HEIN-WERNER AUTOMOTIVE HW93692 Instructions for use

Operating Instructions & Parts Manual

SFA Companies ©2004

10939 N. PomonaAve. Kansas City, MO 64153

816-891-6390

Model Number Capacity

HW93692 7 Ton

AirOperated End Lift

Made in

North America

-Before using this product, read this manual and follow all its Safety Rules and Operating Instructions

HW93692-M0

Warranty P2

Save These Instructions P3

Product Description P3

Specifications & Safety Instructions P3

Assembly P4

Operation P5

Maintenance P6

Troubleshooting P6

Replacement Parts P6

TWO YEAR LIMITED WARRANTY

Fora periodof two(2) yearsfrom dateof purchase,SFA Companieswill repair or replace, atits option,without charge,any

of its products which fails due to a defect in material or workmanship, or which fails to conform to any implied warranty not

excludedhereby.

Performance of any obligation under this warranty may be obtained by returning the warranted product, freight prepaid, to

SFA Companies WarrantyService Department,10939 N. PomonaAve., Kansas City,MO 64153.

Except where such limitations and exclusions are specifically prohibited by applicable law:

(1)THECONSUMER'SSOLEANDEXCLUSIVEREMEDYSHALLBETHEREPAIRORREPLACEMENT OF DEFECTIVE

PRODUCTSAS DESCRIBEDABOVE.

(2) SFACOMPANIESSHALLNOTBELIABLEFORANYCONSEQUENTIALORINCIDENTALDAMAGEORLOSSWHAT-

SOEVER.

(3)THEDURATION OFANYANDALLEXPRESSEDANDIMPLIEDWARRANTIES, INCLUDING WITHOUT LIMITATION,

ANYWARRANTIESOFMERCHANTABILITYANDFITNESS FORA PARTICULARPURPOSE,ISLIMITED TOAPERIOD

OF TWO (2) YEARS FROM DATE OF PURCHASE.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusionmay not applyto you. Thiswarranty gives youspecific legalrights, and youmay also haveother rightswhich vary

from state to state. 2

TABLE OF CONTENTS

HW93692-M0

SAVE THESE INSTRUCTIONS

Foryour safety, read,understand,and follow the information providedwith andon thisjack. Theowner and operator of this

equipmentshallhavean understanding ofthisjackand safe operatingproceduresbeforeattempting to use.Theownerand

operatorshallbe awarethat use andrepair of thisproduct mayrequirespecial skillsand knowledge. Instructionsand safety

informationshall beconveyed in the operator's nativelanguage before use of this jack isauthorized. If any doubt exists as

tothe safe and proper use of this jack, remove from serviceimmediately.

Inspect before each use. Donot use if there are broken, bent,cracked, ordamaged parts(including labels). Anyjackthat

appears damaged in any way, operates abnormally or is missing parts, shall be removed from service immediately. If the

jack has been or suspected to have been subjected to a shock load (a load dropped suddenly, unexpectedly upon it),

immediately discontinue to use until jack has been inspected by a Hein-Werner authorized service center. It is recom-

mended that an annual inspection be done by qualified personnel. Labels and Operator's Manual are available from

manufacturer.

PRODUCT DESCRIPTION

TheHein-WernerAir OperatedEnd Liftis designed tolift, but notsustain, ratedcapacity loads. Thedual hydraulicdampers

providesafetyrestraintifloadis suddenly removed. Intended use: To engagethemetalbumperofavehicleandraiseforthe

purposeof serviceand/or repairof vehiclecomponents.Afterlifting, loads must be immediatelysupported byappropriately

ratedjack stands.Check vehicle'sfactory serviceand/or repair manual for proper lift points.

DO NOT USE TO DOLLY OR MOVE VEHICLE. DO NOT USE FOR ANY PURPOSE OTHER THAN THOSE USES

OUTLINED ABOVE !

3

SAFETY INSTRUCTIONS

BEFORE USE

1.Verify thatthe product and the application are compatible,if in doubt call Hein-Werner Technical Service(816)891-6390.

2. Read this manual completely and familiarize yourself thoroughly with the product, its components and recognize the

potential hazards associated with its misuse before using this product.

3.Ensure thatjack rolls freely, the air cylinder andcontrol valve operates smoothly, raises and lowers the unloaded saddle

throughoutthe lift range before putting into service.

4. Loosen air vent screws (upper screws) on each hydraulic damper located on side of air cylinders.

5. Ensure the jack is loaded on center with the saddles placed equal distance from the center.

6. Replace worn or damaged parts and assemblies with Hein-Werner Replacement Parts only. (See Replacement Parts

Section). Lubricate as instructed in Maintenance Section.

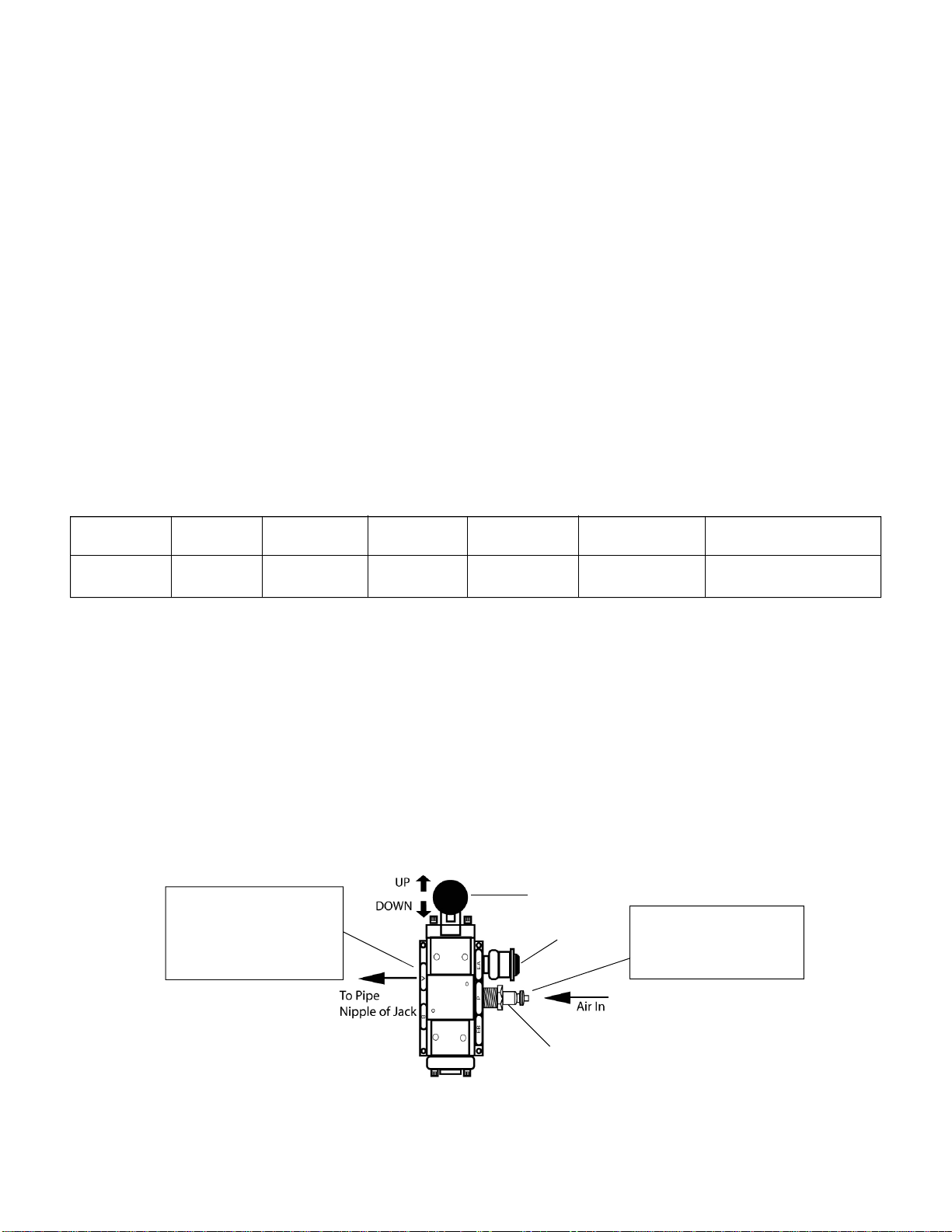

7. Connect lift control valve as shown in Figure 1. Connect air nipple to air input port before connecting air hose.

Note:Use only NPTthread sizeair nipple. Tightensecurely toprevent accidental removalof componentswhile in use.Take

care not to introduce compound into port orifices.

SPECIFICATIONS

Capacity

58-1/2"

Model Min. Height Max. Height

13-1/2"

HW93692 7Ton

PowerRaise

32-1/2"

SaddleSpread Min. PSI for Rated Load

29" to 41" 200

Figure 1. Lift Control Valve Illustration

Control Knob

Air Filter

1/4" NPT Air Nipple (not provided)

Step 1:

Threadliftcontrolvalvein

clockwise direction onto

the pipe nipple of jack

Step 2:

Connect air hose to 1/4"

NPTAirNipple

HW93692-M0

• Study, understand, and follow all instructions

provided with and on this device before operating this

device.

• Do not exceed rated capacity.

• This is a lifting device only.

• Center load on saddle.

•Never lift vehiclewhich cannot rollfreely forward and

backwardduring lift.

• After lifting, immediately transfer the load to

appropriately rated vehicle stands.

• Never work on, under, or around a load supported by

this device.

• Use only on hard, level surfaces capable of

sustaining rated capacity loads.

• Do not move or dolly loads with this device.

• Do not modify this device.

• Do not use adapters or accessories that are not

provided initially.

• Lift only on areas of the vehicle as specified by the

vehiclemanufacturer.

• Failure to heed these markings may result in

personal injury and/or property damage.

• Leer, comprender, y seguir las instrucciónes antes

de utilizar el aparato.

• El manual de instrucciónes y la información de

seguridaddeben estar comunicado en lengua del

operadorantes del uso.

• No seguir estas indicaciónes puede causar daños

personaleso materiales.

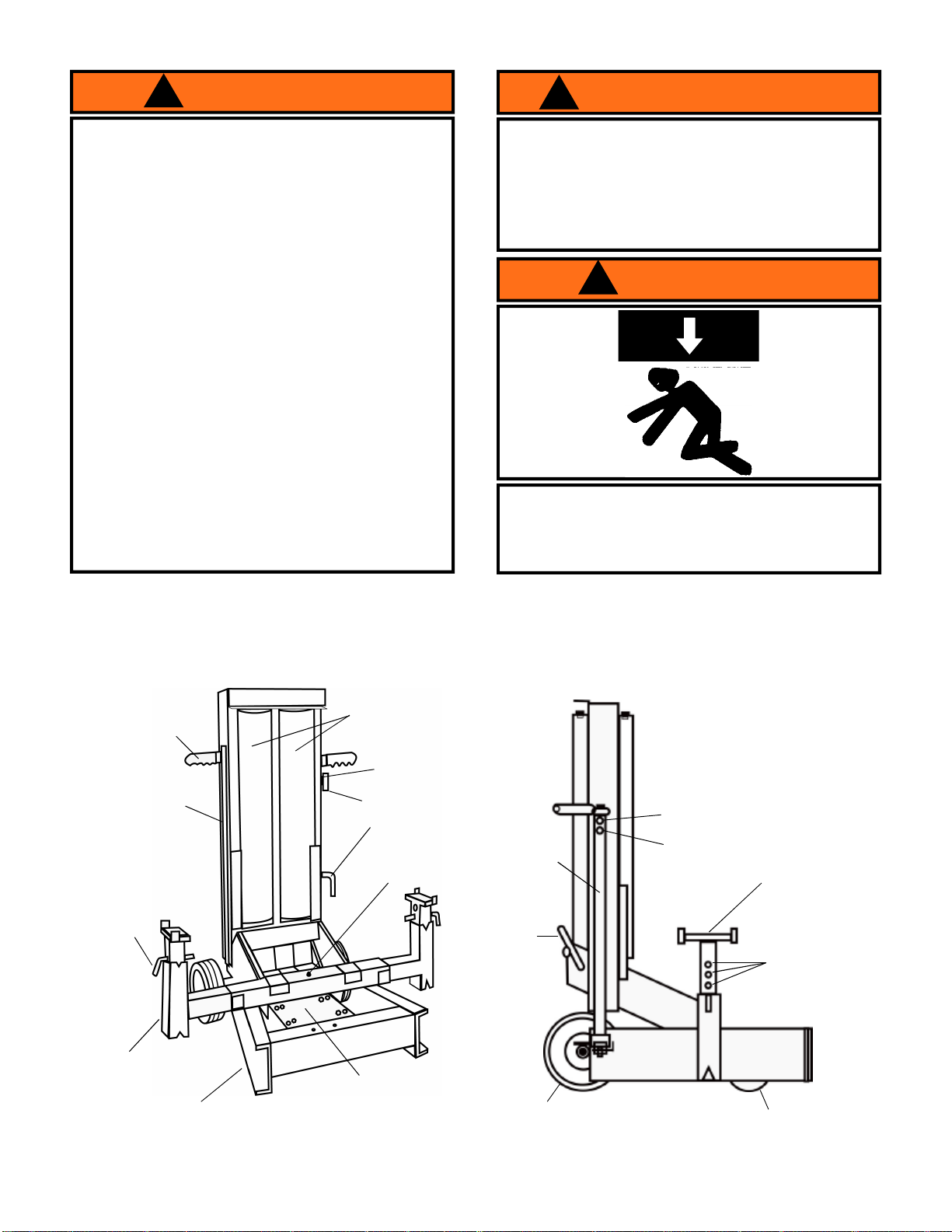

!WARNING

ASSEMBLY

Little, if any, assembly is required of this jack.Make sure lift control valve is secured into the pipe nipple of the jack.

Familiarize yourself with the illustrations in the operator's manual. Know your jack and how it operates before attempting

to use.

4

!WARNING

Toavoid crushing and related injuries:

NEVERwork on,under oraround aload supported

only by a jack. Immediately transfer the load to

adequately rated jack stands.

!ADVERTENCIA

Air Cylinders

Handle Bar Grip

Position Pin

Base Section

Lifting Beam Bumper Bolt

(Underneath the

lifting beam)

Lift Control Valve

Locking

Pin

Figure2.AirOperatedEnd Lift Components

SafetyBar

Level

Figure3.Air Operated EndLift Components(side view)

Saddle Height

Adjustment

Holes

Saddle

Rear Wheel Caster

Air Vent Screw (1 per damper)

Oil Filler Screw (1 per damper)

Hydraulic Damper

(1 per air cylinder)

Hydraulic

Damper

Safety

Bar

Pipe Nipple

(not shown)

HW93692-M0

OPERATION

Lifting

1. Ensure that the vehicle is on a flat, hard and level surface and is free to roll forward and backward during the lift.

2. Connect 1/4" NPT air nipple and air hose to lift control valve air inlet port. (See Figure 1 on page 3)

3. Loosen air vent screws (upper screws) on each hydraulic damper located on side of air cylinders.

4. Insert lifting beams fully to engage lock. For low pickup height, rotate the beams 180 degrees.

5. To adjust the location of the lifting beams, push the locking pin upward from underneath and pull out the lifting beams.

(seeFigure 4)

6. Adjust bumper bolt to increase ground clearance. (see Figure 2 on page 4)

7.Make sure both saddles are positioned directlyunder the vehicle manufacturer's recommendedlift points.

8. To raise jack, slowly press the lift control valve lever toward the position marked "UP" until saddles contact with the lift

point.!STOP! RELEASE GRIP ON THE LIFT CONTROL VALVE! Confirmthat the saddlesare positioned correctly,then

continue to press the lever until load reaches desired height. Simply release the lever to stop.

9. Transfer the load immediately to appropriately rated jack stands.

Lowering

1. Raise load high enough to clear the jack stands, then carefully remove jack stands (always used in pairs).

2. Slowly lower the load by disengaging safety bar* and press lift control valve lever "DOWN".

* To disengage safety bar: Push safety bar lever towards front end of the jack. (see Figure 5)

Note: RefertoTable 1for forair pressure rating for different load application

5

!WARNING

To reduce the risk of personal injury and property

damage, NEVER extendliftingbeams beyond

locked position

AIR PRESSURE

PSI LOAD

(LBS)

200 14,000

180 12,000

160 11,000

140 9,500

120 8,000

Table 1. Recommended Air Pressure for Different Load

Application

Figure4.

RetainingBars Locking Pin

LiftingBeams

Figure5.Air OperatedEnd LiftComponents (rear view)

SafetyBar

Lever Stopper

Be sure all tools and personnel are clear before

lowering load. Only attachments and/or adapters

supplied by the manufacturer shall be used. Lift

only on areas of the vehicle as specified by the

vehiclemanufacturer.

! Safety Messages !

HW93692-M0

6

REPLACEMENT PARTS

Not all components of the jack are replacement items, but are illustrated as a convenient reference of location and

position in the assembly sequence. When ordering parts, give Model number, parts number and description on page 7.

Callorwrite forcurrent pricing: Phone:(816)891-6390or contact Hein-Werner Customer Support,

MAINTENANCE

1. Lubricate all moving parts with oil/grease.

2. Fill the hydraulic damper with 10W40 motor oil only. Fill the oil through the lowest hole located on the hydraulic damper

when jack is fully lowered.

Important: Useonly 10W40motor oil.Avoid mixingdifferent types of fluid and Never usebrake fluid,turbine oil, transmis-

sion fluid, or glycerin.

3. Fill with oil until level with the oil filler screw hole. Reinstall the oil filler screw.

Lubrication

A periodic coating of light lubricating oil to pivot points, axles and hinges will help to prevent rust and assure

that wheels, and caster assemblies move freely.

Storage

When not in use, store the jack with cylinder fully lowered.

TROUBLESHOOTING

PossibleCauses Corrective Action

Jack will not lift load •Air pressure too low

• Air hose kinked or plugged

•Air hose inner diameter too

small

• Air cylinder / components

damaged

• 200 psi minimum air pressure required to lift

ratedload

•Remove kinks andobstruction from air hose

•Consult air compressormanufacturer for the

correct size of hose

•ContactHein-Werner repair center

Jackwill notlower after unloading

Symptom

•Liftcontrolvalveimproperly

assembled and / or attached

•Safety bar engaged

• Structural damage to jack assy

•Assemble as shown in Figure 1on page 3

• Press lift control valve to raise jack slightly,

thendisengage safety bar

•ContactHein-Werner repair center

Jack raises or lowers with jerky

motion • Cylinder need lubrication •Apply #630-AAA LUBRIPLATE to cylinder

wall

HW93692-M0

7

Item no.

Part no. Qty. Description

Item no.

Part no. Qty. Description

Item no.

Part no. Qty. Description

1200472 2Screw 26 221778 4Washer 50 227646 1Hose coupling

2201086 1Lockwasher 27 221820 2Retaining ring 51 227647 1Air hose (short)

3201789 4Lockwasher 28 *223575 2U-cup 52 227648 1Air hose (long)

4203202 1Ball 29 223707 2Spring 53 227649 2Wheel (rear)

5203272 4Nut 30 223964 3Elbow 54 227651 2Position Pin

6203273 3Nut 31 224641 2Handle Bar Grip 55 227652 1Cross Pin

7204271 2Washer 32 225254 4Lockwasher 56 227654 2Pin

8204530 2Cotter Pin 33 226228 2Bushing 57 *227655 2Slip Ring

9204543 2Cotter Pin 34 226318 2Grease Fitting 58 228061 1Positioning Bar

10 207167 1Nut 35 226503 2Roller Wheel 59 228263 1Caster

11 207169 8Nut 36 226603 1Roll Pin 60 228264 1Caster Plate

12 209746 26 Roller 37 227616 1Handle Stop 61 229456 1Skid Ring

13 209967 4Lockwasher 38 227619 2Saddle Arm 62 229869 1Bolt

14 210735 4Washer 39 227622 2Saddle 63 230438 1Bottom Cap

15 †212374 2Washer 40 227626 1Air Cylinder Ass'y (R.H.) 64 230441 1Piston Rod

16 212540 1Screw 41 227629 1Air Cylinder Ass'y (L.H.) 65 231136 2Hydraulic Damper Ass'y

17 212562 1Screw 42 227631 2Elbow 66 231138 1Cylinder Plug

18 212622 1Bolt 43 227633 1Tank Retainer 67 231139 1Damper Cylinder

19 212624 5Bolt 44 227637 1Pin 68 231141 1Piston Rod

20 212688 4Bolt 45 227638 1Spacer 69 231168 2Bolt

21 214120 2Spacer 46 227639 1Axle 70 †231241 1Quad Ring

22 †214555 2O-ring 47 227640 2Piston 71 233072 2Wheel & Busing Ass'y

23 †216258 1Pump Gland Cover 48 227643 1Safety Stop Handle 72 234844 1Washer

24 220018 3Retaining Ring 49 227644 1Safety Stop Spring 73 248799 1Lift Control Valve

25 221356 1Pipe Nipple

* Included in 240513 Repair Kit. † Included in 240512 Repair Kit for 231136 Hydraulic Damper Assembly

SERVICE PARTS

HW93692-M0

memo.

Table of contents

Other HEIN-WERNER AUTOMOTIVE Lifting System manuals

Popular Lifting System manuals by other brands

Extreme Max

Extreme Max Boat Lift Boss 3005.7216 installation instructions

AmeriGlide

AmeriGlide Infinity Curved Stair Lift installation guide

Rev-A-Shelf

Rev-A-Shelf RAS-ML Series installation instructions

Meyer

Meyer E-58H installation instructions

Invacare

Invacare Birdie user manual

EZTRUNK

EZTRUNK 1900 0072 Assembly manual