8

6.0 Commissioning

Never use the hose reel without connecting it to a swit-

ched-on fan (and an open damper). If there is no air pre-

sent or if the volume of air is not correct (too low), then

the hose will melt or become deformed (turn oval).

In cases where the exhaust gasses have a temperatu-

re higher than 150°C (e.g. if the motor starts running),

then the hose may also melt and/or become deformed.

In such cases, you must ensure to adapt the material/

solution to the job. Check the temperature of the exhaust

gasses before commissioning. Do so by testing with a

probe thermometer in the airflow.

It is important that the fan is always switched on during

use of the hose reel. If you have automatics ensuring

that the fan starts, when using the reel, it is important

that the hose reel is not running in the opposite directi-

on at the commissioning, so that the actuation lever tips

back. If this happens, then the fan will be deactivated

and the hose may melt.

Thus, always check that there is suction on the nozzle,

when fixing it to the hose/upon commissioning.

IMPORTANT! WE SUPPLY HOSE REEL GTE PRE-

PROGRAMMED. I.E. THE REMOTE CONTROL IS CO-

DED FOR THE INDIVIDUAL HOSE REEL AND THE

END STOP IS SET.

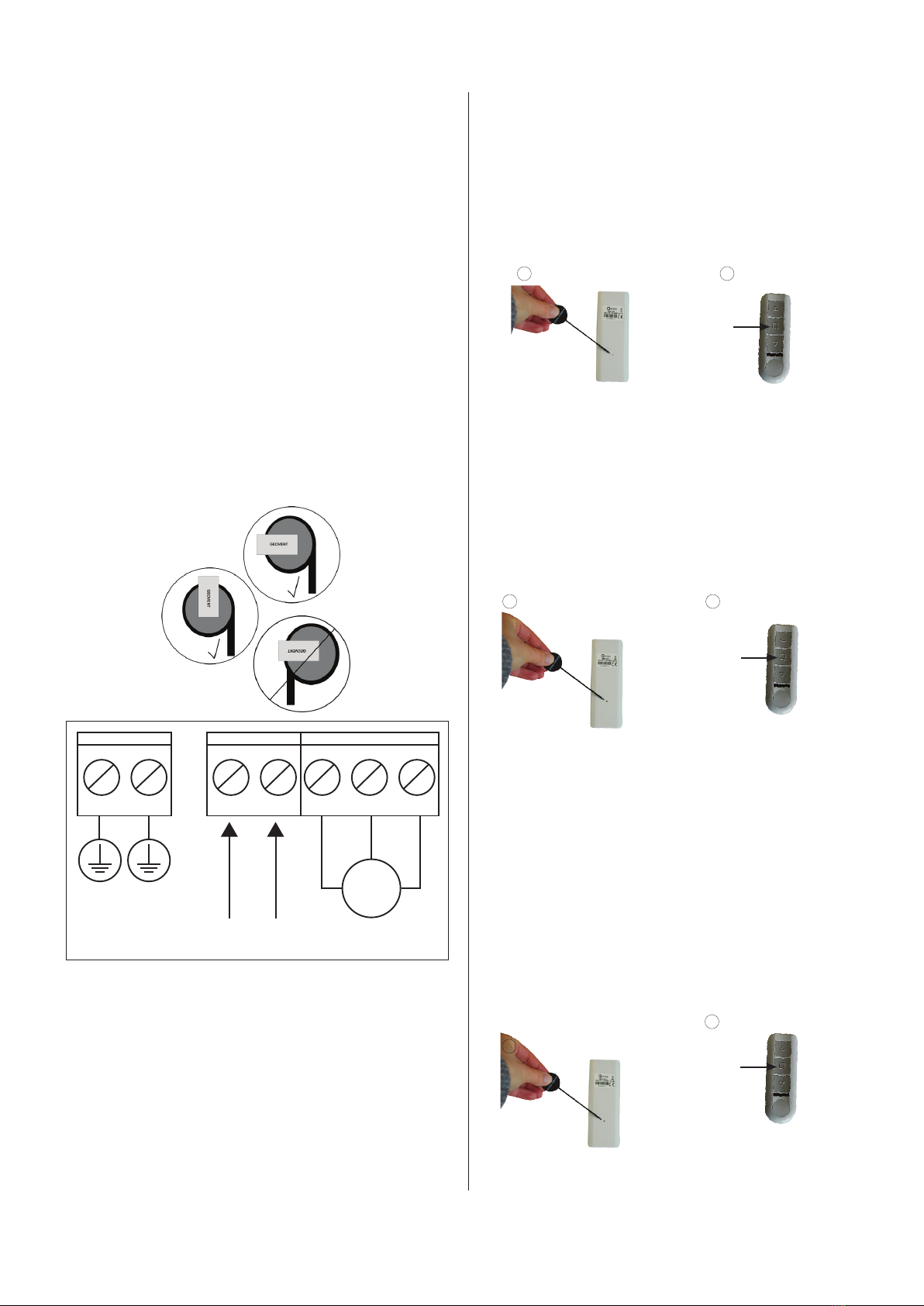

Using the remote control:

The top button (UP), coils up the hose. A push on the

button (DOWN) coils the hose down. The button in the

middle stops the hose. If you push the opposite directio-

nal button during operation, the drive will stop and then

start turning in the opposite direction.

The hose reel is not functioning as intended, if:

• Unauthorized parts are mounted on the Hose reel.

• The total lifting capacity of 22 kg has been exceeded.

See section 5.2 for re-programming the roller.

Coiling up:

When coiling the hose up, it is important to guide the

hose by hand.

The hose must not be rolled up when it is hot

6.1 After installation

Check the installation according to chapter 5.3.

7.0 Control, test and maintenance

7.1 Control

Check the installation according to chapter 5.3.

7.2 Maintenance

Periodic maintenance:

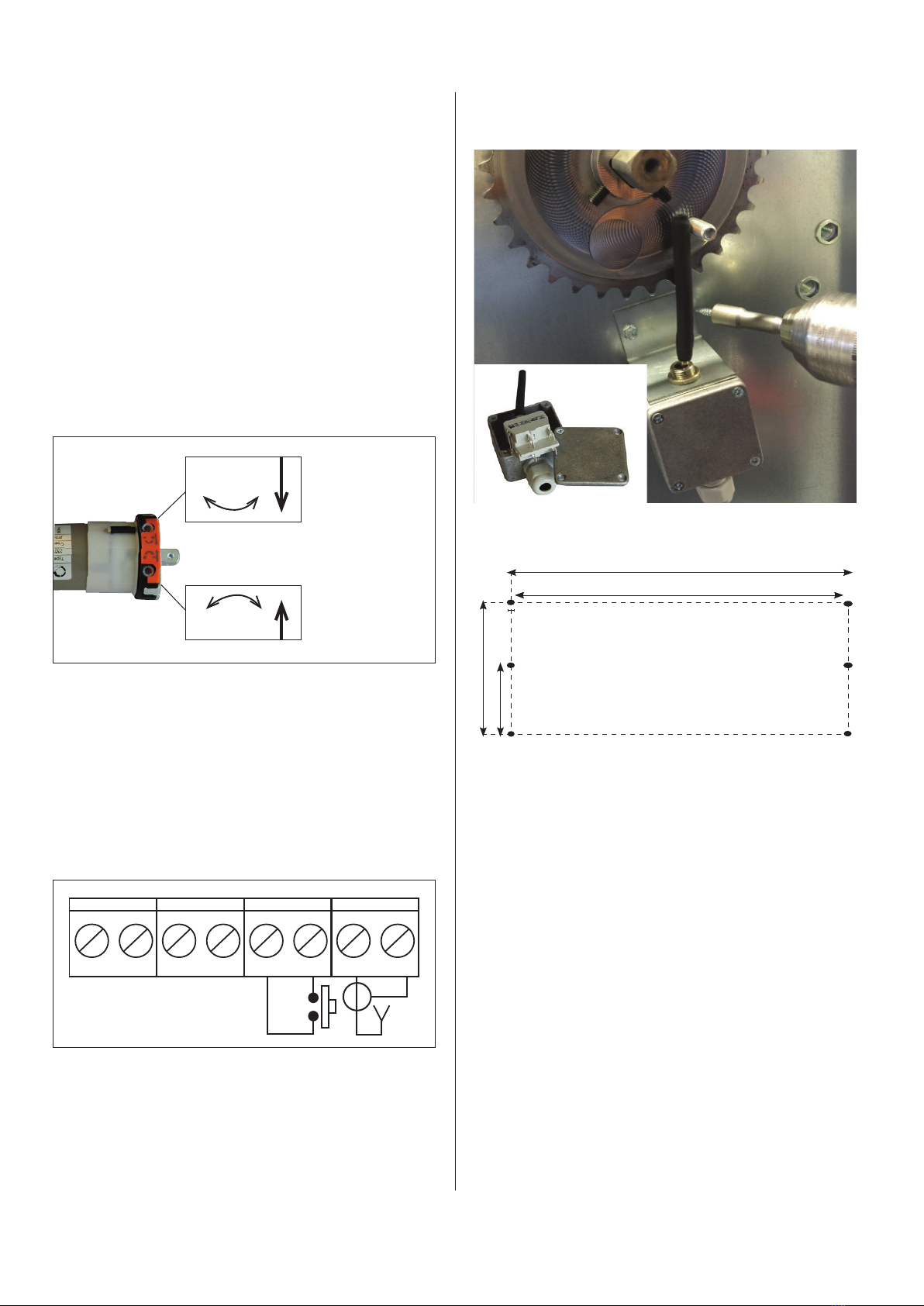

• At least once every year, grease the V-ring of the

hose reel in order to avoid deformation. Also, grease

between pipes and connecting branch. Failing to

maintain the hose reel will lead to squeaky noise

coming from the hose reel.

• You cannot carry out maintenance on the hose, how-

ever. To secure a long service life, try to avoid run-

ning over the hose with vehicles etc., make sure to

extract adequate volumes of air and ensure that the

hose does not bend too much immediately after the

exhaust pipe.

• Measure the volume of air on the hose reel at least

once every year. If the volume of air is inadequate, it

may result in burning a hole in the hose.

At least once every year, arrange for an authorized

service engineer to carry out an inspection of the

complete extraction system.

8.0 Cleaning

The outside of the product is cleaned with a vacuum

cleaner or a cloth.

9.0 Troubleshooting

In case of problems with the hose reel, check the fol-

lowing:

Problems with the operation of the hose reel:

• The pawl of the hose reel will not engage. Typically,

the pawl is worn or the spring for the pawl is defective.

Exchange defective parts.

• The hose reel coils slowly. Perhaps it is mounted on

an uneven surface, or the bracket of the hose reel is

deformed. Rectify by mounting the hose reel on an

even surface or by correcting the bracket.

Noise problems

• If the hose reel emits a squeaking noise, typically, the

V-ring of the inlet bearing is defective or out of positi-

on. Rectify it by replacing the V-ring or by adjusting it.