Heli-Professional REVOLUTION 500E User manual

REVOLUTION 500E RTF

Manual v

1.0

CONTENTS

Page

Introduction

2

Product Contents

2

Specifications

3

General Safety Instructions

3

Flight Battery Safety Instructions

3-4

Checklist Maiden Flight

4

Checklist Regular Flights

4-5

Charging the Flight Battery

5

Insert the Batteries in the Transmitter

6

Inserting the Flight Battery

6

Transmitter Settings

6-9

Control Test

9-12

Control Functions During Flights

13-16

Preparing the Maiden Flight

17

Adjusting the Rotor Blade Tracking

17

Manual Xelaris 80A Brushless ESC

18-19

Assembly instructions Revolution 500E

21-40

©Heli-Professional 2012

www.heli-professional.com

2

Dear

Customer,

thank you for choosing the

Revolution 500E RTF helicopter.

PLEASE READ THIS MANUAL CAREFULLY BEFORE THE INITIAL STARTUP.

The Revolution 500E Ready To Fly is a high performance model helicopter that was specifically designed for beginners

with sufficient experience of pitch-controlled models. The helicopter is completely assembled, tested and ready for

use. The model is equipped with high-quality RC components. Besides a 4S 4250mAh lithium polymer battery, digital

servos, a brushless motor, a 2.4 GHz transmitter with receiver and the Xelaris Flybarless-3X System (FBL-3X) are in-

cluded.

Due to its various settings, the model is extremely versatile and offers setups for the individual needs of every pilot.

Since piloting a remote controlled model helicopter is very complex, we strongly recommend taking model helicopter

flight lessons or using a flight simulator when you are a beginner.

Although the Revolution 500E is a Ready To Fly model, we also strongly recommend to read this manual carefully.

Please don’t hesitate to contact your local dealer if you have any questions.

Product Contents

Revolution 500E RTF

FBL

-3X flybarless system

520mm GFK

main rotor blades

Digital swash plate and tail rotor servos with plastic

gearing

85mm

tail rotor blades

4S 4250mAh

battery

Bicolor plastic canopy

X

-4DC charger

4S 1300kv

brushless motor

2.4GHz

Transmitter and receiver

4S LiPo Brushless

ESC

www.heli-professional.com

3

Specifications

Main rotor diameter

:

approx

. 1200 mm

Take

-off weight:

approx

. 2800 g

Height

:

approx

. 340 mm

Length

:

approx

. 1100 mm

Tail rotor diameter

:

approx

. 235 mm

LiPo

battery:

4S 4250 mAh

General Safety Instructions

A model helicopter is a very powerful flying device and not a toy. Disregarding our instructions, inappropriate use,

and insufficient maintenance by persons lacking necessary competence may result in injuries for the user and can

cause damage to the surroundings and to materials. Therefore, we strongly recommend to get insurance. Children

and juveniles should operate a model helicopter only under supervision of an experienced adult.

Make sure that all necessary batteries for regular flights are fully charged. Do not fly on public roads, in residential

areas or close to people. Contact with rotating blades can cause severe injuries or even death.

Heli Professional will not accept responsibility for any damage caused by products of the delivery program and

rejects any liability, as we are not in a position to supervise proper operation, handling, and maintenance by the

user. Furthermore, we ask you to follow our operating instructions carefully and to use only original Heli Profes-

sional parts.

Flight Battery Safety Instructions

Inappropriate use can cause lithium polymer batteries to burn, explode, and release toxic gas which

can cause severe burns and poisoning.

Heli Professional will not accept responsibility for any damage caused by inappropriate use and rejects

any liability, as we are not in a position to supervise proper operation, handling, and maintenance. You are also

obliged to comply to the safety regulations in dealing with lithium polymer batteries. If you disagree with these

safety regulations, we kindly ask you to return the helicopter boxed as new and in unused condition to your dealer.

·Charge and store the battery ALWAYS in a non-flammable environment resp. in a fireproof container (e.g. LiPo-

bag), which prevents a flashover in case of a battery ignition.

·Never charge the battery unattended.

·The battery must always be charged outside the helicopter model. Therefore, remove the battery including the

battery plate from the model.

·Only use the battery in combination with the included charger. Other uses are prohibited.

·Always store the battery in a dry and dark environment at room temperature. Never expose the battery to direct

insolation or intense heat. When transporting the battery, the temperature must be between +10°C and +35°C.

Never store the battery in your vehicle as it may catch fire or explode due to heat development in the interior.

·Should the battery bloat during the charging or discharging process, disconnect the charger or the ESC immedi-

ately from the battery. Danger of fire! A bloated battery can never be used again and must be disposed properly.

·In case of a crash: Disconnect the battery as fast as possible from the ESC. Make sure the battery doesn’t bloat

and check it for mechanical damages. Store the battery in a LiPo-bag or outside. The battery can still catch fire

even after several hours.

·Keep the battery away from children and unauthorized persons.

·Let the battery cool down after each flight and before every charge.

www.heli-professional.com

4

·The battery must neither be overcharged nor exhausted. The battery is totally damaged and cannot be used an-

ymore in case of an exhaustive discharge. Therefore do not exceed following flight times:

Flight Style

3D Mode

Max. Flight Time*

Hover

Off

6.5 Minutes

Basic Flight

Off

5.5 Minutes

Aerobatics

On

4 Minutes

* Please note: the max. flight time will be shorter in cold condition or with old batteries.

·Heli Professional will not accept responsibility for any damage or secondary failures caused by inappropriate use

and rejects any liability, as we are not in a position to supervise proper operation, handling, and maintenance.

Checklist Maiden Flight

Attention: This checklist is supposed to give you a short overview of the preparations for the maiden flight and does

not replace the contents of this manual.

·Unbox and check all parts for damage.

·Check if all screws are fully tighten

·Check if all connectors are plugged in securely

·The main blade screws must be tightened until the blades can only be moved with a lot of force

·Charge the battery with the included charger according to the instructions. Notice the safety instructions and pay

attention to the correct polarity of the charger, the balancer and the ESC of the model.

·Insert AA batteries into the Transmitter. Do not change the settings of the transmitter in any way!

·Position and tighten the fully charged battery according to the picture on the battery plate with the included

hook and loop fasteners and secure it with O-rings in the helicopter model.

·Secure the balancer plug under the hook and loop fastener according to the picture.

·Test all functions of the model. The FBL-3X system and the transmitter are already programmed. No further set-

tings are required.

·The initial startup should be done on an appropriate airfield. Local clubs generally offer the best possibilities for

safe and fun helicopter flying.

Checklist Regular Flights

Attention: This checklist is supposed to give you a short overview of regular flights and does not replace the contents

of this manual.

·Check all connections and screws before every flight

·Secure the battery with O-rings in the battery rails and connect the ESC with the battery.

www.heli-professional.com

5

·To avoid the main blades from fold together when starting or landing, the main blade screws must be tighten

very hard, so that the blades can only be moved with a lot of force. If the main blades fold together, they start an

extreme vibration which can destroy the helicopter! If this happens, due to less tightened main blade screws, it

can be stopped by pushing the pitch stick hard and fast to positive pitch (Motor must be cut off!). If you do this,

you can avoid the helicopter from destroying itself.

·Always switch on the transmitter first! Throttle/pitch stick and other switches must be set on their zero position

beforehand!

·Wait until the ESC and the FBL-3X system have initialized. The FBL-3X system has initialized when the swash plate

has rotated once. The helicopter must stand absolutely still and leveled during this procedure.

·Check the function of all servos (direction of movement, etc.). Therefore, put the autorotation switch in the po-

sition “lock”. This prevents the motor from running unintendedly.

·Fly with your model.

·Start the landing procedure before the battery is low.

·Disconnect the ESC from the battery and switch off the transmitter finally.

Charging the Flight Battery

Charge the 4S 4250mAh lithium polymer battery only with the included charger, which is optimally

adjusted to charge and balance the battery. Disregarding this procedure may cause damage to the bat-

tery, the charger and the immediate environment (danger of fire). Never charge the battery unattended!

We recommend to charge and store the battery in a non-flammable environment (e.g. LiPo-bag). Pay attention to

the correct polarity when connecting the charger and the balancers with the battery.

Power supply:

·12V car battery: Use a 12V lead gel battery to connect directly to the charger (no power adaptor necessary).

·230V power supply: Use the charger only with an appropriate power adaptor (Not included. Ord. no. 01.1378

and 01.1376).

Charging the battery:

1. Disconnect the battery from the ESC and remove the battery with the battery plate from the model.

2. Connect the charger first with the 12V power supply. All LEDs must blink red and green.

3. Now connect the battery with the charger and the balancer plug of the battery with the balancer socket of the

charger according to the picture. The LEDs are blinking red.

4. Choose the charging current with the knob (recommendation: 4.5A).

5. Press the start button. All LEDs must glow red.

6. When the charging is finished, you will hear a whistling sound and all LEDs must glow green.

7. Disconnect the battery from the charger and disconnect the charger from the power supply.

www.heli-professional.com

6

Insert the Batteries in the Transmitter

Insert 8 AA batteries (not included) into the 2.4 GHz transmitter. Pay attention to the correct polarity. Check the pow-

er level of the batteries on the voltage display. Change the batteries immediately when the voltage is too low and the

acoustic warning signal sounds.

Inserting the flight battery

Slide the battery plate including the flight battery into the battery rails of the front porch and secure it with O-rings.

Sliding in the battery plate. Securing the battery plate with O-rings.

Transmitter settings

Do not change any settings or the programming of the transmitter. All settings are optimally configured ex works.

Any changes whatsoever are at your own risk. Heli Professional will not accept responsibility for damages or any

secondary failures.

Two throttle curves are programmed ex works: a hovering/normal flight curve (switch position “Normal”) and a

3D/stunt flight curve (switch position “3D”).

Hovering/Normal Flight Mode (Pitch Range -5°/+12°): When switching

on the transmitter or starting the model, always put the pitch stick in

its lowest position. If you tilt the pitch stick slowly upwards, the collec-

tive pitch angle of the main blades will increase, and the helicopter will

start to climb. If you lower the pitch stick, the collective pitch angle of

the main blades will decrease and the helicopter will start to descent.

www.heli-professional.com

7

Never change the stick positions of the aileron, elevator and rudder stick while the helicopter lifts off! You are only

allowed to actually pilot the helicopter after it has lifted off from the ground completely. Otherwise, the gyro stabi-

lizer system can be interfered.

3D/Stunt Flight Mode (Pitch Range -12°/+12°): In contrast to the hovering/normal flight mode, the maximum nega-

tive pitch range is -12°. This means that you have a collective pitch angle of 0°in the mid-position of the pitch stick. So,

when switching on the transmitter or starting the model, always put the pitch stick in a position some degrees below

the mid-position. If you tilt the pitch stick slowly upwards, the collective pitch angle of the main blades will increase,

and the helicopter will start to climb. If you lower the pitch stick towards the mid-position, the collective pitch angle of

the main blades will decrease and the helicopter will start to descent. If you lower the pitch stick below the mid-

position, the collective pitch angle of the main blades (in the negative direction) will increase again and you are able to

fly loops, rolls and 3D maneuvers.

Never change the stick positions of the aileron, elevator and rudder stick while the helicopter lifts off! You are only

allowed to actually pilot the helicopter after it has lifted off from the ground completely. Otherwise, the gyro stabi-

lizer system can be interfered.

Do not toggle between the flight modes during 3D flights or normal flights. Set the pitch stick in mid-position and

hover or land the helicopter to toggle between the flight modes!

Autorotation: Set the autorotation switch during regular flights to

“Unlock”. Otherwise, the motor will not run.

If you want to initiate an autorotation, put the autorotation switch

into the “Lock” position. The motor will immediately stop running

and you land the helicopter with the residual energy of the rotor

blades.

Attention: An autorotation is a difficult maneuver, needs training

and should not be performed by beginners!

If you lose control of the helicopter and a crash is imminent, use

the autorotation switch to stop the motor from running. This will

reduce the damage on the model.

For safety reasons: Always put the autorotation switch into the

“Lock” position when you perform a function control, change

settings, carry the helicopter, etc. This avoids the motor from unintentional starting which can lead to serious inju-

ries.

Dual Rate: The “Dual Rate” switch limits the servo deflection. Limit-

ing the servo deflection can be helpful to get used to the model and

to avoid oversteering.

This helpful function has already been programmed: If you put the

D/R switch into position “0”, the servo deflections are not limited

(100% servo deflection). If you put the D/R switch into position “1”,

the servo deflections are limited to 80%. We recommend beginners

to limit the servo deflection to 80%.

www.heli-professional.com

8

Standard Transmitter Configuration

Menü 1

Menü SET

Menü CUV

Mode

Helimode

D/R Channel 1

80%

Throttle Normal

0-25- 65-84-100

Model Nr.

1 of 12

D/R Channel 2

80%

Pitch Normal

35-43-50- 75-100

Menü Reverse

D/R Channel 4

100%

Throttle 3D

100-87-80-87-100

Kanal 1

Normal

Expo Channel 1

25%

Pitch 3D

0-25-50-75-100

Kanal 2

Reverse

Expo Channel 2

25%

Menü PLS

Kanal 3

Normal

Expo Channel 4

25%

Timer Start

20%

Kanal 4

Reverse

Endpoint 1 –6

Individuell

Mode

2

Kanal 5

Normal

Gyro U

40%

Kanal 6

Reverse

Gyro D

40%

1

2

3

4

5

6

7

8

9

10

11

12

13

1

1

2

3

2

4

2

4

2

5

2

6

2

7

2

8

2

9

2

10

11

12

13

Keys:

www.heli-professional.com

9

Gyro Sensitivity: The “CH 5” switch controls the gyro sensitivity. 40%

sensitivity is factory-adjusted which turned out to be the perfect ad-

justment for all flight modes. So, both switch positions are set to the

same value and you are not allowed to change this setting. The switch

position is irrelevant.

Control Test

Although the helicopter was mounted, adjusted and tested ex works, it is necessary to check all functions of the mod-

el to exclude any damages that might have arisen during the transport. Before you start the function test, you have to

adjust the steering mode configuration. There are two options to choose from: Mode 1 and Mode 2. Mode 2 is the

default configuration. If you want to change the mode, see the included transmitter manual for detailed instructions.

Mode 2:

The left stick controls collective pitch/throttle (climb/sink) and rud-

der/tail rotor pitch (left/right).

The right stick controls the swash plate movements, i.e. elevator

(forwards/backwards) and aileron/roll (left/right).

www.heli-professional.com

10

Mode 1:

The left stick controls the swash plate movements, i.e. elevator

(forwards/backwards) and aileron/roll (left/right).

The right stick controls collective pitch/throttle (climb/sink) and

rudder/tail rotor pitch (left/right).

The following control test is explained on the basis of mode 2! If you use mode 1, the control commands change

accordingly.

Place the helicopter on a flat surface and position yourself in a way that you can look at the model from all angles.

1. It is absolutely necessary to disconnect the plugs between motor and ESC.

Rudder

(left)

Rudder

(right)

Aileron /

Roll

(left)

Aileron /

Roll

(left)

www.heli-professional.com

11

2. Put the pitch/throttle stick into its lowest position and switch on the transmitter.

3. Connect the flight battery and the ESC and wait until both the ESC and the FBL-3X have initialized.

4. Put the autorotation switch into the position “Lock”!

5. Move the pitch stick all the way up and down and check the vertical movement of the swash plate on the main

rotor shaft as well as the ease of movement of all linkage rods.

Mode 2: Topmost position of the pitch/throttle stick Mode 2: Lowest position of the pitch/throttle stick.

(seen from the left side in direction of flight). (seen from the left side in direction of flight).

6. Check the rudder/tail rotor pitch function by moving the stick all the way from left to right. Check the ease of

movement of the tail pitch control lever on the tail rotor shaft. When you move the stick to the left, the tail pitch

control lever must move to the right and vice versa.

Mode 2: Left position of the rudder/tail rotor pitch stick. Mode 2: Right position of the rudder/tail rotor pitch stick.

www.heli-professional.com

12

7. Move the elevator stick all the way up and down and check the tilt direction of the swash plate. When you move

the stick forwards, the swash plate must tilt forwards (in the direction of flight) and vice versa.

Mode 2: Topmost position of the elevator stick (seen Mode 2: Lowest position of the elevator stick (seen

from the left side in direction of flight). from the left side in direction of flight).

8. Move the aileron/roll stick all the way from left to right and check the tilt direction of the swash plate. When you

move the stick to the left, the swash plate must tilt to the left (in the direction of flight) and vice versa.

Mode 2: Left position of the aileron stick (seen from Mode 2: Right position of the aileron stick (seen from

behind the swash plate in direction of flight). behind the swash plate in direction of flight).

www.heli-professional.com

13

Control Functions During Flights

This chapter explains the basic control/steering functions of the helicopter based on Mode 2.

In general

:Steering one of the four control functions (e.g. pitch/throttle) does always lead to a change in t

he overall

flight position of the model. This means that you always have to

steer the other three control functions according

ly

to keep the helicopter in the desired flight position.

Important:

Steering the rudder/tail rotor pitch function changes the position of the tail boom, but in fact, you a

l-

ways steer the nose of the model

(see rudder/tail rotor pitch function for more details).

Pitch/Throttle Function

If you move the pitch/throttle stick forwards, the main rotor blade angle will change and the helicopter will climb. If

you move the pitch/throttle stick backwards, the main rotor blade angle will change and the helicopter will descend.

Rudder/Tail Rotor Pitch Function

If you move the rudder/tail rotor pitch stick to the left, the tail blade angle will change and the helicopter will turn

around its vertical axis. Consequently, the nose of the helicopter will turn to the left in the direction of flight.

www.heli-professional.com

14

If you move the rudder/tail rotor pitch stick to the right, the tail blade angle will change and the helicopter will turn

around its vertical axis. Consequently, the nose of the helicopter will turn to the right in the direction of flight.

Elevator Function

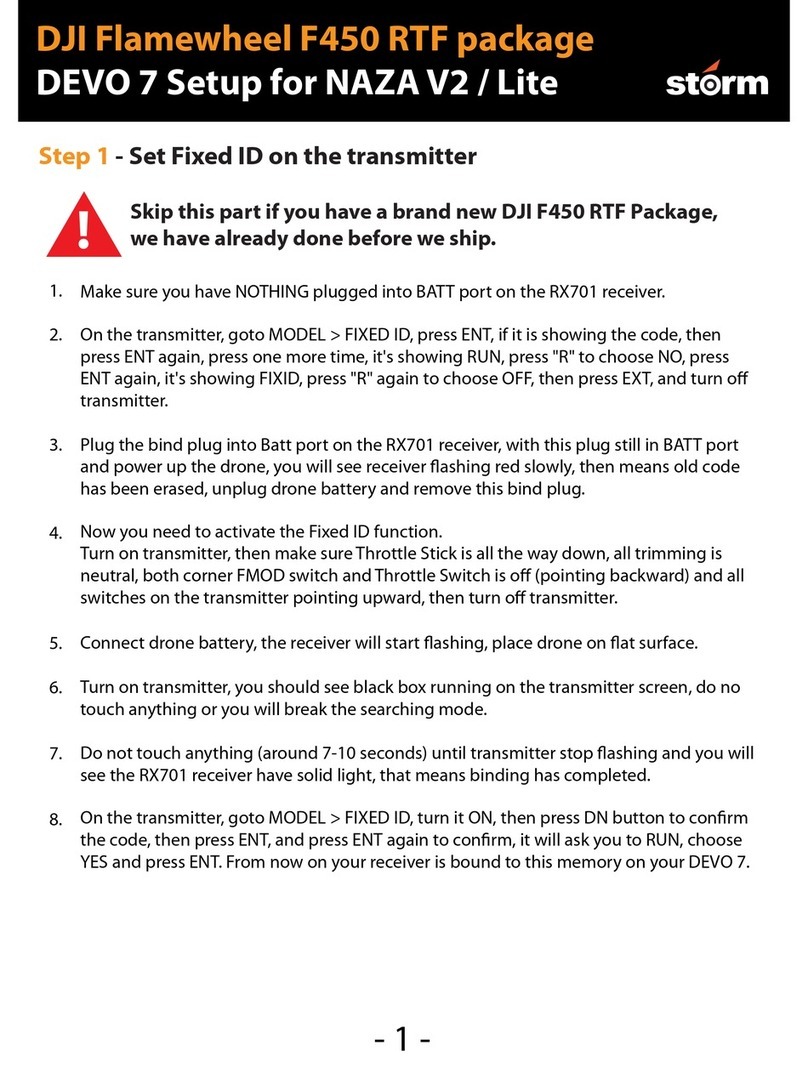

If you move the elevator stick forwards, the main rotor blade angle will change and the helicopter will turn around its

lateral axis. Consequently, the helicopter will tilt forwards and fly forwards.

If you move the elevator stick backwards, the main rotor blade angle will change and the helicopter will turn around

its lateral axis. Consequently, the helicopter will tilt backwards and fly backwards.

www.heli-professional.com

15

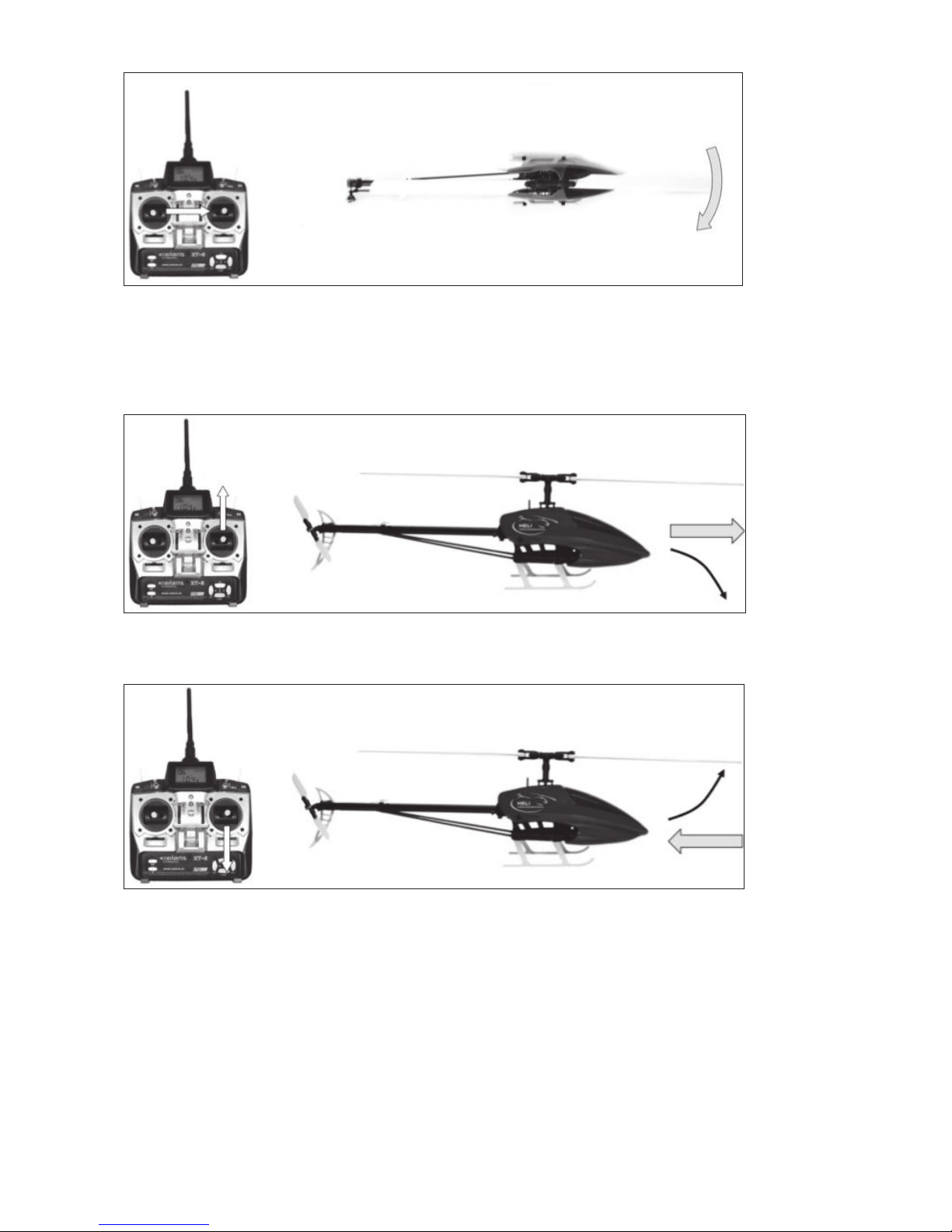

Aileron/Roll Function

If you move the aileron/roll stick to the left, the main rotor blade angle will change and the helicopter will turn around

its longitudinal axis. Consequently, the helicopter will tilt and fly to the left.

If you move the aileron/roll stick to the right, the main rotor blade angle will change and the helicopter will turn

around its longitudinal axis. Consequently, the helicopter will tilt and fly to the right.

www.heli-professional.com

16

Trim Functions

The trim functions allow you to adjust the flight characteristics and to avoid an unintended drift of the helicopter via

the longitudinal and lateral axis. Do not trim the rudder/tail rotor pitch because this is done automatically by the

gyro system. However, should the tail rotor drift away unintentionally, switch off the helicopter, disconnect all

plugs and then, reconnect all plugs so that the ESC and the FBL-3X gyro system can initialize again.

Nevertheless, the helicopter will never remain absolutely stable in its hovering position even with a perfect trimming.

A steady correction of all control functions is always necessary to keep the helicopter in the intended flight position.

Mode 2: Hovering/Normal Flight Mode and 3D/Stunt Flight Mode: Trimming the

pitch/throttle is never necessary. Leave the slide control in mid-position.

Mode 2: Use the elevator trim slide control if the helicopter drifts forwards or back-

wards when hovering with no elevator stick input.

Mode 2: Use the aileron/roll trim slide control if the helicopter drifts to the left or

right when hovering with no aileron/roll stick input.

www.heli-professional.com

17

Preparing the Maiden Flight

Although the helicopter was mounted, adjusted and tested ex works, it is necessary to check the following functions.

·Check the tail drive belt tension: It is sufficiently tense when you can push it down max. 5 mm in the tail rotor

housing with normal force. Check the tension regularly. Tensing the tail drive belt: Loosen both M3x20 mm bolts

of the tail boom housing in the frame. Loosen the M3x35 mm bolt of the stabilizer fin. Tense the tail drive belt by

pulling the tail boom backwards. Level the tail boom exactly horizontally and tighten all bolts again. A too loose

or too tense tail drive belt can wear out quickly or can even jump out of its guidance (failure of the tail rotor).

·Check the fastenings of all electronical parts and the wiring. Cables must not come in contact with rotating parts.

·Check the main and tail rotor blades for firm seating. Tighten the blades until they can only be moved with a lot

of force.

·Check all bolts for firm seating. Tighten loose bolts if necessary.

·All bolts must always be secured with thread lock!.

You are finally ready for the maiden flight with your new Revolution 500E RTF.

Adjusting the Rotor Blade Tracking

Although the rotor blade tracking was adjusted ex works, it is absolutely necessary to check it during the maiden flight

and on a regular basis afterwards. In addition, you must adjust the rotor blade tracking after every crash. If the main

blades are running out of track, vibrations, loss of power and instability will be the result. Hence, adjusting the rotor

blade tracking is a crucial process and should be done with special diligence.

Attention: Adjusting the rotor blade tracking is executed with rotating blades. Always keep a safety distance of at

least 10 m between you and the model.

1. Switch the model on and bring the rotor blades to hovering speed. If both blades are running at one level, no

further adjustments will be necessary.

2. If you see two rotor blade levels (as in the illustration below), adjustments will be necessary.

3. Switch the model off and wait until the blades stop to rotate. Mark one rotor blade with thin, colored duct tape

or a clearly visible, colored pen.

4. Switch the model on again and bring the rotor blades to a hovering speed. You can either check the rotor blade

tracking on the ground or in the air at approximately eye level. It is useful to have an assistant who eyeballs the

rotor blade tracking. By targeting the marked rotor blade, you can easily spot whether the rotor blade is running

out of track upwards or downwards.

5. Bring the rotor blades to a standstill.

6. A: The rotor blade, which runs out of track upwards, has too much pitch. This means that you have to shorten

the pitch linkage rod between the blade holder and the swash plate by screwing in one ball link for one full rota-

tion. Never screw in the ball link for only half a rotation!

7. B: The rotor blade, which runs out of track downwards, has not enough pitch. This means you have to lengthen

the pitch linkage rod between the blade holder and the swash plate by unscrewing one ball link for one full rota-

tion. Never unscrew the ball link for only half a rotation!

Change the lengths of the linkage rods only on one rotor blade at a time and check the rotor blade tracking

again.

8. Repeat this procedure until the rotor blade tracking is adjusted almost perfectly. Minimal deviations do not com-

promise the flight characteristics.

Manual xelaris 80A Brushless ESC

www.heli-professional.com

18

Thanks for purchasing a Xelaris Brushless Electronic Speed Controller (ESC). High power system for RC model is very dangerous,

please read this manual carefully. In that we have no control over the correct use, installation, application, or maintenance of

our products, no liability shall be assumed nor accepted for any damages, losses or costs resulting from the use of the product.

Any claims arising from the operating, failure or malfunctioning etc. will be denied. We assume no liability for personal injury,

property damage or consequential damages resulting from our product or our workmanship. As far as is legally permitted, the

obligation to compensation is limited to the invoice amount of the affected product.

Specifications:

Current: 80A

Peaks: 100A

BEC: Switch BEC

BEC output: 5V –4A

Cells: 2 –4 LiPo Cells / 5 –12 NiMH Cells

Weight: 82g

Size (L x W x H) 86x38x12

Programmable Items (The option written in bold font is the default setting):

1. Brake Setting˖Enabled / Disabled

2. Battery Type˖Lipo / NiMH

3. Low Voltage Protection Mode(Cut-Off Mode): Soft Cut-Off (Gradually reduce the output power) /Cut-Off (Immediately stop

the output power)

4. Low Voltage Protection Threshold(Cut-Off Threshold)˖Low / Medium / High

1) For lithium battery, the battery cell number is calculated automatically. Low / medium / high cutoff voltage for

each cell is: 2.85V/3.15V/3.3V. For example: For a 3S Lipo, when “Medium” cutoff threshold is set, the cut-off

voltage will be: 3.15*3=9.45V

2) For NiMH battery, low / medium / high cutoff voltages are 0%/50%/65% of the startup voltage (i.e. the initial

voltage of battery pack), and 0% means the low voltage cut-off function is disabled. For example: For a 10 cells

NiMH battery, fully charged voltage is 1.44*6=8.64V, when “Medium” cut-off threshold is set, the cut-off voltage

will be:8.64*50%=4.32VDŽ

5. Startup Mode˖Normal /Soft /Super-Soft (300ms / 1.5s / 3s)

Normal mode is suitable for fixed-wing aircraft. Soft or Super-soft modes are suitable for helicopters. The initial acceleration of

the Soft and Super-Soft modes are slower, it takes 1.5 second for Soft startup or 3 seconds for Super-Soft startup from initial

throttle advance to full throttle. If the throttle is completely closed (throttle stick moved to bottom position) and opened again

(throttle stick moved to top position) within 3 seconds after the first startup, the re-startup will be temporarily changed to

normal mode to get rid of the chance of a crash caused by slow throttle response. This special design is suitable for aerobatic

flight when quick throttle response is needed.

6. Timing˖Low / Medium / High,( 3.75°/15°/26.25°)

Usually, low timing is suitable for most motors. To get higher speed, High timing value can be chosen.

Begin to use your ESC

IMPORTANT! Because different transmitter has different throttle range, please calibrate throttle range before flying.

Throttle range setting: (Throttle range should be reset whenever a new transmitter is being used)

Normal startup procedure:

Protection Function

1. Start up failure protection: If the motor fails to start within 2 seconds of throttle application, the ESC will cut-off the output

power. In this case, the throttle stick MUST be moved to the bottom again to restart the motor. (Such a situation happens in

the following cases: The connection between ESC and motor is not reliable, the propeller or the motor is blocked, the gearbox

is damaged, etc.)

2. Over-heat protection: When the temperature of the ESC is over about 110 Celsius degrees,the ESC will reduce the output

power.

3. Throttle signal loss protection: The ESC will reduce the output power if throttle signal is lost for 1 second, further loss for 2

seconds will cause the output to be cut-off completely.

Move throttle stick

to bottom position

and then switch on

transmitter.

Connect battery pack to

ESC, special tone like

“123”means power

supply is OK

When self-test is

finished, a long

“beep-----”tone

should be emitted

Move throttle stick

upwards to

go flying

Several “beep-”tones

should be emitted to

present the amount of

lithium battery cells

Switch on the

transmitter,

move throttle

stick to the top

position

Connect battery

pack to the ESC,

and wait for

about 2 seconds

The “Beep-Beep-”tone

should be emitted,

means the top point of

throttle range has been

confirmed

Move throttle stick to the

bottom position, several

“beep-”tones should be

emitted to present the

amount of battery cells

A long “Beep-”tone

should be emitted,

means the lowest point

of throttle range has

been correctly confirmed

Manual xelaris 80A Brushless ESC

www.heli-professional.com

19

Trouble shooting

Program the ESC with your transmitter (4 Steps)

Note: Please make sure the throttle curve is set to 0 when the

throttle stick is at bottom position and 100% for the top position.

1. Enter program mode

2. Select programmable items

3. Set item’s value (Programmable value)

4. Exit program mode

Trouble

Possible Reason

Action

After power on, motor does not work, no

sound is emitted

The connection between battery pack

and ESC is not correct

Check the power connection.

Replace the connector.

After power on, motor does not work, such

a

n alert tone is emitted:

“beep

-beep-, beep-beep-,beep-beep-”

(Every “beep

-beep-

” has a time interval of

about 1 second)

Input voltage is abnormal, too high or

too low.

Check the voltage of battery pack

After power on, motor does not work, such

an al

ert tone is emitted:

“beep

-, beep-, beep- ”(Every “beep-

” has a

time interval of about 2 seconds)

Throttle signal is irregular

Check the receiver and transmit-

ter

Check the cable of throttle chan-

nel

After power on, motor does not work, such

an alert tone

is emitted:

“beep

-, beep-, beep-” (Every “beep-

” has a

time interval of about 0.25 second)

The throttle stick is not in the bottom

(lowest) position

Move the throttle stick to bottom

position

After power on, motor does not work, a

special tone “

” is

emitted after 2

beep tone (beep-beep-)

Direction of the throttle channel is

reversed, so the ESC has entered the

program mode

Set the direction of throttle

channel correctly

The motor runs in the opposite direction

The connection between ESC and the

motor

need to be changed.

Swap any two wire connections

between ESC and m

otor

1. Enter program mode

1)

Switch on transmitter, move throttle stick to top

position, connect the battery pack to ESC

2) Wait for

2 seconds, the motor should emit special

tone like “beep-beep-”

3)

Wait for another 5 seconds, special tone like

“” should be emitted

, which means

program mode is entered

3. Set item value (Programmable value):

You will hear several tones in loop. Set th

e value matching to a tone by moving throttle stick to top

when you hear the tone, then a special tone “

” emits, means the value is set and saved.

(Keeping the throttle stick at top, you will go back to Step 2 and you can select other items; or

moving the stick to bottom within 2 seconds will exit program mode directly)

Tones

Items

“beep-”

1 short tone

“beep-beep-”

2 short tones

“beep-beep-beep”

3 short tones

Brake

Off

On

-

Battery type

Lipo

NiMH

-

Cutoff mode

Soft-Cut

Cut-Off

-

Cutoff threshold

Low

Medium

High

Start mode

Normal

Soft

Super soft

Timing

Low

Medium

High

2. Select programmable items:

After entering program mode, you will hear 8 tones in a loop with

the following sequence. If you move the throttle stick to bottom

within 3 seconds after one kind of tones, this item will be selec

t-

ed.

1. “beep” brake (1 short tone)

2. “beep-beep- battery typ (2 short tone)

3. “beep-beep-beep-”cutoff mode (3 short tone)

4. “beep-beep-beep-beep-”cutoff threshold (4 short tone)

5. “beep-----”startup mode (1 long tone)

6. “beep-----beep-”timing

(1 long 1 short)

7. “beep-----beep-beep-”set all to default

(1 long 2 short)

8. “beep-----beep-----”exit (2 long tone)

4. Exit program mode

There are 2 ways to exit

program mode:

1.

In step 3, after

special tone “

”,

please move

throttle stick to the

bottom position

within 2 seconds.

2.

In step 2, after tone

“beep-----beep-----

”(ie.The item #8),

move throttle stick

to bottom within 3

seconds.

Other manuals for REVOLUTION 500E

3

Table of contents