Hedy HD700 Series Instructions for use

HD700 Easy start guide

(0.4kW~90

kW)

V1.

4

.0

HD700 AC Drive Easy Start Guide

Copyright © 2011 by Guangzhou HEDY Industrial Automation. Co. Ltd.

All rights reserved.

About this manual

Thank you for choosing the HD700 AC Drive from HEDY.

This manual provides asic information which will allow the user to install, setup and commission the HD700

drive for simple applications.

For full & detailed information on the drive and its options please refer to further documentation that can e

found on the HEDY we site: www.hedyiad.com

Please read the information in this manual carefully.

This user guide is for use with version V2.06 firmware.

Declaration of Conformity (size A B C)

Guangzhou HEDY Industrial Automation. Co. Ltd

No.63, Punan Road, Yunpu Industry Park, Huangpu District, Guangzhou, Guangdong, 510760, China

HD700-20D00040 HD700-20D00075 HD700-20D00150 HD700-20D00220

HD700-20T00400 HD700-40T00075 HD700-40T00150 HD700-40T00220

HD700-40T00400 HD700-40T00550 HD700-40T00750

The AC varia le speed drive products listed a ove have een designed and manufactured in accordance with

the following European harmonised standards:

EN 61800-5-1: 2007 Adjusta le speed electrical power drive systems — Part

5-1: Safety requirements — Electrical, thermal and

energy

EN 61800-3: 2004 Adjusta le speed electrical power drive systems — Part

3: EMC requirements and specific test methods

EN 50581:2012 Technical documentation for the assessment of

electrical and electronic products with the respect to

the restriction of hazardous su stances

These products comply with the Low Voltage Directive 2006/95/EC, the Electromagnetic Compati ility (EMC)

Directive 2004/108/EC, the RoHS2.0 Directive 2011/65/EU and the CE Marking Directive 93/68/EEC.

Zhao Dawei

R&D Director

Date: 12

th

Sept, 2013

These electronic drive products are intended to e used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. Compliance with

safety and EMC regulations depends upon installing and configuring drives correctly, including using the

specified input filters. The drives must e installed only y professional assem lers who are familiar with

requirements for safety and EMC. The assem ler is responsi le for ensuring that the end product or system

complies with all the relevant laws in the country where it is to e used. Refer to the User Guide. An EMC Data

Sheet is also availa le giving detailed EMC information.

HD700 AC Drive Easy Start Guide

Declaration of Conformity (size D E)

Guangzhou HEDY Industrial Automation. Co. Ltd

No.63, Punan Road, Yunpu Industry Park, Huangpu District, Guangzhou, Guangdong, 510760, China

HD700-40T01100 HD700-40T01500 HD700-40T01850 HD700-40T02200

The AC varia le speed drive products listed a ove have een designed and manufactured in accordance with

the following European harmonised standards:

EN 61800-5-1: 2007 Adjusta le speed electrical power drive systems — Part

5-1: Safety requirements — Electrical, thermal and

energy

EN 61800-3: 2004 Adjusta le speed electrical power drive systems — Part

3: EMC requirements and specific test methods

EN 50581:2012 Technical documentation for the assessment of

electrical and electronic products with the respect to

the restriction of hazardous su stances

These products comply with the Low Voltage Directive 2006/95/EC, the Electromagnetic Compati ility (EMC)

Directive 2004/108/EC, the RoHS2.0 Directive 2011/65/EU and the CE Marking Directive 93/68/EEC.

Zhao Dawei

R&D Director

Date: 12th Sept, 2013

These electronic drive products are intended to e used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. Compliance with

safety and EMC regulations depends upon installing and configuring drives correctly, including using the

specified input filters. The drives must e installed only y professional assem lers who are familiar with

requirements for safety and EMC. The assem ler is responsi le for ensuring that the end product or system

complies with all the relevant laws in the country where it is to e used. Refer to the User Guide. An EMC Data

Sheet is also availa le giving detailed EMC information.

HD700 AC Drive Easy Start Guide

Declaration of Conformity (size F G)

Guangzhou HEDY Industrial Automation. Co. Ltd

No.63, Punan Road, Yunpu Industry Park, Huangpu District, Guangzhou, Guangdong, 510760, China

HD700-40T03000 HD700-40T03700 HD700-40T04500 HD700-40T05500

HD700-40T07500 HD700-40T09000

The AC varia le speed drive products listed a ove have een designed and manufactured in accordance with

the following European harmonised standards:

EN 61800-5-1: 2007 Adjusta le speed electrical power drive systems —

Part 5-1: Safety requirements — Electrical, thermal

and energy

EN 61800-3: 2004 Adjusta le speed electrical power drive systems —

Part 3: EMC requirements and specific test methods

EN 50581:2012 Technical documentation for the assessment of

electrical and electronic products with the respect to

the restriction of hazardous su stances

These products comply with the Low Voltage Directive 2006/95/EC, the Electromagnetic Compati ility (EMC)

Directive 2004/108/EC, the RoHS2.0 Directive 2011/65/EU and the CE Marking Directive 93/68/EEC.

Zhao Dawei

R&D Director

Date: 12

th

Sept, 2013

These electronic drive products are intended to e used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. Compliance with

safety and EMC regulations depends upon installing and configuring drives correctly, including using the

specified input filters. The drives must e installed only y professional assem lers who are familiar with

requirements for safety and EMC. The assem ler is responsi le for ensuring that the end product or system

complies with all the relevant laws in the country where it is to e used. Refer to the User Guide. An EMC Data

Sheet is also availa le giving detailed EMC information.

HD700 AC Drive Easy Start Guide

Contents

1 Safety information ............................................................................................ 1

1.1 General ................................................................................................... 1

1.2 Safety Symbols ....................................................................................... 1

2 Technical specification ..................................................................................... 2

2.1 How to identify the drive from the model reference ............................. 2

2.2 Ratings ..................................................................................................... 2

2.3 Maximum motor cable length .................................................................

2. General technical data ............................................................................

3 Installation ....................................................................................................... 5

3.1 Mechanical installation ........................................................................... 5

3.1.1 Parts of the drive ........................................................................... 5

3.1.2 Drive mounting & dimensions ....................................................... 5

3.1.3 Drive clearances ............................................................................ 9

3.2 Electrical installation ............................................................................. 10

3.2.1 How to remove & fit the terminal cover ..................................... 10

3.2.2 Power terminals .......................................................................... 10

3.2.3 Typical power connections .......................................................... 11

3.2. Recommended fuses, power & control cables ............................ 12

3.2.5 Default control connections ........................................................ 13

3.2.6 Control terminals specification.................................................... 1

3.2.7 EMC ............................................................................................. 15

3.2.8 RCD Compatibility and earth leakage .......................................... 15

3.2.9 How to remove the internal EMC filter ....................................... 15

4 Using the keypad ........................................................................................... 18

.1 Display overview ................................................................................... 18

.2 Key function .......................................................................................... 18

.3 Changing parameters ........................................................................... 20

5 Quick commisioning ...................................................................................... 20

5.1 Quick commisioning in keypad control ................................................ 20

5.2 Quick commisioning in terminal control ............................................... 21

5.3 Quick commisioning in for fixed speed ................................................ 22

P00 Parameters............................................................................................... 23

6.1 P00 Menu group overview .................................................................... 23

6.2 P00 Parameter descriptions .................................................................. 2

7 Troubleshooting ............................................................................................. 31

7.1 Faults and Corrective actions ................................................................ 31

7.2 Alarms ................................................................................................... 33

HD700 AC Drive Easy Start Guide

P a g e | 1

1

Safety information

1.1 General

This chapter provides very important information so that you can use the HD700 drive safely, prevent injury or

death, or damage to equipment. Please read this information thoroughly and make sure you o serve all the

safety information shown elow and elsewhere in this manual. Please make this manual availa le for the end

user.

1.2 Safety symbols

•The HD700 AC drive should O LY be installed, commissioned and maintained by qualified and

competent personnel.

•Before power is applied to the drive ensure all covers are fitted to the drive and that the drive is

fitted in a suitable enclosure.

•Dangerous voltages are present when the input power supply is connected to the drive. Before

attempting any work on the drive or motor, isolate and lock off the input power supply. After

disconnecting the supply, wait at least 10 minutes (to let the drive’s internal capacitors discharge)

before removing the cover. Prove dead using a voltage tester. The voltage tester itself should be

proved immediately before and after testing using a proving unit with a low power output.

•The drive must be connected to system ground using the drive’s PE terminals. The size of the earth

conductor and earth loop impedance must comply with national and local electrical regulations.

•Do not flash test the drive.

•If the drive is supplied from a pluggable power connector, the drive must be turned off for 10

minutes before unplugging the connector.

•The HD700 is not a field repairable unit. Contact the supplier of the drive.

•The drive must be protected by the recommended fuses or MCB.

•All machinery, in which this drive is used, within the European Union, must comply with directive

98/37/EC, Safety of Machinery.

•The HD700 has an Ingress Protection rating of IP20 and therefore must be installed in a suitable

enclosure, according to relevant local codes and standards.

•Do not install the drive in an explosive environment.

•Install the drive on a suitable nonflammable material e.g. metal back plate.

•The HD700 drive control functions (for example the STOP key) must not be relied upon in safety

critical applications. Any application where malfunction or a fault could cause damage to

equipment or injury to personnel, a risk assessment must be carried out to ensure precautions are

taken to avoid the risk.

•The drive must be installed within the limits specified in the technical data section.

•The motor must be used within the manufacturer’s guidelines.

•Please note that when using the “External fault” trip feature which can be programmed to a digital

input terminal to cause the HD700 to trip on (F018), the trip condition must be present for > 2

seconds for the trip to latch under all conditions.

•Do not allow conductive material to enter the drive, e.g. from drilling during installation.

Danger of e

lectrical shock which can cause injury or death, or damage to equipment

Danger

:

Warning:

Potential hazard, other than electrical, that can cause physical injury or damage to equipment

Danger

Warning

P a g e | 2

HD700 AC Drive Easy Start Guide

2

Technical Specification

2.1 How to identify the drive from the model reference

The model reference can be found on the drive rating label

HD700 4 0 T 00550

Family

Supply volta e

2 = 230V

4 = 400V

Brake unit

0 = Internal Brake (22 W and below, the

internal brake unit is standard).

1 = No Internal Brake

Input Phase

D = 1/3PH

T = 3PH

Power size

00040 = 0.4kW 00750 = 7.5kW 03700 = 37kW

00075 = 0.75kW 01100 = 11kW 04500 = 45kW

00150 = 1.5kW 01500 = 15kW 05500 = 55kW

00220 = 2.2kW 01850 = 18.5kW 07500 = 75kW

00400 = 4kW 02200 = 22kW 09000 = 90kW

00550 = 5.5kW 03000 = 30kW

2.2 Ratin s

Supply volta e = 200 - 240V (+/- 10%), Sin le/Three phase, 48-62Hz

Model Size

Motor

power

(kW)

Rated Input

current Rated

Output

Current

Rated

Output

Overload

(1 minute)

Minimum

Brake

Resistance

Sin le

Phase

Three

Phase

kW A A A A Ω

HD700-20D00040

A

0.4 7.1 4

100%

2.8

150%

4.2

41 HD700-20D00075 0.75 12.8 7.1 5 7.5

HD700-20D00150 1.5 20.5 11.3 8 12

HD700-20D00220 B 2.2 24 14.5 11 16.5 20

HD700-20T00400 C 4 32 16.5 17.6 26.4 12

NOTE: The HD700-20T00400 can be supplied with either single or three phase, 200-240V AC supply

HD700 AC Drive Easy Start Guide

P a g e | 3

2

Technical Specification

Supply volta e = 380 - 480V (+/- 10%), Three phase, 48-62Hz

Model Size

Motor

power

Rated

Input

Current

Rated

Output

Current

Rated

Output

Overload

(1 minute)

Minimum

Brake

Resistance

kW A A A Ω

HD700-40T00075 A 0.75 3.6

100%

2.5

150%

3.75 120

HD700-40T00150 1.5 5.7 4.2 6.3

HD700-40T00220 B 2.2 8.3 5.8 8.7 65

HD700-40T00400 4 13.2 9.5 14.25 50

HD700-40T00550 C 5 12.4 13 19.5 24

HD700-40T00750 7.5 16.1 17 25.5

The models shown below have dual overload ratin s:

G = Heavy duty overload (150% rated output current, 1 minute)

Heavy duty is an industry standard name given to the current rating of a drive that is used in constant torque

applications or applications that require a high overload capacity. Examples of high overload capacity

applications can be cranes and hoists. A heavy duty drive will typically have an overload capacity of 150% drive

rated current.

P = Normal duty overload (110% rated output current, 1 minute)

Normal duty is an industry standard name given to the current rating of a drive that is used in variable torque

applications or applications that require low overload capacity. Examples of low overload capacity applications

can be fans or pumps. A normal duty drive will typically have an overload capacity of 110% drive rated current.

With a dual rated drive, the drive rated current by default is set for heavy duty overload, the drive rated

current can be increased to give a higher drive rated current but a lower overload for normal duty applications.

Supply volta e = 380 - 480V (+/- 10%), Three phase, 48-62Hz

Model Size

G (150% overload, 1 minute) P (110% overload, 1 minute)

Minimum

Brake

Resistance

Motor

power

Rated

Input

Current

Rated

Output

Current

Motor

power

Rated

Input

Current

Rated

Output

Current

kW A A kW A A Ω

HD700-20T01100 D 11 24 25 15 31 32 24

HD700-20T01500 15 31 32 18.5 36 38

17

HD700-20T01850 E 18.5 36 38 22 44 46

HD700-20T02200 22 44 46 30 58 60

HD700-40T03000

F

30 58 60 37 72 75

HD700-40T03700 37 72 75 45 93 96

HD700-40T04500 45 93 96 55 121 125 9

HD700-40T05500 55 121 125 75 151 156 7

HD700-40T07500 75 151 156 90 175 180

HD700-40T09000 G 90 175 180 110 204 210 4.2

P a g e | 4

HD700 AC Drive Easy Start Guide

2

Technical Specification

2.3 Maximum Motor Cable Len ths

The maximum motor cable lengths for standard SWA (steel wire armoured) or standard SY cable is 100m for all

HEDY HD700 drives.

If high capacitance motor cables are used, the maximum motor cable should be halved to 50m.

If the maximum motor cable length is to be exceeded, an output motor reactor or sine filter must be used. See

the Technical Data Guide for details. www.hedyiad.com

2.4 General Technical Data

Note: For full & detailed technical data please refer to the HEDY website: www.hedyiad.com

Approvals

UL approval E348255

CE approval

Environment

Altitude

1000m rated

1000m

~

3000m, 1% rated current de-rating per

100m

Operatin Temperature −10°C

~

+40°C

Max. Humidity ≤90%RH, non-condensing

Vibration ≤5.9m/s

2

(0.6g)

Stora e Temperature −40°C

~

+70°C

Runnin Environment

Non-flammable, No corrosive gasses, no

contamination with electrically conductive

material, avoid dust which may restrict the fan

Supported Power Supply Systems

TT

TN

IT (removal of internal EMC filter and MOV

required)

Enclosure IP20

HD700 AC Drive Easy Start Guide

P a g e | 5

3

Installation

3.1 Mechanical installation

3.1.1 Parts of the drive

3.1.2 Drive Mounting & Dimensions

The HD7 has an Ingress Protection rating of IP2 and therefore must be installed in a suitable

enclosure, according to relevant local codes or standards.

Mechanical dimensions and mounting (Size A, B, C)

EMC filter link

Terminal

Co er

Fan

Rating Label

Power Terminals

Control Terminal

s

Option

Connector

R

J45 Port

Keypa

d

Barcode

Warning:

P a g e | 6

HD700 AC Drive Easy Start Guide

3

Installation

Mechanical dimensions and mounting (Size D, E)

Mechanical dimensions and mounting (Size F)

HD700 AC Drive Easy Start Guide

P a g e | 7

3

Installation

W

W1

W2

Ø

Ø

D

D1

Mechanical dimensions and mounting (Size G)

P a g e | 8

HD700 AC Drive Easy Start Guide

3

Installation

Size Model W W1 W2 H H1 D D1 Mounting

Hole Ø Weight

(mm) (mm) (mm)

(mm) (mm) (mm) (mm) (mm) (kg)

A

HD700-20D00040

97.4 80 − 202.4 190 148.8 − 5 1.4

HD700-20D00075

HD700-20D00150

HD700-40T00075

HD700-40T00150

B

HD700-20D00220

142.4 123.5 − 220.4 208 155.5 − 5 2.2 HD700-40T00220

HD700-40T00400

C

HD700-20T00400

163.1 142 − 300 280 176.8 − 6 4.5 HD700-40T00550

HD700-40T00750

D HD700-40T01100 238.5 184 92 370 356.5 189 − 7 8.8

HD700-40T01500

E HD700-40T01850 238.5 184 92 435.5 422 200.3 − 7 12.1

HD700-40T02200

F

HD700-40T03000

355.5 221 − 573 552.5 315.5 310 10 40

HD700-40T03700

HD700-40T04500

HD700-40T05500

HD700-40T07500

G HD700-40T09000 445.6 340 170 725 701.5 355 349.5 10 63

HD700 AC Drive Easy Start Guide

P a g e | 9

3

Installation

3.1.3 Drive clearances

Note: Dimension X

Size A, B & C: ≥ 10mm

Size D & E: ≥ 20mm

Size F: ≥ 30mm

Size G: ≥ 50mm

≥

50mm

≥

Xmm

≥

50mm

≥100mm

≥100mm

Note: In ertical installations where dri es

are mounted abo e each other, there should

be suitable air flow to keep the dri es cool.

Hot air from the lower dri es should not flow

into the cooling fan/heatsink of the upper

dri es. Air flow should be drawn in and

expelled as illustrated in the picture abo e.

P a g e | 1

HD700 AC Drive Easy Start Guide

3

Installation

3.2 Electric installation

Recommendations made in this section may be superseded by local regulations. The user is responsible for

making sure that local regulations are complied with.

3.2.1 How to remove & fit the terminal cover

3.2.2 Power terminals

Size A and B Power terminals layout

Size C Power terminals layout

L1 L2 L3/N U V W

L1 L2 L3 U V W

PE +DC +DC1 BR -DC PE

PE +DC BR -DC PE

Size D and E Power terminals layout

+DC BR -DC L1 L2 L3 PE PE U V W

HD700-xxT03000 – HD700-xxT04500

HD700-xxT05500 – HD700-xxT07500

PE L1 L2 L3

PE +DC +DC1 PE L1 L2 L3

Size F Power terminals layout

Size F Power terminals layout

BR +DC -DC PE U V W

BR +DC -DC PE U V W

HD700-xxT09000

+DC +DC1

L1 L2 L3 PE

Size G Power terminals layout

BR +DC -DC U V W PE

Terminal Function

L1, L2, L3/N AC power supply. For single phase supply on size A and B use L1, L3/N.

+DC Positi e DC bus connection.

+DC1

For DC choke. Linked to +DC by busbar from factory when external choke not required. Where

the choke is required it is supplied with the dri e. This terminal is not present on sizes where

there is a DC choke fitted inside the dri e. See Technical Data Guide for DC choke information

BR Brake resistor. The other side of the resistor is connected to +DC or +DC1 as indicated by the

shaded +DC/+DC1 in the diagrams abo e.

−DC Negati e DC bus connection.

U, V, W Output terminals. (Connect U,V,W on dri e to U, V, W on motor for forward motor rotation)

PE Protecti e earth terminal.

Remo e:

•Untighten the screw M4x10

•Pull the top of the co er towards you

Fit:

•Insert the co er’s clips into the slots (located as

shown), push the co er into to place

•Tighten the screw M4×10 (Torque 1.2Nm)

Co er

slots

Warning:

HD700 AC Drive Easy Start Guide

P a g e | 11

3

Installation

3.2.3 Typical power connections

The dri e must be connected to system ground using the dri e’s PE terminals. The size of the earth conductor

and earth loop impedance must comply with local electrical regulations.

If there is a contactor between the dri es output and the motor, the dri e must be disabled before

opening/closing the contacts.

The dri e must be protected by the recommended fuses or Type C MCB.

If a braking resistor is required for the application, the resistor should be sized correctly and its resistance

greater than the minimum resistance specified in the Technical Specification section. Additional precautions

must be taken to ensure that the supply to the HD700 is disconnected if a fault occurs with the internal brake

circuitry or connected brake resistor. Fitting of a suitably sized thermal o erload relay can pro ide these

additional precautions.

Brake resistors can get hot; therefore sufficient cooling is required and precautions should be taken to pre ent

contact and risk of fire.

See the Technical Data Guide for information on sizing brake resistors.

NOTE: If a contactor is to be fitted between the dri e and the motor, the dri e must be disabled/stopped

when the contactor is opened or closed. If the contactor is opened or closed while the dri e is

enabled/running, this can cause o er current trips, output phase loss trips, increased le els of radio noise

emissions and increased contactor wear.

Warning:

Warning:

Warning:

Warning:

P a g e | 12

HD700 AC Drive Easy Start Guide

3

Installation

3.2.4 Recommended fuses, power & control cables

Model

Input Current

(A)

Supply Fuses

IEC gG

MCB

(Type C)

Supply Cable &

Earth

conductor

(mm

2

)

Motor

Cable

(mm

2

)

Control

cable

(mm2)

Single

phase

Three

phase

Single

phase

Three

phase

Single

phase

Three

phase

Single

phase

Three

phase

Three

phase

HD700-20D00040 7.1 4 10 8 10 6 1.5 1 1 ≥0.5

HD700-20D00075 12.8 7.1 16 10 16 10 2.5 1 1 ≥0.5

HD700-20D00150 20.5 11.3 25 16 32 16 2.5 1.5 1 ≥0.5

HD700-20D00220 24 14.5 32 20 32 20 4 2.5 1.5 ≥0.5

HD700-20T00400 32 16.5 40 20 40 20 6 2.5 2.5 ≥0.5

HD700-40T00075

3.6

8

6 1 1 ≥0.5

HD700-40T00150 5.7 10 10 1 1 ≥0.5

HD700-40T00220 8.3 16 10 1.5 1 ≥0.5

HD700-40T00400 13.2 20 16 2.5 1.5 ≥0.5

HD700-40T00550 12.4 20 16 2.5 2.5 ≥0.5

HD700-40T00750 16.1 25 20 2.5 2.5 ≥0.5

Input Current

(A)

Supply Fuses

(A)

IEC gG

MCB

(Type C)

Type

G

Type

P

Type

G

Type

P

Type

G

Type

P

HD700-40T01100 24 31 32 40 32 40 4 4 ≥0.5

HD700-40T01500 31 36 40 50 40 50 6 6 ≥0.5

HD700-40T01850 36 44 50 63 50 50 10 10 ≥0.5

HD700-40T02200 44 58 63 80 63 63 16 16 ≥0.5

HD700-40T03000 58 72 80 110 80 80 25 25 ≥0.5

HD700-40T03700 72 93 100 125 100 100 25 25 ≥0.5

HD700-40T04500 93 121 125 150 125 125 35 35 ≥0.5

HD700-40T05500 121 151 150 200 150 200 70 70 ≥0.5

HD700-40T07500 151 175 200 200 200 200 95 95 ≥0.5

HD700-40T09000 175 204 200 250 250 250 120 120 ≥0.5

•Cable sizes abo e are typical and gi en as a guide only, the installer should confirm cable sizes to be

used comply with local regulations.

•Use 105

o

C (221

o

F) (UL 60/75

o

C temp rise) PVC-insulated cable with copper conductors ha ing a

suitable oltage rating

•Fuses and MCB ratings gi en abo e are specified to protect the dri e, not the supply cable being used.

It is the installer’s responsibility to ensure the cable is protected.

Type G – 150% o erload for 60s

Type P – 110% o erload for 60s

Warning:

HD700 AC Drive Easy Start Guide

P a g e | 13

3

Installation

3.2.5 Default control connections

Note: The dri e is in keypad control as default

HD7

Run Forward

Run Re erse

Jog

Select Preset 1

(P00.16)

as speed reference

Enable

Reset

DI1 (Digital input 1)

DI2 (Digital input 2)

DI3 (Digital input 3)

DI4 (Digital input 4)

DI5 (Digital input 5)

DI6 (Digital input 6)

DI7 (Digital input 7)

24V

10V

AI2 (Analogue input 2)

AI1 (Analogue input 1)

0V

0 - 10V

DO1 (Digital output 1)

DO2 (Digital output 2)

0V

24V

AO1 (Analogue output 1)

0V

Output frequency 0 - 10V

Zero speed

(24V when at zero speed)

Dri e alarming

(24V when alarming)

RLY 1

RLY 2

RLY 3

RLY 4

Dri e healthy

(Closed when dri e is healthy)

RJ45 port

RS485 terminals

Keypad

connector

Option

connector

A+

B -

NO contact

NO contact

Dri e acti e

(Closed when dri e is acti e)

P a g e | 14

HD700 AC Drive Easy Start Guide

3

Installation

3.2.6 Control terminals specification

Note: For full detailed specification & functionality of the control terminal please refer to the HD7 Technical Data Guide

Type Terminal

Name Function Specification

Serial

Communications.

RS485 RJ45 Port Two lines, Modbus RTU protocol

A RS485 + signal

Same function with RJ45 port, mainly for multi network

B RS485 - signal

Digital Input DI1

~

DI7 Programmable digital

input terminals

The common can be 0V or +24V by setting the P09.21 (default is

+24V – positi e logic)

Input resistance: 10 kΩ

High, low logic threshold: 10V±1V

Digital output DO1

~

DO2 Programmable digital

output terminals

Output: 24V/0V

Max. output current: 50mA

Analogue Input

& Output

AI1 Programmable

Analogue input1

0V

~

10V

Input resistance: 100kΩ

0 (4) mA

~

20mA

Load resistance:188Ω

Min. Potentiometer resistance: 2kΩ

Resolution: 0.1%

Accuracy: 2%

Sampling period: 5ms

AI2 Programmable

Analogue input 2

0V

~

10V

Input resistance: 30kΩ

Min. Potentiometer resistance: 2kΩ

Resolution: 0.1%

Accuracy: 2%

Sampling period: 5ms

AO1 Programmable

Analogue output

0V

~

10V

Max. output current: 5mA

Resolution: 0.4%

Accuracy: ±5%

Update rate: 5ms

Rail supply

+10V Analogue reference

supply

Accuracy: 2%

Maximum output current: 5mA

+24V User supply Accuracy: ±15%

Maximum output current: 100mA

0V Common Common connection for all external de ices

Relay

RL1 & RL2

RL3 & RL4

Programmable Relay

output contacts

Type: Normally open

Update rate: 5ms

Contact rating:

250VAC/2A(cosφ=1)

250VAC/1A(cosφ=0.4)

30VDC/1A

Default: Relay 1 = Closed when dri e is powered up and healthy

Relay 2 = Closed when dri e is acti e.

HD700 AC Drive Easy Start Guide

P a g e | 15

3

Installation

3.2.7 EMC

EMC recommendations:

Immunity

•The dri e should be installed onto a metal back plate

•360 degree ground clamps should be used to connect the screen of the cable; a oid "Pigtail"

ground connection

•Control and power cables should be separated by a metal partition.

•Use good quality shielded, low capacitance motor cable. The motor cable shield should be

connected to both sides – dri e and motor.

•Control cables: Use shielded twisted pair and earth at the dri e side.

•The earth conductor in the motor cable must be connected directly to the earth terminal of the

dri e and the motor.

Cable clearance

•Do not place control cables in a zone extending 300mm around the dri e and power cables

EMC Filters

•When using an optional EMC filter, place the EMC filter as close to the dri e as possible, and keep the

cable between the filter and dri e as short as possible. The metal enclosure of the filter must be

connected with the dri es earth terminal.

3.2.8 RCD (residual current device) compatibility and Earth leakage

•Single phase dri es are suitable to be used with a Type A RCD

•Three phase dri es are only suitable to be used with a type B RCD

•Earth leakage currents are higher with the internal EMC filter fitted. Actual earth leakage will depend

on a number of factors including motor cable type and length, stray capacitance in the motor, mains

supply conditions etc. Where earth leakage causes nuisance tripping of RCD’s, the dri e’s internal

EMC filter can be remo ed as follows:

3.2.9 How to remove the internal EMC filter

The EMC filter can be remo ed as follows:

Note: The EMC performance of the dri e will be affected by remo ing the internal EMC filter, the user is

responsibility for ensuring that the end application complies with EMC standards that apply.

Fit and remove the internal EMC filter (Size A)

Internal EMC filter

Internal EMC filter

Tighten the screw to

connect the EMC filter

Remo e the screw to

remo e the EMC filter

This manual suits for next models

11

Table of contents

Popular Controllers manuals by other brands

Integra

Integra PIPETBOY acu 2 operating instructions

Elko

Elko COS-1 manual

Honeywell

Honeywell MO953 Series Service data

Tranquil-Easy

Tranquil-Easy HC 7360H operating instructions

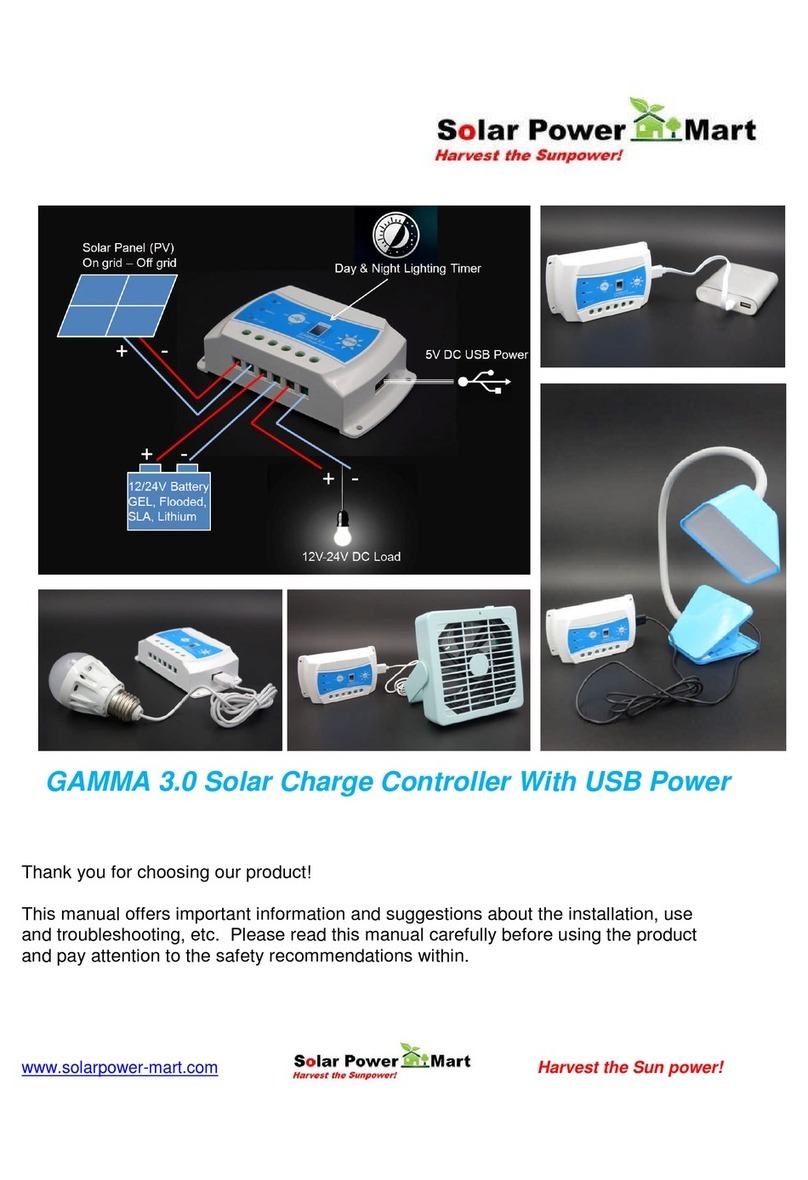

Solarpower mart

Solarpower mart GAMMA 3.0 Solar Charge Controller user manual

Parker

Parker ER032 Maintenance Instructions & Parts List