Table of Contents

1.

Maintain list ..................................................................................................................................1

a.

Main part overview....................................................................................................................1

b.

Lubrication

points......................................................................................................................3

c.

Check and refill hydraulic

oil

.....................................................................................................4

d.

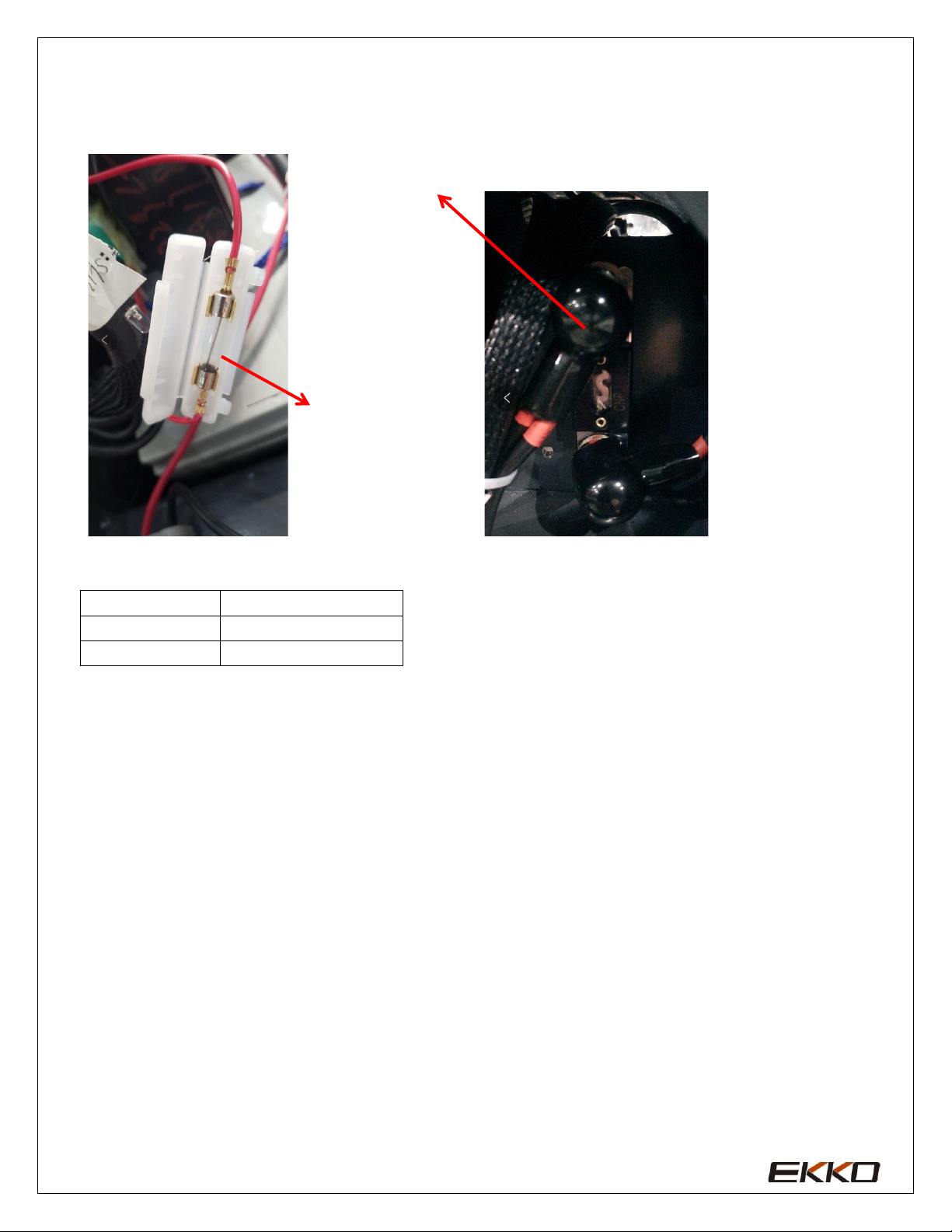

Check electrical fuses ................................................................................................................5

2.

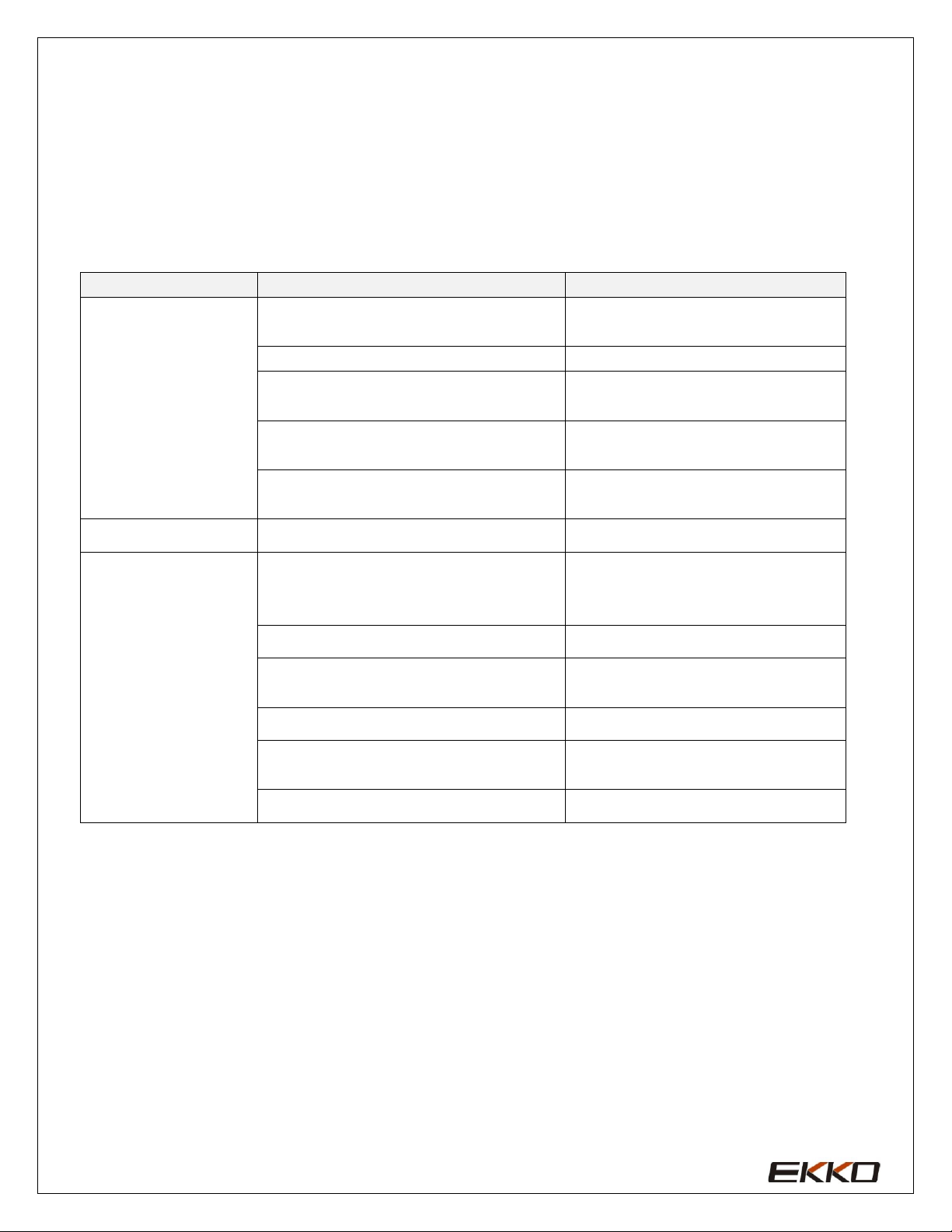

Failure

analysis..............................................................................................................................6

a.

Common

failure

analysis

............................................................................................................6

b.

Controller fault code

display

......................................................................................................7

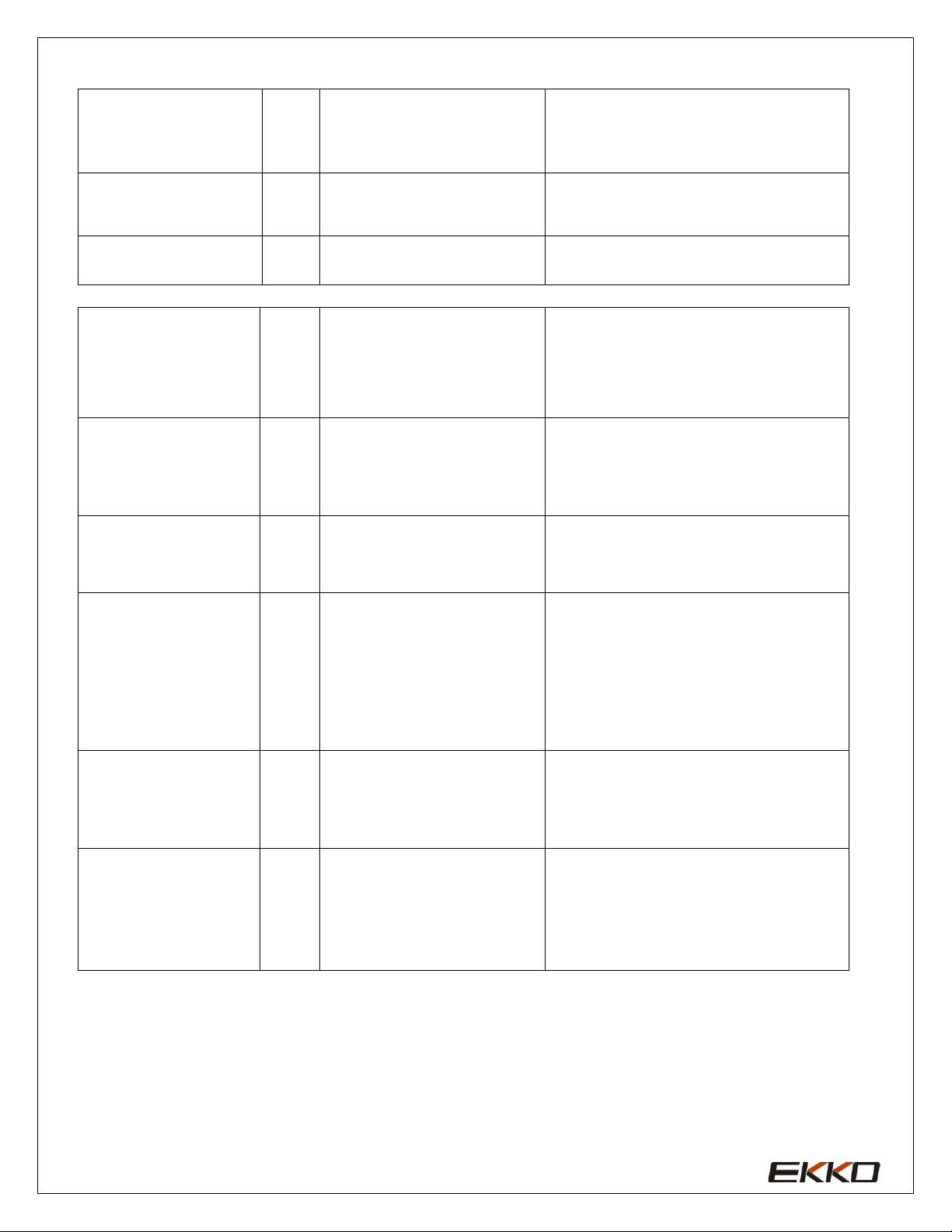

c.

Troubleshooting for common faults...........................................................................................9

3.

Wiring/circuit

diagram................................................................................................................14

a.

Circuit diagram........................................................................................................................14

b.

Hydraulic

circuit......................................................................................................................16

4.

Disassembly of main parts...........................................................................................................17

a.

Electromagnetic

brake

adjustment

............................................................................................17

b

Disassembly

of

driving

assembly

.............................................................................................17

c.

Disassembly

of

Electromagnetic

brake

.....................................................................................18

d.

Drive

internal

gear,

Bearing

......................................................................................................

18

e.

Operating

handle

assembly

.......................................................................................................19

5.

CURTIS Hand

programmer

..........................................................................................................19