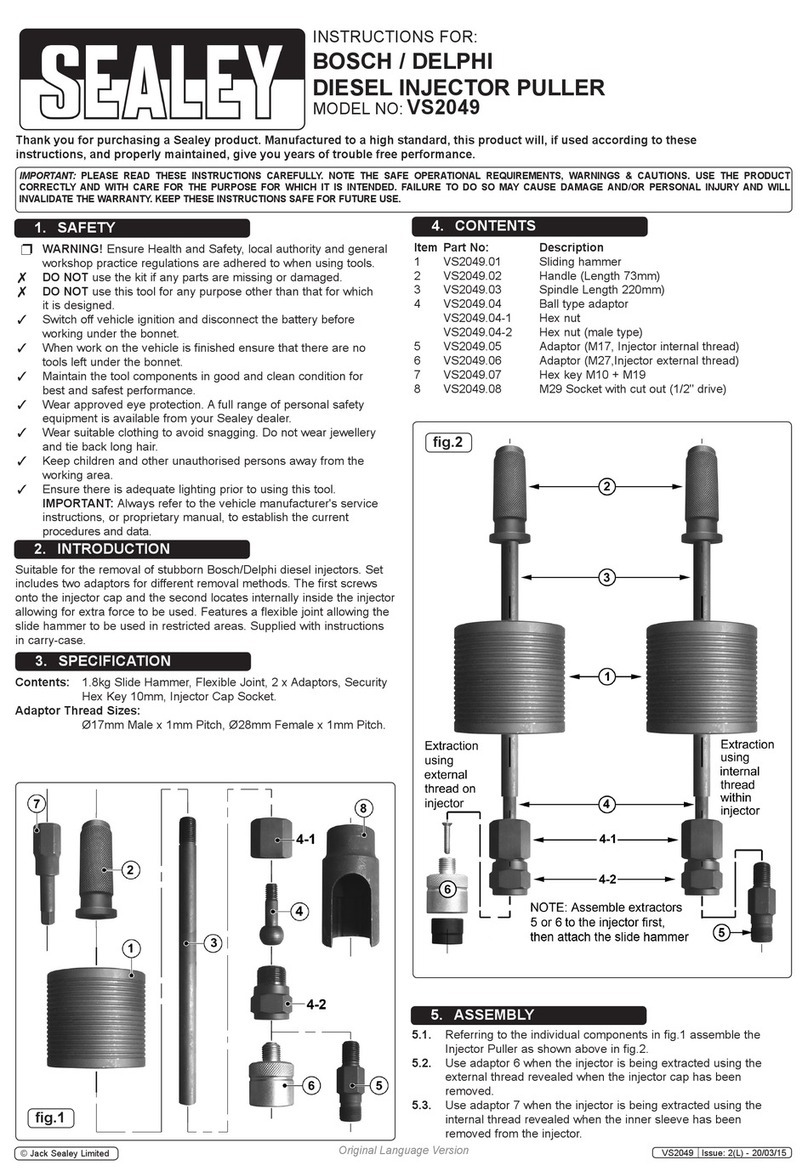

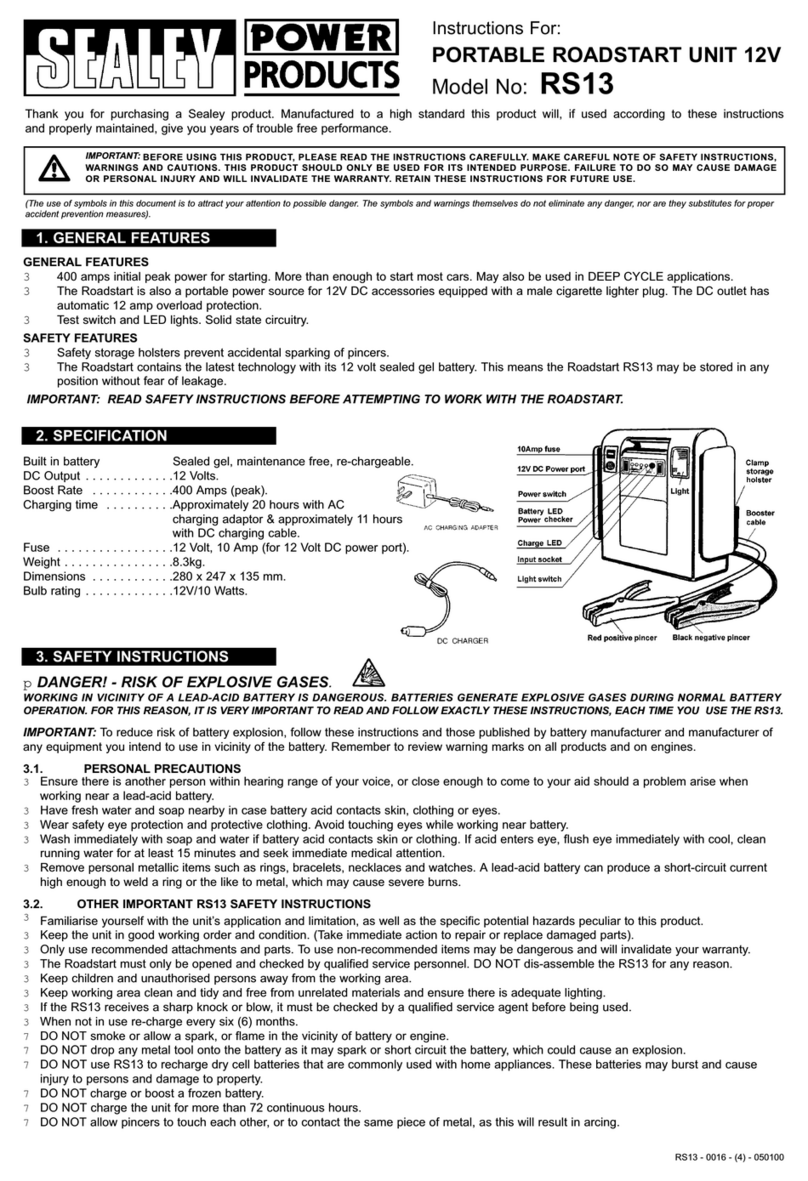

fig.3 fig.4

5.3.3. FittheCamshaftLockingPlateVSE135.V2-01/VSE135.V2-02(g.4).

5.3.4. Slackentheexhaustcamshaftsprocketxingbolts.

5.3.5. Compress the secondary timing chain tensioner and lock it in its retracted position using a suitable pin.

5.3.6. Oninletcamshaftdrivesprocketswithoutaspringplatetted,removetheVanosunit,thecamshaftsprocketxingnutsandthethrust

washer.

5.3.7. Oninletcamshaftdrivesprocketsthatdonothaveaspringplatetted,removetheVanosunitwhileturningtheexhaustcamshaftsprocket

inaclockwisedirection.Removethecamshaftsprocketxingnutsandthespringplate.

5.3.8. It is now possible to remove the timing chain, sprockets, guides and tensioners.

WARNING: The tensioner has a very strong spring.

5.4. Reassembly

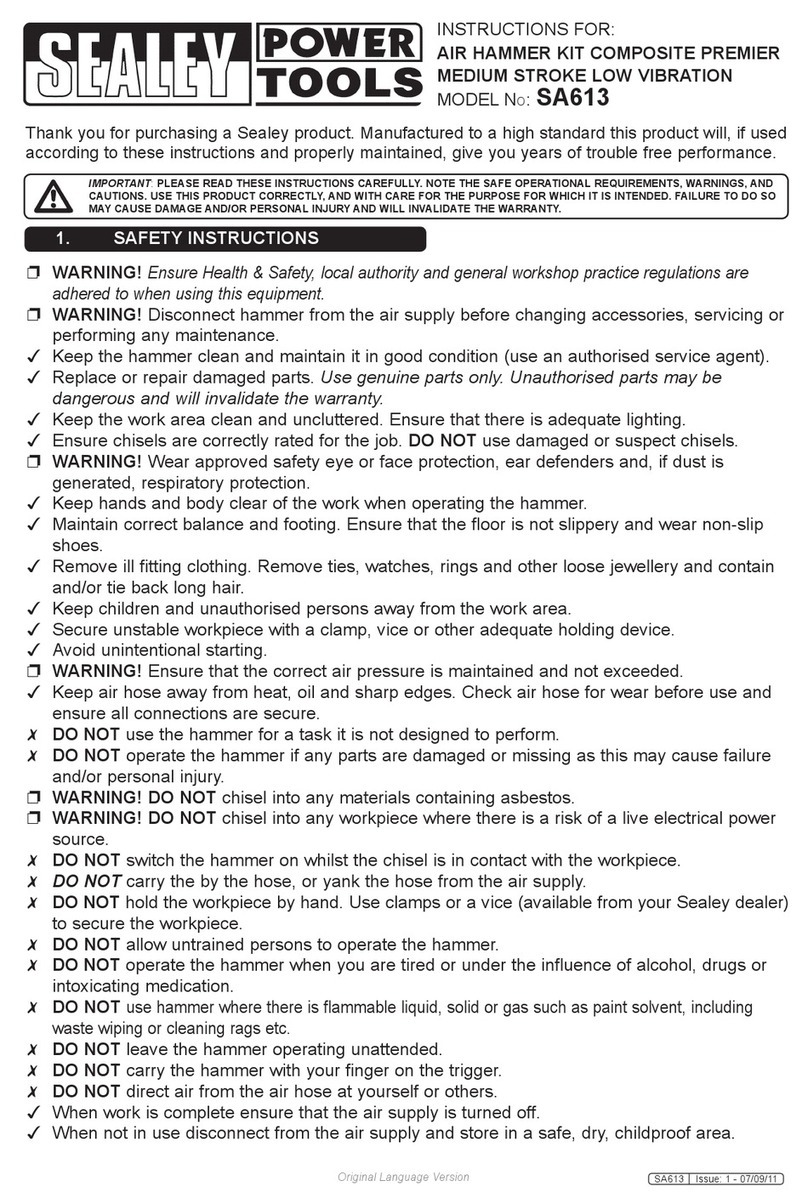

5.4.1. Fit the camshaft drive sprocket, ensure the arrow is pointing upwards and that the threaded holes are positioned on the left side of the slots

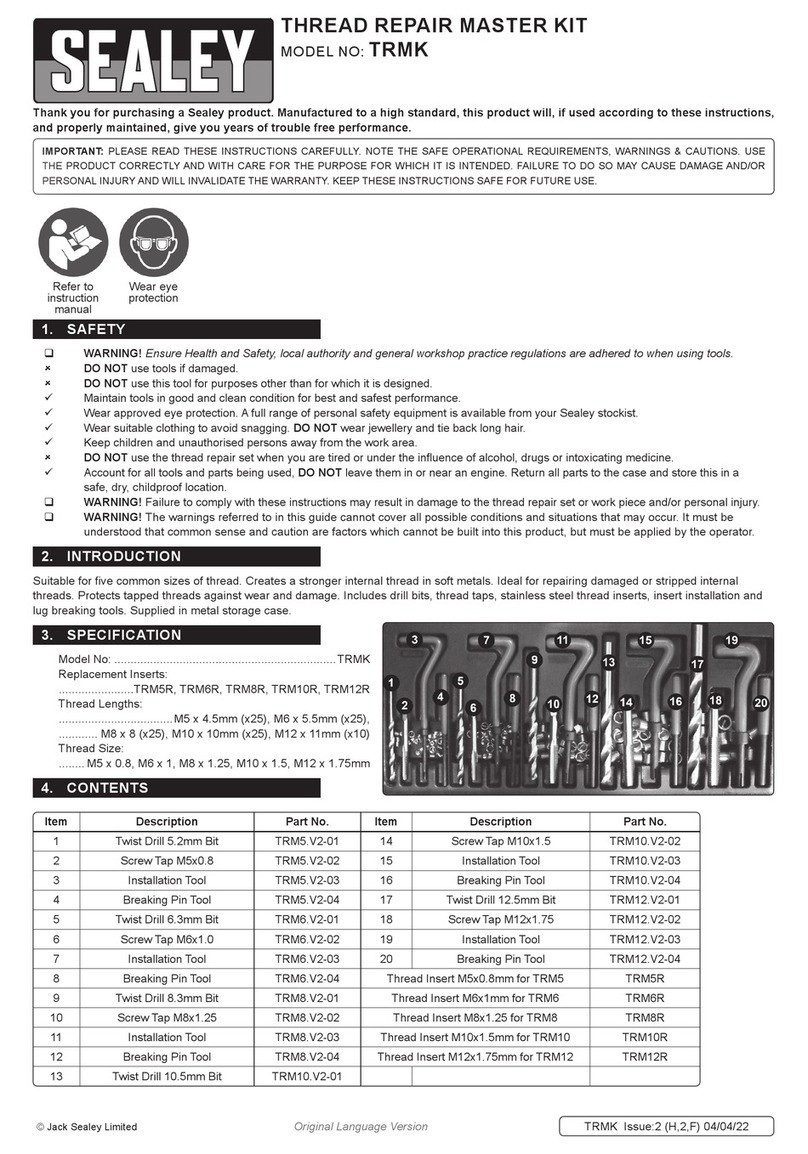

inthesprocket(g.5).

5.4.2. Fit the Timing Chain Pre-tensioning tool VSE135.V3-07 and screw the adjuster in until

it comes into contact with the guide rail; do not tighten further past this point.

5.4.3. Fit the timing chain guide and secondary timing chain tensioner.

5.4.4. Fit the secondary timing chain and sprocket; ensure that the threaded holes are

positioned on the left side of the slots in the sprocket.

5.4.4. Fitthethrustwashers,andspringplate,totheinletcamshaftandtightenthexingnuts

to 10Nm

5.4.5 On inlet camshaft sprockets that do not have a spring plate, turn the sprocket clockwise

until the detent position is reached.

5.4.6. Turn the sprocket ant-clockwise whilst inserting the Vanos unit, turn the splined shaft

until it engages.

5.4.7 On inlet camshaft sprockets without the spring plate, turn the sprocket clockwise as far

as the stop.

5.4.8. Turnthesprocketanti-clockwisewhilstinsertingtheVanosunituntiltheunittsush

with the cylinder head.

5.4.8. Tighten the Vanos unit securing bolts.

5.4.9. Remove the locking pin from the secondary timing chain tensioner.

5.4.10. Preload the timing chain by tightening the Timing Chain Pre-tensioning tool

VSE135.V3-07 to 1.3 Nm.

5.4.11. Tighten the exhaust camshaft sprocket securing bolts initially to 1.5Nm followed by 2.22 Nm.

5.4.12 Removethetimingchainpre-tensionerandretthetimingchaintensioner.

5.4.13 Remove all tooling, turn the crankshaft through two revolutions clockwise. Ensure the Crankshaft Timing Pin VSE135.V3-02 and the

CamshaftLockingPlateVSE135.V2-01/VSE135.V2-02canberetted.

5.4.13. Oncethetimingisconrmedascorrect,removealltoolingandreassembletheengineinthereverseorderofdismantling.

5.5. M60 and M62 Engines

5.5.1. Note: To remove the timing chain on these engines the sump will need to be removed.

This kit does not contain the tooling to set the camshaft sensor plate positions if the

engineissotted.

5.5.2. If the transfer chains need to be removed, their tensioners will need to be locked in their

retracted position using suitable tensioner locking pins.

5.5.3. Dismantling

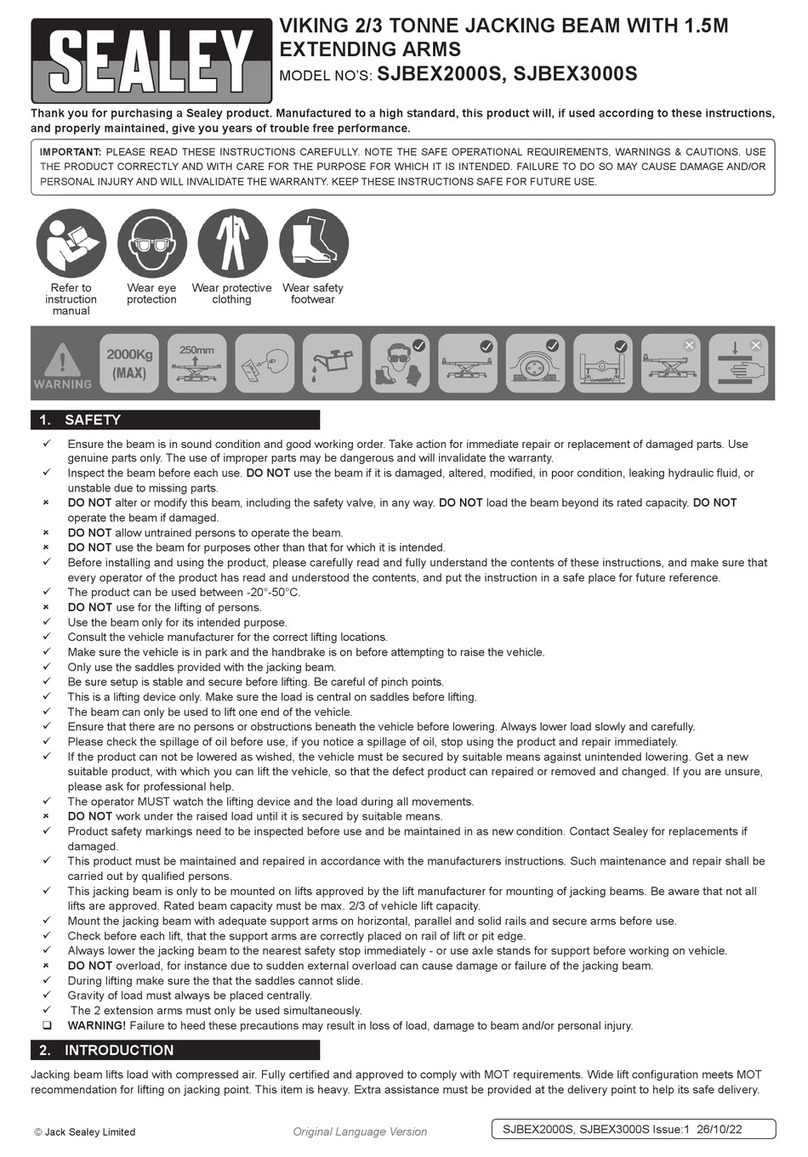

Turn the engine in the direction of rotation and insert the appropriate Crankshaft Timing

PinVSE135.V3-02throughthedatumholeinthebellhousing(g.1).

5.5.4. There is a stamped mark on the lower timing case "OT" that must match up with the

same mark on the crankshaft pulley "OT".

(DO NOT use the 45 .VOT marking on the pulley).

5.5.5. To ensure the engine is correctly positioned at TDC check that the camshaft lobes on

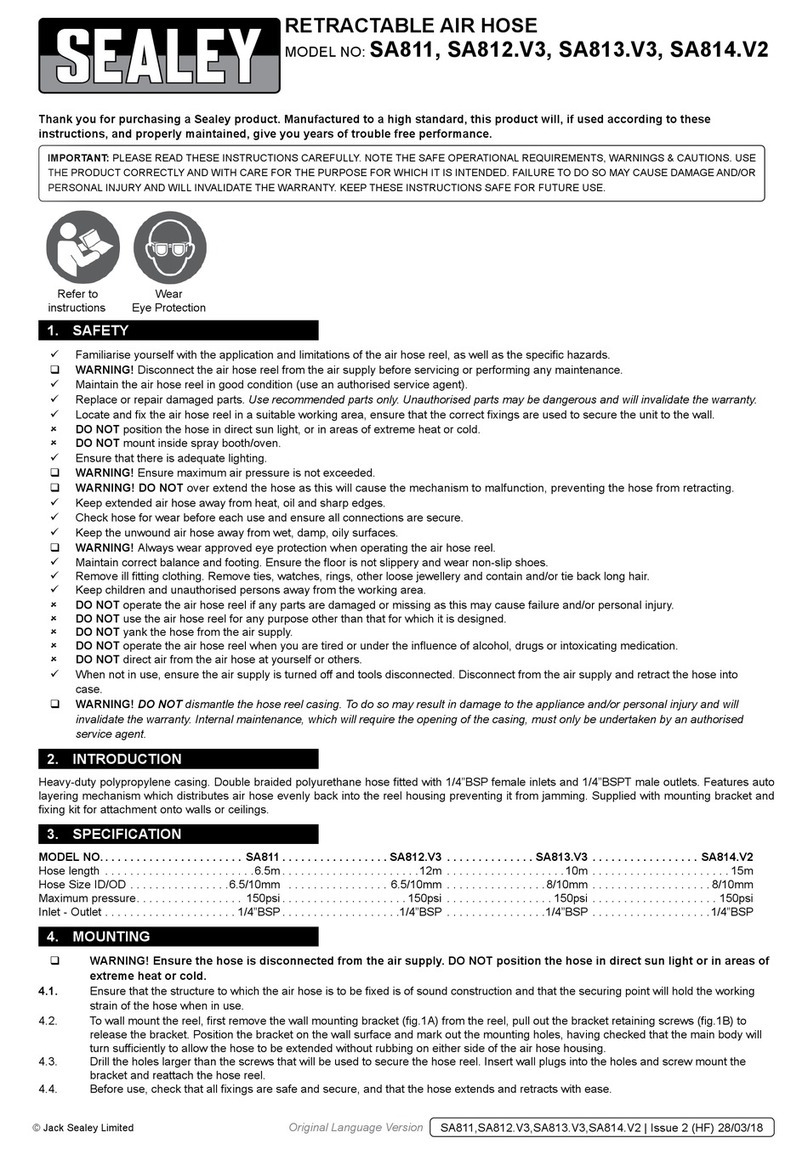

numberonecylinderarealmostfacingeachotherasshown(g.6)

5.5.6. Oncetheengineiscorrectlypositionedthecamshaftlockingtoolscanbetted.

fig.5

fig.6

VSE135.V3 Issue:2(I) - 26/02/15

© Jack Sealey Limited Original Language Version