231135 rev.3 2019-06-26

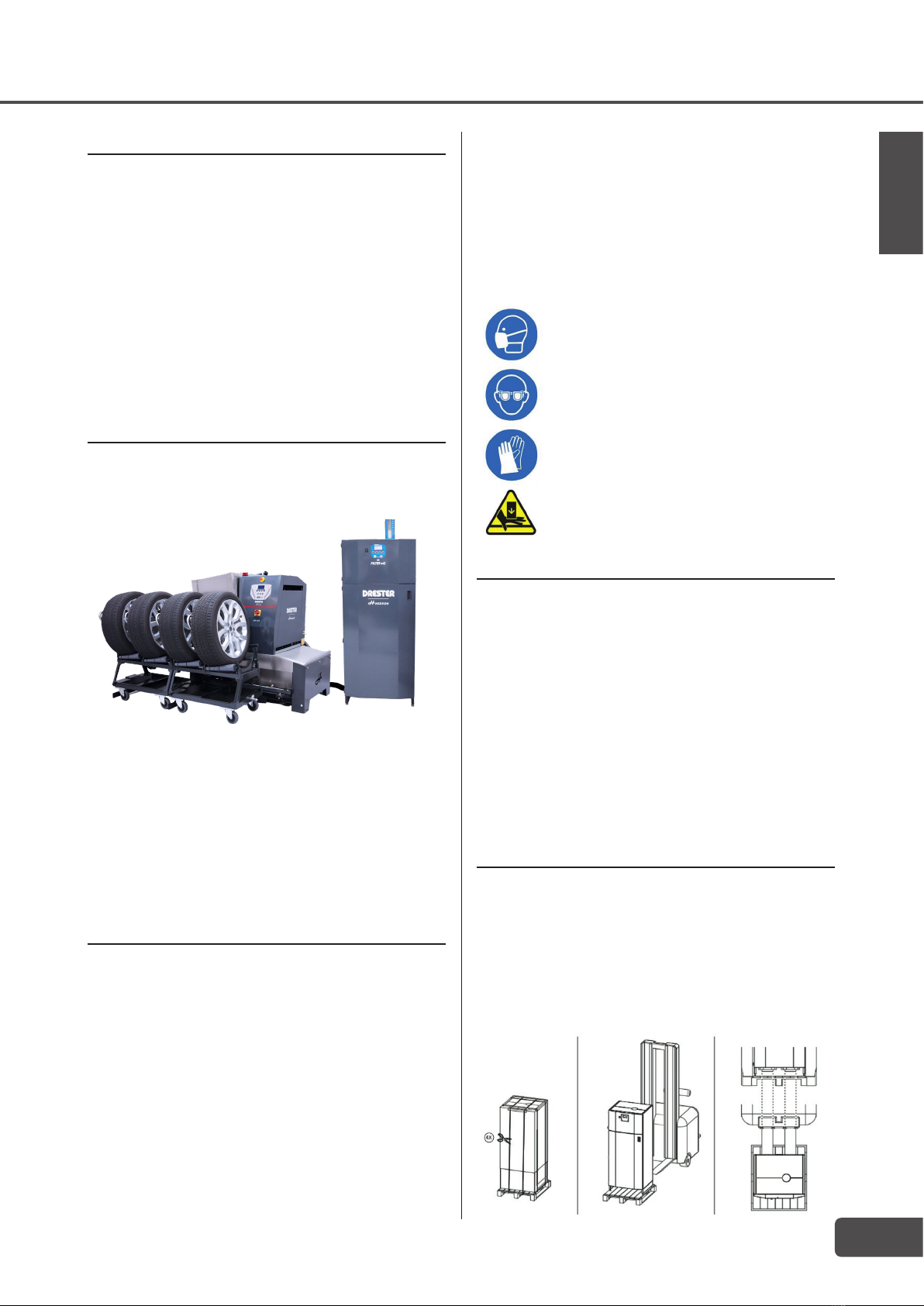

Drester GP Filter eQ

4. Turn off WW Main Switch

Ensure that the main switch on the wheel washer is

turned off. Confirm with “Enter” on the GP Filter eQ

display.

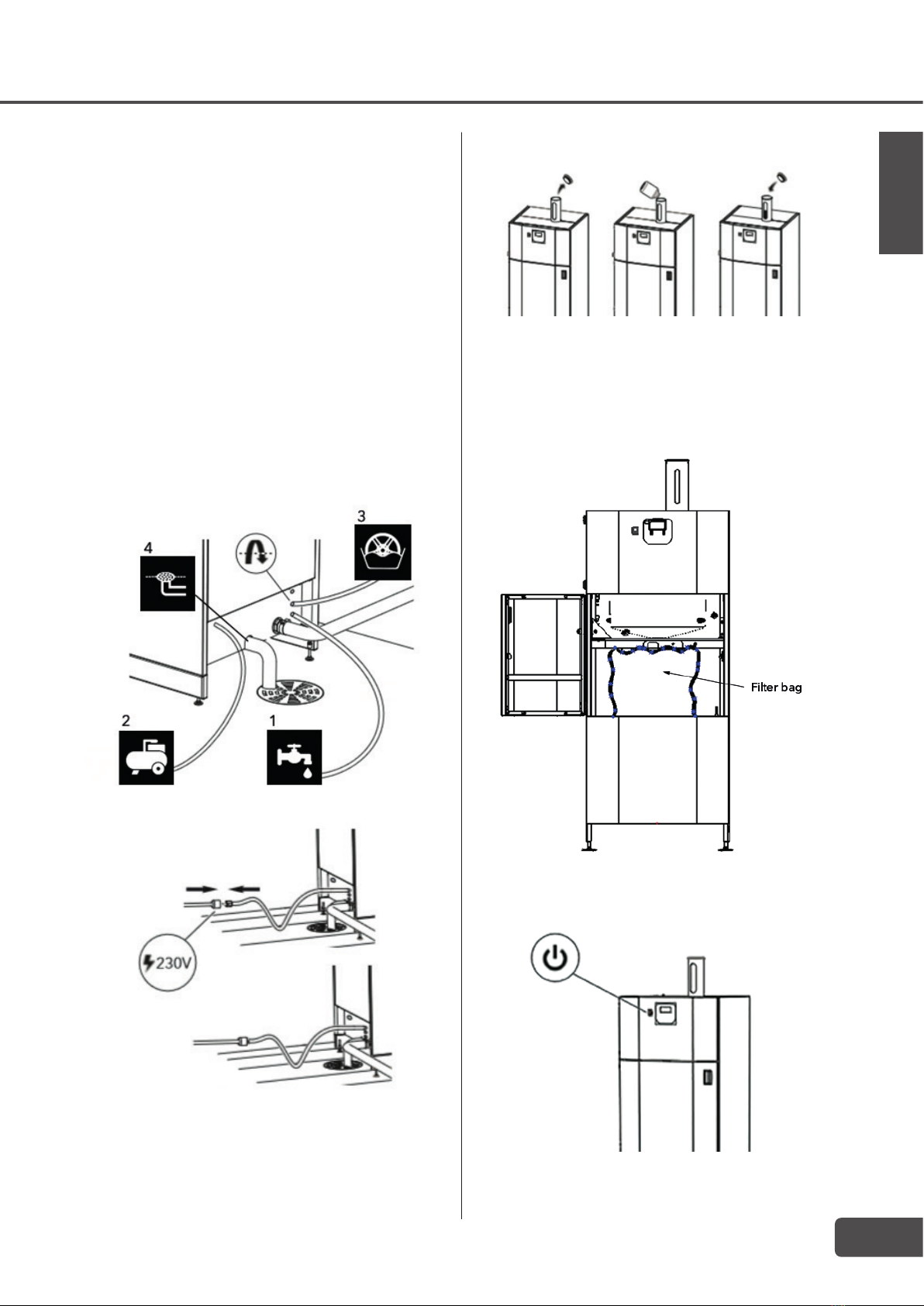

5. Refill Flocculation Powder and Replace Filter

Check the status of the filter and flocculation

powder and confirm with “Enter”.

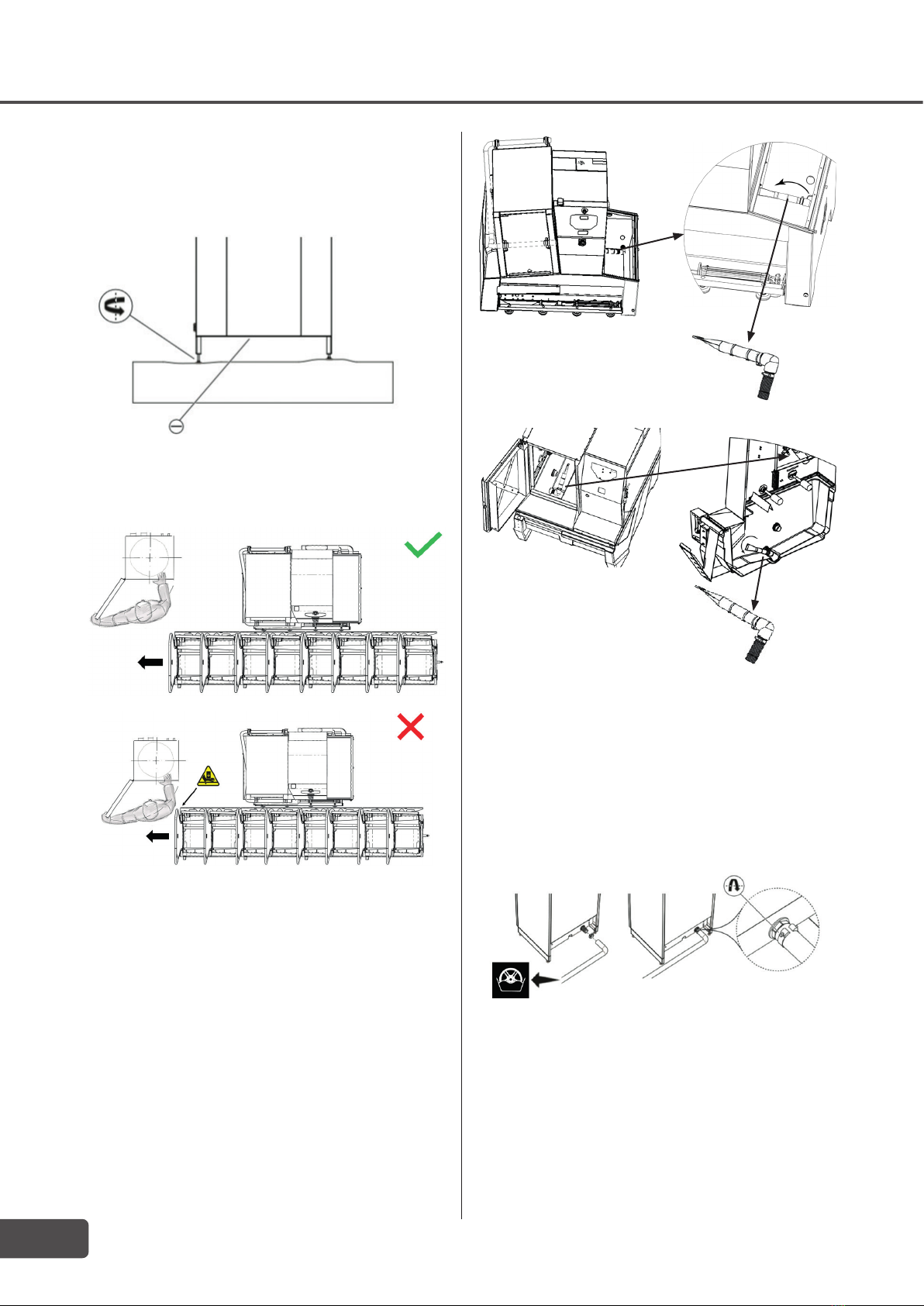

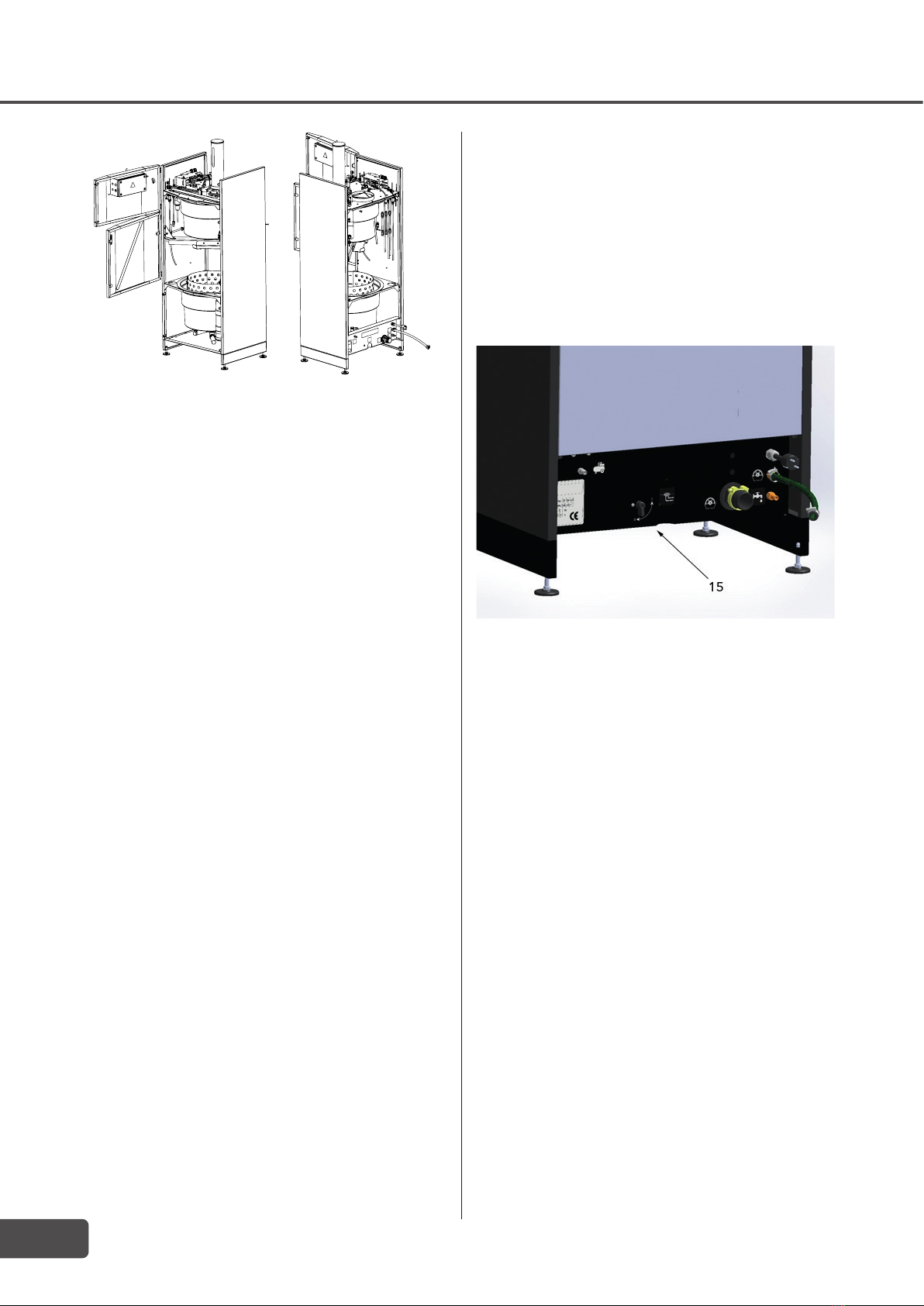

6. Close Valve to level Tube on Filter eQ

This procedure ensures that air is not suctioned

via the level tube during the final part of water

discharge. Close the ball valve (see figure below,

position 15) then confirm with “Enter” on the display.

NOTE: Control questions listed above are not displayed

during a scheduled water change.

IMPORTANT: When automatic water change is

activated, the wheel washer will be emptied of water. To

avoid damaging the wheel washer immersion heaters,

the wheel washer must be turned off at the main switch

before activating or starting a scheduled discharge.

NOTE: Before starting an automatic water change, a

new filter bag must be mounted in GP Filter eQ and the

flocculation powder container filled.

NOTE: Since the wheel washer software is independent

from GP Filter eQ, the wheel washer will signal “water

change” (granulate collection) after a certain interval.

Depending on the type of wheel washer – delete the

water change reminder and/or set the water change

interval to the maximum number of washes, alternatively

disregard the wheel washer’s recommendations for water

change to take place. However, the amount of granules

should be checked at regular intervals to ensure that

the washing results are good (the amount of granules

decreases slightly during washing and handling).

Read more about how to perform a water change in the

previous section “Menu-Water Change” under “User

Interface”.

9.3.1.2 Activating Manual Water Change

When activating manual water change, the same

process as described in the previous section “Automatic

Water Change Activation” is performed.

9.3.1 Changing Water in the Wheel Washer

When the water is to be changed in the wheel washer,

GP Filter eQ should be used for draining and filtering

the water. This should be done at least once per season,

depending on the number of washed wheels and how

dirty the wheel wash water is (and therefore the wash

result). As a rule, up to 5000 wheels can be washed

before the water in the wheel washer needs to be

changed. Shorter water change intervals can always be

scheduled because GP Filter eQ automatically empties

the wheel washer after activating the water change.

This process means that the wheel washer is emptied of

water in 15 litre increments. In total, the process takes

about 4 – 5 hours.

This process therefore replaces, to a large extent, the

“WATER CHANGE” chapter of the wheel washer manual

(which is essentially a manual process).

NOTE: The filtration process (water change) only

helps the cleaning of the wheel washer water. Any

accumulated dirt and residue inside the wheel washer

itself must therefore be removed manually.

9.3.1.1 Automatic Water Change Activation

Automatic draining of the wheel washer water can be

started directly via the menu system or programmed to

be performed at a specific time, e.g. evening when the

wheel washer is not being used or during a weekend.

See also “Menu - Water Change”.

After activating the water change, GP Filter eQ displays

the following control questions that need to be

confirmed before the process starts:

1. Start Water Change?

Confirm with “Enter” on the GP Filter eQ display.

2. Start Water Change and Follow Instructions in WW

menu

Initiate water change in the wheel washer menu.

Confirm with “Enter” on the GP Filter eQ display.

3. Granules collected?

Ensure that the granules in the wheel washer are

collected according to the procedure described

in the wheel washer manual. After completed

collection - Confirm with “Enter” on the GP Filter eQ

display.

10