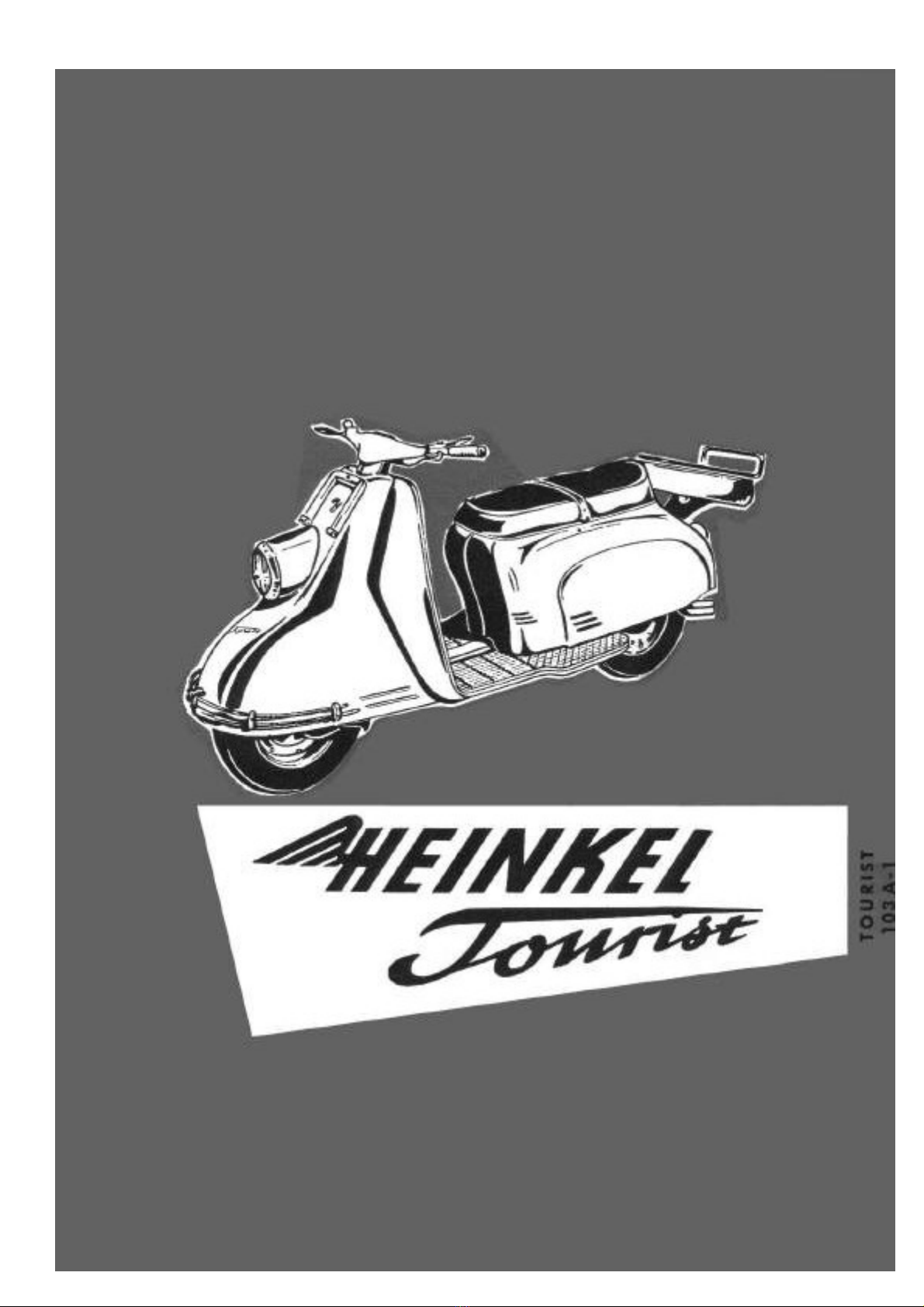

HEINKEL-TOURIST 103 A-1 Instruction manual

Workshop Manual Heinkel Tourist 103 A-1 page 1

To all HEINKEL Dealers

This Manual is intended to assist you in carrying out all

maintenance and repair work in your HEINKEL workshop.

Detailed drawings make the text easy to understand so that no

motor fitter should have any difficulty in carrying out any

repairs quickly and rationally.

Correlation of the illustration references with the text is

simplified by figures. For example 10/2 : 10 is the number of

the illustration and the figure 2 after the oblique stroke refers to

the part number in the illustration in question.

All repairs particularly on the engine of the vehicle should only

be carried out with the proper special tools. For repairs never

use any but Original HEINKEL spare parts or Original

HEINKEL Exchange Parts as otherwise our part of the

Guarantee becomes invalid.

Our Customers' After-sale Service Department will always

welcome any hints and suggestions which you may care to give

us for the enlargement and improvement of this Manual.

ERNST HEINKEL AKTIENGESELSCHAFT

STUTTGART-ZUFFE HAUSE

Workshop Manual Heinkel Tourist 103 A-1 page 1

a

To all HEINKEL Owners

This Manual is intended to assist you in having carried out all

maintenance and repair work in your HEINKEL dealer's

workshop. Besides we believe that many of you are interested

in knowing more about your HEINKEL TOURIST motorscooter

than we can tell you in the Owner's Manual. Furthermore this

Manual might help you when travelling abroad especially

when travelling in countries where on account of importation

restrictions or for other reasons no HEINKEL workshops can

be found in case of trouble you might show this copiously

illustrated Manual for information to the workshop people and

thus save precious time and money.

We draw your attention to the fact that all repairs particularly

on the engine of the vehicle should always be carried out with

the proper special tools. For repairs never use any but

Original HEI KEL Spare Parts or

Original HEI KEL Exchange Parts,

as otherwise our part of the Guarantee becomes invalid.

Detailed drawings make the text of this Manual easy to

understand. Correlation of the illustration references with the

text is simplified by figures. For example 10/2 : 10 is the

number of the illustration and the figure 2 after the oblique

stroke refers to the part number in the illustration in question.

ERNST HEINKEL AKTIENGESELSCHAFT

STUTTGART-ZUFFE HAUSE

Workshop Manual Heinkel Tourist 103 A-1 page 2

Contents

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1, 1a

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Exchange Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Dismantling and reassembling the engine . . . . . . . . . . . . . . . . .

9

Dismantling the Cylinder Head, Cylinder and Piston

. . . . . . . . . . . . .

11

Reassembling the Cylinder Head, Cylinder and Piston

. . . . . . . . . . . .

12

Adjusting the valves . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dismantle, ream but and assemble connecting rod bush

. . . . . . . . . . .

14

Dismantle and assemble cylinder Head, grind in valves

. . . . . . . . . . .

15

Check Piston and Cylinder

. . . . . . . . . . . . . . . . . . . . . . .

17

Table of Measurements and Oversizes (Cylinder and Piston)

. . . . . . . . .

18

Dismantling the Clutch . . . . . . . . . . . . . . . . . . . . . . . .

19

Fitting the Clutch . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Dismantling the Dynamo . . . . . . . . . . . . . . . . . . . . . . . .

23

Assembling the Dynamo . . . . . . . . . . . . . . . . . . . . . . . .

25

Adjusting the Ignition . . . . . . . . . . . . . . . . . . . . . . . . .

27

Measuring voltage and current on Dynamo and Governor Switch . . . . . . . .

28

Measuring Voltage on the Dynamo . . . . . . . . . . . . . . . . . . . 28

Measuring charging current . . . . . . . . . . . . . . . . . . . . . .

28

Dismantling the Swinging arm . . . . . . . . . . . . . . . . . . . . .

29

Fitting the Swinging Arm

. . . . . . . . . . . . . . . . . . . . . . . .

31

Table of Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33

Tightening Torques for Bolts and uts . . . . . . . . . . . . . . . . . . 33

Dismantling Crankshaft and Bearing . . . . . . . . . . . . . . . . . . .

34

Fitting Crankshaft and Bearing . . . . . . . . . . . . . . . . . . . . .

35

Dismantling the Gears . . . . . . . . . . . . . . . . . . . . . . . . 37

Fitting the Gears . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Removing, dismantling and refitting of Carburettor . . . . . . . . . . . . .

39

Removing, dismantling and refitting of BI G Carburettor

. . . . . . . . . . .

39

Removing, dismantling and refitting of PALLAS Carburettor

. . . . . . . . . .

41

Removing and Fitting the Front Fork

. . . . . . . . . . . . . . . . . . .

43

Disassembling and Fitting of the Front Fork . . . . . . . . . . . . . . . . 44

Removing and Fitting of Frame and Fork Ball Races . . . . . . . . . . . . .

44

Removing and Fitting of Front Wheel Hub

. . . . . . . . . . . . . . . . .

45

Removing and Fitting Brake Shoes . . . . . . . . . . . . . . . . . . .

45

Adjusting the Gear Shift Arrangement . . . . . . . . . . . . . . . . . .

46

Adjusting the Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

46

Adjusting the Headlamp . . . . . . . . . . . . . . . . . . . . . . . .

47

Removing and Fitting of Frame

. . . . . . . . . . . . . . . . . . . . .

48

Power Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Speed Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49

Climbing Performance Curve . . . . . . . . . . . . . . . . . . . . . . 49

Fuel Consumption Curve . . . . . . . . . . . . . . . . . . . . . . .

49

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Table of Loads . . . . . . . . . . . . . . . . . . . . . . . . . . .

51

Drawing of Assembly Jig for Scooter . . . . . . . . . . . . . . . . . .

52

Drawing of Assembly Jig for Scooter Engine

. . . . . . . . . . . . . . . .

53

Table for Service, Maintenance and Greasing . . . . . . . . . . . . . . . . .54

Workshop Manual Heinkel Tourist 103 A-1 page 3

Technical data of motorscooter »HEINKEL-TOURIST«, model 1 3 A-1

Engine

Engine model 407 A-1

Engine cycle Four-stroke

umber of cylinders 1

Arrangement of Cylinders Vertical

Bore 60 mm. Ø

Stroke 61.5 mm.

Swept Capacity 174 cc.

Clearance volume 27.5 cc.

Compression ratios 1:7.4

Output 9.2 h.p. at 5500 r.p.m.

Compression pressure 130 lbs per sq. inch. (When fuel valve is open and

the engine is warm)

Piston play 0.05–0.06 mm.

Diameter of gudgeon pin 18 mm. Ø DI 73121 (watch the identification colours)

+ 0.025 mm.

Bore of compression ring 18 mm. Ø + 0.040 mm.

Seating of crank assembly 2 × annular groove bearings 6305 C 3

Seating for clutch shaft 1 × annular groove bearings 6203 C 3

Valve arrangement Overhead valves (V-type) in fully enclosed light-metal

cylinder head

Inlet valve 0.15 mm.

Valve clearance Exhaust valve 0.20 mm. measured on cold engine

Inlet/Exhaust 18° after t.d.c.

Inlet/Inlet 17° after b.d.c.

Exhaust/Exhaust 18° before b.d.c.

Valve timing

Exhaust/Inlet 19° before t.d.c.

± 1° measured with

2mm valve clearance

Inlet 6.975 mm. Ø — , 1 mm.

Diameter of valve stems Exhaust 6.965 mm. Ø — 0,01 mm.

Inlet 7 mm. Ø + 0.028 mm.

Bores of valve guides Exhaust 7 mm. Ø

+ 0.013 mm.

Valve spring pressure 30.0 kg (valve open)

10.3 kg (valve closed)

Cooling Fan-cooling

Lubricating system Oil-bath centrifugal lubrication

Ignition

Type of ignition Starter/Generator unit "BOSCH" 12 volt coil ignition with

automatic timing, 12 volts, 90 watts

(AZ/DAQ 90/12/1700 + 0.2 R 2)

Spark timing Retarded ignition

0.6—0.8 mm. before t.d.c, using timing tool (404/W 10)

or 8°—10° before t.d.c. (when setting by means of the graduated

disc)

Advanced ignition

6.5—7 mm. before t.d.c. or 33°—35° before t.d.c.

(when setting with the governor fully open)

Gap between contact breaker points 0.35—0.45 mm.

Spark plug calorific value 225 *) today: BOSCH W5 AC or NGK B7 HS

or Champion L81C

Spark plug thread M 14 X 1.25

Spark gap 0.5—0.6 mm.

Carburettor

eedle type carburettor with

accelerating pump

Pallas Type 20/14 P Bing Type 1/20/46

Carburettor passage 20 mm. 20 mm.

Main jet 80(85) 85

Slow-running jet 25 35

eedle jet 2701 2.66

eedle setting 3 3

Jet needle, conical 15 x 1.95 Ø

number 3

Mixture screw 2½ x turns open 1½ turns open

adjust to best idling

Air filter "Knecht" micronic air filter

*) see pteng (www.pteng.de)

Workshop Manual Heinkel Tourist 103 A-1 page 4

Clutch

Clutch Oil-bath multiple-disc clutch

Operation of clutch By hand on left handlebar

Clutch spring pressure 60—70 kg.

Thickness of outer plate max. 5.0 mm. min. 4.0 mm.

Clutch adjustment 2—3 mm. on the clutch lever (on handlebars)

Gearbox

Gearbox Four-speed type

Method of engagement dogs

Power Transmission

Engine-Gearbox

Single enclosed chain, ⅜“ x ⅜“ (56 links endless) , fully enclosed and

oil-bath immersed.

Power transmission

Gearbox-Rear wheel

Single roller chain, ½“ x 5/16“ reinforced, (70 links endless), fully

enclosed and oil-bath immersed.

Reduction Engine-Gearbox 1.882:1

Gear reduction ratios 1st Gear 3,51 : 1

2nd Gear 2,07 : 1

3rd Gear 1.38 : 1

4th Gear 1 : 1

Solo With Sidecar

Reduction ratio Reduction ratio

Gearbox-Rear wheel 2.727:1 Gearbox-Rear wheel 3.10 :1

Chain Wheels Chain Wheels

Gearbox 11 teeth Gearbox 10 teeth

Rear wheel 30 teeth Rear wheel 31 teeth

Total reduction Total reduction

1st gear 18.05:1

2nd gear 10.60:1

3rd gear 7.10:1

4th gear 5.13:1

1st gear 20.50:1

2nd gear 12.02:1

3rd gear 8.06:1

4th gear 5.83:1

Chassis

Frame Torsion-free tubular steel frame

Engine suspension Rubber-Insulated 3-point-suspension

Front wheel suspension Telescopic form with hydraulic shock-absorber

Rear wheel suspension Fully-enclosed swinging arm, with telescopic, hydraulically damped

suspension unit

Offset of front axle 92 mm. (unchanging)

Caster action 18—20 mm.

Handlebar steering range 50 degrees to left and right-hand sides

Steering (vertical) angle 25°

Toe-in of sidecar wheel 18—20 mm.

(please respect any special stipulations of the sidecar manufacturers)

Camber of the machine Up to 4 degrees (inclining towards sidecar) (please respect any

special stipulations of sidecar manufacturers)

Handlebars Pressed-steel handlebars with built-in speedometer (calibrated

either in kilometers or in miles) and with twist -grip gear shift.

Brakes Mechanical internally-expanding brakes, drum 140 mm. diam,

width 25 mm.

Operation of brakes Hand-lever for front-wheel brake,

Foot-operated pedal for rear wheel

Wheels All interchangeable

Rims Flat-base rims s. 50X10"

Tyres 4.00 x 10“

Tyre pressure Front wheel Rear wheel Sidecar

driver only 18 psi 26 psi

driver and passenger 18 psi 29 psi

driver with sidecar passenger 22 psi 29 psi 22 psi

driver with pillion passenger

and sidecar passenger

22 psi 36 psi 29 psi

Workshop Manual Heinkel Tourist 103 A-1 page 5

imensions and Weights

Wheelbase 1375 mm.

Overall length 2085 mm. (without rear luggage carrier)

Maximum width 710 mm.

Maximum height 1000 mm.

Height of seat 735 mm.

Ground clearance approx. 145 mm.

Weight of vehicle, ready to be driven 150 kg.

Total weight admissible 350 kg.

Total weight admissible with sidecar 450 kg.

Fuel and lubricants

Fuel Use a proprietary brand

At least 82 octane (ROZ)

Fuel tank Holds 11.3 litres, of which approx. 1 litre forms a reserve.

Lubricant Use a proprietary brand, such as MOBILOIL SPECIAL,

for the whole year round. *)

Oil in the engine Approx. 1.5 litres (to the mark on the dipstick)

Oil in the swinging arm Approx. 0.15—0.20 litres

Fuel consumption, to DI 70030 standards 3 litres per 100 km

Maximum speed Approx. 92 km/h

*) Hint in year 2004: because of difficulties with the clutch, never use modern HD-oil or synthetic oil. Only use

classic oil for the engine. See pteng (www.pteng.de)

In the interests of technical development, we reserve the right to make modifications.

Workshop Manual Heinkel Tourist 103 A-1 page 6

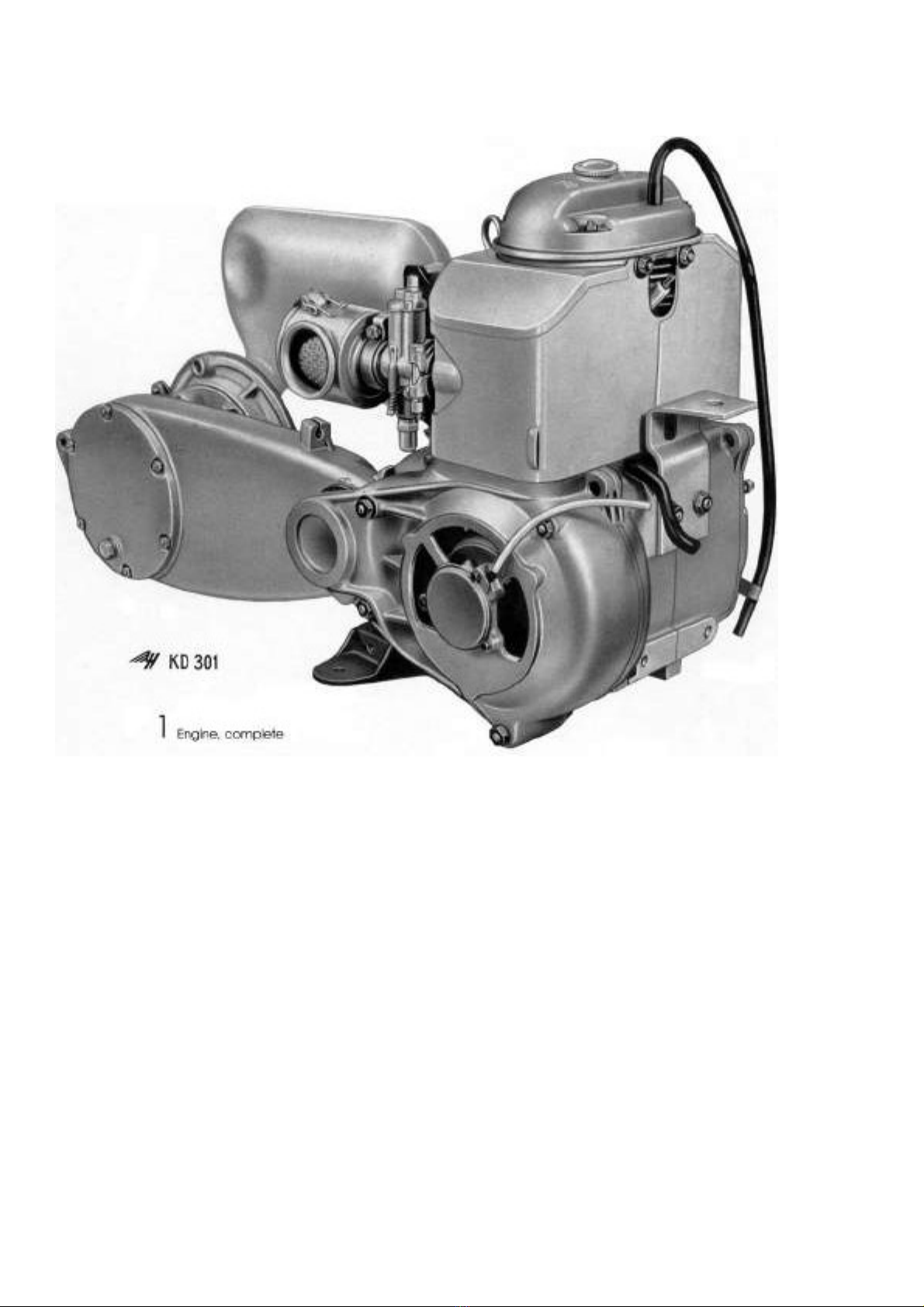

Engine » H E I N K E L - T O U R I ST «, model 4 7 A-1

Exchange engine:

Engines to be returned to the factory under the exchange scheme must be

as follows:

with swinging arm, complete, carburettor, exhaustmanifold, cooling baffles,

dip stick, magneto, complete, with spark plug, clutch lever with traction

spring and retainer plate, rear wheel hub with brake lever, all nuts, bolts

and discs, and the support for the mounting of the exhaust silencer,

without air filter, exhaust silencer, air outlet tube, guiding piece for the

Bowden cable operating the rear wheel brakes, support with sleeve for

Carburettor Bowden cable.

Note: Owing to import restrictions, import duties and for other reasons it

has not, unfortunately, been possible for the Factory to apply the German

Engine Exchange Scheme to foreign countries.

Workshop Manual Heinkel Tourist 103 A-1 page 7

Special Tools for »HEINKEL-TOURIST«

2 Special Tools

Key to illustration above:

o

.

Drawing o. Description

1 401/W 22 Extractor for driven pinion

2 408/W 14 Clutch retainer

3 401/W 20 Retainer plate for piston

4 401/W 19 Guide pin for rocker arm axle

5 407.201/W 5 Ball-bearing extractor, Type 6305

6 404/W 7 Extractor for starter dynamo

7 401/W 25 Clutch compressor

8 401/W 26 Gudgeon pin extractor

9 407/W 20 Piston ring clamp

10 407/W 21 Retainer for starter dynamo

11 401 /W 21 Snap ring opener

12 401/W 8 Assembly pliers for brake shoes

13 401/W 10 Assembly pliers for brake shoes

14 commercial type Meter for use with ignition timer

15 commercial type 5 mm. key for starter dynamo

16 407/W 30 Assembly sleeve for radial gasket

17 407/W 29 Assembly sleeve for sealing cap

18 commercial type Tension wrench (Torque-metering spanner) 0-6 mkg.

19 404/W 10 Ignition timer

Workshop Manual Heinkel Tourist 103 A-1 page 8

3 Special Tools

Key to illustration above:

o. Drawing o. Description

1 self-made Retainer for exhaust silencer

2 self-made Retainer for Engine

3 self-made Wooden punch for frame ball-races

4 commercial type Grease gun

5 407/W 37 Retainer for brake plate

6 self-made Extractor and refitter for connecting rod bushes

7 commercial type Reamer guide

8 commercial type Reamer for connecting rod bushes

9 commercial type Holder for hand milling cutter

10 commercial type Pilot for hand milling cutter

11 commercial type Milling cutter 29 mm diam. 77.5°

12 commercial type Milling cutter 32 mm diam. 45.0°

13 commercial type Milling cutter 32 mm diam. 30.0°

14 commercial type Cutter for adjusting valve seating

15 commercial type Guide for cutter for adjusting valve seating

Workshop Manual Heinkel Tourist 103 A-1 page 9

4 Scooter frame assembly jig

General ata

In order to facilitate repair work on the scooter frame we recommend

using an assembly jig (fig. 4, drawing on page 52) which can be

made by the dealer in his own workshop. The same applies to the

assembly jig for the engine (fig. 5, drawing on page 53).

When carrying out any major overhaul and/or fitting work on the

engine such an assembly jig and corresponding special tools should

in all cases be used.

Prior to carrying out repair work the vehicle should be cleaned most

thoroughly. After having been cleaned, the removed components

should be checked, for wear and tear, and, if necessary, be replaced.

Worn and damaged components should be exchanged for

Genuine HEI KEL Exchange Parts or

Genuine HEI KEL Spare Parts.

In order to fit correctly all moving parts, such as ball bearings,

shafts, axles, bushings, radial gaskets, pistons etc. should be lubri-

cated. To obviate leakage renew all gaskets, cleanse face surfaces

of the housings (housing halves) and seal with securing lacquer all

threads on parts that are in contact with oil.

All HEI KEL-Spares should be ordered by HEI KEL-Owners from

the HEI KEL-dealers and/or distributors, and not direct from the

HEI KEL factory. Overseas HEI KEL dealers order HEI KEL spares

from the distributors or from the importers. Only the importer may

order the spares direct from the HEI KEL factory in Western Ger-

many, or distributors direct, with the importer's authorization.

When ordering, the order should specify

1. name and address of ordering firm

2. mode of despatch requested

3. frame and engine number of vehicle involved

4. correct specification (nomenclature) of spare parts requested and

drawing number.

5. Quantity ordered.

ismantling and reassembling the engine

Raise the vehicle and, with the central stand set up, place it on

the jig. Place the two pegs of the cross-member into the two

middle holes provided on the gusset plate of the scooter frame,

fix frame tube on jig cross-member by means of screwing clamp,

fix central stand of scooter by means of clamping clip.

1. Remove spare wheel and spare wheel carrier. Raise the seat

cushion from the middle section. Take out the leads to the brak-

ing and licence plate light at the socket plug. Undo two hex.

bolts for the pipe clamps, open the side flap and remove the rear

coachwok.

2. Undo and disconnect battery cable. Remove the battery.

3. Undo and remove the leads which lead to the engine at the

governor and at the ignition coil. Remove the governor switch.

4. Close the fuel cock, disconnect the fuel line at the carburettor;

remove fuel tank. (Also remove rubber cushions beneath fuel

tank.)

5. Undo air filter locking screw and remove air filter, take off car-

burettor.

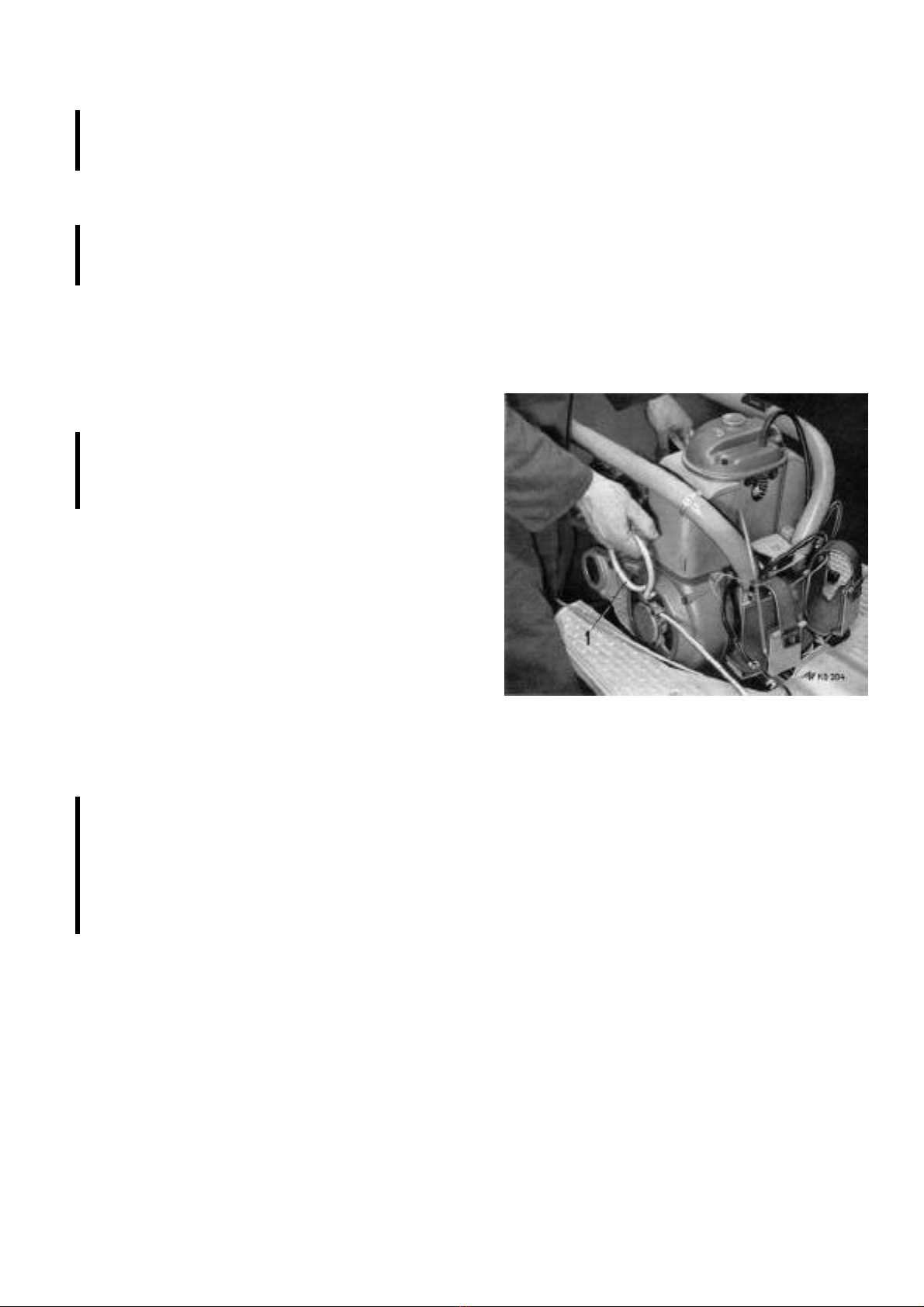

5 Assembly jig for scooter engine

Workshop Manual Heinkel Tourist 103 A-1 page 10

6 Lifting the engine out

6. Remove exhaust silencer and air outlet pipe.

Please note:

Avoid stress when fitting exhaust silencer as otherwise exhaust

manifold might break!

7. Undo four nuts on the rear wheel and remove the rear wheel.

Undo fixing bolts and nuts on the spring leg and remove spring

leg.

Please note:

When fitting the rear wheel, tighten wheel nuts at 6.0 mkg. Insert

upper fixing bolt of spring leg from inside!

8. Disengage rear wheel brake cable from the brake lever and

unscrew the brake cable set-screw from the support on the

swinging arm.

9. Disconnect the clutch control cable from the clutch lever. Unscrew

adjusting screw.

10. Undo cylinder screw on the shift lever and push lever off gear

selector. (Do not damage rubber ring!) Remove adjusting screw

for the clutch cable from the support on the clutch cover.

Please note:

When fitting the shift lever, the marks on the gear selector and

the shift lever have to correspond. Grease both rubber sleeves

on the switch cable by grease gun.

11. Undo the hex. nuts of the rubber elements for engine suspension

with a box spanner, push back hex. bolts (Box spanner SW 17.)

12. Loosen hex. bolt (SW 17) of clamp (right-hand side) (this makes

engine removal easier).

13. Lift the engine with swinging arm out to the rear, as shown on

fig. 6. It would be advantageous to use retaining jig 6/1

If further repair work is to be carried out on the engine, undo

two hex. nuts with box spanner (SW 15), remove internal toothed

disc and clamp for engine suspension. Fix engine on flange 5/2

of engine assembly jig by means of knurled screw 5/5 and

special nut 5/4. When engine in horizontal position, use piece

5/3 for support and fix fan wheel and armature by means of

retaining jig 5/1.

Reverse the procedure when reassembling.

Please note:

For connecting electric cables, proceed in accordance with wir-

ing diagram, page 50.

When fitting Genuine HEI KEL Exchange Engine, check oil level.

If necessary, fill in oil of well-known brand, such as e.g. Mobil

Oil Special.

Prior to operating, change Micronic filter insert.

Workshop Manual Heinkel Tourist 103 A-1 page 11

Engine

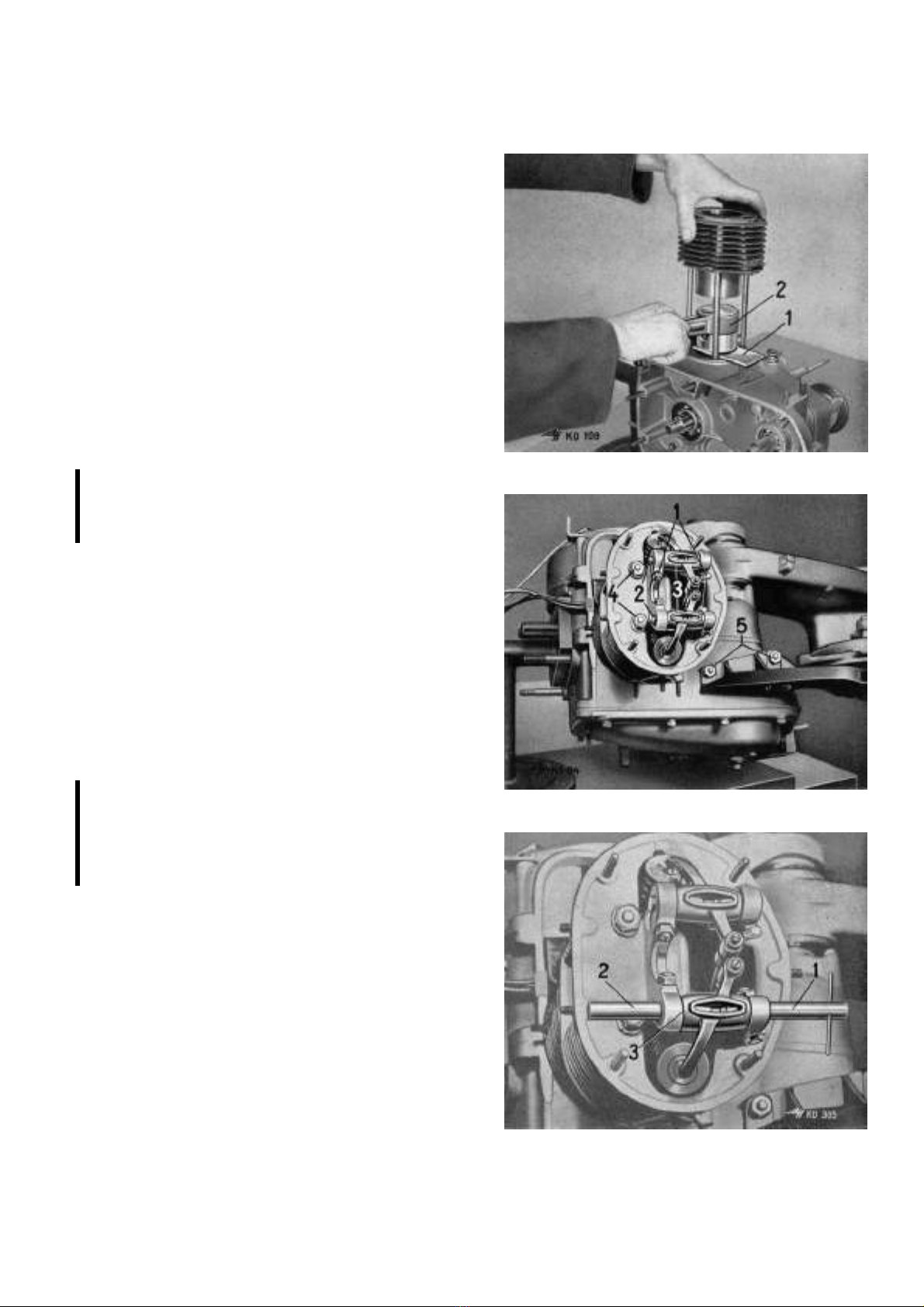

ismantling of cylinder head, cylinder and piston

Please note:

If you wish to carry out the above mentioned repair work, do

not remove the engine; just proceed as per page 9, "Dismantling

and Reassembling of Engine", paragraphs 1, 4, 5 and 6. (How-

ever, please bear in mind that this applies only to the above

repair work!):

1 . Undo the nuts on the cylinder head cover with box spanner

(SW 10), remove air-vent hose and cylinder head cover. Remove

cooling baffles, dismantle induction and exhaust manifolds.

2. Unscrew and remove spark plug. Place piston at t.d.c. with valves

closed and loosen clamp nuts 7/1 and nuts for rocker arm shafts-

Cover push rod channel with clean rag. Undo two nuts (SW 10)

on rocker arm and slightly loosen the ball-shaped screw for

valve setting, so that the rocker arm shafts 7/2 can be pushed

out of their Journals with a pin without forcing.

Take off rockers 7/3 (and the spacing washers) and remove push

rods.

3. Using box spanner (SW 14), undo cylinder head fixing nuts 7/4

and take off cylinder head and cylinder. (Watch out for the soft-

iron washers, since these have to be used again when re-

assembling).

4. For better dismantling of the piston, use the forked retainer plate

(401/W 20) 8/1. Cover crank case with a piece of clean rag.

With a pair of pointed pliers, remove both wire snap rings from

the piston. Push out the piston gudgeon pin with gudgeon pin

extractor (401/W 26) 8/2 and remove piston.

Please note:

To avoid bending the connecting rod, on no account knock the

gudgeon pin out.

5. To strip the engine completely, undo nuts 7/5 and take off the

bracket.

7 Cylinder head with rocker arms

8 Dismantling the piston

Workshop Manual Heinkel Tourist 103 A-1 page 12

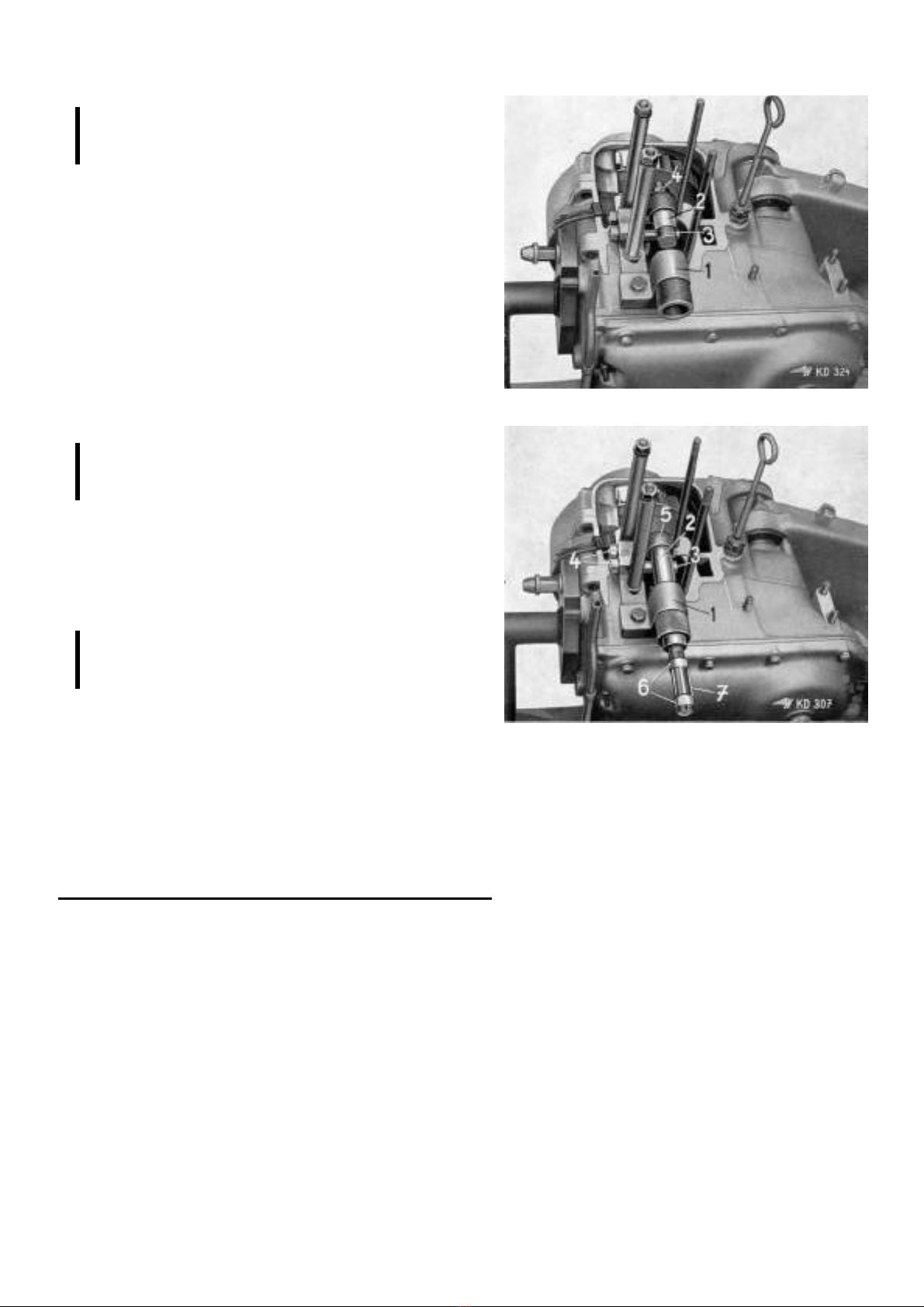

Reassembling piston, cylinder and cylinder head

9 Fitting the cylinder

10 Cylinder head with rocker arms

1 . Tighten tie rod for cylinder (3 mkg). To obtain safe sealing, wipe

tie rod on crank case with sealing lacquer.

2. Lay on to the crankcase the cylinder foot gasket (dry) and the

forked retaining piece (401/W 20) 9/1.

3. Fit the wire snap ring for the piston gudgeon pin in the piston.

Place the piston on connecting rod, insert the gudgeon pin into

piston and connecting rod bush as far as the wire snap ring,

holding the piston tightly with the left hand.

Cover crank case with a clean rag.

4. Insert the wire snap ring with a pair of pointed pliers. Make sure,

by twisting them, that the snap rings are properly seated.

5. Oil the working surfaces of the cylinder and also the piston.

Twist the piston rings, so that the gaps are not all facing in the

same direction.

6. Using the piston ring tightener (407/W 20) 9/2, squeeze the

piston rings together, fit the cylinder and lower carefully over

the piston. Remove piston ring tightener and forked retaining

piece (401/W 20).

Please note:

When using oversize cylinder and piston, the corresponding

measurements will be found listed on Genuine HEI KEL Ex-

change Cylinders. (See Page 18.)

7. Lay on cylinder head gasket (dry) and fit cylinder head. Lay on

washers 12/3 and wipe stay bolts with sealing lacquer. Using the

tension wrench, secure cylinder head by alternately tightening

diagonally-opposite bolts. (3 mkg). Once nuts 10/4 have been

tightened, seal with sealing lacquer.

8. Move crankshaft by rotating fan wheel and set piston at its top

dead center. Fit push rods and make sure that they are all set

at the same height. Fit rocker arms 10/3. To center rocker arms,

insert guide pin (401/W 19) 11/1 into bearing blocks and rocker

arms. If there should happen to be a relatively large lateral play

between rocker arm and bearing blocks, eliminate it by fitting

spacing shims, drawing number 408.300-014 (0.4 mm.), 408

300-015 (0.3 mm.), 408.300-016 (0.2 mm.).

Please note:

If a lateral play of rocker arms of up to 0.4 mm. is found, those

spacing shims are to be inserted on the pressure side (i.e. on the

side opposite to the push rods). If said play exceeds 0.4 mm.,

those spacing shims are to be inserted on both sides of the

rocker arm.

9. Fit shaft 11/2, tighten clamping screws 10/1 for rocker arm

shafts.

10. Adjust the valves (see page 13).

11. Screw in sparking plug. Fit induction and exhaust manifolds and

gaskets.

12. Lay on cylinder head cover gasket and fit cylinder head cover.

Fit cooling baffles and air outlet hose.

13. For further assembly, reverse the procedure as outlined, under

"Dismantling the Engine - Reassembling the Engine", page 9,

paragraphs 6, 5,4 and 1.

11 Fitting rocker arm shafts

Workshop Manual Heinkel Tourist 103 A-1 page 13

12 Adjusting the valves

Adjusting the valves

Please note:

Remove spare wheel and spare wheel carrier. Raise seat

cushion on middle section of rear cowling. Disconnect at plug the

cables for braking and rear licence plate light.

Undo two hex. nuts for pipe clamp. Remove rear cowling.

The valves should only be adjusted while the engine is cold.

1. Undo the nuts on cylinder head cover by using box spanner

(SW 10). Remove air-outlet hose and cylinder head cover.

2. Set piston at top dead center position. Both valves must be

closed.

3. Adjust the valves. (See fig. 12).

The valve tappet clearances are:

Inlet valve 12/1 0.15 mm.

Exhaust valve 12/2 0.20 mm.

4. Once adjusted, lock the setscrews with nuts.

5. For assembly, the reverse procedure is to be applied.

Workshop Manual Heinkel Tourist 103 A-1 page 14

Removing and fitting connecting rod bush, reaming out the bush

13 Inserting connecting rod bush

14 Centering connecting rod bush

Please note:

Proceed as outlined on page 11, "dismantling cylinder head,

cylinder and piston". Cover crankcase with clean rag.

1. Place and fix retaining jig with guide bush 13/1 on crankcase.

2. Turn both eccentric pins 14/3 on jig against connecting rod and

tighten nuts 14/4.

3. Place extractor with spacing pipe. By using two fork spanners

(SW 17), screw on nut and extract bush.

4. Mark lubrication hole on new bush. Drill lubrication hole with

twist drill 4.5 mm. + 0.5 mm. diam. (at an angle of 90 degrees to

bore of connecting rod bush.) Remove burr from inside and

outside of bush.

5. Place thus prepared bush on guide pin 13/3.

6. Center bush on top end of connecting rod. Put on guide pin of

guide jig and fit nut 13/4.

Insert bush 13/2 by screwing on nut, using two fork spanners

(SW 17).

Please note:

Lubrication holes of bush and top end of connecting rod must

correspond. Check alignment by using wire or needle.

7. Remove retaining jig with guide bush, undo nuts and turn both

eccentric pins away from connecting rod.

8. Center connecting rod 14/5 by using conical part 14/2 of the

reamer.

9. Turn both eccentric pins on jig against connecting rod and

tighten nuts.

Please note:

Prior to tightening, make sure by feel that the connecting rod

has not been tilted.

10. Loosen both adjusting nuts (SW 16) 14/6 on the reamer. Adjust

the cutters 14/7 to required diameter and then tighten adjusting

nuts again.

11. Insert reamer into connecting rod bush and slowly but conti-

nuously ream out the bush, constantly pressing forward. (Use

tap wrench or spanner.)

Permissible tolerances

Colour marks Ø hole for piston piston connecting

mm gudgeon gudgeon rod bush

White 18 + 0.003 0

+ 0.0005 - 0.0025 + 0.0425

Black 18 + 0.0005 - 0,0025 + 0.0275

- 0.002 - 0.005 + 0.0450

Workshop Manual Heinkel Tourist 103 A-1 page 15

ismantle and assemble cylinder head, grind in valves

15 Dismantling cylinder head

16 Hand-milling valve seats

Please note:

Proceed first as per page 11, "Dismantling the Cylinder head,

cylinder and piston, paragraphs 1, 2 and 3 (without removing

cylinder).

1. Place cylinder head onto jig (see fig. 15). Push lever and thus

compress valve springs, remove the conical valve cotters. Re-

move upper and lower spring plates, also remove external and

internal valve springs.

2. Clean cylinder head and remove oil carbon deposits.

3. Place cylinder head onto jig (see fig. 16) and fix by means of

retaining bolt 16/5.

4. Using a hand-milling cutter 16/4 mill inserted valve seats. Use

guide pin 7 mm. Ø + 0,013 mm.

+ 0,028 mm.

a) mill the channel, using cutter 29 mm. Ø. 77.5° 16/2.

b) mill the inserted valve seat, using cutter 32 mm. Ø

45.0°, 16/3.

c) mill the valve-bearing section of the inserted valve seat,

using cutter 32 mm. Ø, 30.0°, 16/1.

Inserted valve seats can also be milled by means of the

"HU GER"-Milling Tool for Inserted Valve Seats.

5. Place cylinder head 17/2 onto jig 17/1 and fix.

6. Firmly insert guide pin 17/3, using no lubricant, into the cleaned

valve guide.

7. Using hand-milling cutter, 29 mm. Ø, 77,5°, 16/2, mill the

channel.

8. Place on guide pin 17/3 the Milling Tool for Inserted Valve Seats

(sightly lubricate the top section of guide pin before). Loosen

fixing screw 17/5, while maintaining in position the Milling Tool

to prevent the cutter tip 17/6 damaging the valve seat.

9. Using fork spanner (SW 7), loosen lock nut 17/7 and adjust the

Rapid-Action Regulator 17/8 so that the cutter tip is positioned

in the middle of the valve seat.

10. Tighten set-screw 17/5.

11. Turn rapid-action regulator 17/8 anti-clockwise until cutter tip

17/6 is positioned at approx. 1 mm distance from the internal

edge of the valve seat.

12. Tighten lock nut 17/7.

13. Maintain annular support 17/9 in position while turning the crank

17/4 in direction indicated by arrow in fig. 17 until all of the

valve-bearing section is being milled until the cutter will run idle.

Please note:

If by the above procedure the valve seat has not been smoothly

milled (smooth surface!), proceed as follows:

14.Loosen lock nut 17/7, turn anti-clockwise rapid-action regulator

17/8 so that the cutter tip is positioned at approx. 1 mm. distance

from the internal edge of the valve seat. Tighten lock nut.

15. Loosen knurled screw 17/10 and turn milling regulator 17/11 to

the left (as indicated by arrow on fig. 17) by one line mark.

Tighten knurled screw again.

Please note:

1 line mark of the calibration about equals 0.1 mm.

16. Proceed as outlined under paragraph 13 above.

17. As after carrying out the above procedure the valve seat has

been milled smoothly (smooth surface!), proceed to finish-mill.

For this purpose, leave milling operator in same position. Only

operate rapid-action regulator 17/7 and 17/8 (see paragraph 14)

and repeat procedure as outlined in paragraph 13.

17 Milling valve seats, using special milling tool

Workshop Manual Heinkel Tourist 103 A-1 page 16

18 Measering spring pre-tension

18.Remove Milling Tool for Inserted Valve Seats.

19. Using hand-milling tool 32 mm Ø 30.0° 16/1, mill the valve-

bearing section of the valve seat. Remove guide pin.

Please note:

Widths of the valve-bearing sections of the valve seats

Inlet valve 1.1-1.2 mm

Exhaust valve 1.5 mm

20. Using a fine-grade grinding paste, grind the valves until all of

the bearing sections of valves and valve seats (on cylinder head

and valves) show a uniformly grey shine without any bright

grooves.

21. After grinding, clean valves and cylinder head.

22. Check that valve-seats have been thoroughly finished by using

engineers' marking blue.

23. Insert valves in cylinder head. Using depthmeter 18/1, measure

distance between top surface of the valve stem 18/2 and the

milled surface 18/3. (Support of lower spring plate.)

Please note:

This distance - for pre-tension of the spring - has to be:

for inlet valve 31.0-31.8 mm.

for exhaust valve 31.5-32.3 mm.

24. Compensate possible tolerances by using spacing discs (shims),

drawing number 404.300-005 (0.2 mm), 404.300-006 (0.5 mm.),

404.300-007 (1.0 mm.). Those spacing shims are to be placed

beneath the lower spring plate.

25. lnsert valves and place cylinder head onto jig (see fig. 15).

26. Lay on lower spring plate (if necessary, also lay on spacing

shims), internal and external valve springs and the top spring

plate. Compress lever of jig and thus compress valve springs;

insert conical valve cotters.

Please note:

The external valve spring, when in released position, has a total

length of 30.5 mm. Under 6.9 kg. pressure its length has to be

27.0 mm., under 20.0 kg. pressure 20.3 mm.

The internal valve spring, when in released position, has a total

length of 26.5 mm.. Under 3.4 kg. pressure its length has to be

23.0 mm., under 10.0 kg. pressure 16.3 mm.

Having fitted the valves, it is recommended to apply a few tap

hammer strokes on the end of the valve stem, using a plastic or a

rubber hammer, thus smoothening the valve seat sections and

obtaining perfect seating.

It is recommended, besides, to pour some petrol into the valve

ports to ascertain, by having a look at the bottom side of the

cylinder head, that the valves are a perfect fit.

Use an Exchange Cylinder Head if valve guides are so worn as

to exceed 7 mm. Ø + 0.013 mm.

+ 0.028 mm.

and/or if valve seat rings are very worn.

27. For further assembly, reverse the procedure as explained under

"Reassembling the Cylinder Head, Cylinder and Piston",

page 12, paragraphs 7, 8 etc.

Workshop Manual Heinkel Tourist 103 A-1 page 17

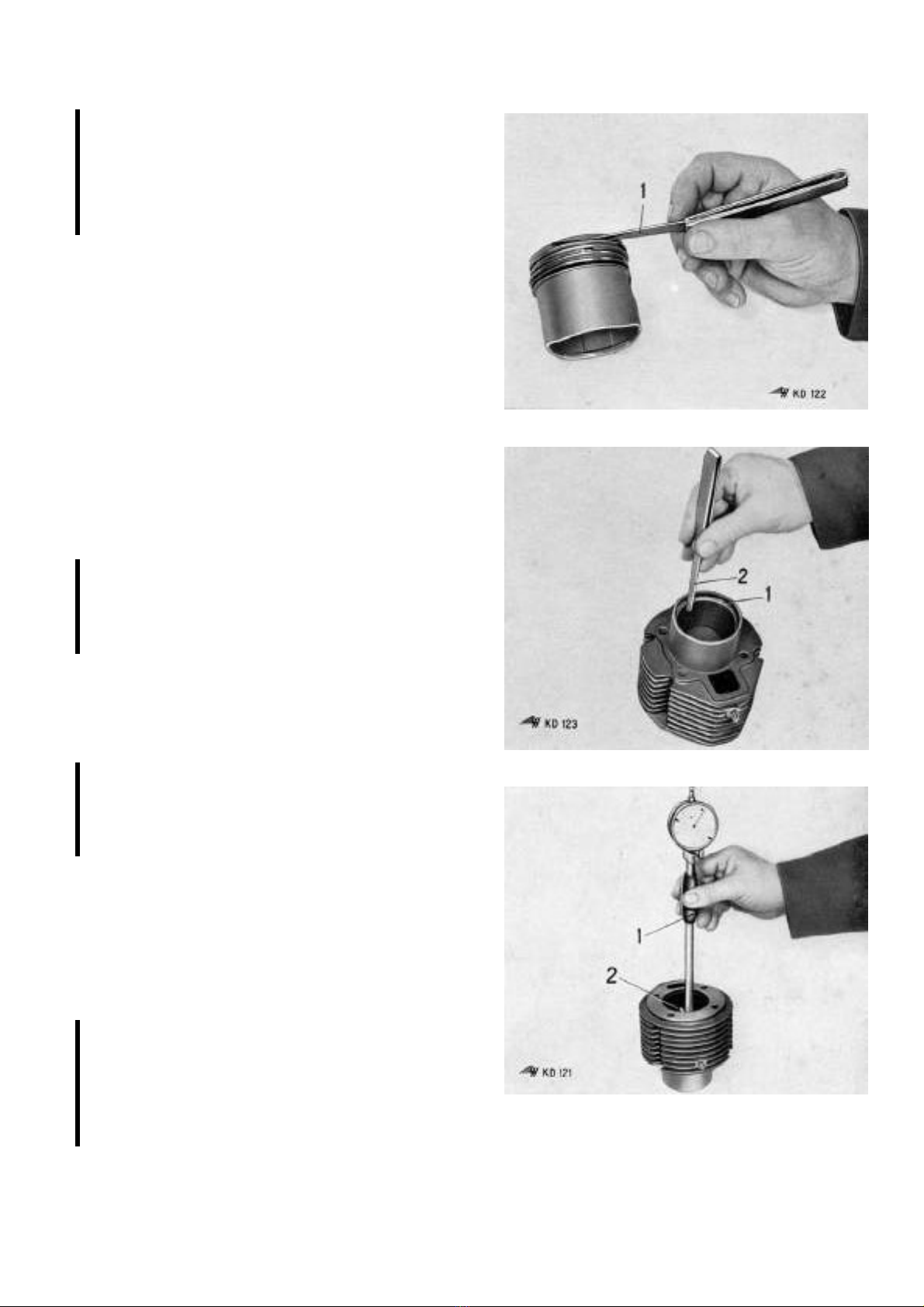

Check piston and cylinder

19 Testing the height play

20 Testing the gap

Please note:

Proceed as explained on page 11, "Dismantling Cylinder Head,

Cylinder and Piston".

Cover the crankcase with a clean rag.

When refitting a used piston, remove all traces of oil carbon from

the piston head and the cylinder, take care that the piston is

fitted in the same direction as before (i.e. front to front).

1. Check piston (i.e. surface of contact) for grooves, traces of

piston seizures, worn spots (light grey surface!); check piston

rings for burns.

2. Using a feeler gauge 19/1, check the height play of the piston

rings, the permissible tolerance between the piston ring and the

ring groove being:

Ring Groove Piston Ring Minimum Maximum

I Compression ring (chromium) 0.060 mm. 0.090 mm.

II Compression ring 0.035 mm. 0.070 mm.

III Oil scraper ring 0.025 mm. 0.060 mm.

3. To check piston rings for gap, singly place one ring 20/1 at a

time in the foot of the cylinder and press flat with the skirt of the

piston.

Check gap of each individual ring by using feeler gauge 20/2.

Said play is not to exceed 0.40 mm.

Please note:

If the wear of the cylinder bore (ovality!) still lies within per-

missible tolerances (0.10 mm.), new piston rings may be fitted to

the piston. If not, the cylinder and the piston have to be ex-

changed.

4. By using a commercial-type cleaning tool or a section of the

piston ring, thoroughly and cautiously clean the ring grooves;

the grooves are, however, not to be enlarged thereby.

5. Fit the piston rings, taking care that the manufacturers' markings

are turned towards the piston head. The rings must be easily

turnable in their grooves.

Please note:

If fitting a new piston and gudgeon, take care that the colour

markings coincide. (See page 14). Those coloured dots are to be

found a) on the inside of the gudgeon pin boss on the piston,

b) on the end face of the gudgeon pin.

6. Clean the cylinder, remove all traces of oil carbon.

7. Check cylinder bore for grooves and spots of seizure.

8. Assess exact amount of wear on the cylinder; Insert cylinder

meter 21/1 in the bore of the cylinder, so that the feeler and the

guide pin 21/2 slide on the bearing surfaces of the cylinder.

Measure the cylinder bearing surface at at least 3 different spots:

at top dead centre, in the middle, at approx. 10 mm. from the

foot of the cylinder.

Please note:

The internal measuring gauge is to be adjusted, prior to its

application, to the "ORIGI AL" diameter, this adjustment being

carried out with the aid of a gauge ring or a micrometer.

(See Table of Original and Oversize groups on page 18). Should

the wear exceed the adjusted ORIGI AL size by 0.15 mm. or

more, the cylinder and the piston have to be exchanged.

21 Measuring the cylinder

Workshop Manual Heinkel Tourist 103 A-1 page 18

Please note:

Size groups are marked on the cylinders of new HEI KEL ve-

hicles, these marks are to be found opposite to the push rod

channel.

Size groups of new vehicles are marked opposite to the push rod

channel, size groups of oversize cylinders on the left- and/or

right-hand side of the cylinder top.

9. For further assembly proceed as explained under "Reassembl-

ing of Piston, Cylinder and Cylinder Head", page 12, para-

graphs 1-12.

Table for original and oversize groups

Cylinder Piston

ew vehicles Oversize Size Groups Tolerance

normal Y X W

0

0 - 0.010 59.94 Ø

0

1 + 0.010 59.95 Ø

+ 0.010

2 + 0.020 59.96 Ø

+ 0.020

60.0 Ø

3 + 0.030 59.97 Ø

0

0 - 0.010 60.04 Ø

0

1 + 0.010 60.05 Ø

+ 0.010

2 + 0.020 60.06 Ø

+ 0.020

60.1 Ø

3 + 0.030 60.07 Ø

0

0 - 0.010 60.44 Ø

0

1 + 0.010 60.45 Ø

+ 0.010

2 + 0.020 60.46 Ø

+ 0.020

60.5 Ø

3 + 0.030 60.47 Ø

0

0 - 0.010 60.94 Ø

0

1 + 0.010 60.95 Ø

+ 0.010

2 + 0.020 60.96 Ø

+ 0.020

61.0 Ø

3 + 0.030 60.97 Ø

Other manuals for 103 A-1

1