HEIN-WERNER AUTOMOTIVE HW93667 Instructions for use

Operating Instructions & Parts Manual

SFA Companies

10939 N. Pomona Ave. Kansas City, MO 64153

Model Number

HW93657

HW93667 (Air/Manual)

HW93660

HW93662 (Air/Manual)

Service Jacks

Model No. HW93657 & HW93660 Model No. HW93667 & HW93662

Capacity

4

Ton

4

Ton

10 Ton

10 Ton

Made in the

U.S.A.

HW93657-M0 rev A

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!

Read this manual and follow all the Safety Rules and Operating Instructions before using this product.

SAFETY and GENERAL INFORMATION

Save these instructions.

For your safety read, understand, and follow the information provided with and on this jack.

Theownerandoperator ofthis equipmentshall havean understanding of thisjack andsafe operatingprocedures before

attempting to use. The owner and operator shall be aware that use and repair of this product may require special skills

and knowledge. Instructions and safety information shall be conveyed in the operator's native language before use of

this jack is authorized. If any doubt exists as to the safe and proper use of this jack, remove from service immediately.

Inspect before each use.

Do not use if broken, bent, cracked, or damaged parts (including labels) are noted.Any jack

that appears damaged in any way, operates abnormally or is missing parts, shall be removed from service immediately

and the manufacturer notied. If you suspect that the jack was subjected to a shock load (a load dropped suddenly,

unexpectedly upon it), immediately discontinue use until the jack has been checked by a factory authorized service

center (contact distributor or manufacturer for list of Authorized Service Centers). It is recommended that an annual

inspection be done by qualied personnel.

Replace worn or damaged parts with Hein-WernerAuthorized Replacement

Parts only.

Labels and owner’s manuals are available from manufacturer.

2

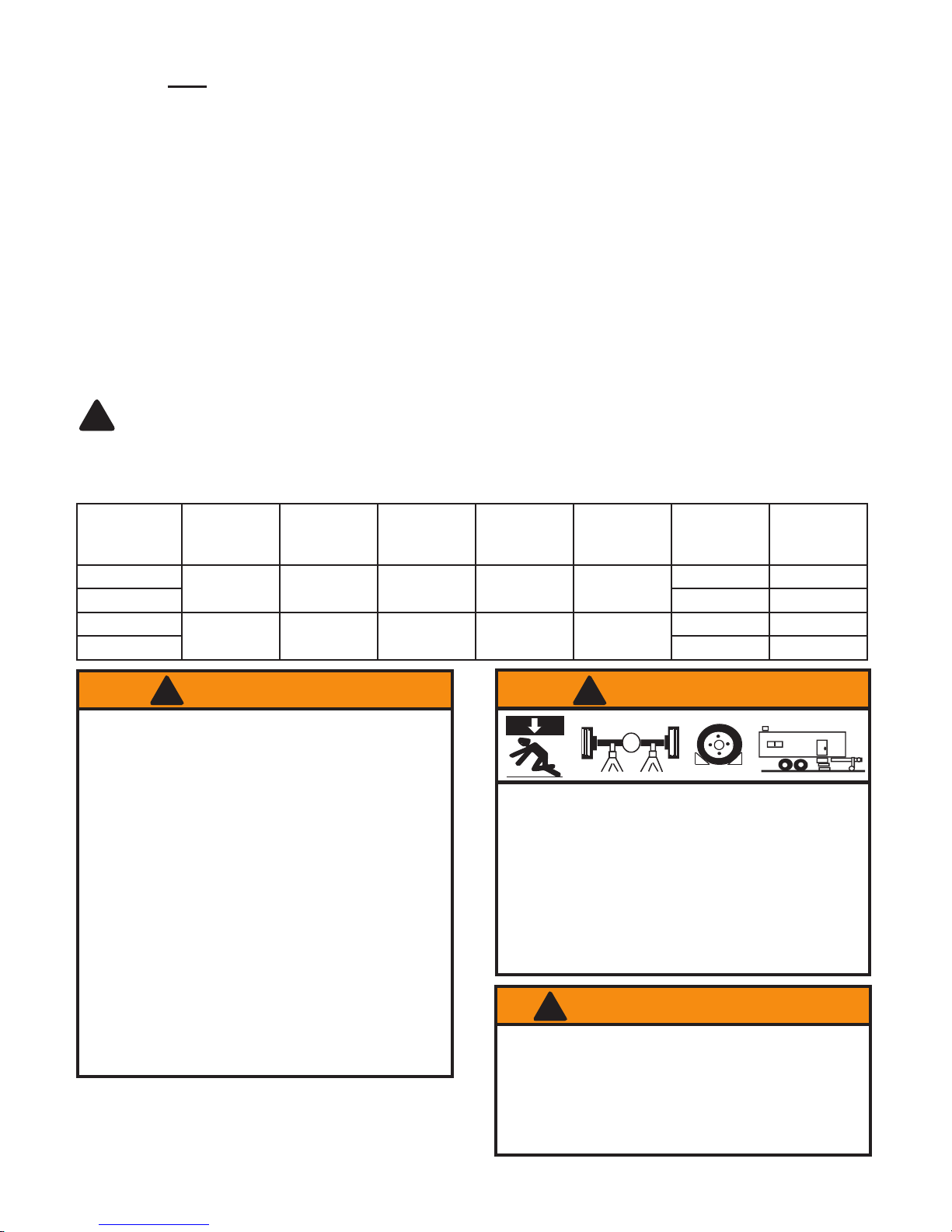

SPECIFICATIONS

Model Capacity Min. Height Max. Height Chassis

Length Wheel to

Wheel

Width

Min. Air

Pressure for

Rated Load

Gross

Weight

HW93657 4 Ton 5" 25-3/4" 49" 15" N/A 219 lb.

HW93667 140 psi 233 lb.

HW93660 10 Ton 6-3/4" 25-1/2" 53-1/2" 20 1/2" N/A 420 lb.

HW93662 140 psi 435 lb.

!WARNING

• Study, understand, and follow all printed materials

provided with/on this product before use.

• Do not exceed rated capacity.

• This is a lifting device only!

• Immediately after lifting, support the load with

a pair of appropriately rated jack stands.

• Use only on hard, level surfaces capable of

supporting rated capacity loads.

• On air actuated unit, never wire, clamp or otherwise

disable the lift control valve to function by other than

operator's hand.

• Do not use adapters or accessories that are not

provided initially.

• Lift only on areas of the vehicle as specied by the

vehicle manufacturer.

• Do not move or dolly loads with this device.

• No alterations shall be made to this product.

• Failure to heed these markings may result in

personal injury and/or property damage.

• Leer, comprender, y seguir las instrucciónes antes

de utilizar el aparato.

• El manual de instrucciónes y la información de

seguridad deben estar comunicado en lengua del

operador antes del uso.

• No seguir estas indicaciónes puede causar daños

personales o materiales.

!ADVERTENCIA

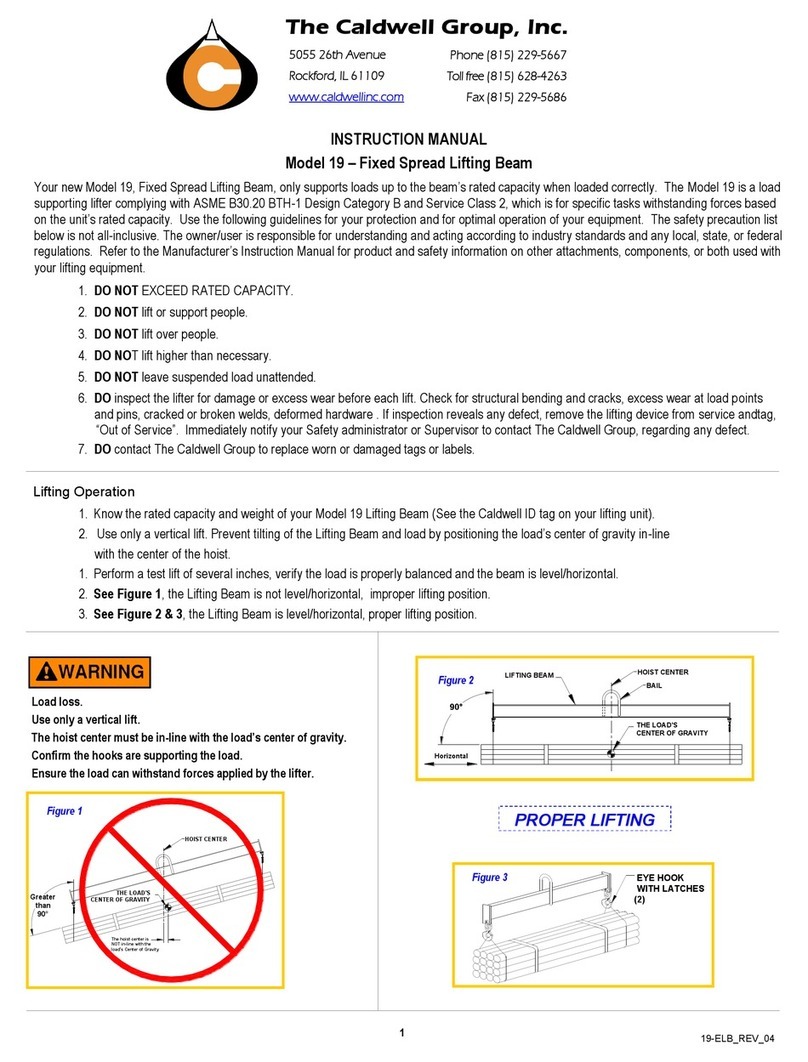

To avoid crushing and related injuries:

•

Never work on, under or around a load supported

only by hydraulic jack.

•

Always use adequately rated jack stands.

• Chock each unlifted tire in both directions.

• Do not use this device to lift, level, lower, support nor

move a house, mobile home, travel trailer, camper or

any building structure.

• Be alert and sober when using this product. Do not

operate under the inuence of drugs or alcohol.

!WARNING

X

PRODUCT DESCRIPTION

Hein-Werner Hydraulic Service Jacks are designed to lift, not support, rated capacity loads consisting of one end of a

vehicle. Immediately after lifting, the load must be supported by a pair of appropriately rated jack stands.

!NEVER use a hydraulic jack as a stand-alone device.After lifting, immediately support the lifted vehicle with

a pair of appropriately rated jack stands. NEVER place any portion of your body beneath the vehicle when

lifting OR lowering!

3

PREPARATION (REFER TO FIGURES 3 & 4)

Before Use

1. Verify that the product and application are compatible, if in doubt call Hein-Werner technical service.

2. Beforeuse,readtheoperator'smanualcompletelyandfamiliarizeyourselfthoroughlywiththeproduct,itscomponents

and recognize the potential hazards associated with its use.

3. To familiarize yourself with the basic operation of these jacks, locate and turn the release valve knob:

a.

Clockwise until rm resistance is felt to further turning. This is the ‘CLOSED’ release valve position used to raise

the load.

b.

Counter-clockwise,

but no more than

1/2

full turn

from the closed position. This is the ‘OPEN’ release valve position

used to lower the load. The more you turn the release valve knob Counter-clockwise, the faster the load descends.

4. With saddle fully lowered, locate and remove cover plate, then remove air vent screw. Pump the operating handle

through 6 to 8 full strokes. Check the oil level. Ensure the oil level is within ~3/16" from the inner cylinder as viewed

from the air vent screw hole.

5. Reinstall the air vent screw.

6. Check to ensure that the jack rolls freely. Raise and lower the unloaded saddle throughout the lift range before

putting into service to ensure the pump and release valve operate smoothly.

7. Replace worn or damaged parts and assemblies with Hein-Werner Replacement Parts only. Lubricate as instructed

in Maintenance Section.

ASSEMBLY

Equipment needed

1. Needle nose locking pliers

2.

Snap-ring pliers (

Model HW93657 & HW93667 only

)

3. 15 /16" wrench (

Model HW93660 & HW93662 only

)

4. Hammer

5. All necessary hardware is assembled loosely onto

the jack.

Instructions

1. ForHW93657andHW93667:(see gure 1) Remove

the retaining rings and the handle pin from the jack

base that connects through the handle fork.

ForHW93660andHW93662:(see gure 2) Remove

the 5/8"-18 bolts and the handle pin from the jack

base that connects through the handle fork.

2. Remove the#6-32 screwand nutfrom theuniversal

receptacle.

3.

Pull the universal assembly out a minimum of 1-3/4".

4. Clamp the needle nose locking pliers onto the rod

so that the universal assembly will not retract back

into the handle.

5. Slide the universal assembly into the handle socket

so that it extends out the other side.

6. Push the pivot pin that was removed in step 1 back

through the handle and handle socket (may have to

gently tap the pin with a hammer).

7. For HW93660 & HW93662, align the pivot pin with

the holes on the side plates that the pivot pin was

removed from and tighten the 5/8"-18 bolts into the

pivot pin until secure.

8. Connect the universal assembly to the universal

receptacle rod using the #6-32 screw and nut (nger

tighten only).

9. Remove the needle nose locking pliers.

10. Replace plug on hydraulic unit with vent screw

from owners manual bag.

11. Jack is now operational and ready for use.

Figure 2- Assembly Illustration for HW93660 & HW93662

Handle Pin

5/8"-18 Bolt

#6-32 Screw & Nut

Clamp Lock Pliers Here

Universal

Assembly

Universal

Receptacle

Figure 1- Assembly Illustration for HW93657 & HW93667

Handle Pin

Retaining Ring & Washer

#6-32 Screw & Nut

Clamp Lock Pliers Here

Universal

Assembly

Universal

Receptacle

OPERATION

Lifting

Only attachments and/or adapters supplied by the manufacturer shall be used. Lift only on areas of the

vehicleasspeciedbythevehiclemanufacturer.

1. Follow the vehicle manufacturer’s recommended guidelines for lifting. Engage the emergency brake and chock each

unlifted wheel in both directions to prevent inadvertent vehicle movement.

2. Locate and close the release valve by turning the release valve knob clockwise until rm resistance is felt.

3. Refer to the vehicle manufacturer owner’s manual to locate approved lifting points on the vehicle. Center jack saddle

under lift point.

4. Verify lift point then use handle pump to contact lift point. To lift, pump handle or squeeze air control valve (model

HW93667 & HW93662) until load reaches desired height.

5. Transfer the load immediately to appropriately rated jack stands.

NEVER use hydraulic jack as a stand alone device! ALWAYS transfer the lifted load IMMEDIATELY to a

pair of appropriately rated jack stands. Use one pair of jack stands per vehicle. Rated capacity is per pair

only! Do not exceed rated capacity.

Overloading may cause hydraulic system failure.

Lowering

Be sure all tools and personnel are clear before lowering load. Slowly open the release valve!

The more you turn the release valve knob counter-clockwise, the faster the load will come down. Maintain

control of the rate of speed at which the load lowers at all times!

1. Raise load high enough to clear the jack stands.

2. Remove jack stands, carefully (always used in pairs).

3. Slowly turn the release valve knob counter-clockwise, but no more than 1/2 full turn. If the load fails to lower:

a. Use another jack to raise the vehicle high enough to reinstall jack stands.

b. Remove the malfunctioning jack and then the jack stands.

c. Using the functioning jack, lower the load by turning the release valve knob counter-clockwise, but no more

than 1/2 full turn.

4. After removing jack from under the load, push saddle down to reduce ram exposure to rust and contamination.

4

Release Valve Knob

Figure 3 - Model HW93657 & HW93660 Nomenclature Figure 4 - Model HW93667 & HW93662 Nomenclature

Air Control Valve

Saddle

Handle

Lift Arm

Handle

Fork

Caster Front Wheel

Release Valve Knob

Saddle

Handle

Caster

Air Motor

Air Vent Screw

(below cover plate,

on power unit)

Air Vent Screw

(below cover plate,

on power unit)

Handle Fork

Lift Arm

Front Wheel

!

!

!

!

TROUBLESHOOTING

5

MAINTENANCE

Important: Use only a good grade hydraulic jack oil. Avoid mixing different types of uid and Never use brake uid,

turbine oil, transmission uid, motor oil or glycerin. Improper uid can cause failure of the jack and the potential for

sudden and immediate loss of load. We recommend Hein-Werner hydraulic jack oil HW 93291 or equivalent.

Adding oil

1. Lower saddle fully.

2. Set jack in its upright, level position.

3. Locate and remove air vent screw.

4. Fill with oil until ~3/16" above the inner cylinder as seen from the air vent screw hole.

5. Reinstall the air vent screw.

Changing oil

For best performance and longest life, replace the complete hydraulic uid at least once a year.

1. Lower saddle fully.

2. Remove the air vent screw.

3. Lay the jack on its side and drain the uid into a suitable container.

Note: Dispose of hydraulic uid in accordance with local regulations.

4. Fill with oil until ~3/16" above the inner cylinder as seen from the air vent screw hole.

5. Reinstall the air vent screw.

Lubrication

Aperiodiccoatingoflightlubricatingoiltopivotpoints,axlesandhingeswillhelp to preventrustandassurethatwheels,

castors and pump assemblies move freely.

Cleaning

Periodically check the pump piston and ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth

.

Note: Never use sandpaper or abrasive material on these surfaces!

Storage

Lower the saddle to its lowest position when not in use.

REPLACEMENT PARTS (refer to page 6 thru 19)

Not all components of the jack are replacement items, but are illustrated as a convenient reference of location and

position in the assembly sequence. When ordering parts, give model number, part number and parts description.

Call or write for current pricing: Hein-Werner Customer Support, 10939 N. PomonaAve. Kansas City, MO 64153.

Phone: (816)891-6390; E-mail: [email protected]

Symptom Possible Causes Corrective Action

Jack will not lift load • Release knob not tightly closed

• Overload condition

• Ensure release knob tightly closed

• Remedy overload condition

Jack bleeds off after lift • Hydraulic unit malfunction • Discontinue use, contact Hein-

Werner Technical Service

Jack will not lower after unloading • Reservoir overlled

• Linkages binding

• Fluid level low

• Drain uid to proper level

• Clean and lubricate moving parts

• Ensure proper uid level

Will not lift to full extension • Fluid level low • Ensure proper uid level

Model HW93657 Replacement Parts Illustration Part I (refer to parts list on page 8)

6

Figure 5 - Parts Illustration for Model HW93657

241990

Handle

Assembly

(ANDLE!SSEMBLY

0ARTSNOTINCLUDED

228354

227399

241982

234696

234695

7

Figure 6 - Parts Illustration for Model HW93657 (Hydraulic Unit)

Model HW93657 Replacement Parts Illustration Part II - Hydraulic Unit (refer to parts list on page 8)

(YDRAULIC5NIT!SSEMBLY

230583

Ram

Assembly

2AM!SSEMBLY

203199 (1/4” O.D.)

8

Model HW93657 Replacement Parts List (refer to gures on page 6 & 7)

Part# Description Qty.

200003* Gasket 1

200472 Screw 2

201110 Lockwasher 4

201479 Lockwasher 2

201733 Plug 1

201779 Lockwasher 2

201784 Lockwasher 1

N/A Rivet 2

203198* Ball (7/32" O.D.) 1

203199* Ball (1/4" O.D.) 1

203200* Ball (9/32" O.D.) 1

203201* Ball (5/16" O.D.) 1

203205* Ball (7/16" O.D.) 1

203299 Jam Nut 4

203313 Jam Nut 2

203332 Nut 1

203344 Jam Nut 2

204270 Washer 2

204277 Washer 1

204301 Washer 1

204303 Washer 1

204343 Washer 4

204372 Washer 1

204444 Cotter Pin 3

204461 Cotter Pin 1

204842* Copper Gasket 1

209964 Lockwasher 2

210225 Spacer 1

210311 Pipe Plug 3

210411* Washer 1

211341 Rivet 1

212227 Release Valve 1

213152* Packing Ring 2

213171* Packing Ring 2

214538 Groove Pin 4

214555* O-ring 1

214699 Bushing 1

214700 Handle Segment Assy.1

216645 Pin 1

216646 Pump Pin 1

218988 Roll Pin 1

219451 Hex Nut 2

220769 Cross Pin 1

221739* Poppet 1

221740 Ball Stop Plug(7/16" L)1

Part# Description Qty.

221742 Ball Stop Plug (3/4" L) 1

221764* Ram Quad Ring 1

221766 Cylinder 1

221770 Low Pressure Pump 1

221771* Washer 1

221772* Quad ring 1

221778 Washer 4

221781 Handle and Cross Bar 1

221798 Retainer Ring 4

221817 Retainer Ring 2

N/A Parallel Link 2

221829 Pin 1

221937 Turning Knob 1

221938 Roll Pin 1

222095 Release Stem Kit 1

222098 Speed Pump Assy. 1

222201* Spring 1

222257 Plug Poppet Valve 2

222533* Screen 2

223166* Ram Screen 1

226314 Gland Nut 1

226318 Grease Fitting 1

226324 Pressure Plug 1

226325 Pump Link 2

226326 Nut 1

226327 Slotted Tube 1

226329 Pin 1

226331* Spring 1

226353* Spring 1

226366 Hex Head Bolt 1

226372 Spring 1

226615 Front Wheel 2

227395 Plunger Assy. 1

227397 Release Link 1

227399 Extension Rod 1

227436 Turning Rod Assy. 1

228257* U-cup 1

228354 Universal Assy. 1

228875 Spring 1

228881 Grip 2

N/A Serial Plate 1

229748* Heel Plate 3

229749 Washer 1

229750 Ram 1

229751 Pin 1

Part# Description Qty.

230583 Ram Assy. 1

231316 Vent Valve Assy. 1

231583 Rear Caster 2

231638 Filler Screw 1

231710 Oil Tank 1

232968* Back-up Washer 1

232969* U-cup 1

232970 Pressure Pump 1

232971 Pressure Pump Kit 1

233798 Tank Nut 1

N/A Tank Nut and Quad Ring1

233917* Plastic Spring 1

233921 Release Stem 1

234695 Bellcrank Pin 3/4x3.38 1

234696 Parallel Link Pin 1

234976 Cap Housing 1

N/A Bellcrank 1

241887 Handle Socket 1

241889 Lift cap 1

N/A Sideplate Assy 1

N/A Sideplate Assy 1

241895 Hydraulic Unit Cover 1

241907 Repair Kit (Hyd. Unit) -

241982 Fulcrum Pin 1

241983 Sideplate Tie Rod 2

241985 Support Rod 1

241986 Front Axle 1

241987 Retainer Ring 2

241988 Handle Pivot Pin 1

241989 Extension Spring 2

241990 Handle Assy. 1

N/A Hydraulic Unit Casting 1

241993 Hydraulic Unit Assy. 1

HW93657-K0 Label Kit (not shown)

HW93657-M0 Manual

(*) Items included in Repair Kit 241907

9

Model HW93660 Replacement Parts Illustration Part I (refer to parts list on page 11)

Figure 7 - Parts Illustration for Model HW93660

`

241551

(ANDLE!SSEMBLY

230407

230006

244317

214538

244253

10

Model HW93660 Replacement Parts Illustration Part II - Hydraulic Unit (refer to parts list on page 11)

Figure 8 - Parts Illustration for Model HW93660 (Hydraulic Unit)

245119

229956 229900

(YDRAULIC5NIT!SSEMBLY

2AM!SSEMBLY

Model HW93660 Replacement Parts List (refer to gures on page 9 & 10)

Part# Description Qty.

200003 Gasket 1

200472 Bolt 2

201110 Lockwasher 4

201115 Lockwasher 2

201481 Lockwasher 2

201733 Expansion Plug 1

201784 Lockwasher 1

201789 Lockwasher 2

203198* Ball 1

203199* Ball 1

203200* Ball 1

203201* Ball 1

203207* Ball 1

203272 Nut 2

203297 Nut 2

203299 Nut 2

203323 Nut 2

203332 Nut 1

203344 Nut 2

204270 Washer 2

204277 Washer 1

204301 Washer 1

204303 Washer 1

204372 Washer 1

204444 Cotter Pin 4

204461 Cotter Pin 1

204842* Gasket 1

207169 Nut 2

209964 Lockwasher 2

210225 Spacer 1

210311 Pipe Plug 3

210411* Washer 1

211341 Rivet 1

212227 Release Valve 1

212689 Bolt 2

213152* Packing Ring 2

213171* Packing Ring 2

214538 Groove Pin 4

214555* O-ring 1

214699 Bushing 1

214700 Handle Segment 1

& Bushing

216645 Pin 1

216646 Pin 1

217653 Roll Pin 2

218988 Roll Pin 1

218991 Roll Pin 1

Part# Description Qty..

220769 Cross Pin 1

221739 Poppet 1

221742 Ball Stop Plug 1

221770 Speed Pump 1

221771* Back-up Washer 1

221772 Quad Ring 1

221781 Handle & Cross Bar 1

221809 Handle Grip 2

221937 Release Knob 1

221938 Roll Pin 1

222095 Release Stem Assy. 1

222098 Speed Pump Assy. 1

222201* Spring 1

222257 Plug 1

222533* Screen 2

223166* Screen 1

224253 Cover 1

N/A Fulcrum Pin 1

226314 Gland Nut 1

226318 Grease Fitting 5

226325 Pump Link 2

226326 Gland Nut 1

226331 Spring 1

226353* Spring 1

226366 Bolt 1

226372 Plunger Spring 1

227397 Link 1

227436 Turning Rod Assy. 1

228875 Spring 1

229887* O-ring 1

229888* O-ring 1

229889* O-ring 1

N/A Ram & Cylinder Assy. 1

229898 Cylinder 1

229899* U-cup Packing 1

229900* Back-up Washer 1

229902 Cross Pin 1

229903 Pin 1

229904 Plug 1

229905 Plug 1

229908 Spacer 1

229909 Slotted Tube 1

229910 Retaining Ring 2

229911 Retaining Ring 2

229912 Washer 4

N/A Bell Crank 1

231963 Front Wheel 2

Part# Description Qty.

229927 Cap Housing 1

229929 Bearing 1

229932 Spring 2

229933 Plate 2

229934 Pin 1

229937 Caster 2

229938 Pin 1

229939 Front Axle 1

229946 Pin 1

229947 Retaining Ring 4

N/A Handle Socket 1

229951 Extension Rod 1

229952 Plunger Assy. 1

229956 Heel Plate 1

230006 Bumper Pin 1

230407 Universal Assy. 1

231316 Filler Plug & Gasket Assy. 1

231419 Fulcrum Pin 1

231420 Bolt 2

N/A Parallel Link 2

N/A Bell Crank & Fittings 1

231638 Filler Plug & Vent Valve 1

231717 Base 1

231718 Oil Tank 1

231945 Ram Assy. 1

231962 Handle Assy. 1

231963 Front Wheel Assy. 2

232619 Lifting Cap 1

232620 Swivel Pin 1

232968* Back-up Washer 1

232969* U-cup Packing 1

232970 Pressure Pump 1

232971 Pressure Pump & 1

Gland Packing Assy.

233917 Plastic Spring 1

233921 Release Stem 1

240616 Repair Kit (Hyd. Unit) -

241482 Tank Nut 1

241483* Seal 1

241551 Hydraulic Unit Assy. 1

244317 Pin 1

245119 Ram 1

HW93660-K0 Label Kit (not shown)

HW93657-M0 Manual

(*) Items included in Repair Kit 240616

11

Model HW93662 Replacement Parts Illustration Part I (refer to parts list on page 14)

12

Figure 9 - Parts Illustration for Model HW93662

229999

(ANDLE!SSEMBLY

13

Model HW93662 Replacement Parts Illustration Part II - Hyd. Unit (refer to parts list on page 14)

Figure 10 - Parts Illustration for Model HW93662 (Hydraulic Unit)

2AM!SSEMBLY

Note:

Poppet valve operates until it reaches

150 psi. then the Poppet valve opens

& allows the high presure circuit to

open for raising the load.

(YDRAULIC5NIT!SSEMBLY

14

Model HW93662 Replacement Parts Illustration Part III - Air Hyd. Pump

Figure 11 - Parts Illustration for Model HW93662 (Air Hyd. Pump)

200003 Gasket 1

200472 Bolt 2

201110 Lockwasher 4

201115 Lockwasher 2

201481 Lockwasher 2

201733 Expansion Plug 1

201784 Lockwasher 1

201789 Lockwasher 2

203198* Ball (7/32" O.D.) 1

203199* Ball (1/4" O.D.) 1

203200* Ball (9/32" O.D.) 1

203201* Ball (5/16" O.D.) 1

203202 Ball (11/32" O.D.) 1

203207* Ball 1

203272 Nut 2

203297 Nut 2

203299 Nut 2

203301 Jam Nut 1

203323 Nut 2

203332 Nut 1

203344 Nut 2

204270 Washer 2

204277 Washer 1

204301 Washer 1

204303 Washer 1

204372 Washer 1

204444 Cotter Pin 4

204461 Cotter Pin 1

204842* Gasket 1

207169 Nut 2

209964 Lockwasher 2

210225 Spacer 1

210311 Pipe Plug 3

210411* Washer 1

211341 Rivet 1

212227 Release Valve 1

212689 Bolt 2

213152* Packing Ring 2

213171* Packing Ring 2

214538 Groove Pin 4

Model HW93662 Replacement Parts List (refer to gures on page 12, 13 & 14)

...Continue on next page (page 15)

Part# Description Qty

214555* O-ring 1

214699 Bushing 1

214700 Handle Segment & 1

Bushing

216645 Pin 1

216646 Pin 1

217653 Roll Pin 2

218988 Roll Pin 1

218991 Roll Pin 1

219861 O-ring 1

220769 Cross Pin 1

221013# U-cup Packing 1

221739 Poppet 1

221742 Ball Stop Plug 1

221770 Speed Pump 1

221771* Back-up Washer 1

221772 Quad Ring 1

221809 Handle Grip 2

221820 Retaining Ring 2

221937 Release Knob 1

Part# Description Qty Part# Description Qty

Piston Assembly

0ISTON!SSEMBLY

!IR(YDRAULIC0UMP!SSEMBLY

CAUTION

Do not overtighten.

229754 tube must not

protude into I.D. pump

cylinder

Piston

35100007

15

Model HW93662 Replacement Parts List (Cont.)

221938 Roll Pin 1

222095 Release Stem Assy. 1

222098 Speed Pump Assy. 1

222201* Spring 1

BJ479096 Elbow 1

222257 Plug 1

222288# O-ring 1

222533* Screen 2

223166* Screen 1

223172 Hose Clip 1

223173 Return Spring 1

223176 Cylinder, Air 1

223179 Hose Clip 2

223183 Plug 1

223184 Spring 1

223187# Valve & Plunger 1

223194 Spring & Cushion 1

223203 Trip Washer 2

223220 Handle & Cross Bar 1

223678 Packing & Piston 1

223680 Screen 1

224021 Hose, Air 1

224081 Screw 2

224156 Spring 1

224469 Washer 1

225371 Rubber Cushion 1

225384 Trip Spring 1

225906 Bracket, Speed pak 1

226153 Spring 1

226271 Fulcrum Pin 1

226314 Gland Nut 1

226318 Grease Fitting 5

226325 Pump Link 2

226326 Gland Nut 1

226331 Spring 1

226353* Spring 1

226366 Bolt 1

226372 Plunger Spring 1

226373 Adjusting Screw 1

226401 Spring 1

226450 End Block 1

226451 Set Screw 2

226483 Pipe Nipple 1

227397 Link 1

227436 Turning Rod Assy. 1

227713 Lockwasher 1

228235 Cotter Pin 1

228813 Washer 1

228814# Gland Nut 1

228815# U-cup Packing 1

228816# Washer 1

228875 Spring 1

229754 Pin 1

229887* O-ring 1

229888* O-ring 1

229889* O-ring 1

N/A Ram & Cylinder Assy.1

229898 Cylinder 1

229899* U-cup Packing 1

229900* Back-up Washer 1

229902 Cross Pin 1

229903 Pin 1

229904 Plug 1

229905 Plug 1

229908 Spacer 1

229909 Slotted Tube 1

229910 Retaining Ring 2

229911 Retaining Ring 2

229912 Washer 4

N/A Bell Crank 1

231963 Front Wheel 2

229927 Cap Housing 1

229929 Bearing 1

229932 Spring 2

229933 Plate 2

229934 Pin 1

229938 Pin 1

229939 Front Axle 1

229946 Pin 1

229947 Retaining Ring 4

N/A Handle Socket 1

229951 Extension Rod 1

229952 Plunger Assy. 1

229956 Heel Plate 1

229999 Air Hyd. Pump Assy. 1

230000 Pump Cylinder 1

230003 Back-up Washer 1

230005 Gland Nut 1

230006 Bumper Pin 1

230007 U-bolt 1

230008 Bracket 1

230010 Caster 2

230011 Spacer 1

230407 Universal Assy. 1

231316 Filler Plug & 1

Gasket Assy.

231347 Piston & Roll Pin 1

231419 Fulcrum Pin 1

231420 Bolt 2

N/A Parallel Link 2

N/A Bell Crank & Fittings 1

231572 Cylinder Cap 1

231604 Piston Assy. 1

231619 Rod, Pump 1

231638

Filler plug & Vent Valve

1

231733 Base 1

231718 Oil Tank 1

231945 Ram Assy. 1

231963 Front Wheel Assy. 2

231990 Handle Assy. 1

232619 Lifting Cap 1

232620 Swivel Pin 1

232968* Back-up Washer 1

232969* U-cup Packing 1

232970 Pressure Pump 1

232971 Pressure Pump & 1

Gland Packing Assy.

233110 Pump U-cup 1

233622 Screw 4

233897 Ring, Sealing 1

233917 Plastic Spring 1

233921 Release Stem 1

240564 Repair Kit (Air Pump)-

240616 Repair Kit (Hyd. Unit) -

241482 Tank Nut 1

241483* Seal 1

241552 Hydraulic Unit Assy. 1

244253 Cover 1

244317 Pin 1

245119 Ram 1

35100007 Air Valve 1

HW93662-K0 Label Kit (not shown)

HW93657-M0 Manual

(*) Items included in Repair Kit 240616

(#) Items included in Repair Kit 240564

Part# Description Qty Part# Description Qty Part# Description Qty

16

Model HW93667 Replacement Parts Illustration Part I (refer to parts list on page 18)

Figure 12 - Parts Illustration for Model HW93667

(ANDLE!SSEMBLY

(ANDLE!SSEMBLY

0ARTSNOTINCLUDED

241990

17

Model HW93667 Replacement Parts Illustration Part II - Hyd. Unit (refer to parts list on page 18)

Figure 13 - Parts Illustration for Model HW93667 (Hyd. Unit)

(YDRAULIC5NIT!SSEMBLY

2AM!SSEMBLY

18

Model HW93667 Replacement Parts Illustration Part III - Air Hyd. Pump

Figure 14 - Parts Illustration for Model HW93667 (Air Hyd. Pump)

Model HW93667 Replacement Parts List (refer to gures on page 16, 17 & 18)

Part# Description Qty Part# Description Qty Part# Description Qty

200003* Gasket 1

200472 Screw 2

201110 Lockwasher 4

201479 Lockwasher 2

201733 Plug 1

201779 Lockwasher 2

201784 Lockwasher 1

N/A Rivet 2

203198* Ball (7/32" O.D.) 1

203199* Ball (1/4" O.D.) 1

203200* Ball (9/32" O.D.) 1

203201* Ball (5/16" O.D.) 1

203202 Ball (11/32" O.D.) 1

203205* Ball (7/16" O.D.) 1

203299 Jam Nut 4

203313 Jam Nut 2

203332 Nut 1

203344 Jam Nut 2

204270 Washer 2

204277 Washer 1

204301 Washer 1

204303 Washer 1

204343 Washer 4

204372 Washer 1

204444 Cotter Pin 3

204461 Cotter Pin 1

204842* Copper Gasket 1

209964 Lockwasher 2

210225 Spacer 1

210311 Pipe Plug 4

210411* Washer 1

211341 Rivet 1

212227 Release Valve 1

213152* Packing Ring 2

213171* Packing Ring 2

213639 Bolt 1

214538 Groove Pin 4

214555* O-ring 1

214699 Bushing 1

214700 Handle Segment Assy. 1

216645 Pin 1

216646 Pump Pin 1

218988 Roll Pin 1

219451 Hex Nut 2

220769 Cross Pin 1

221013# U-cup Packing 1

221377 Roll Pin 1

221739* Poppet 1

221740

Ball Stop Plug (7/16" L)

1

221742 Ball Stop Plug (3/4" L)1

221764* Ram Quad Ring 1

N/A Cylinder 1

221770 Low Pressure Pump 1

221771* Washer 1

221772* Quad ring 1

221778 Washer 2

221798 Retainer Ring 4

221817 Retainer Ring 2

221820 Retaining Ring 1

N/A Parallel Link 2

...Continue on next page (page 19)

0ISTON!SSEMBLY

!IR(YDRAULIC0UMP!SSEMBLY

Piston

Assembly

242162

35100007

BJ479096

19

Model HW93667 Replacement Parts List (cont.)

Part# Description Qty Part# Description Qty Part# Description Qty

234696 Parallel Link Pin 1

221829 Pin 1

221937 Turning Knob 1

221938 Roll Pin 1

222088 Screen Assembly 1

222095 Release Stem Kit 1

222098 Speed Pump Assy. 1

222201* Spring 1

BJ479096 Elbow 1

222257 Plug Poppet Valve 2

222288# O-ring 1

222533* Screen 2

223166* Ram Screen 1

223172 Hose Clip 1

223173 Return Spring 1

223179 Hose Clip 2

223183 Plug 1

223184 Spring 1

223187# Valve & Plunger 1

223203 Trip Washer 2

223213 Gland Nut 1

223220 Handle & Cross Bar 1

223678 Packing & Piston 1

223680 Screen 1

224034 Air Cylinder 1

224038 Pump Rod 1

224081 Screw 3

224156 Spring 1

224344 Ball Stop Plug 1

224414 Retaining Ring 1

224469 Washer 1

225371 Rubber Cushion 1

225384 Trip Spring 1

225906 Bracket, Speed Pak 1

226019 Lock Nut 4

226153 Spring 1

226314 Gland Nut 1

226318 Grease Fitting 1

N/A Bellcrank Pin 1

226324 Pressure Plug 1

226325 Pump Link 2

226326 Nut 1

226327 Slotted Tube 1

226329 Pin 1

226331* Spring 1

226353* Spring 1

226366 Hex Head Bolt 1

226372 Spring 1

226373 Adjusting Screw 1

N/A End block 1

226451 Set Screw 2

226483 Pipe Nipple 1

226615 Front Wheel 2

227052 Washer 1

227395 Plunger Assy. 1

227397 Release Link 1

227399 Extension Rod 1

227436 Turning Rod Assy. 1

228235 Cotter Pin 1

228257* U-cup 1

228354 Universal Linkage 1

228813 Washer 1

228814# Gland Nut 1

228815# U-cup Packing 1

228816# Washer 1

228875 Spring 1

228881 Grip 2

N/A Serial plate 1

229748* Heel Plate 3

229749 Washer 1

229750 Ram 1

229751 Pin 1

229754 Extension Tube 1

230003* Back-up Washer 1

230007 U-bolt 1

230430 Air Hose Assy. 1

230583 Ram Assy. 1

230753 Suction Tube 1

231316 Vent Valve Assy. 1

N/A Cylinder Cap 1

231583 Rear Caster 2

231638 Filler Screw 1

231710 Oil Tank 1

232968* Back-up Washer 1

232969* U-cup 1

232970 Pressure Pump 1

232971 Pressure Pump Kit 1

233110 Pump U-cup 1

233798 Tank Nut 1

N/A Tank Nut & Quad

Ring 1

233917* Plastic Spring 1

233921 Release Stem 1

234976 Cap Housing 1

236684 Piston 1

236685 Sealing Ring 1

240564

Repair Kit (Hyd. Pump)

1

241990 Handle 1

N/A Bellcrank 1

241887 Handle Socket 1

241889 Lift Cap 1

N/A Sideplate Assy 1

241895 Hydraulic Unit Cover 1

241907 Repair Kit (Hyd. Unit) -

N/A Sideplate Assy 1

241982 Fulcrum Pin 1

241983 Sideplate Tie Rod 2

241985 Support Rod 1

241986 Front Axle 1

241987 Retainer Ring 4

241988 Handle Pivot Pin 1

241989 Extension spring 2

241992

Hydraulic Unit Casting

1

241994 Hydraulic Unit Assy. 1

242160 Air Hyd. Pump Assy. 1

242161 Pump Cylinder 1

242162 Piston Assembly 1

243098 U-bolt 1

243101 Sleeve 1

35100007 Air Valve 1

HW93667-K0 Label Kit (not shown)

HW93657-M0 Manual

(*) Items included in Repair Kit 241907

#Items included in Repair Kit 240564

TWO YEARS LIMITED WARRANTY

For a period of two (2) years from date of purchase, SFACompanies will repair or replace, at its option, without charge,

any of its products which fails due to a defect in material or workmanship under normal usage. This limited warranty is

a consumer's exclusive remedy.

Performance of any obligation under this warranty may be obtained by returning the warranted product, freight prepaid,

to SFA Companies Warranty Service Department, 10939 N. Pomona Ave., Kansas City, MO 64153.

Except where such limitations and exclusions are specically prohibited by applicable law:

(1) THE CONSUMER'S SOLE AND EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF DEFECTIVE

PRODUCTS AS DESCRIBED ABOVE

(2) SFA COMPANIES SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGE OR LOSS

WHATSOEVER.

(3) ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL BE LIMITED TO TWO YEARS,

OTHERWISE THE REPAIR, REPLACEMENT OR REFUND AS PROVIDED UNDER THIS EXPRESS LIMITED

WARRANTY IS THE EXCLUSIVE REMEDY OF THE CONSUMER, AND IS PROVIDED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

(4) ANY MODIFICATION, ALTERATION, ABUSE, UNAUTHORIZED SERVICE OR ORNAMENTAL DESIGN VOIDS

THIS WARRANTY AND IS NOT COVERED BY THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specic legal rights, and you may also have other rights which

vary from state to state.

SFA Companies

10939 N. Pomona Ave. Kansas City, MO 64153

816-891-6390

This manual suits for next models

3

Table of contents

Other HEIN-WERNER AUTOMOTIVE Lifting System manuals