5.1 TESTING THE DETECTOR..............................................................................................31

7.5.2 OPTIMIZING THE DETECTOR POSITION......................................................................32

7.5.3 REPLACING THE DETECTOR ........................................................................................33

7.6 DOCUMENT EMITTER .......................................................................................34

7.7 FEED MOTOR ..................................................................................................35

7.8 FEED ROLLS ...................................................................................................38

7.9 FEED TIMING BELT........................................................................................... 40

7.10 FOAM ROLLS................................................................................................. 42

7.11 FUSES ..........................................................................................................43

7.12 MEDIA FEED SWITCH .....................................................................................44

7.13 PADDLE WHEEL ............................................................................................45

7.14 PAPER GUIDES.............................................................................................. 48

7.15 PLATEN GAP (WIDENING)...............................................................................50

7.16 POWER ENTRY CASING ..................................................................................51

7.17 POWER SWITCH ............................................................................................52

7.18 SEPARATORS ................................................................................................54

7.19 SIGNATURE MOTOR .......................................................................................56

7.20 SIGNATURE TIMING BELT................................................................................58

7.21 TIMING BELT .................................................................................................58

7.22 TRANSFORMER..............................................................................................62

8. SYSTEM DIAGRAM .......................................................................................63

9. ILLUSTRATED PARTS GUIDE...................................................................... 64

DI-100 Document Imprinter

Service Manual

4/00 1

1. INTRODUCTION

1.1 What’s

Expected of

the Technician

This service manual assumes the Service Technician is

skilled at installing and operating the DI-100.

1.2 Service Level

This service manual contains procedures which will:

1. Identify faulty or worn parts and assemblies.

2. Provide procedures for the removal and replacement of

faulty or worn parts and assemblies.

Every effort has been made to include accurate and

complete servicing instructions. Both HEDMAN and the

manufacturer assume the availability of experienced

personnel who are familiar with servicing machines.

Although the procedures contained in this service manual

present the manufacturer’s recommended methods for

testing and repairing the DI-100, certain servicing

techniques may be implied.

1.3 Additional

Service Support

Before servicing the DI-100, read the Operating Manual. If

you need additional support, contact the Customer Service

Center of The HEDMAN Company at (800) 872-2788.

Please be prepared to state your name, company and serial

number of the machine.

DI-100 Document Imprinter

Service Manual

2 7/01

1.4 Safety Terms

The following highlighted blocks are used throughout this

guide to emphasize important information. Pay very

careful attention to this information.

WARNING

USED TO ALERT YOU TO ACTIONS OR

CONDITIONS WHICH MAY PRESENT HAZARDS

OR CAUSE INJURY TO PERSONNEL.

CAUTION

USED TO ALERT YOU TO ACTIONS WHICH MAY

DAMAGE DOCUMENTS OR EQUIPMENT.

NOTE

Used to identify unusual or unexpected

conditions or to point out the need for alternate

procedures. A NOTE may also be used for

emphasis when a WARNING or CAUTION are not

required.

TIP

A suggestion to enhance the DI-100’s

productivity.

DI-100 Document Imprinter

Service Manual

4/00 3

1.5 Safety

Precautions

Observe the following safety precautions and warnings at

all times while operating, cleaning, servicing or repairing

the DI-100. Failure to so may result in physical injury or

damage to the DI-100. Neither HEDMAN nor the

manufacturer assumes any liability for your failure to

comply with these requirements.

WARNING

READ ALL WARNINGS AND CAUTIONS.

WARNING

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM SERVICE AND REPAIRS.

WARNING

NEVER CLEAN, CLEAR OR DISASSEMBLE THE

DI-100 WITHOUT FIRST UNPLUGGING THE

POWER CORD.

WARNING

KEEP LOOSE CLOTHING, TIES, SCARVES AND

HAIR AWAY FROM ALL MOVING PARTS.

WARNING

DO NOT PLACE FINGERS BETWEEN OR NEAR

MOVING PARTS.

DI-100 Document Imprinter

Service Manual

4 7/01

1.6 Frequently-

Used Terms

leading edge The edge of the document that

enters and exits the DI-100 first.

trailing edge The edge of the document that

enters and exits the DI-100 last.

imprint position The point at which the document

is imprinted.

imprint saddle Contains a plastic relief of the

imprint; 2 imprint saddles are in

the rounded imprint saddle

holder - as one is imprinting, the

other is being inked.

operator side The side of the DI-100 where

most of the controls are located.

input end The end of the DI-100 where the

document enters the DI-100.

output end The end of the DI-100 where the

document exits the DI-100.

DI-100 Document Imprinter

Service Manual

4/00 5

1.7 Repacking

Instructions

If it is necessary to return the DI-100 to HEDMAN, pack it

in the original shipping container and material. If the

original container is not available, the DI-100 and its

accessories should be carefully packed so that they will not

be damaged in transit.

NOTE

If the DI-100 is packed correctly, your Shipping

Carrier is liable for any shipping damage.

Use the following instructions to pack the DI-100 with

commercially available materials.

1. Double wrap the machine in plastic.

2. Use a heavy duty, double-walled container of 350-

pound test material.

3. Surround the DI-100 on ALL sides with at least 4 to 5

inches of shock absorbing packaging material. This will

provide firm cushioning and prevent movement inside

the container.

4. Seal the top and bottom of the shipping container with

strong tape or banding.

5. Clearly and legibly mark the shipping container

FRAGILE.

6. Ship the DI-100 prepaid and insured.

DI-100 Document Imprinter

Service Manual

6 7/01

2. SPECIFICATIONS & REQUIREMENTS

2.1 Physical

Specifications

Size

19½" (49.53 cm) W x 10" (25.43 cm) H x

19" (48.26 cm) D

The receiving tray is not measured.

Weight

Machine alone: 50 pounds (22.68 kg )

Shipping weight: 57 pounds (25.85 kg)

Speed

19"(45.72 cm) per second

2.2 Electrical

Requirements

CAUTION

ONLY OPERATE THE DI-100 ON A GROUNDED

POWER LINE TO AVOID MICRO-PROCESSOR

DAMAGE CAUSED BY POWER SURGES.

Power

The DI-100 is rated for continuous operation using a

variety of supply voltages. Possible line voltages are

240V, 220V, 120V and 100V at 50-60 Hz

DI-100 Document Imprinter

Service Manual

4/00 7

2.3 Operating

Requirements

Document Size

Maximum length: 14" (35.56 cm)

Minimum length: 31/8" (10.92 cm)

Maximum width: 14" (35.56 cm)

Minimum width: 27/8" (7.3 cm)

Weight: 20# - 125# stock

Range of Imprint Placement

Approximately 9" (22.86 cm) from the leading edge

toward the trailing edge.

Approximately 6½" (16.51 cm) left or right from the

center of the document.

Range of Accuracy

±1/8"

2.4 Necessary

Tools

• hex key - 1/8"

• hex key - 3/16"

• hex key - 5/64"

• wrench - 9/16"

• holt driver - size 6

• holt driver - size 10

• screw driver - or similar tool

• pliers

• ring puller

• super glue

• V-O-M

DI-100 Document Imprinter

Service Manual

8 7/01

3. OPERATION

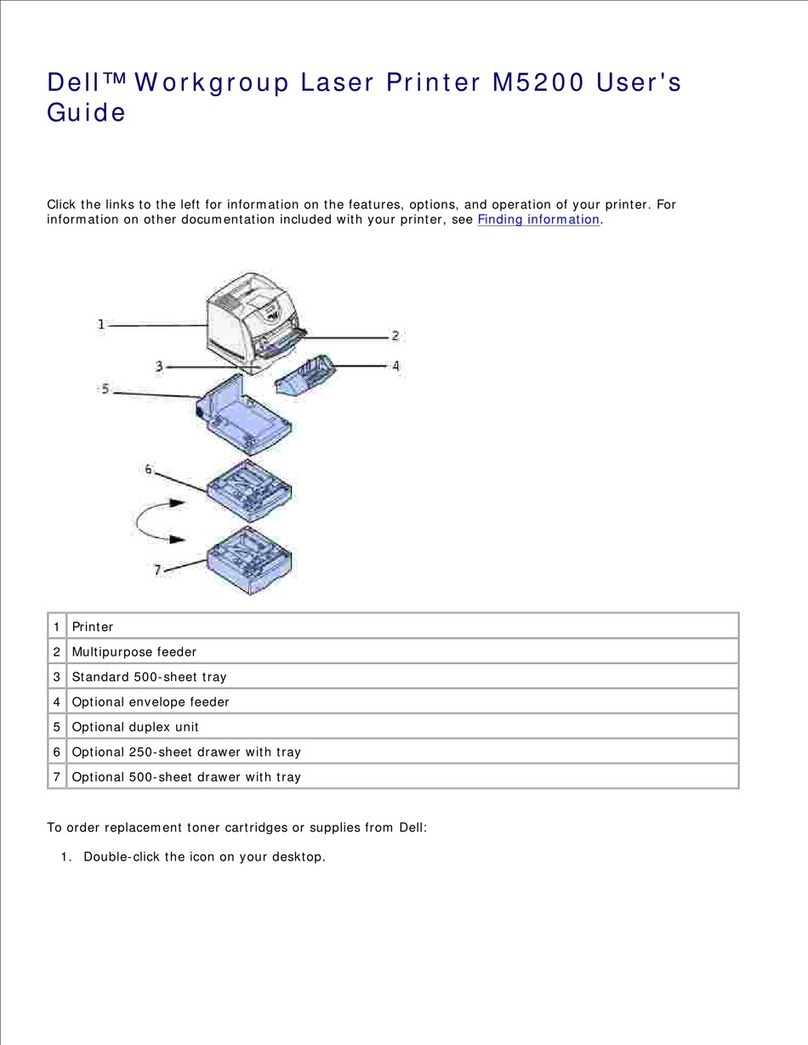

3.1 DI-100

Description

The DI-100 is a document imprinter used for signing,

endorsing and validating cut-sheet documents.

3.2 Sequence of

Operation

1. Documents to be imprinted are stacked in the FEED

TRAY.

2. The SEPARATOR separates the stack into single

pieces as the FEED ROLL feeds them through the DI-

100.

3. A DC MOTOR drives the PADDLE WHEEL, FEED

ROLL and BACKUP PLATEN. Power to the motor is

supplied by, and can be interrupted by, the MEDIA

FEED SWITCH.

4. The leading edge of each document is sensed when it

breaks a beam of infrared light near the SADDLE

HOLDER. This beam is supplied by the DOCUMENT

EMITTER and sensed by the DOCUMENT

DETECTOR. The DOCUMENT DETECTOR

transmits this information to the MICROPROCESSOR.

5. Sensing the leading edge of a document triggers the

MICROPROCESSOR to start a time delay routine. The

length of time is determined by the selected imprint

position using the IMPRINT POSITION CONTROL.

6. When the time delay is finished, the SIGNATURE

MOTOR rotates the SADDLE HOLDER if the

IMPRINT KEY is turned on. The SIGNATURE

MOTOR rotates 180 degrees when the first IMPRINT

SADDLE imprints the document and the second

IMPRINT SADDLE is inked. Two IMPRINT

SADDLES are always required.

7. The SADDLE HOLDER reaches its correct position

when the integral infrared light of the PULSE WHEEL

PHOTOCELL detects the PULSE SLOTS on the

PULSE WHEEL.

DI-100 Document Imprinter

Service Manual

4/00 9

8. The POWER INTERLOCK SWITCH and the

EXECUTIVE MICROSWITCH detect the position

(locked or unlocked) of the EXECUTIVE KEY.

Turning the EXECUTIVE KEY to the unlocked

position (clockwise) interrupts the power supplied to

the DI-100. Turning the EXECUTIVE KEY to the

locked position (counterclockwise) supplies power at

the POWER INTERLOCK SWITCH and engages the

EXECUTIVE MICROSWITCH. Under this condition,

the SIGNATURE MOTOR rotates the SADDLE

HOLDER to position the IMPRINT SADDLES for

accurate imprinting.

If the EXECUTIVE KEY is in the locked position

when the POWER SWITCH is turned on, power is

supplied at the POWER INTERLOCK SWITCH but

the SIGNATURE MOTOR does not rotate the

SADDLE HOLDER.

9. The FEED indicator (light) flashes on and off as

documents feed through the DI-100.

10. The IMPRINT light flashes on and off as the IMPRINT

SADDLES rotate. This indicator is linked to the

PULSE WHEEL.

11. The COUNTERS count documents as they are

imprinted.

12. Documents exit the DI-100 and stack on the

RECEIVING TRAY.

DI-100 Document Imprinter

Service Manual

10 7/01

3.3 Operating

Instructions

Use the following instructions to eliminate operator errors:

1. Load the SADDLES for the desired function. Two

IMPRINT SADDLES are required.

2. Adjust the gap between the SEPARATOR and the

FEED ROLL to feed one document at a time.

3. Place a stack of documents in the FEED TRAY.

NOTE

NCR, pin-fed and perforated paper require fine

adjusting in order to feed properly.

a. Lift the PAPER WEIGHT and center one document

against the SEPARATOR and the FEED ROLL and

move the PAPER GUIDES against both sides of the

document without binding it. Once that document is

ready to be fed, place a stack of documents in the

FEED TRAY.

b. Load a stack of documents no more than 1½"high

at one time in the FEED TRAY. Lower the PAPER

WEIGHT if necessary.

c. Although it is possible, loading documents while

the

DI-100 is feeding is not recommended.

4. Feed several documents before imprinting to make sure

the documents are feeding straight, smooth and one at a

time.

a. It is best to center the document with the

SEPARATOR and the FEED ROLL. To adjust the

imprint position, move the SADDLE

HOLDER.

b. Place the DOCUMENT STOPS on the

RECEIVING TRAY far enough from the machine

to allow the documents to fall freely out of the

machine. If the DOCUMENT STOPS are too close

to the machine, documents will back up into the

machine, confuse the PHOTOSENSOR and cause a

DI-100 Document Imprinter

Service Manual

4/00 11

jam. Always let the documents fall freely from the

machine and into the RECEIVING TRAY.

c. Place a single sheet of paper in the RECEIVING

TRAY to prevent exiting documents from catching

on the bottom of the DOCUMENT STOPS.

5. Turn the IMPRINT KEY to IMPRINT and the

EXECUTIVE KEY to LOCKED.

NOTE

Turn the EXECUTIVE KEY slowly. If the SADDLE

HOLDER does not index, turn the key slower.

6. Set the IMPRINT POSITION.

7. PRESS MEDIA FEED ON.

NOTE

Always imprint several test documents until the

imprint position is exactly where desired. If the

IMPRINT POSITION is placed beyond the trailing

edge, the document is counted but not imprinted.

DI-100 Document Imprinter

Service Manual

12 7/01

3.4 Operating Tips

3.4.1 Endorsing Short

Documents

Turn short documents 90º to feed the long way. Make sure

proper IMPRINT SADDLES are used for imprinting.

3.4.2 Calculating Pieces

Fed Per Minute

1. Add 1” to the length of the document. Example. If

document is 11”, add 1”to get 12”

2. Divide the sum into 20 to get documents fed per

second.

3. Multiply this number by 60 to get documents per

minute.

3.4.3 Finding A

Non-Imprinted

Document

If a certain number of documents are fed into the DI-100

and the COUNTER displays one less:

1. Feed the same stack of documents again without

imprinting.

2. Watch for the one document missing an imprint.

3. Once found, stop feeding the stack and feed the single

document, imprint and resume counting.

DI-100 Document Imprinter

Service Manual

4/00 13

3.4.4 Feeding Various

Sized Documents

Place the documents between the PAPER GUIDES. Justify

the documents to the right with the leading edge as shown

below in Figure 3.1.

Figure 3.1 -- Right Justified Documents

DI-100 Document Imprinter

Service Manual

14 7/01

4. POWER CONNECTION

WARNING

READ THE FOLLOWING INFORMATION ABOUT

LINE VOLTAGE, FUSES AND THE POWER CORD

BEFORE PLUGGING THE DI-100 INTO AN

OUTLET.

4.1 Safety

The DI-100 can connect to any power distribution system,

including the European IT Power System. Because the

European IT Power System does not have a grounded

neutral leg, the DI-100 uses protective fusing in both the

neutral and hot supply lines of power.

WARNING

A BLOWN FUSE IN THE NEUTRAL LEG COULD

MEAN INTERIOR PARTS OF THE DI-100 REMAIN

AT A HAZARDOUS VOLTAGE. ALWAYS UNPLUG

THE POWER CORD BEFORE REMOVING THE

COVERS FROM THE DI-100.

4.2 Line Voltage

The DI-100 is rated for continuous operation using a

variety of supply voltages. Possible line voltages are 240V,

220V, 120V and 100V at 50 to 60 Hz. The manufacturer

configures the DI-100 to operate with the voltage requested

by the customer.

CAUTION

VERIFY THE CORRECT VOLTAGE SETTING

BEFORE PLUGGING THE DI-100 INTO AN

OUTLET.

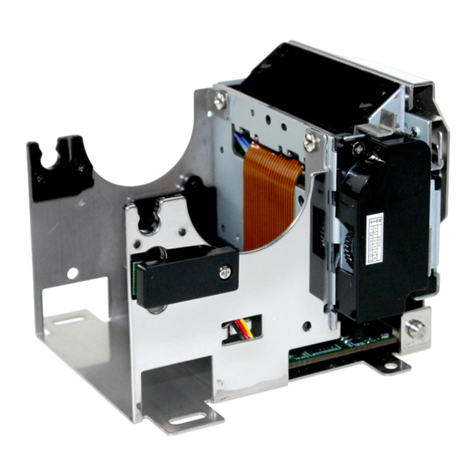

Read the selected voltage through the VOLTAGE

SELECTOR WINDOW at the input end of the DI-100.

DI-100 Document Imprinter

Service Manual

4/00 15

(Refer to Figure 4.1.) To select a different voltage, use the

following instructions:

NOTE

The detachable POWER CORD may have to be

changed to match the particular power-source

output.

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to push up on

and release the FUSE DRAWER LOCKING TAB.

3. Pull the FUSE DRAWER out of the POWER ENTRY

CASING.

4. Pull the VOLTAGE SELECTOR out of the FUSE

DRAWER.

5. Rotate the VOLTAGE SELECTOR until the correct

voltage is on the same side as the VOLTAGE

SELECTOR WINDOW.

6. Place the VOLTAGE SELECTOR in the FUSE

DRAWER and verify the correct voltage selection.

7. Place the FUSE DRAWER in the POWER ENTRY

CASING.

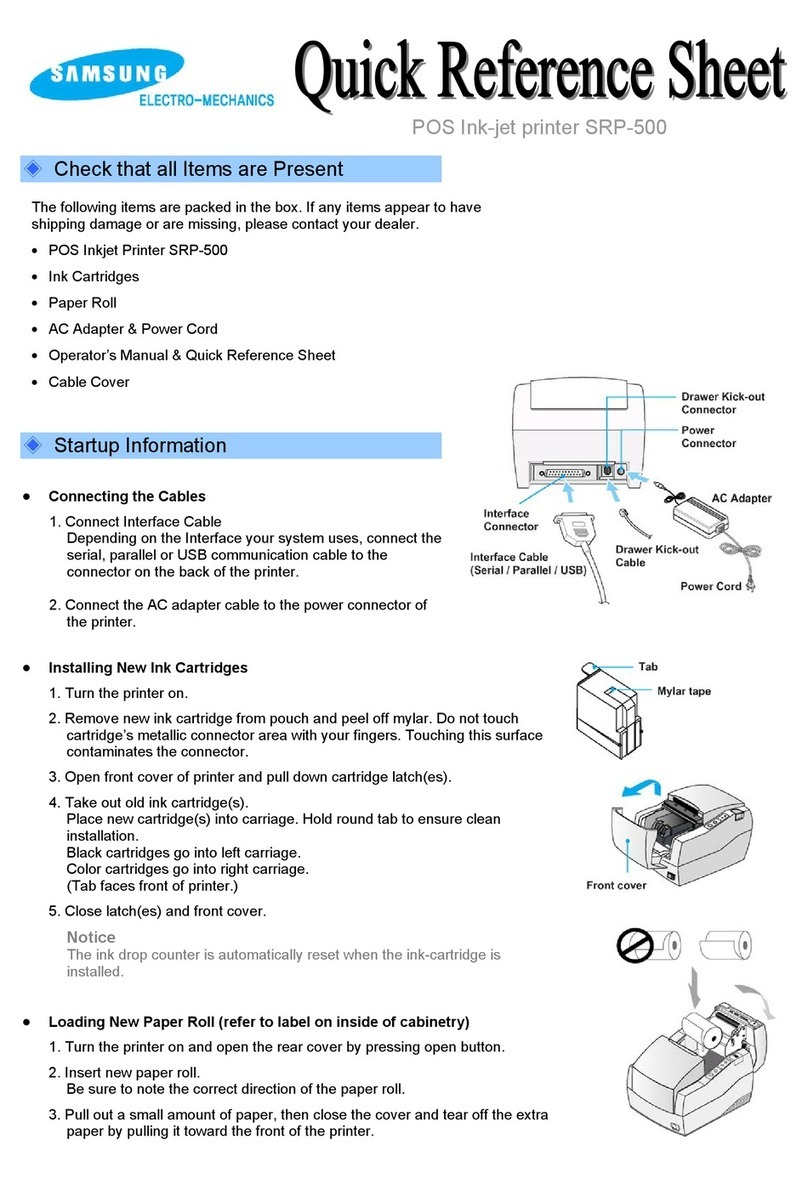

Figure 4.1 -- Power Entry

CORD

POWER

FUSE DRAWER

SELECTOR

WINDOW

VOLTAGE

LOCKING TAB

SELECTOR

VOLTAGE

FUSE DRAWER

POWER

SWITCH

FUSE

INLET

ENTRY

APPLIANCE

CASING

POWER

DI-100 Document Imprinter

Service Manual

16 7/01

4.3 Line Fuses

The FUSE DRAWER, located on the input end, contains

two LINE FUSES. (Refer to Figure 4.1.) The neutral and

hot lines of power are fused. Both LINE FUSES must be in

place for the DI-100 to operate properly.

CAUTION

VERIFY THAT THE LINE FUSE VALUE IS

CORRECT FOR THE VOLTAGE SETTING.

UNPLUG THE DI-100 BEFORE STARTING THIS

PROCEDURE.

Use the following instructions to verify that the installed

LINE FUSES have the proper fuse value:

1. Unplug the POWER CORD.

2. Use a small screwdriver or similar tool to push up on

and release the FUSE DRAWER LOCKING TAB.

3. Pull the FUSE DRAWER out of the POWER ENTRY

CASING. The attached LINE FUSES are inside.

4. Determine the proper fuse value as well as the

condition of the LINE FUSE. The fuse value is shown

on the metal tip of the LINE FUSE. The chart below

lists the selected voltage in the left column followed by

the proper fuse value in the right column.

Selected Voltage Line Fuse Value

100V 1.0A (250V time delay)

120V 1.0A (250V time delay)

220V 0.5A (250V time delay)

240V (or 230V) 0.5A (250V time delay)

5. Replace the LINE FUSE if necessary. Both LINE

FUSES must be in place for the DI-100 to operate

properly.

6. Install the FUSE DRAWER in the POWER ENTRY

CASING.

DI-100 Document Imprinter

Service Manual

4/00 17

4.4 Power Cord

The DI-100 comes with a three-wire POWER CORD. The

POWER CORD grounds the DI-100 when connected to an

approved three-contact electrical outlet.

1. Plug the POWER CORD into the APPLIANCE INLET

on the non-operator side. (Refer to Figure 4.1.)

2. Plug the POWER CORD into a grounded outlet.

WARNING

TO PREVENT ELECTRICAL SHOCK, ONLY PLUG

THE POWER CORD INTO A GROUNDED OUTLET.

Table of contents

Other Hedman Printer manuals