Hein-werner HW93642 User manual

Operating Instructions & Parts Manual

SFA Companies ©2005

10939 N. Pomona Ave. Kansas City, MO 64153

816-891-6390

Model Number Capacity

HW93642 2 Ton

HW93652 3 Ton

Service Jacks

Made in the USA

-Before using this product, read this manual and follow all its Safety Rules and Operating Instructions

HW93642-M0

Warranty P2

Save These Instructions P3

Product Description P3

Specifications & Safety Instructions P3

Assembly & Operation P4

Maintenance P5

Troubleshooting P5

Replacement Parts P5

TWO YEAR LIMITED WARRANTY

Fora periodof two(2) yearsfrom dateof purchase,SFA Companieswill repairor replace,at itsoption, withoutcharge, any

of its products which fails due to a defect in material or workmanship, or which fails to conform to any implied warranty not

excluded hereby.

Performanceof any obligationunder thiswarranty maybe obtained byreturning thewarranted product,freight prepaid, to

SFA Companies WarrantyServiceDepartment, 10939N.PomonaAve., KansasCity,MO64153.

Except where such limitations and exclusions are specifically prohibited by applicable law:

(1)THECONSUMER'SSOLEANDEXCLUSIVEREMEDYSHALLBETHEREPAIRORREPLACEMENTOFDEFECTIVE

PRODUCTSASDESCRIBEDABOVE

(2)SFA COMPANIES SHALL NOTBELIABLEFORANYCONSEQUENTIALORINCIDENTALDAMAGEORLOSSWHAT-

SOEVER.

(3)THEDURATIONOFANYANDALLEXPRESSEDANDIMPLIEDWARRANTIES,INCLUDINGWITHOUTLIMITATION,

ANYWARRANTIESOFMERCHANTABILITYANDFITNESSFORAPARTICULARPURPOSE,ISLIMITEDTOAPERIOD

OFTWO(2)YEARSFROMDATE OF PURCHASE.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusionmay notapplyto you. Thiswarranty givesyouspecific legalrights, and youmay alsohaveother rightswhich vary

from state to state.

2

TABLE OF CONTENTS

HW93642-M0

SAVE THESE INSTRUCTIONS

For your safety,read,understand,and follow theinformation providedwith andon thisjack. The ownerand operatorof this

equipmentshall havean understanding ofthis jackand safe operatingprocedures beforeattempting to use.The ownerand

operator shall be aware that the use and repair of this product may require special skills and knowledge. Instructions and

safety information shall be conveyed in the operator's native language before use of this jack is authorized. If any doubt

exists as to the safe and proper use of this jack, remove from service immediately.

Inspect before each use. Do not use if there are broken, bent, cracked, or damaged parts (including labels). Any jack

thatappears damaged inany way,operates abnormally or is missingparts, shallbe removed from service immediately.If

the jack has been or suspected to have been subjected to a shock load (a load dropped suddenly, unexpectedly upon it),

immediatelydiscontinueto use untiljackhasbeen checked byaHein-Wernerauthorized service center.Itisrecommended

thatanannualinspection bedonebyqualifiedpersonnel.Labels andOperator'sManualareavailable from manufacturer.

PRODUCT DESCRIPTION

Hein-Werner Hydraulic Service Jacks are designed to lift,not sustain, rated capacityloads. Theyare designedtobe

used in conjunction with jack stands.Intended use: To lift one wheel or one axle of a vehicle for the purpose of service

and/orrepair ofvehicle components.After lifting,loads mustbe immediatelysupported byappropriately ratedjack

stands.Check withvehicle owner'smanual for properlift points.

DO NOT USE TO DOLLYOR MOVE VEHICLE.

DONOT USE FOR ANYPURPOSEOTHERTHAN THOSE USES OUTLINEDABOVE!

3

SPECIFICATIONS

Capacity

20"

Model Min.Height Max. Height

3-3/4"

HW93642

Jack Size ( L x H )

2Ton

3Ton 4" 23"

26-3/4"x6-3/4"

30-3/4"x7-1/4"

HW93652

HW93642-M0

• Study, understand, and follow all instructions

providedwith andonthis device

beforeoperatingthis device.

• Do not exceed rated capacity.

• This is a lifting device only.

•After lifting,immediately transferthe loadto

appropriatelyratedvehicle stands.

• Never work on, under, or around a load

supported only by this device.

• Use only on hard, level surfaces capable of

sustaining rated capacity loads.

• Do not move or dolly loads with this device.

• Do not modify this device.

• Do not use adapters or accessories that are

notprovidedinitially.

• Lift only on areas of the vehicle as specified

bythe vehiclemanufacturer.

• Failure to heed these markings may result in

personal injury and/or property damage.

!WARNING

SAFETY INSTRUCTIONS

BEFORE USE

1.Verify thattheproduct andthe applicationarecompatible, ifindoubt

call Hein-WernerTechnicalService(816) 891-6390.

2. Read the operator's manual completely and familiarize yourself

thoroughly with the product, its components and recognize the

potential hazards associated with its usebefore using this product.

3.Assemblehandle, thensecureit inthehandlefork withprovidedbolt.

4.Open therelease valveby turningthe handlecounterclockwise.

5.Remove shippingscrewon power unit.

6.Lower saddlefully.

7. Pump the handle 6 to 8 full strokes. Ensure the oil level is within

~3/16"fromtheinnercylinder as viewedfromtheairventscrewhole.

8.Install theair ventscrew provided.

9.Close releasevalve by turning the handle clockwise untilfirm

resistance is felt.

10. Roll the jack to ensure that it rolls freely and smoothly.

11. Raise and lower the unloaded saddle throughout the lift range to

ensureproper operationof thepump and releasevalve before

placing any load on the product.

12.Replace wornor damagedparts and assemblieswithHein-Werner

ReplacementPartsonly. (SeeReplacementPartsSection). Lubricate

as instructed in Maintenance Section.

OPERATION

Lifting

Safety Message! Only attachments and/or adapters supplied by the manufacturer shall be used. Lift only on areas as

specifiedby thevehiclemanufacturer.

1.Place thevehicle in thepark gear,with emergencybrakeon andwheels securelychocked to preventinadvertent vehicle

movement.

2.Closereleasevalvebyturninghandleclockwisefirmly.Centerjacksaddleunderliftpoint.Refertothevehicle manufacturer's

owner'smanual to locateapproved liftingpoints on the vehicle.

3. Verify lift point, then pump handle to contact lift point. Continue to pump handle until load reaches desired height.

4. Transfer the load immediately to appropriately rated jack stands.

.

Lowering

Safety Message!Besure alltools andpersonnel areclear beforelowering load.

1. Raise load high enough to clear the jack stands, then carefully remove jack stands (always used in pairs).

2. Slowly turn the handle counterclockwise, but no more than 1/2 turn.If the load fails to lower:

a. Use another jack to raise the vehicle high enough to reinstall jack stands.

b. Remove the malfunctioning jack and then the jack stands.

c. Using the other jack, lower the load by turning the operating handle counterclockwise, but no more than 1/2 turn.

3.After removing jack from underthe load,push saddledown toreduce ramexposure to rust and contamination.

4

ASSEMBLY

Familiarizeyourself withtheillustrations intheoperator's manual. Knowyourjack andhowit operatesbeforeattempting to

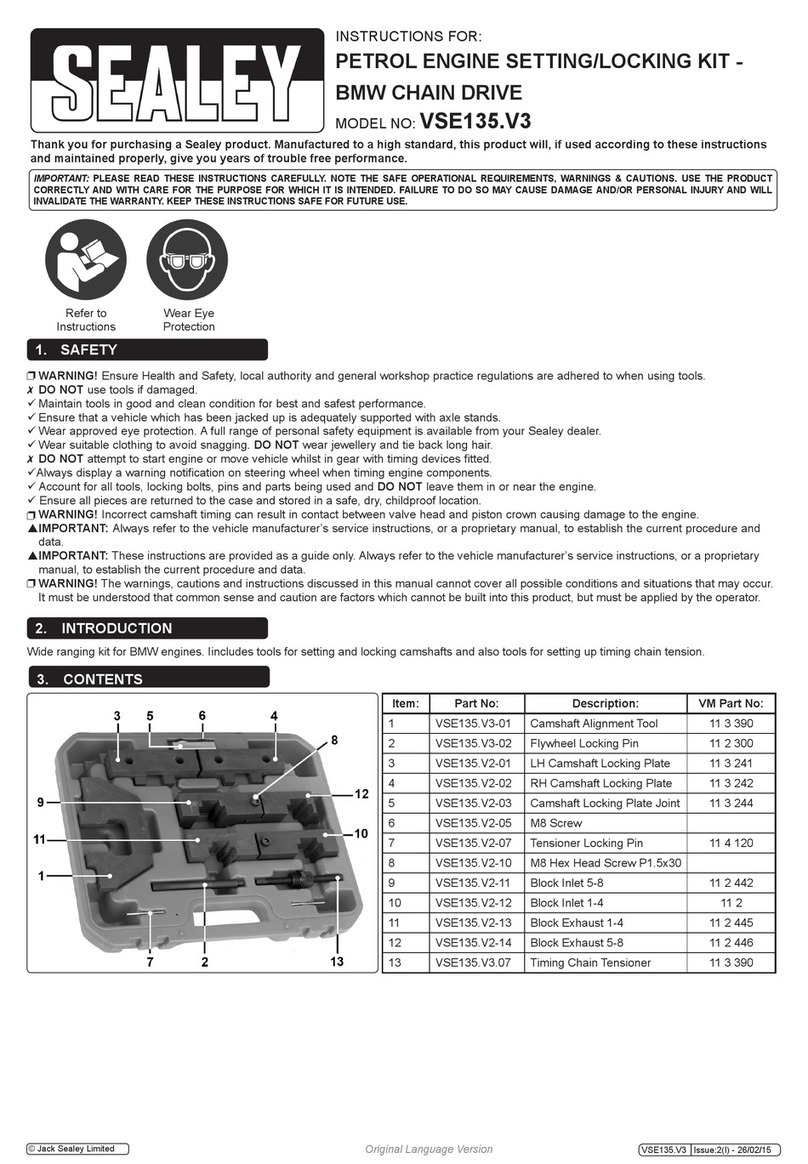

use.Referto Figure 1belowforcomponents location.Tightensecurelytoprevent accidentalremovalofhandle while inuse.

HW93642-M0

!WARNING

Toavoidcrushingand

relatedinjuries:

NEVERwork on,under or

arounda loadsupported

only by a jack. ALWAYS

use adequately rated jack

stands. Immediately tranfer

theload toadequately

rated jack stands.

• Leer, comprender, y seguir las instrucciónes antes

deutilizar elaparato.

• El manual de instrucciónes y la información de

seguridaddeben estarcomunicado enlengua del

operadorantes deluso.

• No seguir estas indicaciónes puede causar daños

personales o materiales.

!ADVERTENCIA

Figure1:TypicalServiceJackComponents

Handle

Handle

Fork

Saddle

Front

Wheel

Caster

AirVent

Screw

LiftArm

5

TROUBLESHOOTING

REPLACEMENT PARTS

Notall componentsof thejack arereplacement items,but areillustrated asa convenientreference oflocation and

positionin the assemblysequence. Whenordering parts,give Model number,parts numberand descriptionon page 6

and 7. Call or write for current pricing: Phone:(816) 891-6390 or contact Hein-Werner Customer Support,

•ContactHein-WernerTechnical Service

PossibleCauses Corrective Action

Jack will not lift load

Jackbleeds offafterlift

Will not lift to full extension

•Releasevalve nottightlyclosed

•Overload condition

•Fluidlevel low

•Fluidlevel low

•Hydraulicunit malfunction

•Ensurereleasevalvetightly closed

• Remedy overload condition

•Ensureproperfluid level

•Ensureproperfluid level

Poor liftperformance

Jackwill notlower after unloading • Reservoir overfilled

• Linkages binding •Drain fluidto proper level

•Cleanand lubricatemovingparts

Symptom

HW93642-M0

MAINTENANCE

Important: Useonly agood gradehydraulic jackoil.Avoid mixingdifferent typesof fluidandNever usebrake fluid,turbine

oil, transmission fluid, motor oil or glycerin. Improper fluid can cause failure of the jack and the potential for sudden and

immediateloss of load.We recommendHein-Werner hydraulic jack oil HW93291.

Adding oil

1. With saddle fully lowered set jack in its upright, level position. Locate and unscrew air vent screw.

2. Fill with oil until ~3/16" above the inner cylinder as seen from the air vent screw hole. Reinstall the air vent screw.

Changing oil

Forbest performance,replacethe hydraulic fluidcompletely annually.

1.With saddle fullylowered, unscrewthe air vent screw.

2. Lay the jack on its side and drain the fluid into a suitable container.

Note: Disposeof hydraulic fluidin accordancewith localregulations.

3. Fill with oil until ~3/16" above the inner cylinder as seen from the air vent screw hole. Reinstall the air vent screw.

Lubrication

Aperiodic coating oflight lubricatingoil to pivot points, axlesand hingeswill help to prevent rustand assure

thatwheels, castersand pumpassemblies movefreely.

Cleaning

Periodically check the pump piston and ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth.

Note: Neverusesandpaperor abrasivematerialonthesesurfaces!

Storage

Lower the saddle to its lowest position when not in use.

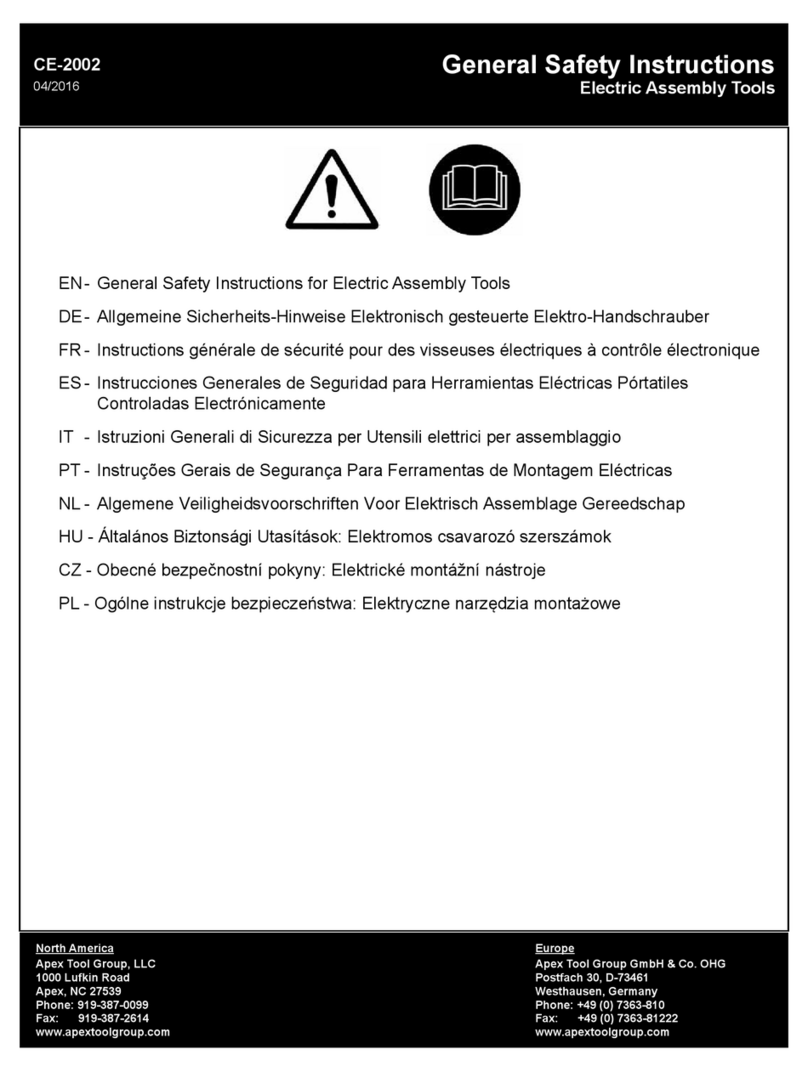

31 30 28

Handle Cross Section

24

40

26

39

25

32

29 27

23

1

10

67

8

3

2

11

12

13

3637

15

14

22

17

20

19

18

21

33 34

5

49

Frame Section

Hydraulic Unit Cross Section

38

Hydraulic Unit Base

35

37

16

6HW93642-M0 Figure2: PartsIllustrationfor HW93642and HW93652

7

Replacement Parts List

HW93642-M0

Item# Part# for HW93642 Part# for HW93652 Qty. Description

1 ο231583 231583 2Caster, 2.5"x1.25"

2 ο201115 201115 2Lock Washer, 3/4"

3 ο219451 219451 2Hex Nut, 3/4"-10

4231584 231584 2Caster Assembly (includes item# 1-3)

5201801 201801 2Retaining Ring

6 #214557 214557 2Retaining Ring

7 #204324 204324 2Flat Washer, 3/4"

8 #234678 234678 2Wheel, 3.75"x2"

9234677 234677 2Front Wheel Assy.(includes item# 6-8)

10 234956 234956 1Hex. Head Bolt, 3/8"-24

11 239304 239304 1Saddle

12 221408 221408 1Cotter Pin, 1/8"

13 243618 243618 2Return Spring

14 ∆243626 243626 1Pump Piston

15 ∆* 201802 201802 1Retaining Ring

16 ∆243628 243628 1Pump Sleeve

17 ∆226348 226348 1Spring

18 ∆243627 243627 1Pump Cylinder

19 ∆* 201828 201828 3Packing

20 ∆204233 204233 1Flat Washer

21 ∆224725 224725 1Hex Nut #10-32

22 890-021-666 890-021-666 1Pump Assembly (includes item# 14-21)

23 * 231301 230301 1Heel Plate

24 * 221318 221318 1Screen

25 * 221748 221748 1Quad Ring

26 * 200003 200003 1Gasket

27 231638 231638 1Vent Screw

28 * 228256 228256 1U-cup

29 * 218043 218043 1Release Valve

30 * 233917 233917 1Plastic Spring

31 * 216143 216143 1Gland O-ring

32 248731 248731 1Universal Assembly

33 * 203196 203196 1Ball, 5/32"

34 * 203198 203198 1Ball, 7/32"

35 * 203201 203201 1Ball, 5/16"

36 * 204842 204842 1Gasket

37 * 201733 201733 2Plug

38 234957 234957 1Handle Assembly

39 248721 890-005-010 1Complete Hydraulic Unit

40 231316 231316 1Vent Screw Assembly

-- 248949 248949 -Repair Kit for Hydraulic Unit

ο-Only availablein CasterAssembly 231584

# -Only availableinWheel Assembly 234677

∆ -Only availableinPump Assembly 890-021-666

* - Included in Repair Kit 248949

This manual suits for next models

1

Table of contents