HELI CPC 20 User manual

FORWARD

The performance, structure, operation and maintenance and other aspects of the K

series 2-3.8t forklift truck are described in this manual in order to guide the operators

to use and maintain the truck properly.

The rules and notices in the manual should be abided seriously by all of relative

person to enable trucks in optimized working state for long period and bring the

highest efficiency.

CONTENTS

FORWARD

I.Driving Operation and Daily Maintenance of Forklift Truck

1. Transport of forklift truck

2. Storage of forklift truck

3. Precautions before operation

4. Operation of forklift truck

5.Cautions on cooling system

6. Oil for forklift truck

7. Lubrication chart

II.Specifications of Forklift Truck

III.Description of Main Parts of Forklift truck

IV.Construction, Principle, Adjustment and Maintenance of Forklift Truck

1. Power system

2. Clutch and clutch pedal

3. Transmission, reduction gear and differential

4. Hydraulic-powered transmission & torque converter

5.Drive axle

6. Steering system

7. Steering axle with lateral positional cylinder

8. Brake system

9. Hydraulic system

10. Lifting system

11. Electric system

1

1

1

1

2

3

5

6

7

10

11

11

14

17

31

41

44

48

52

70

89

92

I.Driving Operation and Daily Maintenance of Forklift Truck

It is important that driving and managing persons for forklift trucks remember

the principle of the“first safety”and ensure the safety operation as the description of

《Operation and Service Manual》.

1. Transport of Forklift Truck

Pay attention to the following items when you transport forklift trucks with

container or trucks:

(1)Apply the parking brake.

(2)Fix the mast and the balance weight with steel wire. Wedge up all wheels.

(3)Sling points should be always at the positions specified in sling index plate

when hoisting up the forklift truck.

2. Storage of Forklift Truck

(1)Drain off fuel completely. Don't drain off the cooling water containing

antifreeze and rustproof agent.

(2)Apply antirust to the surface of the parts not painted. Apply lubrication oil to

the lift chain.

(3)Lowing the mast to the lowest position.

(4)Apply the parking brake.

(5)Wedged up the wheels.

3. Precautions before Operation

(1)Don't check fuel leakage and level or instruments at the place there is open

flame. Never fill the fuel tank with the engine running.

(2)Check the tire inflation pressure.

(3)The forward-reverse lever should be in neutral.

(4)Never smoke while the fuel system is under working or the battery is

inspected.

(5)Check all the levers and pedals.

(6)Complete the provisions before starting.

-1-

(7)Release the parking brake.

(8)Make trial of the mast for lifting, lowing and forward and backward tilting

and the truck for steering and braking.

(9)The contamination level of the hydraulic oil should be lower than 12 as

described in NAS 1638.

4. Operation of Forklift Truck

(1)Only trained and authorized operator shall be permitted to operate the truck.

(2)Wear all the safety guards, such as shoes, helmet, clothing and gloves while

operating the truck.

(3)Check all the control and warning devices before staring the truck. If any

damages or defects are found, operate it after repairing.

(4)The goods handled should not exceed the rated capacity of the truck. Insert

forks deeply under goods and make the loads distribute on the forks evenly. Don't pick

the loads with one fork tip.

(5)The starting, turning, driving, braking and stopping of the truck should be

done smoothly. When steering on the humid or low friction road, the truck should be

decelerated.

(6)Travel with loads as low as possible and tilted backward.

(7)Be careful when traveling on a slope. When climbing grade with a slope more

than 10%, the truck should travel forward, and when descending so grade, backward

travel. Never turn on a slope. Avoid loading and unloading operation when

descending.

(8)Pay attention to pedestrian, obstacle and bumpy road when driving. Pay

attention to the clearance over forklift truck.

(9)Never allow any person(s) to stand on the forks or the truck to carry person.

(10)Never permit anyone to stand or walk under upraised forks.

(11)Don't operate truck and attachment at any position out of the driver seat.

(12)On the high lift forklift truck with the lift more than 3m, it is noted that the

-2-

goods on it should not fall down or the protection measures be taken if necessary.

(13) Tilt the mast of the high lift forklift truck as backward as possible when the

truck works. Use minimum forward and reverse tilt when loading and unloading.

(14)Be careful and slowly driving over a dockboard or bridge-plate.

(15)Shut down the engine and don't stay on the truck when filling fuel. Don't

ignite the engine when checking battery or fuel lever.

(16)The unloaded forklift truck with attachment(s) should be operated as a

loaded truck.

(17) Don't handle unfixed stacked goods. Be careful to balky goods to be

handled.

(18) When leaving lower the forks on the ground and let the shift lever to neutral,

shut down the engine or cut down electric supply. If parking on a grade is unavoidable

apply the parking brake and block the wheels.

(19) Don't open the radiator cap when the engine is warm.

(20) Don't adjust the control valve and relief valve at will to prevent the damage

of hydraulic system and its components because of excessive pressure passing them.

(21) Tyres should be inflated according to the pressure valve specified in the

mark plate of “Tyre pressure”.

(22) According to the measure method specified in JB/T 3300. Max. noise at the

outboard of the truck should be not more than 89dB(A).

5. Cautions on Cooling System

Cooling system which is filled with HELI exclusive coolant free from

maintenance normally before leaving the factory is used to cool engine and hydraulic

powered transmission unit (hydraulic powered type forklift truck). The coolant filled

in the truck can not only protect the truck against freezing above -35℃, but also

protect the cooling system from corrosion, scale-forming and increase the coolant

boiling point remarkable. So the coolant concentration will not be reduced even in the

warm season or area because of water replenishing. If greater anti-freezing protection

-3-

is needed considering climate, please contact with local HELI sales network for HELI

exclusive coolant with greater anti-freezing ability.

(1) If the radiator appears “boiling” or excessive coolant temperature, it is

prohibited strictly to open the radiator cover immediately. Do as the following:

(a) Park the truck at a safe area;

(b) Keep the engine idling and open the engine hood to keep good ventilation;

(c) Shut off the engine when the water temperature indicator points to the normal

range;

(d) Check the following points when the engine is cool completely:

● Check if the coolant lever is correct;

● Check if the fan belt is loose;

● Check the engine oil quality and oil level;

● Check if the radiator is clogged;

● Check if the thermostat can open normally;

(2) Use HELI exclusive coolant in order to keep the engine and cooling system

in good condition. Change it once a year. If the coolant is bad in less than one year,

change it when necessary. When changing the coolant, clean the interior of the cooling

system. The freezing point of the coolant should be at least 10℃ lower than the lowest

environment temperature.

(3) Replenish the coolant with HELI exclusive one only when the engine is cool

when necessary avoiding engine damage. If there is no HELI exclusive coolant in an

emergency, never add any additives. Add water only and contact with local HELI sales

network for proper mixture as possible. Use new HELI exclusive coolant when

replenishing. It is prohibited to add hard water such as tap water, mineral water, river

water, well water to the cooling system avoiding radiator corrosion or scale forming

which will reduce radiator performance and service life.

(4) It is prohibited to contact the radiator core directly with sharp hard objects if

the core is dirty. Clean it with water flow or air flow with the following set pressure

-4-

value. Keep the mouth against the radiator core.

Water flow pressure: no higher than 0.49MPa (5kgf/cm²);

Air flow pressure: no higher than 0.98MPa (10kgf/cm²).

(5) Coolant storage notes:

(a) Avoid direct contact with the coolant which is bad for health;

(b) Store the coolant in proper sealed container because the coolant steam is

harmful. Make sure to keep it out of the reach of children because there is a danger of

poisoning;

(c) Once the coolant goes to eyes, please wash with water and see a doctor;

(d) See a doctor immediately once the coolant is drank carelessly;

(e) Never use the coolant drained from the truck again. Place the coolant drained

from the truck in a special container and deal with environmental rules.

6. Oil for Forklift Truck

Name

Gasoline oil

Diesel oil

Lubricating oil

Hydraulic oil

Torque

converter oil

Gear oil

Brake fluid

Grease

Brand for home users

RQ-85

Selection according to manual for diesel engine or

light diesel oil No. -10 to -35 in winter and No. 0

in summer in GB 252-81

Selection according to manual for engine or

GB 485-84 lubricating oil in gasoline engine and

GB 5323-85 lubricating oil in diesel engine

N32# or N46#

6# torque converter oil

85W/90

4604 compound brake fluid

3# lithium base grease (drop point 170)

Brand for abroad users

JISK 2202 2#

JISK 2204 2#

(GENERAL region)

JISK 2204 3#(Cold region)

SAE 10W (winter)

SAE 30 (summer)

ISO VG30

SAE 10W

SAE 90/SAE 80W

JISK-2233

JISK-2220, 1#, 2#

-5-

7.Lubrication Chart

-6-

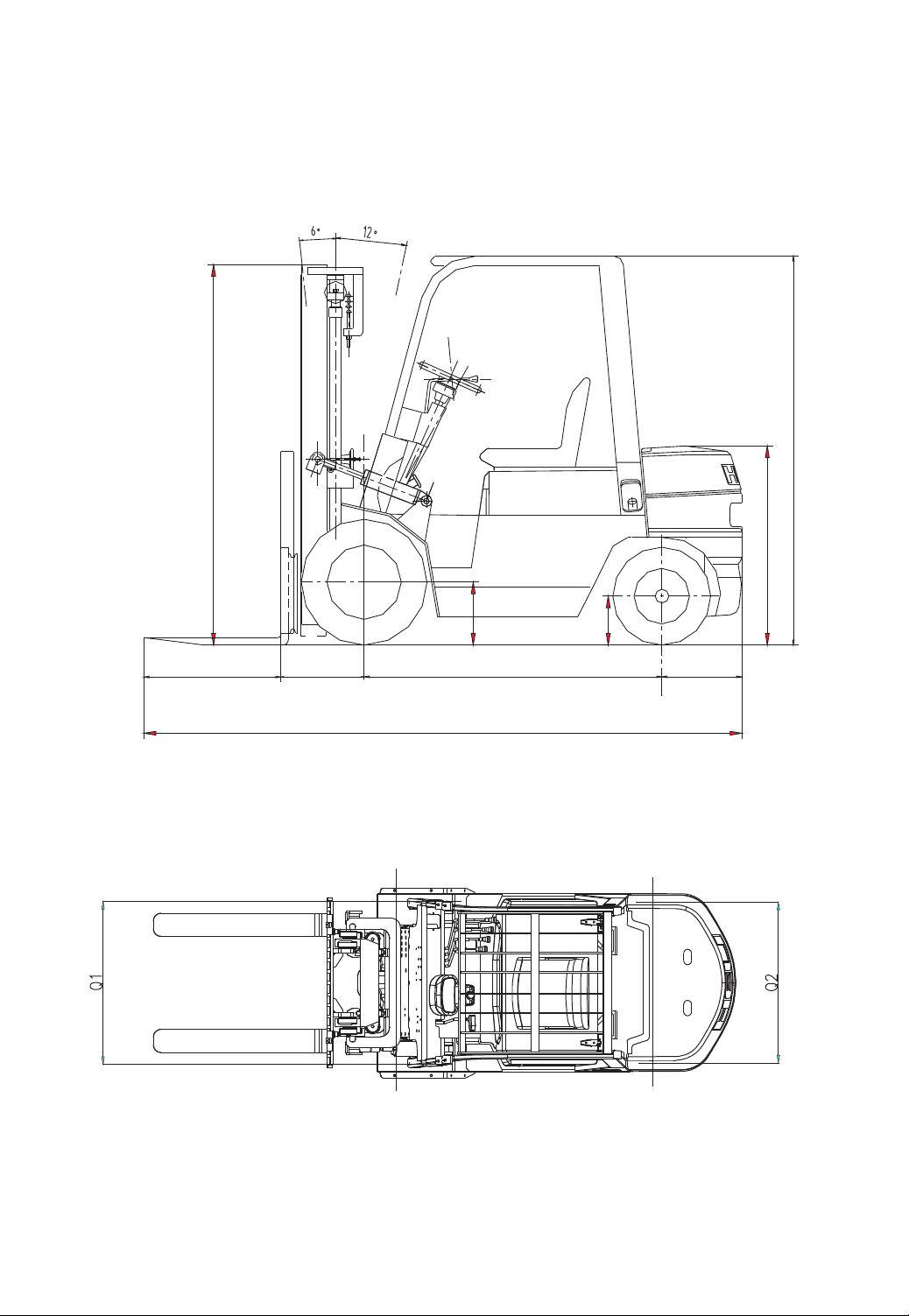

II.Specifications of Forklift Trucks (See Table 1)

External View of Forklift Trucks

-7-

L

L1 B F C

D

1040(1150)

245(275)

320(345)

2100(3.8t 2195)

Specifications of Forklift Trucks

Table 1

kg

mm

mm

mm

Fwd/Rwd

mm

mm

2000

500

3000

155

6°/12°

580

550

2170

1920

2500

2230

1940

3000

160

470

450

3500 3800

170 150

370 400

340 360

2420 2590

2110 2415

CPC 20

CPCD 20

CPC 25

CPCD 25

CPC 30

CPCD 30

CPC 35

CPC 38

CPCD 35

CPCD 38

20

19

20

19

8.3

12.1

20

21

20

19

20

19

8.3

14.7

20

27

20

19

20

19

8.9

12.1

18

18

20

19

20

19

8.9

14.7

18

23

20

19

20

19

9.8

11.3

20

15

20

19

20

19

9.8

14

20

18

20

19

20

19

10

11.3

20

15

20

19

20

19

10

14

20

16.5

20

19

20

19

11.7

15

20

15

20

19

20

19

11

20

20

20

Model

Parameters

Rated Capacity

Load Center

Standard Lift Height

Free Lift Height

Mast Tilt Angle

Lifting Speed

mm/s

Travel Speed

km/h

Mechanical

Hydraulic

Max. Drawbar

Force

kN

Gradeability

%

Min. Turning Radius

Min. Intersecting Aisle

Unloaded

Loaded

Unloaded

Loaded

Unloaded

Loaded

Unloaded

Loaded

Unloaded

Loaded

Performance

-8-

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

kg

CPC 20

CPCD 20

CPC 25

CPCD 25

CPC 30

CPCD 30

CPC 35

CPC 38

CPCD 35

CPCD 38

Specifications of Forklift Trucks

Table 1

Model

Parameters

Overall Length L

Overall Width

Overall Height D

Overall Height(extended mast)

Wheelbase F

Tread

Front Overhang B

Rear Overhang C

Forks

Fork Spacing (adjustable)

Underclearance (at mast)

Service Weight (with water & oil)

Dimensions

Front Q1

Rear Q2

Length L1

Width

Thickness

3646

1150

2070

4030

1600

970

970

482

494

1070

100

45

245~1020

110

3680

3752

1225

2090

4250

1700

1000

970

487

495

1070

125

45

250~1090

135

4270

3763

1225

2090

4250

1700

1000

970

498

495

1070

125

50

250~1090

135

4700

3962

1225

2090

4265

1900

1000

970

497

495

1070

150

50

300~1080

135

4850

3422

1150

2070

4030

1600

970

970

482

420

920

100

45

245~1020

110

3320

-9-

III.Description of Main Parts of Forklift Truck

Power System — Transmission System —

Clutch — Mechanical Transmission

Torque Converter — Hydraulic Transmission

Reduction Gear & Differential — Drive Axle — Steering System — Steering Axle —

Lifting System —

Operation of Brake and Clutch Pedals (Clutch type truck)

Operation of Brake and Inching Pedals

(Torque converter type truck)

Parking Brake

Operation of Accelerator

Operation of Choke

— Hydraulic System — Electric System

Operating System —

-10-

IV.Construction, Principle, Adjustment and Maintenance of

Forklift Trucks

We herein explain the construction, basic principle, adjustment, disassembly and

assembly, repair, troubleshooting and other contents of forklift trucks made by us for

the operators to use, maintain and repair them more successfully.

1. Power System

1.1 General Description

The power of K series forklift trucks with 2 to 3.5 ton capacity is provided by

diesel engine Xinchang A490BPG-76, Xinchang C490BPG-200 or Quanchai

QC490GP. DachaiCA498-97,and 3.8 ton capacity is provided by diesel engine

Xinchang A4965BPG, Quanchai QC495G or Dachai CA498-97.Refer to relevant

manual for the details of operation and maintenances for the engine.

1.2 Fuel System

The fuel system is composed of a tank, fuel volume sensor and fuel meter (see

Fig. 1-1).

Fig. 1-1 Fuel tank for 2-3.8 ton forklift trucks

Fuel volume sensor

Highest lever 52L

Lowest lever 52L

To the oil inlet end of the fuel

injection pump of the diesel engine To the oil return end of the diesel engine

-11-

1.2.1 Fuel tank

The fuel tank is a welded construction integrated with the truck frame. It is

located on the left side of the truck frame and has a capacity of 52l for 2-3.8 ton

trucks. The fuel volume sensor is installed on the tank cover to detect the fuel level.

1.2.2 Fuel volume sensor

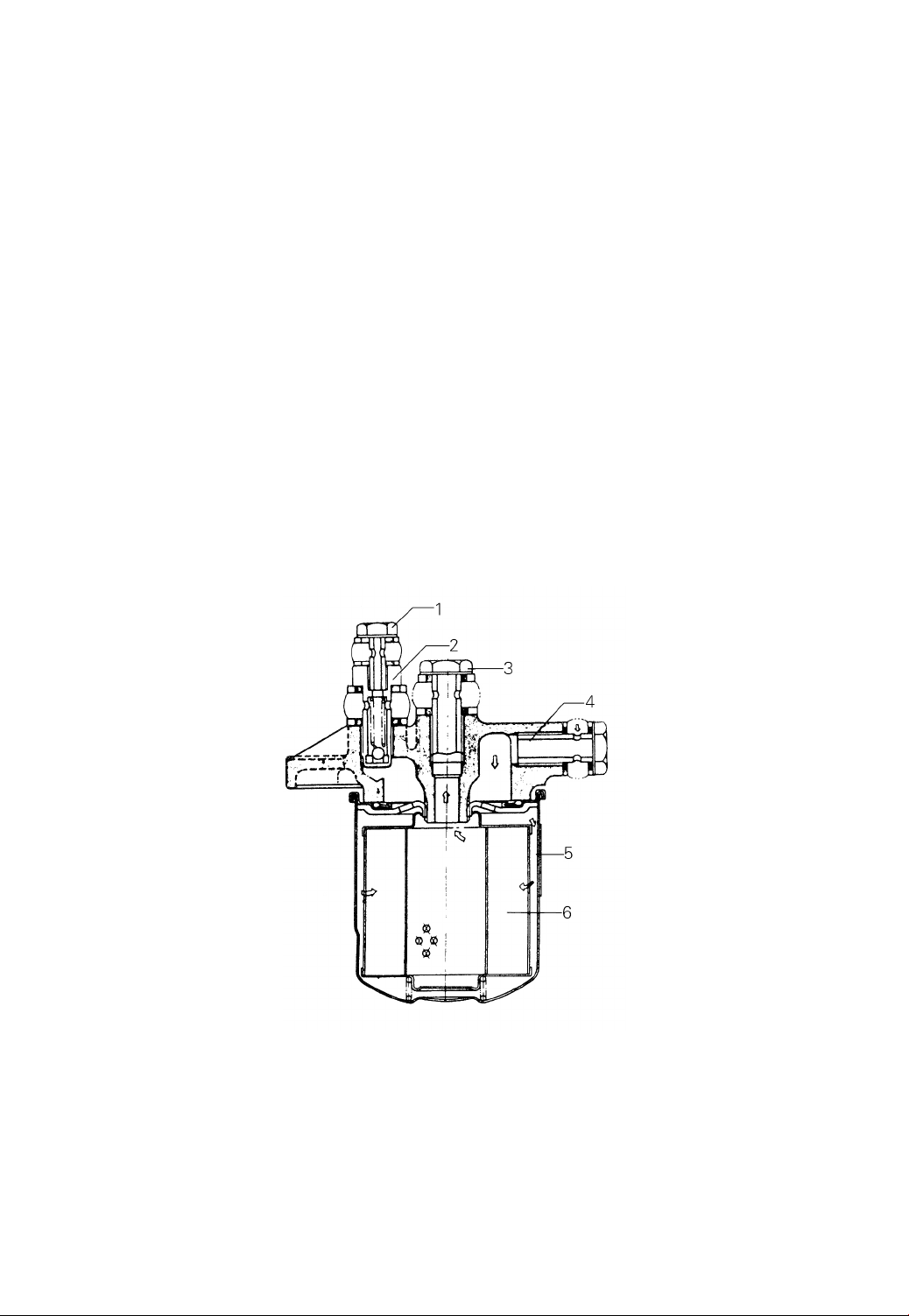

Fig. 1-2 Fuel volume sensor

The sensor is designed to convert the remaining amount of fuel into voltage. (See

Fig.1-2) The sliding type resistor made of alloy steel wire is linked with float. As the

float moves up and down, resistance is changed. With electro-magnetic fuel meter, the

remaining amount of fuel in the fuel tank can be read off the meter panel.

1.2.3 Maintenance

Once every 100 working hours, it is required to maintain the fuel system

according to the following methods. Once every 600 working hours, it is required to

clean the fuel tank.

The highest lever

Float

The lowest lever

Truck capacity

Float position

1

1/2

0

2-3.8 (ton)

Resistance (Ω)

55

43

10

-12-

(1) Fuel filter

The fuel filter is for clearing the fuel of the dust and impurity. It is installed

between the feed pump and injection pump.

The filter is of cartridge type. Generally it can not be disassembled. Replace the

filter assembly when required.

For maintenance of the filter, proceedings are as follows (See Fig.1-3):

a) Once a 100 working hours, it is required to remove the cartridge cover by

specific tools and then take out the filter element.

b) Once a 600 hours operation, it is required to replace the filter assembly.

c) After the re-fitment of filter, check it for leaks.

d) Check overflow valve (1) for correct working.

Fig. 1-3 Fuel filter

(2) Cleaning of fuel tank

Once every 600 working hours, the fuel tank should be cleared.

-13-

2.Clutch and Clutch Pedal

Table 2

2.1 General Description

The clutch consists primarily of pressure plate, friction piece and clutch yoke.

The pressure plate is bolted to the engine flywheel. There is an inspection hole

attached to the clutch cover. The clutch pedal pushes the clutch yoke by push rod in

order to release the friction piece from flywheel which normally mesh together.

2.2 Replacement of Friction Piece

(1) Press the clutch pedal and place three spacers between the pressure plate case

and release lever to cause the friction piece apart.

(2) Turn counter clockwise the slide lead screw in the upper of the transmission

to let the driving shaft go into the transmission (See Fig.3-1).

(3) Remove six mounting bolts on the pressure plate case to cause the flywheel

apart and remove the old friction piece right away.

(4) When a new friction piece is installed, notice the hub (See part 5 in Fig.2-1)

with the longer spline boss being toward the transmission.

(5) Turn the slide lead screw clockwise and pull out the driving shaft step by step

and let its spline match with the hub spline.

CPC20、25、30、35、38

Single plate, dry

275

175

8.0

352

about 10

Foot operated

Truck Model

Parameters

Type

Dimensions

of Friction

Piece

mm

Outer dia.

Inner dia.

Thickness when pressed

2

Friction Surface Area cm

Weight kg

Operation Mode

-14-

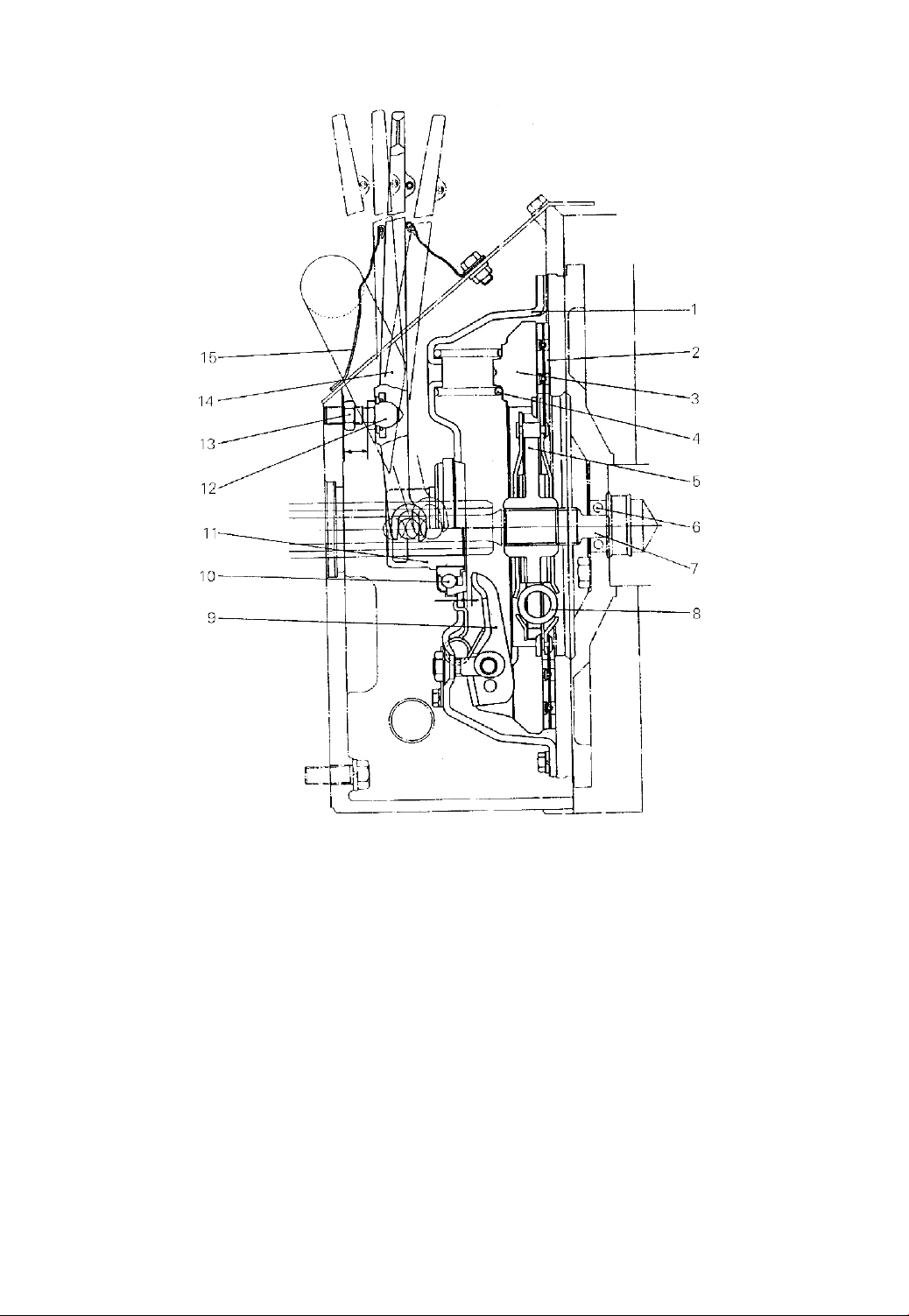

(1) Pressure plate case (2) Friction piece (3) Pressure plate (4) Pressure spring

(5) Hub (6) Bearing (7) Driving shaft (8) Coil spring (9) Release lever

(10) Release bearing (11) Release bearing block (12) Bolt (13) Lock nut

(14) Release yoke (15) Cover

Fig.2-1 Clutch

(6) After making certain that the driving shaft end has entered the middle

bearing of the flywheel, tighten the slide lead screw to the torque of 107-119N.m

(10.9-12.1kgm).

(7) Install the pressure plate case on the flywheel.

-15-

(8) Press the clutch pedal and remove the three spacers.

(9) Adjust the travel of the clutch pedal. (See Fig.2-2)

2.3 Clutch Pedal

The clutch pedal and the brake pedal are fitted on the same bracket. The clutch

pedal is secured on the transmission.

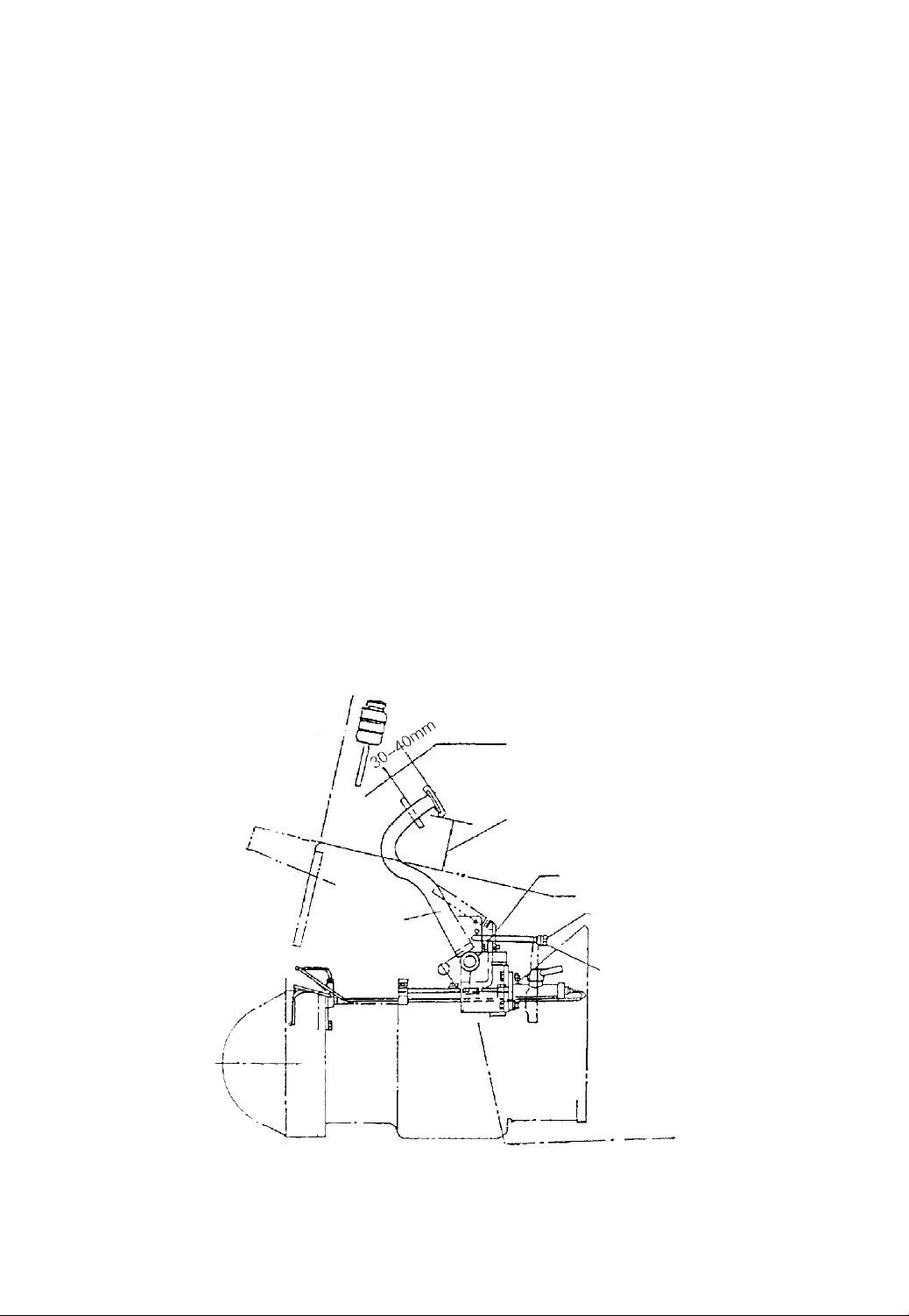

2.4 Adjustment of Clutch Pedal Travel (See Fig.2-2)

(1) Loosen clutch pedal stopper bolt (a).

(2) Using stopper bolt (a) to get a pedal height from the floor of 111mm. Spare

travel is 30-40mm.

(3) Detach the spring at the end of the clutch pedal and loosen the nut (b).

(4) Press the clutch pedal about 30 to 40mm. At this time, pull the release yoke

forward. When resistance is felt, turn spherical nut (b) until it comes into contact with

release yoke and then lock with lock nut (c).

(5) Install the pedal spring properly.

Spare travel

Pedal height 115mm

Stopper bolt (a)

Spherical bolt (b)

Lock nut(c)

Clutch pedal

Fig.2-2 Clutch pedal

-16-

3.Transmission, Reduction Gear and Differential

3.1General Description

The drive unit of clutch type truck is a one-body construction consisting of the

transmission, reduction gear and differential (Fig.3-1). The transmission is provided

with a synchromesh mechanism that synchronizes the rotation of gears which are

about to be meshed, ensuring smooth gear shifting. The transmission of this type

avoids clashing gears and reduces noise arising when shifting, especially shifting from

forward to reverse or vice versa.

3.2 Transmission

The transmission consists mainly of a driving shaft, an output shaft, a main shaft

and an idler shaft, each having gear(s) of different sizes on it. The gear(s) can be

shifted with the aid of the synchromesh mechanism installed on the main shaft by

operation of the shift handle. The power from the output shaft is transmitted through

the reduction gear differential and half shafts to the drive shaft.

3.2.1 Driving shaft and slide lead screw

Transmission

Type

Gears number

Gear ratio FWD 1st/2nd

BWD 1st/2nd

Reduction gear

Gear

Reduction ratio

Differential

Gear

Reduction ratio

Differential gear

Oil amount

Dry weight (no oil)

Manual-shift, slide type synchromesh mechanism

FWD:2 BWD:2

3.253/1.407

3.204/1.386

Spiral bevel gear

2.1

Spur gear

6.182

Bevel gear

8 L

Approx.100kg

-17-

Driving shaft’s end toward the clutch is held by the ball bearing located in

flywheel, another end fitted with input gear is held in transmission case by the ball

bearing and its middle portion is held in the bearing retainer which is fixed in

transmission case with the slide lead screw. When the replacement of the friction piece

is required, the driving shaft along with the bearing retainer is moved axially through

turning the slide lead screw until the shaft end toward the clutch returns inside the

transmission case.

3.2.2 Output shaft

The cluster gear is installed on the output shaft through two needle bearings and

a spacer. Also the output gear is splined to the output shaft through a spacer. The

output shaft is held in the transmission case with two tapered roller bearings and

several shims are used to adjust the backlash between the output gear and the bearing.

The bigger gear of the cluster gear normally meshes with the input gear and high

speed gear while the smaller gear with the low speed gear. The output gear normally

meshes with the forward gear or reverse idler gear.

3.2.3 Main shaft

The high and low speed reverse and forward gears are all installed on the main

shaft through needle bearings. As they normally mesh with the cluster gear, idler gear

and input gear respectively, it’s easy to shift for changing speed or direction

synchronizer by operating the synchromesh mechanism.

3.2.4 Idler shaft

Both ends of the idler shaft are supported by the transmission case and its rear

end is positioned by a steel ball. The idler gear is installed on the idler shaft through

needle bearings and normally meshes with the reverse gear and output gear.

3.2.5 Rotating rod and shift forks (See Fig.3-1 and Fig.3-2)

Two rotating rods are used for performing the changeover in travel speed and

direction respectively. The shift forks are supported on the shift rods. The ball is

designed to rest in the notch of the shift rod to secure gearshifting position.

-18-

This manual suits for next models

9

Table of contents

Other HELI Forklift manuals