Viso Systems LabRail User manual

VISO SYSTEMS LabRail

User Manual

Revision: 17DEC2021

2

Congratulations on purchasing your new Viso Systems LabRail. Before using this

product, please read the Safety Information.

This manual contains descriptions and troubleshooting necessary to install and

operate your new Viso Systems product. Please review this manual thoroughly to

ensure proper installation and operation.

For news, Q&A and support at Viso Systems, visit our website at

www.visosystems.com

3

Contents

Safety Information........................................................................................................4

Disposing of this Product ..............................................................................................4

Introduction..................................................................................................................4

Shipping Dimensions.....................................................................................................5

LabRail installation........................................................................................................5

Power and data connection........................................................................................14

Distance calibration ....................................................................................................17

Sensor Distance...........................................................................................................24

Specifications..............................................................................................................25

4

Safety Information

Warning! This product is not for household use.

Read this manual before installing and operating the LabRail, follow the safety

warnings listed below, and study all the cautions in the manual.

Preventing electric shocks

Make sure the power supply is always grounded.

Use a source of AC power that complies with the local building and electrical codes,

that has both overload and ground-fault protection.

If the controller or the power supply are in any way damaged, defective, wet, or

show signs of overheating, disconnect the power supply from the AC power and

contact Viso Service for assistance.

Do not install or use the device outdoors. Do not spray with or immerse in water or

any other liquid.

Do not remove any covers or attempt to repair the controller or the power supply.

Refer any service to Viso.

Disposing of this Product

Viso Systems products are supplied in compliance with Directive 2012/19/EU on

waste - electrical and electronic equipment (WEEE) together with the RoHS Directive

2011/65/EU with amendments 2015/863. Help preserve the environment! Ensure

that this product is recycled at the end of its lifetime. Your supplier can give details of

local arrangements for the disposal of Viso Systems products.

Introduction

About this document

These guidelines describe the installation process of the LabRail and distance

calibratio procedure.

About the LabRail

The LabRail is a revolutionary new automatic sensor positioning system, which

includes fully motorized sensor positioning include data over power elliminating all

cables.

© 2007 Viso Systems ApS, Denmark

All rights reserved. No part of this manual may be reproduced, in any form or by any means,

without permission in writing from Viso Systems ApS, Denmark. Information subject to change

without notice. Viso Systems ApS and all affiliated companies disclaim liability for any injury,

damage, direct or indirect loss, consequential or economic loss or any other loss occasioned by

the use of, inability to use or reliance on the information contained in this manual.

5

Shipping Dimensions

Box 1: 1050 x 350 x 200 mm (weight: coming soon)

Box 2: 330 x 220 x 150 mm (weight: coming soon)

Box 3: 780 x 380 x 240 (weight: coming soon)

Box 4: 1650 x 280 x 280 mm (weight: coming soon)

LabRail installation

Suspension principle

The standard rail consists of eight 1.5-m rail pieces. Not all pieces need to be

installed for the system to work –just choose your own preferred length. The rail can

also be prolonged with more rail pieces from Viso Systems.

Gravity and symmetry holds the assembly in place.

Hence it is important that eyebolts in your ceiling are firmly attached to the building

structure (not to suspended ceiling parts or the like). It is also important that the

suspension wires are symmetrical around the rail. This is to avoid skewing of the rail

and to secure balance. The rail suspension is very flexible when it comes to ceiling

heights. The suspension wires can be as long or as short as desired.

The rail is intended to be assembled as a whole on the floor. When this is completed,

wires are attached. The whole rail is lifted manually (about 5 people needed) to its

permanent position and wires are tightened and cut to length.

The dolly, end stop, injector, monopod and cables are installed. Your LabSensor fits

directly onto the monopod.

6

Finally, you need to go through a distance calibration procedure.

Standard pliers and a screwing machine with allen key bits are the tools needed.

LabRail Components

The standard rail consists of 8 rail sections each being 1.5 m long. The rail sections

are interconnected using suspension plates on top and bottom.

The LabRail suspension contains:

Qty

Rail parts

Image

8

1.5-m pieces of aluminium

rail

40

Connector Profiles

9

Suspension plates

80

Screw M5x6

20

M6x30 Ring Screw

34

Conductor Rail

40

Safety wire hooks (push-

through)

100

m

Steel Wire 1.5mm Black (2

rolls, each 50 m)

70

Grub Screw M5x6

1

Wire cutter

Qty

System parts

Image

1

Dolly

1

End Stop

7

Qty

System parts

Image

1

Injector

1

Cable IEC 5m Extension

1

Cable Power 2m

1

Cable RJ45 3m

1

Telescopic arm (monopod)

A48

The whole rail is assembled on the floor. The 1.5-m pieces are attached to one

another with suspension plates for firm alignment and electrical connection.

1. Align the aluminium rail pieces on the floor. Put the rail piece with the end

stop closest to the goniometer. Put the rail piece with the injector module

farthest away from the goniometer.

2. Push the connector profiles into the grooves in the rail –4 at each of each

rail pieces: 2 on the top and two in the bottom grooves.

3. Start by joining the rail pieces on the bottom side of the rail: Use the grub

screws M5x6 to fasten the connector profiles into the rail grooves.

Push the rail pieces tightly together.

4. Turn the rail up-side-up.

5. On the top side: Use the M5x6 screws to the suspension plates to the

rail pieces –2 screws into every connector profile.

8

Important: Please check that rail pieces are indeed accurately

aligned by running your finger across the assembly lines. If needed,

loosen the screws and re-align. Even small misalignments may

prevent the dolly from travelling accurately mechanically.

6. Remove the end stop cover and attach the end stop to the rail with

8 grub screw and 4 connector profiles inside the upper and lower

grooves. Note: The end stop should have the spring load part facing

downward

7. Turn the rail up-side-up.

8. Go to the injector unit on the rail end farthest from the goniometer

9. Push the rail conductor pieces into the top groove in both sides of

the rail. Fill each groove.

9

Push all pieces in and check that the first piece meets the spring

load in the end stop:

Also check that the rail conductor pieces all slide freely and that to

can activate the spring load by pushing that all conductor pieces

from the opposite end of the rail.

Spring load

10

10. The last conductor pieces will be too long. Cut the last conductor

pieces to length + 5-10 cm with standard pliers:

11. Then push both conductor line firmly in (thus activating the spring

load at the other end) and tighten the finger screws on each side of

the injector. Use e.g., a ruler in between your hand and the

conductor to make it more comfortable to apply sufficient

pressure.

12. Cut the remaining conductor pieces off if needed.

13. Screw two eye bolts into every suspension plate (for wire

attachment)

14. Please firmly attach your own eyebolts or the like to the building structure.

The suspension hooks in LabRail kit accommodates can open and close

around up 5.5 mm. Important: Each building eyebolt carries two wires and

should be placed between two rail connectors (except maybe the last set).

As gravity and symmetry holds the construction in place, wires should be

angled vertically about 30-60 degrees to the ceiling to improve stability.

11

Place the eyebolts in the same height and symmetrically around the

intended rail position –this is to avoid screwing the rail.

15. Prepare the lengths of suitable lengths of wire: The wires should be long

enough to reach from the eyebolts in the ceiling to the eyebolt on the rail

connectors.

Attach the supplied push-through wire hooks to one end off all wire ends

Then attach the upper hooks of all wires to the eyebolts in the building

structure –the other end hanging loosely down.

The attach the other end of all wire ends hanging from the ceiling

to the lower hooks. Important: Every other wire pair is crossed to

prevent movement sideways. Illustration: All blue wires are crossed:

16. It is time to lift the rail to the desired position –minimum 2.3 m over floor

level (for standard LabSpion goniometer med 1.5 m standard tower). For

LabSpions with 2.0 m tower, the minimum height is 2.55 m over floor level.

17. A small group of people is needed, and each person needs a ladder. The

group simultaneously lifts the rail approximately the desired height while

securing the steel wires with the push-though hook to the eye bolts on the

rail connectors. Then, adjust every wire set to make sure that the whole

rail in the desired height and perfectly levelled.

Push-through wire hook

Push here

to loosen

12

18. Again, test the connections between the rail pieces with your finger to

ascertain smooth transitions:

19. Slide the LabRail dolly onto the rail over the end stop (end stop cover still

detached). The rear end of the dolly must (with labels) face the injector in

the far end

20. Attach the cover to the end stop.

21. Now, screw in the telescopic arm (monopod) to the dolly by turning

clockwise until firmly attached

13

Then turn the adapter to face the goniometer

22. Attach your LabSensor to the adapter on the telescopic rod.

Roughly set the sensor to the same height as the middle of the goniometer

c-plane motor (the sensor height will be adjusted accurately during

calibration.

14

Power and data connection

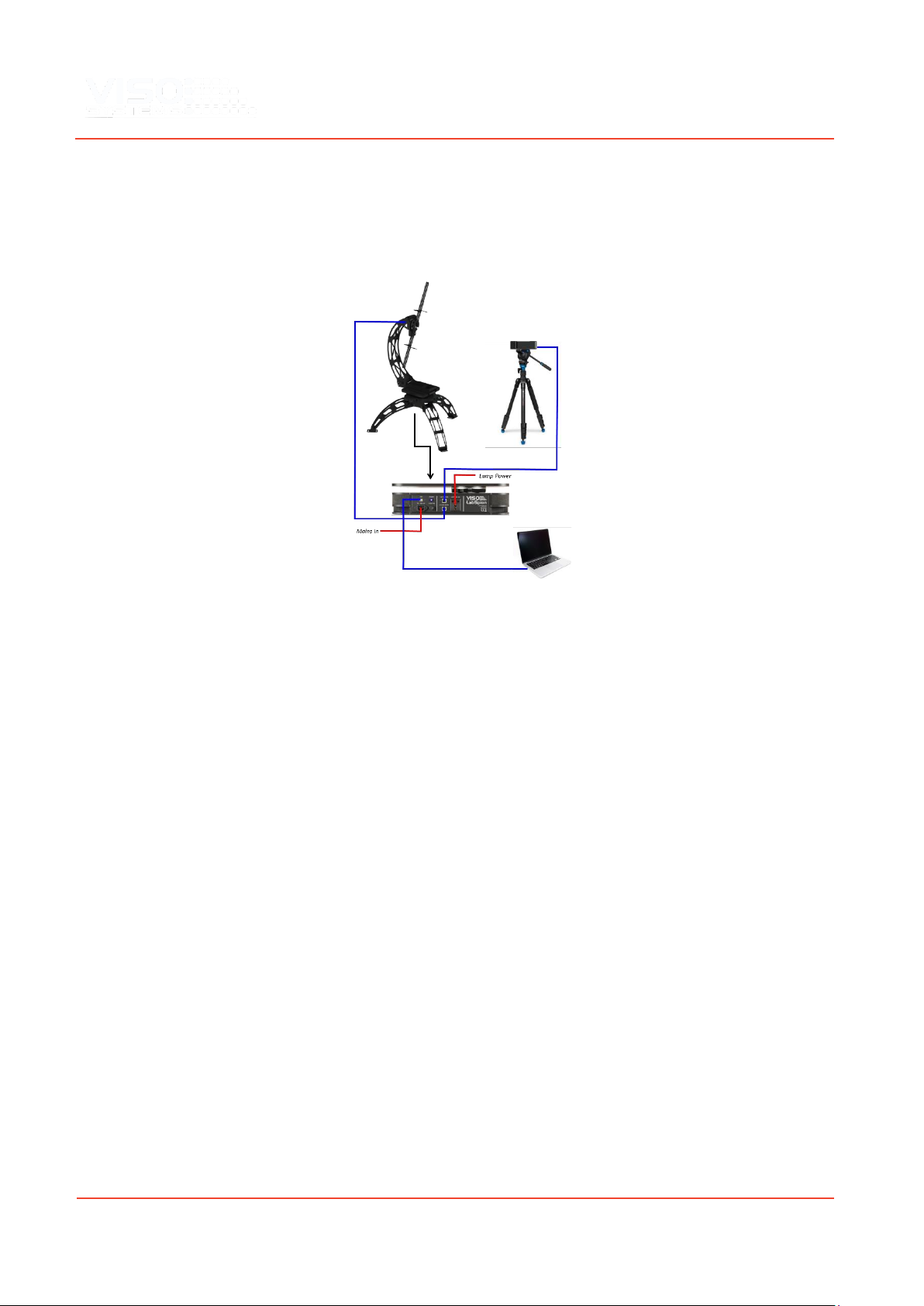

Standard connection when not using LabRail

When the LabRail is not used is the sensor connected directly to the base as shown

below.

15

Connection using LabRail

When using the LabRail is the sensor connected to the LabRail Injector (including

power) and both data and power are transmitted together via the rail.

16

Use the standard 25 m RJ45 cable (normally used to connect the sensor to the

LabSpion mainboard) to connect the LabRail injector to LabSpion mainboard.

Make sure that the cable is secured so that it does not interfere with the function of

the LabRail and out of the way of people working in the laboratory.

Check that the sensor is connected to the system –indicated in the upper right-hand

corner of the software dashboard

Checking connection

To check the connection, you can go to the Help menu and check that the menu

point “LabRail (Firmware) is visible”

You can also click on Setup

→

Labrail

→

Tool:

And the click on the “Check dataline” to ensure that the connection is good.

17

Distance calibration

Before starting distance calibration, is it a good idea to use the LabRail tool to check

the laser from the LabRail is aligned all the way along the rail to the LabRail Injector.

The tool window can be opened by clicking Setup

→

Labrail

→

Tool:

Turn on the laser and use the move buttons to move the LabRail along the rail as

shown above.

Before the rail can be used, the distance between the mounted sensor and the

LabRail must be calibrated and stored in the memory of the LabRail.

Note: Fix the LabSpion goniometer to the floor so that the position does not change.

If the LabRail or the LabSpion are moved, all distance calibration procedures must be

repeated.

To make the calibration please make sure you have installed Viso Light Inspector

version 6.05.2 or later.

Go to menu Setup

→

LabRail and the following dialog will appear

18

Please ensure that the laser hits the center of the target plate on the injector by

adjusting the screws next to laser measurement device as shown below.

Also make sure that the “Setup laser target plate” is mounted on the LabSpion with

the front being at the center of rotation of the LabSpion.

The reason for the “Setup laser target plate” being extended outwards by 10 cm is so

the software can easily ensure that the laser always hits the plate during the setup

process. Otherwise, a significant error of at least 10 cm would be detected by the

software. The “Setup laser target plate” is only used during the setup and is not

needed again after the setup procedure is completed, unless the system is moved.

The sensor must be adjusted in height so that the laser beam is completely

horizontal and points to the center of the “Setup laser target plate” as shown below.

19

Another laser leveler can be used to ensure the sensor laser is in horizontal level

such as the below shown Bosch laser included with the LabSpion.

After the steps above have been completed, please click “Next”.

The system will now ask you to move the sensor to the end-stop. Just use your hand

to gently push the sensor until it touches the end-stop and click “Done”.

Please make sure there are no obstacles in the room as the sensor will now start

moving down the complete traveling range of the rail.

20

The system will now measure the complete length of the rail and it will hit the laser

target plate at different positions.

If you get errors saying the laser target plate was not hit, please check you rail is

straight and that there is no direct strong light hitting the target plate. A sensor is

located inside the target plate ensuring the laser always hits the plate, this too

ensure that correct distance is always measured from the end of the rail.

Strong light on the laser target plate (e.g., from general lighting), must be blocked

with a plate or a dark curtain.

When the rail distance setup is completed, the system will get ready to measure the

sensor laser distance in combination with the rail laser distance to be stored in the

finished calibration. The window below will ask you if you would like to make a

manual pre-check that sensor laser hits the “Setup laser target plate” as shown

below.

If you click the large button on top of the rail image will you be able to move the

sensor manually using the window shown below.

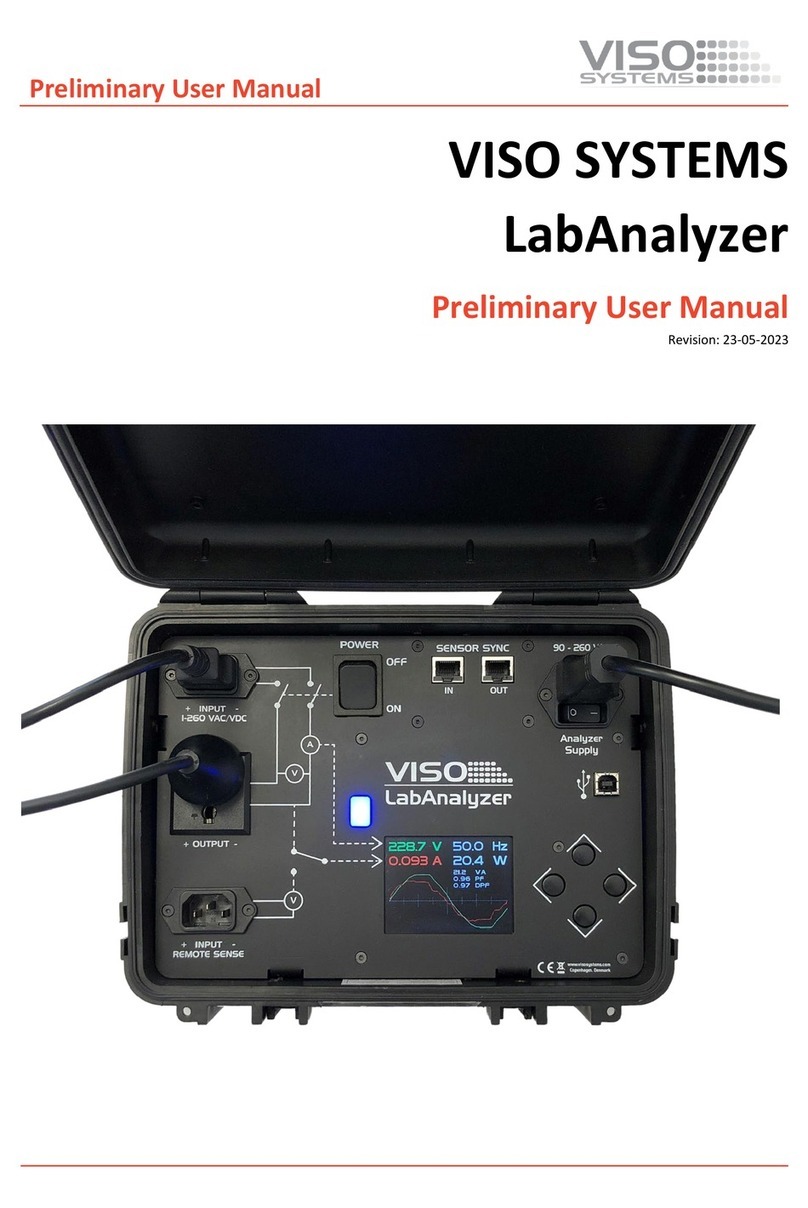

Other manuals for LabRail

1

Table of contents

Other Viso Systems Laboratory Equipment manuals