Heidelberg Engineering MLA 150 User manual

MLA 150

User manual

2

1. Exposing with MLA 150

A. Start

B. Setup job

C. Expose

D. End

2. Design conversion

3. Troubleshooting main error/issues - to be added

4. Mask Fabrication (Backup VPG 740) - to be added

5. MLA 150 - 2 / Greyscale - to be added

6. Theory about the machine - to be added

1.Exposing with MLA 150

4

1. A –Start

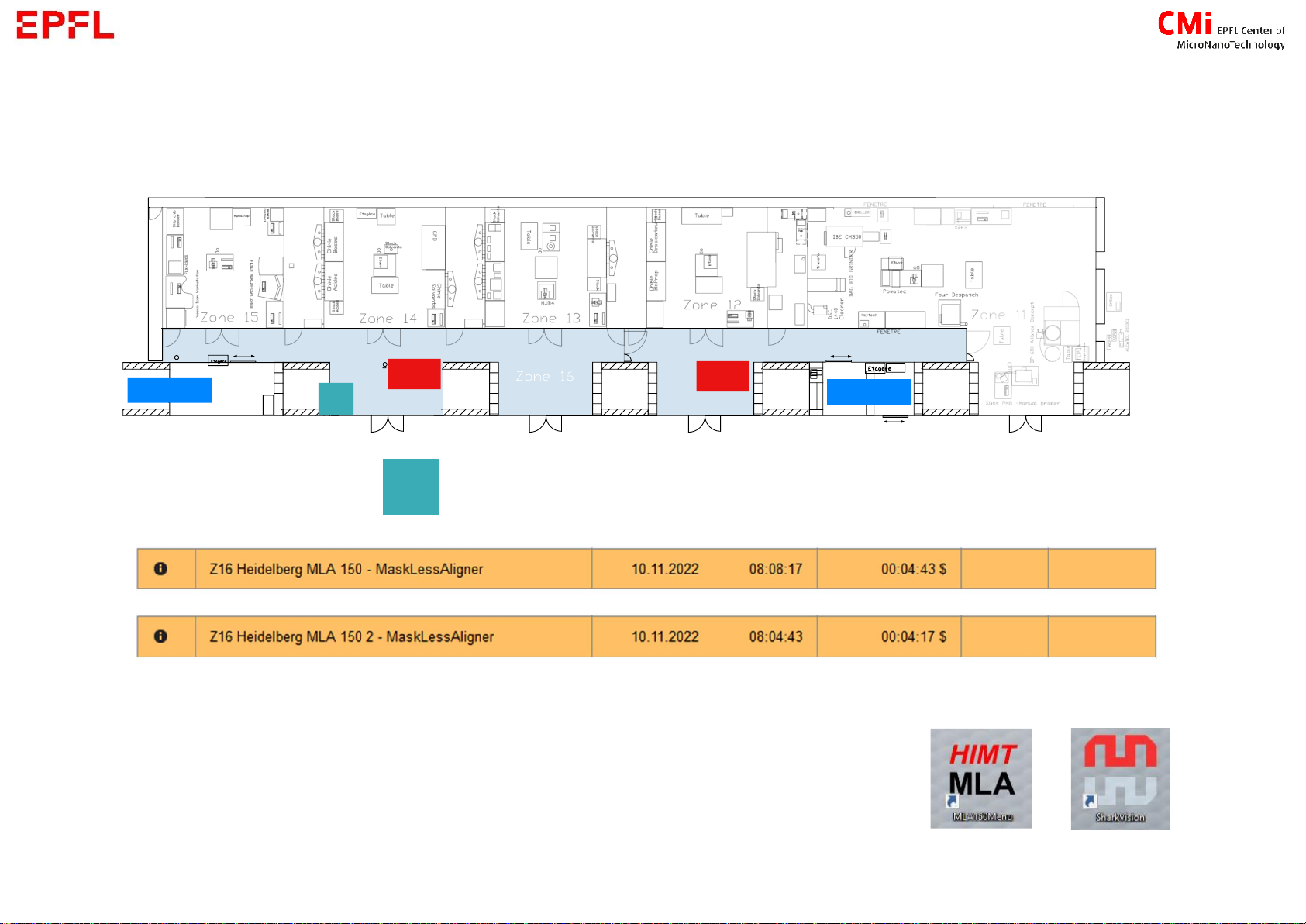

1. log in on CAE PC

Level +1

2. Start the menu

d

→If not started yet, open the desktop applications (control and camera)

5

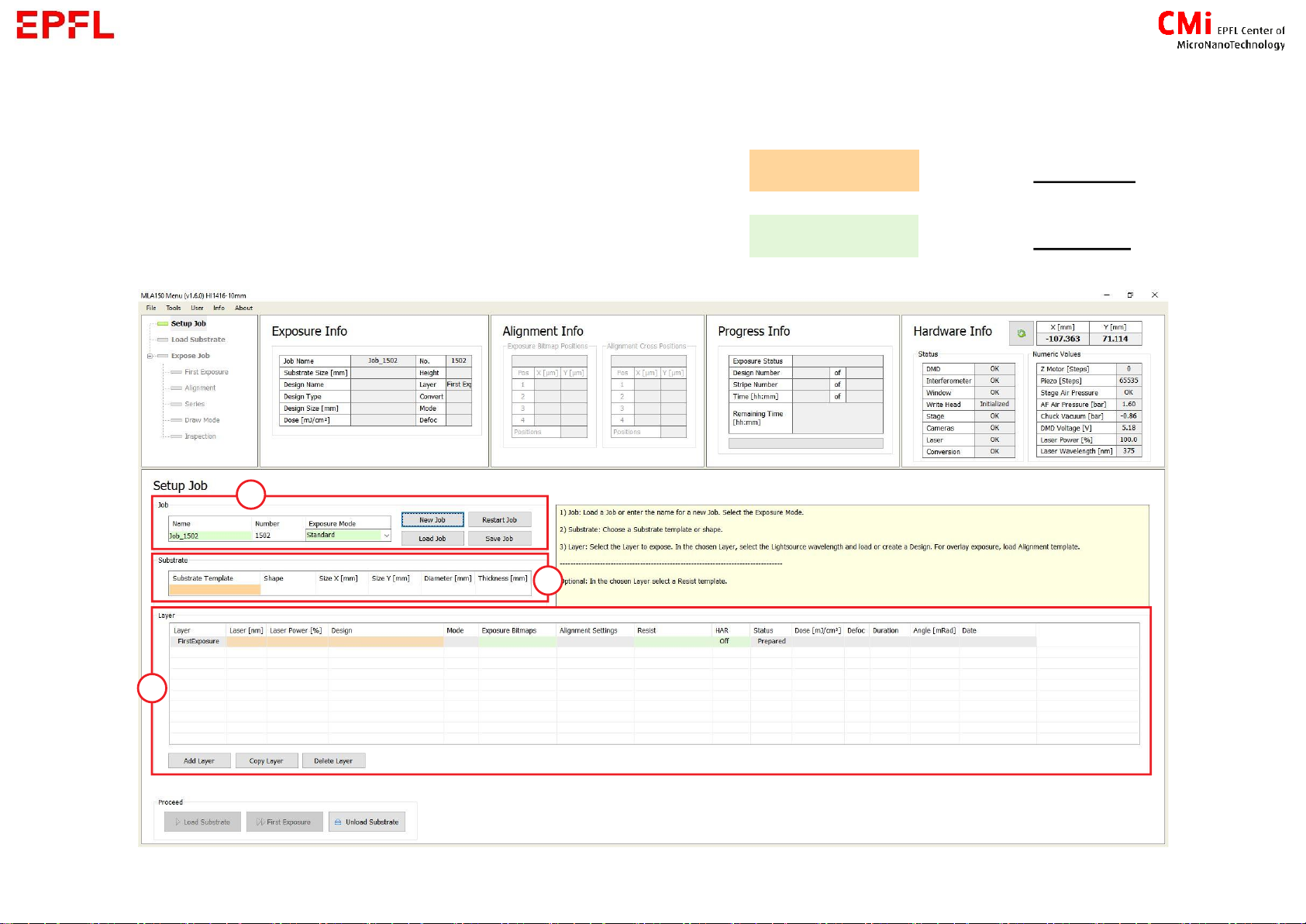

1.B –Setup job

First be aware of this colour rule regarding boxes = input required

= input optional

6

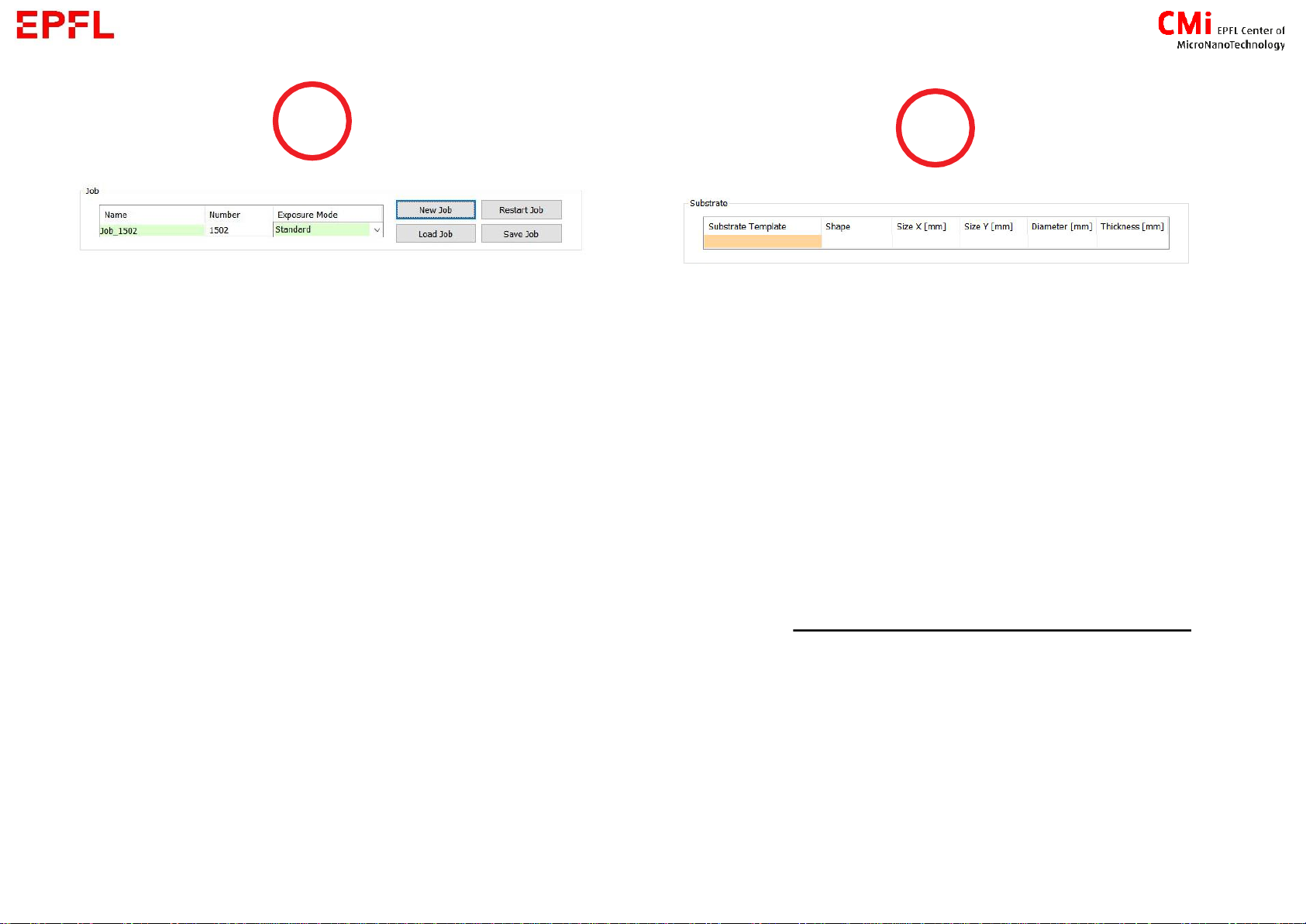

Create a new job or load one

→when done setting a job, you can save it

(please give it a specific name, jobs without

one will be deleted)

Chose the exposure mode :

1. Standard : Expose the design once

2. Series : Expose the design N times with

different parameters for dose and defoc

→how to determine optimal parameters for

your project

3. DrawMode : Use the camera to expose

designs (bitmap format) in specific location

4. Inspection : To inspect the loaded substrate

with the camera

Double click on the orange box to chose

your substrate :

▪Wafer X inch or Mask X inch (X = diameter [in])

▪Small : if your sample is smaller than 50x50mm

▪_Automatic X template : if you are not sure about the

dimensions of your substrate

→Thickness value is not important

7

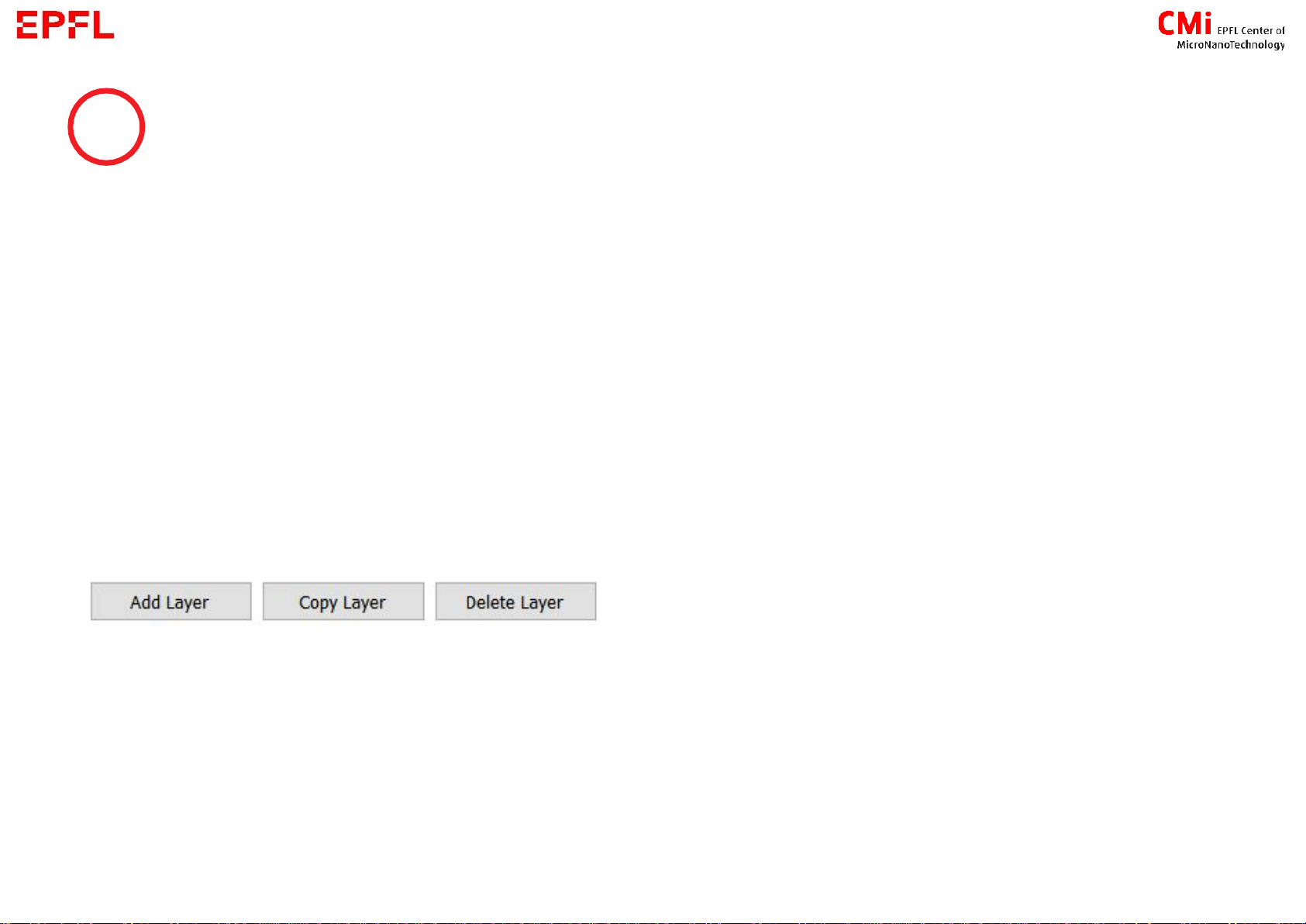

Job layers

→Each layer is determined by : design + laser

parameters for the exposition (Dose and focus are

set later in the process)

→Each lithography step of your process flow can be

represented by a layer (In this case save your job

and reload it [see slide 5] when performing further

steps)

→You can add, copy or delete layers

→It exist 2 types of layer :

- First Exposure = no alignment

-

Job parameters

Laser : choose between 375nm and 405nm

according to recommendation

Laser power : 100% (filter is used for Greyscale)

Design : Choose from the list of converted design

→See Chapter 2 to convert your design

Exposure bitmaps : to add extra bitmaps image to

be exposed in specific positions

Resist :

1 - LargeDefoc = to extend focus range

from [-10;10] to [-25;25] →used with 20 to

100um thick resist

HAR (High Aspect Ratio) : increase the depth of

focus →require higher dose

Large →for 100 to 300um thick resist

X-Large →for >300um thick resist

→Can be set only for non-FirstExposure layers

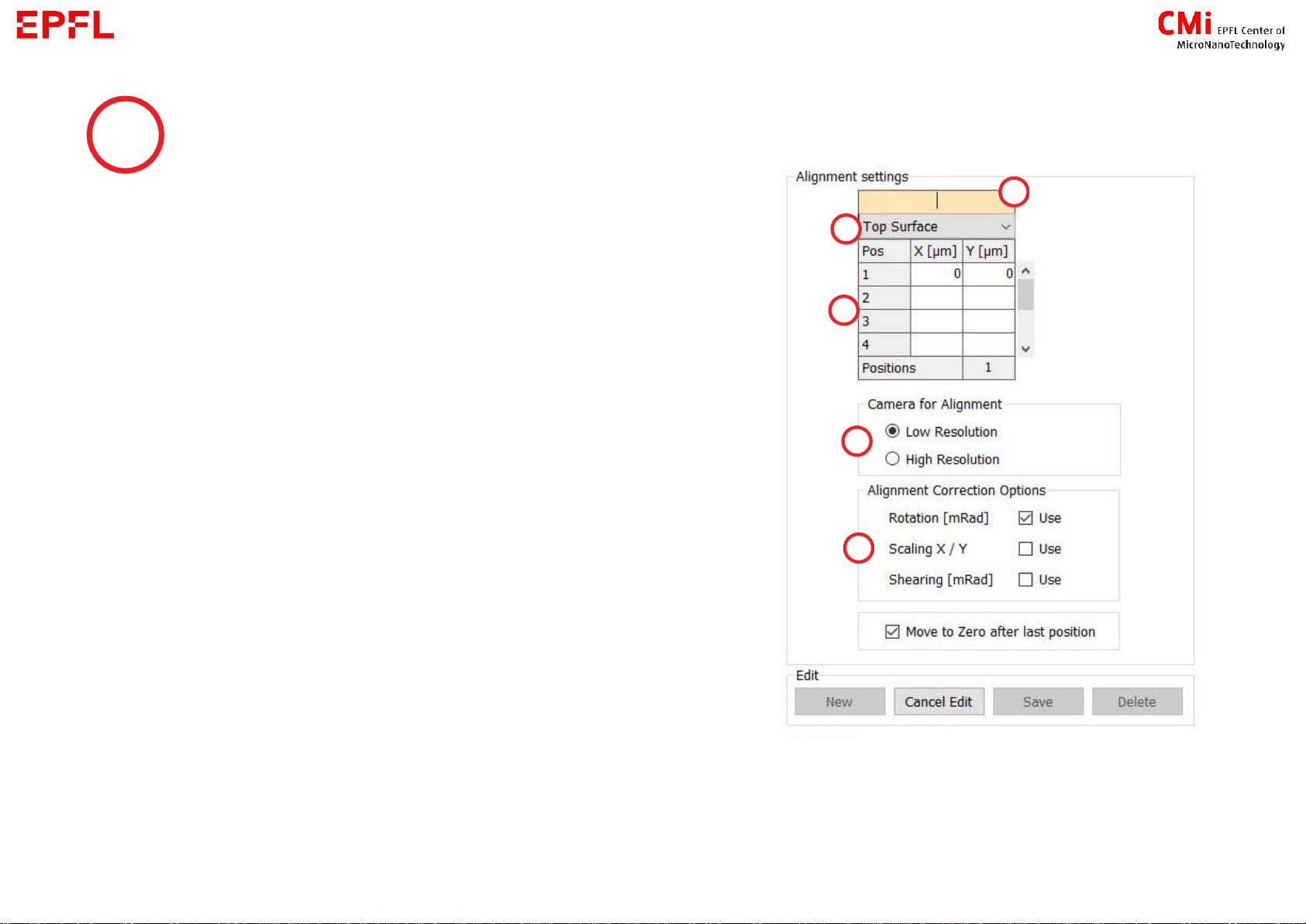

→Load an alignment setting or create one :

a) Name : to find the settings later in the list

b) Top or Back side alignment (see next slide for more

information about backside alignment)

c) Position of the marks : enter the coordinates of your

marks

d) Camera for alignment : the one used during the

procedure

e) Alignment Correction Options :

- Rotation : minimum 2marks

- Scaling and Shearing : minimum 3marks

8

Alignment Settings

→After creating/editing settings, save, and refresh the list if needed

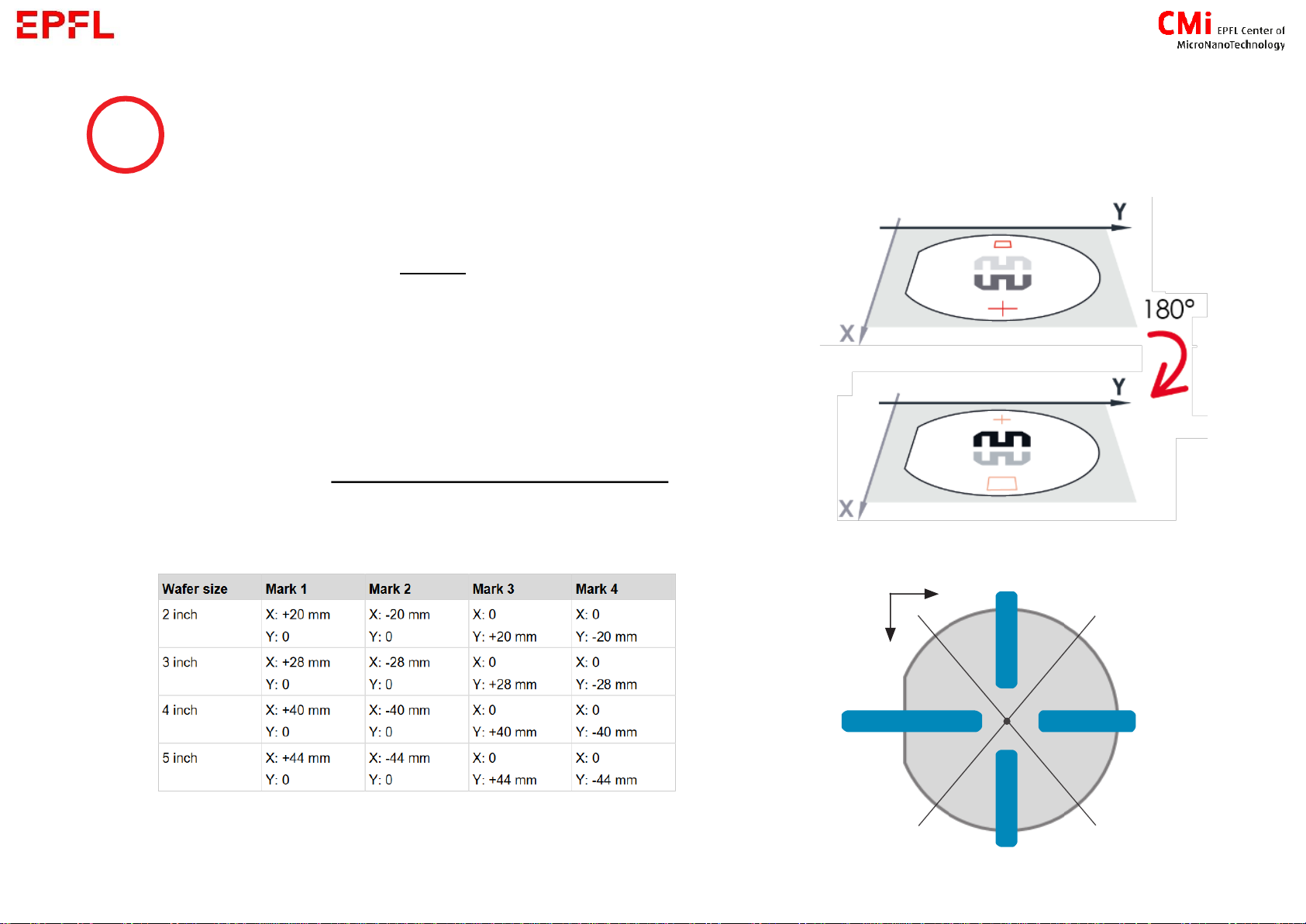

The coordinates on the MLA always refer to the substrate

side that is currently the upper surface (e.g. if an alignment

mark is exposed at the position [X: +20 mm], the alignment

mark will be at position [X: -20 mm] for the backside

alignment.

The alignment marks need to be in a specific area. See blue

zone on the image or layer 65 in the CMi layout template for

exact positions. Example of correct positions :

9

Alignment Settings –Information for backside alignment

Wafer 4 inch

10

1.C Expose

→When your job is ready, select the layer to be exposed and click on

→For wafer :

2. Place the guide

according to your

wafer size

3. Place and centre

the wafer against

the guide

4. Activate the

Vacuum

5. Remove the

guide, close the

door and follow

screen instructions

1. open the window

11

1.C Expose

→For small samples :

1. Open the window 2. Place your sample in the centre of the chuck (best to align it in X

and Y directions) 3. activate the vacuum 4. close the door →Follow screen instructions

→Next steps depend on your job :

1) Standard [s.12] 2) Standard with alignment [s.13] 3) Series [s.15]

You will need to determine the centre of your sample. Move

with the arrows or the target tool to go manually to the

centre of your sample (Target tool is always enable at

beginning, simply click on the substrate where you think is

the middle, you will be able to fine tune the position later)

Validate the position only when you are at the centre of

the substrate !

12

1) Standard

a) Set a dose and focus according to

the Resist Table (Desktop) or from

your own experience

b) The design can be tilted based on

the rotation of your substrate

measured by the machine

c) Enable the exposition of bitmaps

you set previously

d) Delay the exposure [hour:minutes]

e) Auto-unload the substrate if you

want to expose only one layer

Be aware that MLA-1 and MLA-2 have

different Resist Tables

13

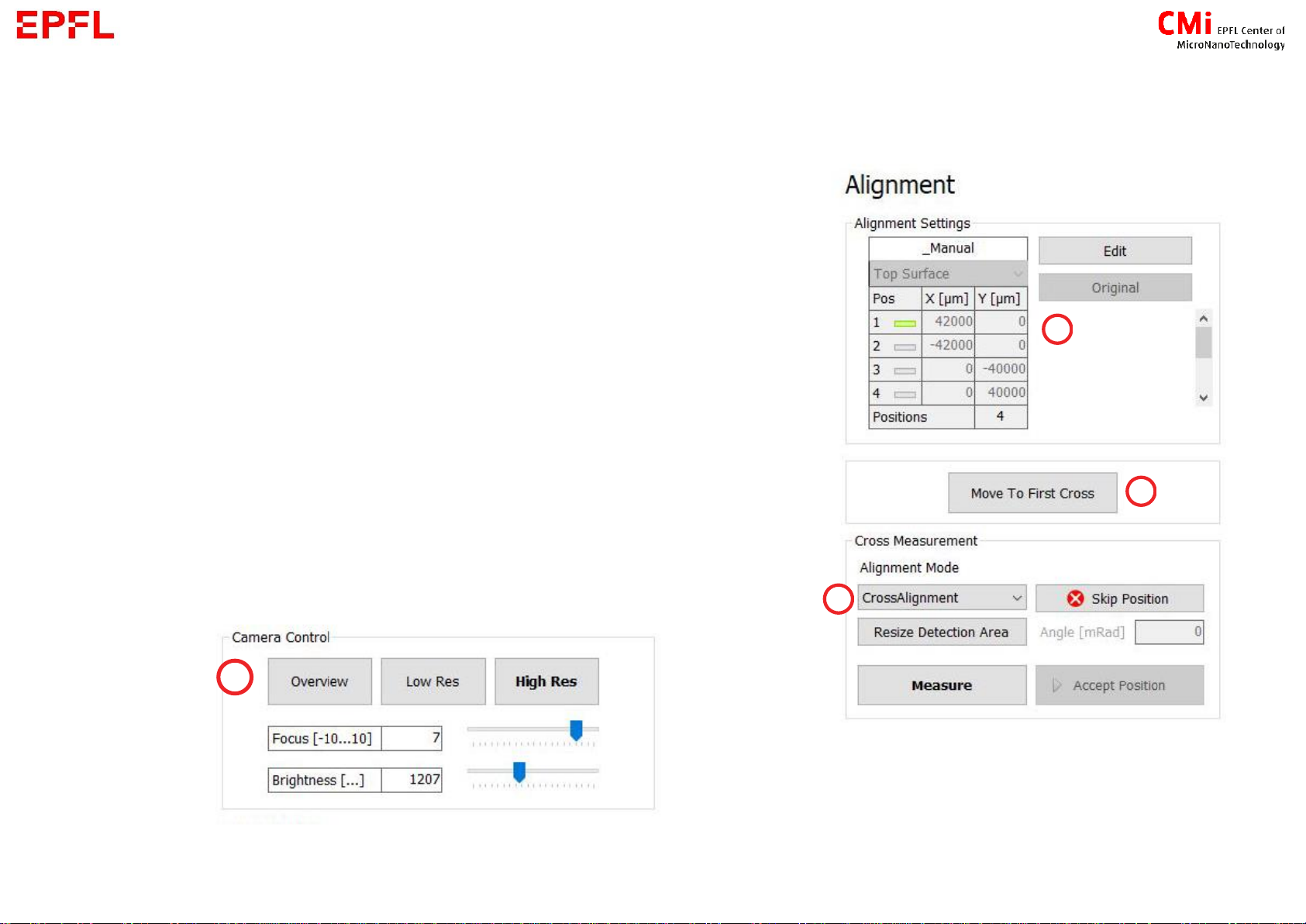

2) Standard with alignment

a) Control if alignment positions are correct and edit if needed

b) Click to start alignment procedure

c) Overview and Low Res camera →move to your mark

High Res →for the measurement

d) Chose measurement mode :

- Automatic : CrossAlignment or RectangleAlignment

- Manual : ManualAlignment

14

2) Standard with alignment

e) For automatic detection, please make sure the feature to

it, press on Resize/Maximize Detection Area and select a zone on

the camera window or slide the sides of the rectangle.

f) Measure:

-automatic detection of the feature

-manual selection of the position with the target tool

→Remeasure or Accept Position

→Repeat c-f for all the marks

15

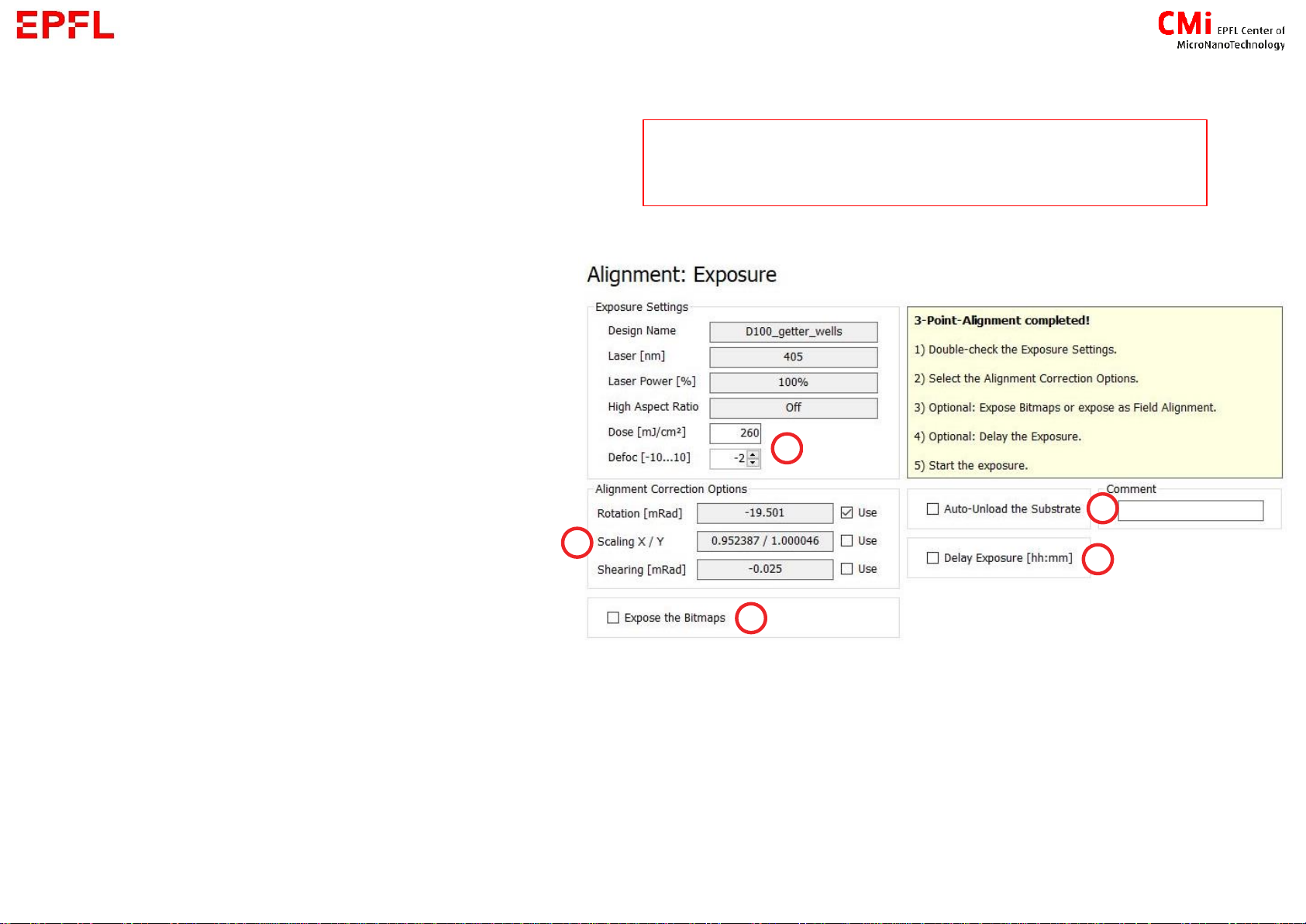

2) Standard with alignment

g) Set a dose and focus according

to the Resist Table (Desktop) or

from your own experience

h) Define which correction based

on alignment you want to apply

i) Enable the exposition of

bitmaps you set previously

j) Delay the exposure

[hour:minutes]

k) Auto-unload the substrate if you

want to expose only one layer

Be aware that MLA-1 and MLA-2 have

different Resist Tables

16

3) Series

a) Choose parameters to test :

dose / focus / dose + focus

b) Define starting value, step and how

many lines (# of fields) should contain

the matrix

c) Distance between 2 dyes in the matrix

(stay orange if overlapping)

d) Label at the bottom left of each dye

containing Dose and Focus

e) Delay the exposure [hour:minutes]

f) Auto-unload the substrate if you

want to expose only one layer

17

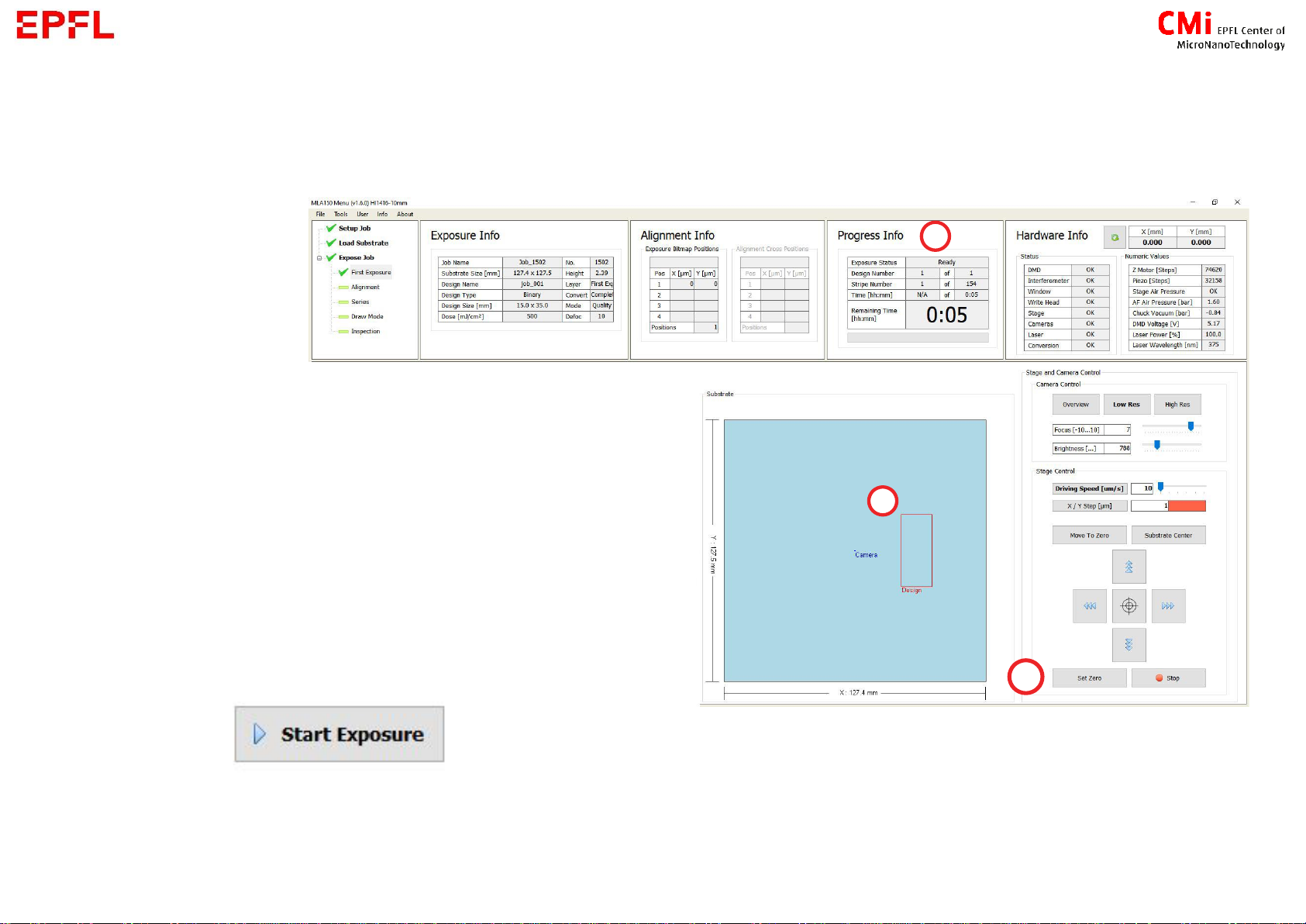

Exposition information and position

a) Estimated maximum time for exposition

b) Position of exposed design. Hold-click on its

side to move it on the substrate.

c) When using the camera to find the appropriate

position for exposition, press Set Zero at the

desired position for the design centre

→If all information on the screen looks correct,

press :

In case you have change the exposition position, an error message about not being in

the centre will appear. You can acknowledge it !

18

1.D End

If not automatically unloaded, your can restart your job in the main menu or expose a

second layer

If you are done, click

→When back to the main menu:

1) open the windows

2) deactivate the vacuum

3) get back your sample

4) close the windows

→Press New Job

→Go to the Zone PC to log out from the CAE

2. Design Conversion

20

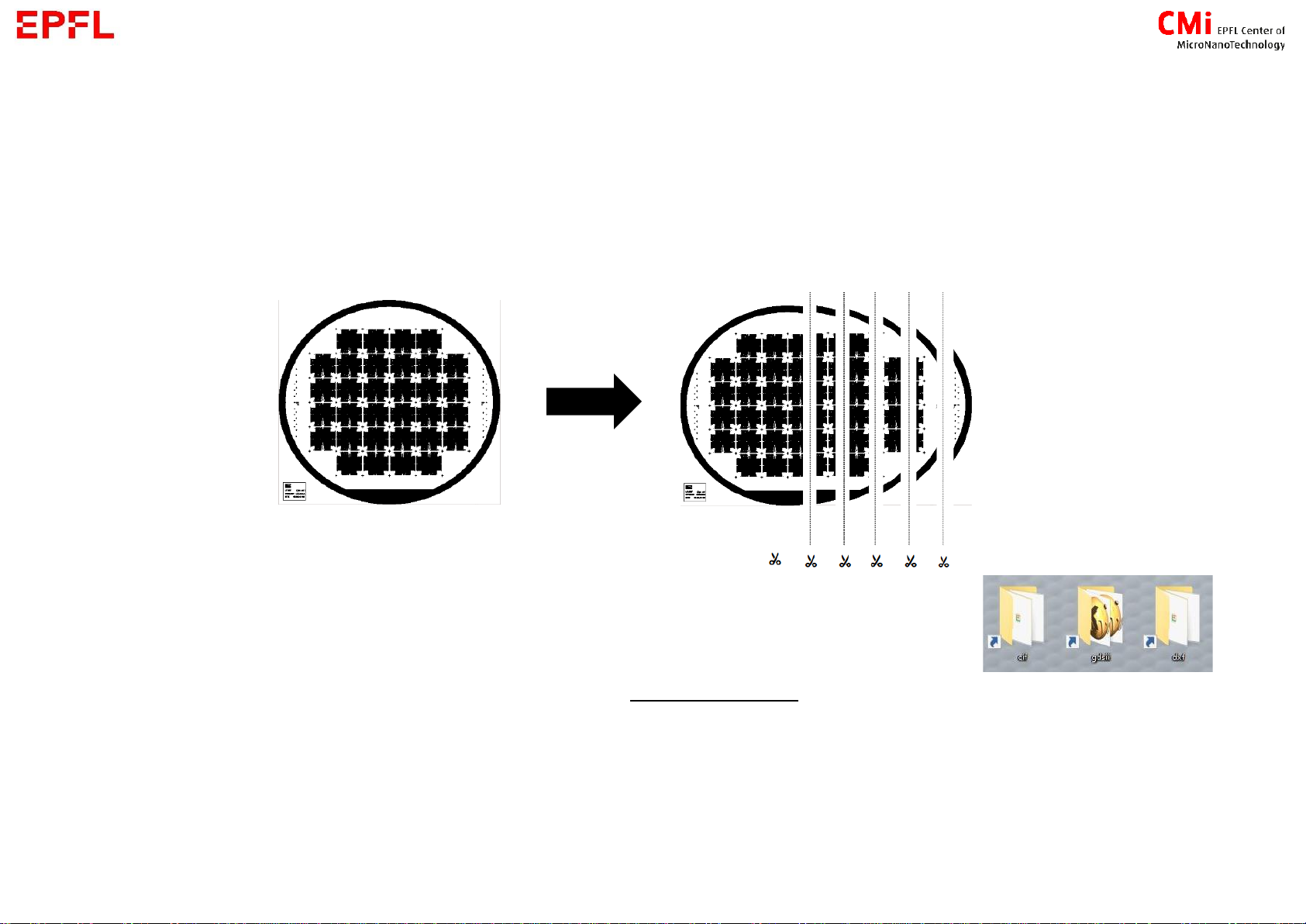

2. Convert

- Goal : convert your design into a series of stripes than can be exposed by the MLA150

1. Copy your design into the corresponding file extension folder

Allowed extension : .gds , .cif , .dxf (no capital letter)

Allowed character for file name

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies InfinityLab LC Series user manual

Cannon

Cannon TE-3000 instruction & operation manual

BioLAB

BioLAB BIFL-204 Operation manual

Ocean Insight

Ocean Insight OCEANHDX RAMAN quick start guide

Qiagen

Qiagen PyroMark Q96 quick start guide

Sterlitech

Sterlitech 1812 Assembly & operation manual