HELI H2000 Series User manual

FOREWORD

FOREWORD

This manual accounts for “HELI” Forklift Truck in H2000 series from 5t to 10t,This manual accounts for “HELI” Forklift Truck in H2000 series from 5t to 10t,

incincludludes es its its perperforformanmance, ce, conconstrstructuctureure, , safsafe e opeoperatration ion and and regregulaular r preprevenventivtivee

maintmaintenancenance, e, so so that operatorsthat operators, , mechamechanics and nics and supersupervisorvisors s of of ForkForklift lift TrucTruck k correcorrectlyctly

operaoperate ate and pnd prevenrevent mat maintenintenance. ance. Read Read and and undeunderstanrstand thd this mis manual anual beforbefore ope operatineratingg

your lift truck! This manual is your guide to safe operation and regular preventiveyour lift truck! This manual is your guide to safe operation and regular preventive

maintenmaintenance. So as to ance. So as to let the Forklift Truck keep good working conditilet the Forklift Truck keep good working conditions.ons.

If any operation or maintenance does’t accord with requires in this manual, ourIf any operation or maintenance does’t accord with requires in this manual, our

related promises is inefficacy.related promises is inefficacy.

Due to continuous improvements in design, it is possible that the latest descriptionDue to continuous improvements in design, it is possible that the latest description

contained herein may differ slightly from the truck delivered to you. Moreover, thecontained herein may differ slightly from the truck delivered to you. Moreover, the

specification of the forklift truck may be changed insignificantly depending on itsspecification of the forklift truck may be changed insignificantly depending on its

destination.destination.

NotNoticeice:De:Desigsignatnationions s in in the the CATCATALOALOGUE GUE are are difdifferferencence e frofrom m thothose se in in proproducductt

nameplates and quaulifying licenses.Designations in the CATALOGUE include enginenameplates and quaulifying licenses.Designations in the CATALOGUE include engine

code and number of remodification.code and number of remodification.

CPCD50 - W2CPCD50 - W2

Engine code and number of remodification.Engine code and number of remodification.

Type.Type.

https://www.besttruckmanuals.com/

CONTENTS

CONTENTS

Ⅰ. Ⅰ. Safe Operation Rules and Daily MaintenSafe Operation Rules and Daily Maintenance for Forkliftance for Forklift

Ⅱ. Ⅱ. Primary TechniPrimary Technic Parameter of Forkliftc Parameter of Forklift

Ⅲ. Ⅲ. Primary AssemblPrimary Assembly Introduce of Forklifty Introduce of Forklift

Ⅳ. The structure, principle, adjustment and maintenance of ForkliftⅣ. The structure, principle, adjustment and maintenance of Forklift

1. Dynamic System1. Dynamic System

1.1 Fuel system1.1 Fuel system

1.1.1 Fuel tank1.1.1 Fuel tank

1.1.2 Fuel sender1.1.2 Fuel sender

1.1.3 Fuel filter1.1.3 Fuel filter

1.2 Cooling system1.2 Cooling system

1.3 Inspection and adjustment1.3 Inspection and adjustment

1.3.1 Air cleaner1.3.1 Air cleaner

1.3.2 Oil filter(fuel)1.3.2 Oil filter(fuel)

1.3.3 Oil filter(machine oil)1.3.3 Oil filter(machine oil)

1.3.4 Cooling system1.3.4 Cooling system

1.3.5 Tightenin1.3.5 Tightening the cylinder head bolts of engineg the cylinder head bolts of engine

1.3.6 Adjustment of cleara1.3.6 Adjustment of clearance of air gatence of air gate

1.3.7 Confirmation of the ignition time of oil injectio1.3.7 Confirmation of the ignition time of oil injectio

1.3.8 Adjustment of ignition time of oil injection1.3.8 Adjustment of ignition time of oil injection

1.3.9 Measurement of the compression pressure1.3.9 Measurement of the compression pressure

1.3.10 Exhaust air of oil injection pump1.3.10 Exhaust air of oil injection pump

2. Electric System2. Electric System

2.1 General description2.1 General description

2.2 Brief explanation for operation2.2 Brief explanation for operation

2.3 Battery2.3 Battery

2.4 Wire harness2.4 Wire harness

3. Transmission Device3. Transmission Device

3.1 General description3.1 General description

3.2 Torque converter3.2 Torque converter

3.3 Oil pump3.3 Oil pump

3.4 Hydraulic clutch group3.4 Hydraulic clutch group

3.5 Control valve & inching valve3.5 Control valve & inching valve

3.6 Hydraulic circulation system in tor-con3.6 Hydraulic circulation system in tor-con

3.7 Cautions when the forklift truck trouble occurs3.7 Cautions when the forklift truck trouble occurs

11

77

1414

1515

1515

1818

1818

1818

2020

2020

2020

2020

2121

2121

2222

2323

2323

2424

2525

2525

2626

2727

2929

2929

3131

3131

4343

4545

4545

4646

4747

4848

4949

5151

https://www.besttruckmanuals.com/

3.8 Trouble shooting

3.8 Trouble shooting

4. Drive Axle4. Drive Axle

4.1 General description4.1 General description

4.2 Differential4.2 Differential

4.3 Hub reduction gear4.3 Hub reduction gear

4.4 Trouble shooting4.4 Trouble shooting

4.5 Data use for service4.5 Data use for service

5. Brake System5. Brake System

5.1 General description5.1 General description

5.2 Power brake5.2 Power brake

5.2.1 Brake pedal device5.2.1 Brake pedal device

5.2.2 Brake valve5.2.2 Brake valve

5.2.3 Accumulator5.2.3 Accumulator

5.3 Vacuum servo brake5.3 Vacuum servo brake

5.3.1 Vacuum booster and main brake cylinder assembly5.3.1 Vacuum booster and main brake cylinder assembly

5.3.2 Installation method for vacuum booster and main brake cylinder assembly5.3.2 Installation method for vacuum booster and main brake cylinder assembly

5.3.3 Points of attention for users5.3.3 Points of attention for users

5.3.4 Trouble shooting and cause analysis5.3.4 Trouble shooting and cause analysis

5.4 Travel brake5.4 Travel brake

5.4.1 Travel brake(5-7t forklift truck)5.4.1 Travel brake(5-7t forklift truck)

5.4.2 Travel brake(8-10t forklift truck)5.4.2 Travel brake(8-10t forklift truck)

5.5 Stop brake5.5 Stop brake

5.6 Trouble shooting5.6 Trouble shooting

6. Steering System6. Steering System

6.1 Steering unit6.1 Steering unit

6.2 Checking after mounti6.2 Checking after mounting on the ng on the machinemachine

6.3 Troubleshooting guide6.3 Troubleshooting guide

6.4 Steering axle6.4 Steering axle

6.4.1 Steering axle body6.4.1 Steering axle body

6.4.2 Left and right steering knuckle assembly6.4.2 Left and right steering knuckle assembly

6.4.3 Wheel hub6.4.3 Wheel hub

6.4.4 Steering oil cylinder6.4.4 Steering oil cylinder

7. Hydraulic System7. Hydraulic System

7.1 General description7.1 General description

7.2 Main pump7.2 Main pump

7.3 Control valve7.3 Control valve

7.4 Operation of control valve7.4 Operation of control valve

5151

5555

5555

5555

5959

6060

6060

6161

6262

6262

6262

6464

6666

6666

6767

6969

7070

7070

7070

7171

7474

7575

7777

7878

8080

8181

8282

8383

8383

8383

8383

8383

8686

8787

8787

8787

8888

https://www.besttruckmanuals.com/

7.5 Operation of relief valve

7.5 Operation of relief valve

7.6 Operation of tilt lock valve7.6 Operation of tilt lock valve

7.7 Operation unit of the control valve7.7 Operation unit of the control valve

7.8 Oil tank7.8 Oil tank

8. Lift Cylinder & tilt cylinder8. Lift Cylinder & tilt cylinder

8.1 Lift cylinder8.1 Lift cylinder

8.2 Cut-off valve8.2 Cut-off valve

8.3 Flow regulator8.3 Flow regulator

8.8.44

9. Hoist System9. Hoist System

9.1 General description9.1 General description

9.2 Outer & inner mast9.2 Outer & inner mast

9.3 Lift bracket9.3 Lift bracket

9.4 Adjustment of hoist system9.4 Adjustment of hoist system

9.4.1 Adjustment of shims of lift cylinder9.4.1 Adjustment of shims of lift cylinder

9.4.2 Carriage adjustment9.4.2 Carriage adjustment

9.5 Roller position of mounting9.5 Roller position of mounting

Tilt cylinderTilt cylinder

8989

9090

9393

9595

9696

9696

9999

9999

101011

101033

101044

101044

101044

101044

101044

101055

101066

https://www.besttruckmanuals.com/

-1

-1 --

Ⅰ. Safety rules for Operation and Daily Maintenance of Forklift TruckⅠ. Safety rules for Operation and Daily Maintenance of Forklift Truck

1. Delivery of Forklift Truck1. Delivery of Forklift Truck

2. Storage of Forklift Truck2. Storage of Forklift Truck

3. Precautions Before Operation3. Precautions Before Operation

4. Operation of Forklift Truck4. Operation of Forklift Truck

It is important that driver and manager for forklift trucks remember the principle ofIt is important that driver and manager for forklift trucks remember the principle of

the “first safety” and ensure the safety operation as the description in 《OPERATIONthe “first safety” and ensure the safety operation as the description in 《OPERATION

AND SERVICE AND SERVICE MANUAL》.MANUAL》.

It must be pay attention to the following items when you delive forklift trucks withIt must be pay attention to the following items when you delive forklift trucks with

container or trucks.container or trucks.

(1) Apply the parking brake.(1) Apply the parking brake.

(2) Fix the mast and (2) Fix the mast and the balancewethe balanceweight with steel wire.Weight with steel wire.Wedge up all wheels.dge up all wheels.

(3) Sling points should be always at the positions specified in sling index plate (3) Sling points should be always at the positions specified in sling index plate whenwhen

hoisting up the forklift truck.hoisting up the forklift truck.

(1) Drain off fuel completely. Don’t drain off the cooling water containing antifreeze(1) Drain off fuel completely. Don’t drain off the cooling water containing antifreeze

and rustproof agent.and rustproof agent.

(2) Apply antirust to the surface of the (2) Apply antirust to the surface of the parts not painted. Apply lubrication oil to theparts not painted. Apply lubrication oil to the

lift chain.lift chain.

(3) Lowing the mast to the lowest position.(3) Lowing the mast to the lowest position.

(4) Apply the parking brake.(4) Apply the parking brake.

(5) Wedged up the wheels.(5) Wedged up the wheels.

(1) Don’t check fuel leakage and lever or instruments at the place there is open(1) Don’t check fuel leakage and lever or instruments at the place there is open

flame. Never fill the fuel tank with the engine running.flame. Never fill the fuel tank with the engine running.

(2) Check the tire inflation pressure.(2) Check the tire inflation pressure.

(3) The forward-reverse lever should be in neutral.(3) The forward-reverse lever should be in neutral.

(4) Never smoke while the fuel system is under working or the battery is inspected.(4) Never smoke while the fuel system is under working or the battery is inspected.

(5) Check all the levers and pedals.(5) Check all the levers and pedals.

(6) Complete the provisions before starting.(6) Complete the provisions before starting.

(7) Release the parking lever.(7) Release the parking lever.

(8) Make trying opteration of the mast for lifting, lowing and Fwd/Bwd tilting and the(8) Make trying opteration of the mast for lifting, lowing and Fwd/Bwd tilting and the

truck for steering and braking.truck for steering and braking.

(1) Only trained and authorized opera(1) Only trained and authorized operator shall be permitted to operate the truck.tor shall be permitted to operate the truck.

(2) Wear all the safety guards, such as shoes, helmet, clothing and gloves while(2) Wear all the safety guards, such as shoes, helmet, clothing and gloves while

operating the truck.operating the truck.

(3) Check all the control and warning devices before starting the truck. If any(3) Check all the control and warning devices before starting the truck. If any

damages or defects are found, operate it after repairing.damages or defects are found, operate it after repairing.

(4) Overload or overload operation is strictly prohibited. The fork should insert(4) Overload or overload operation is strictly prohibited. The fork should insert

https://www.besttruckmanuals.com/

completely under the cargo and make the cargo placed on it evenly. Do not raise an object

completely under the cargo and make the cargo placed on it evenly. Do not raise an object

with one fork end.with one fork end.

(5) The starting, turning, driving, braking and stopping operation (5) The starting, turning, driving, braking and stopping operation of the truck shouldof the truck should

be done smoothly. When steering on the humid or low friction road, the truck should bebe done smoothly. When steering on the humid or low friction road, the truck should be

decelerated.decelerated.

(6) Travel with loads as low as (6) Travel with loads as low as possible and tilted backwapossible and tilted backward.rd.

(7) Be careful when traveling on a (7) Be careful when traveling on a slope. When climbing grades with a slope of moreslope. When climbing grades with a slope of more

than 10%, the truck should forward travel, and when descending so grades, backwardthan 10%, the truck should forward travel, and when descending so grades, backward

travel. Never turning on a slope. Avoid loading and unloading operation when decending.travel. Never turning on a slope. Avoid loading and unloading operation when decending.

(8) Pay attention to pedestrian, obstacle and bumpy (8) Pay attention to pedestrian, obstacle and bumpy road when driving. Pay attentionroad when driving. Pay attention

to the clearance over forklift truck.to the clearance over forklift truck.

(9) Never allow any pers(9) Never allow any persons to stand on the forks or the truck to carry persons.ons to stand on the forks or the truck to carry persons.

(10) Never permit anyone to stand or walk under upraised forks.(10) Never permit anyone to stand or walk under upraised forks.

(11) Don’t (11) Don’t operate trucoperate truck and attachment of it at any positiok and attachment of it at any position out of the drive seat.n out of the drive seat.

(12) On the high lift forklift truck, when the lift high more than 3m, it is noted that the(12) On the high lift forklift truck, when the lift high more than 3m, it is noted that the

goods on it should not fall down or the protectgoods on it should not fall down or the protection measures must be taken if necesion measures must be taken if necessary.sary.

(13) Tilt the mast of the high lift forklift truck as backward as possible while the truck(13) Tilt the mast of the high lift forklift truck as backward as possible while the truck

workingworking. Use minimum forward tilt angle and Min. reverse tilt when loading and unloading.. Use minimum forward tilt angle and Min. reverse tilt when loading and unloading.

(14) Be careful and slowly driving over a dockboard or bridge-pl(14) Be careful and slowly driving over a dockboard or bridge-plate.ate.

(15) Shut down the en(15) Shut down the engine and don’t stay on the truck when fillingine and don’t stay on the truck when filling fuel. Don’t igniteg fuel. Don’t ignite

the engine while checking battery or fuel lever.the engine while checking battery or fuel lever.

(16) The unloaded forklift truck with attachments should be operated as a loaded(16) The unloaded forklift truck with attachments should be operated as a loaded

truck.truck.

(17) Don’t (17) Don’t handle unfixehandle unfixed stacked goods.Bd stacked goods.Be careful to bulky goods to be handled.e careful to bulky goods to be handled.

(18) If leaving the truc(18) If leaving the truck, lower the forks on the ground and let the shift lever to neutrak, lower the forks on the ground and let the shift lever to neutral,l,

shut down the engine or cut down electric supply. If parking on a slope is unavoidable,shut down the engine or cut down electric supply. If parking on a slope is unavoidable,

apply the parking brake and block the wheels.apply the parking brake and block the wheels.

(19) Don’t (19) Don’t open the radiatoopen the radiator cap when the engine is worm.r cap when the engine is worm.

(20) Don’t adjust the control valve and relief valve at will to prevent the (20) Don’t adjust the control valve and relief valve at will to prevent the damage ofdamage of

hydraulic system and its components because of excessive pressure passing them.hydraulic system and its components because of excessive pressure passing them.

(21) According to the measure method specified in JB/T3300,max.noise at the(21) According to the measure method specified in JB/T3300,max.noise at the

outboaroutboard of the d of the truck should be not more than 89dB(A).truck should be not more than 89dB(A).

(22) Notice and be famil(22) Notice and be familiar with all kinds of decal’s iar with all kinds of decal’s functionfunction..

-2-2 --

https://www.besttruckmanuals.com/

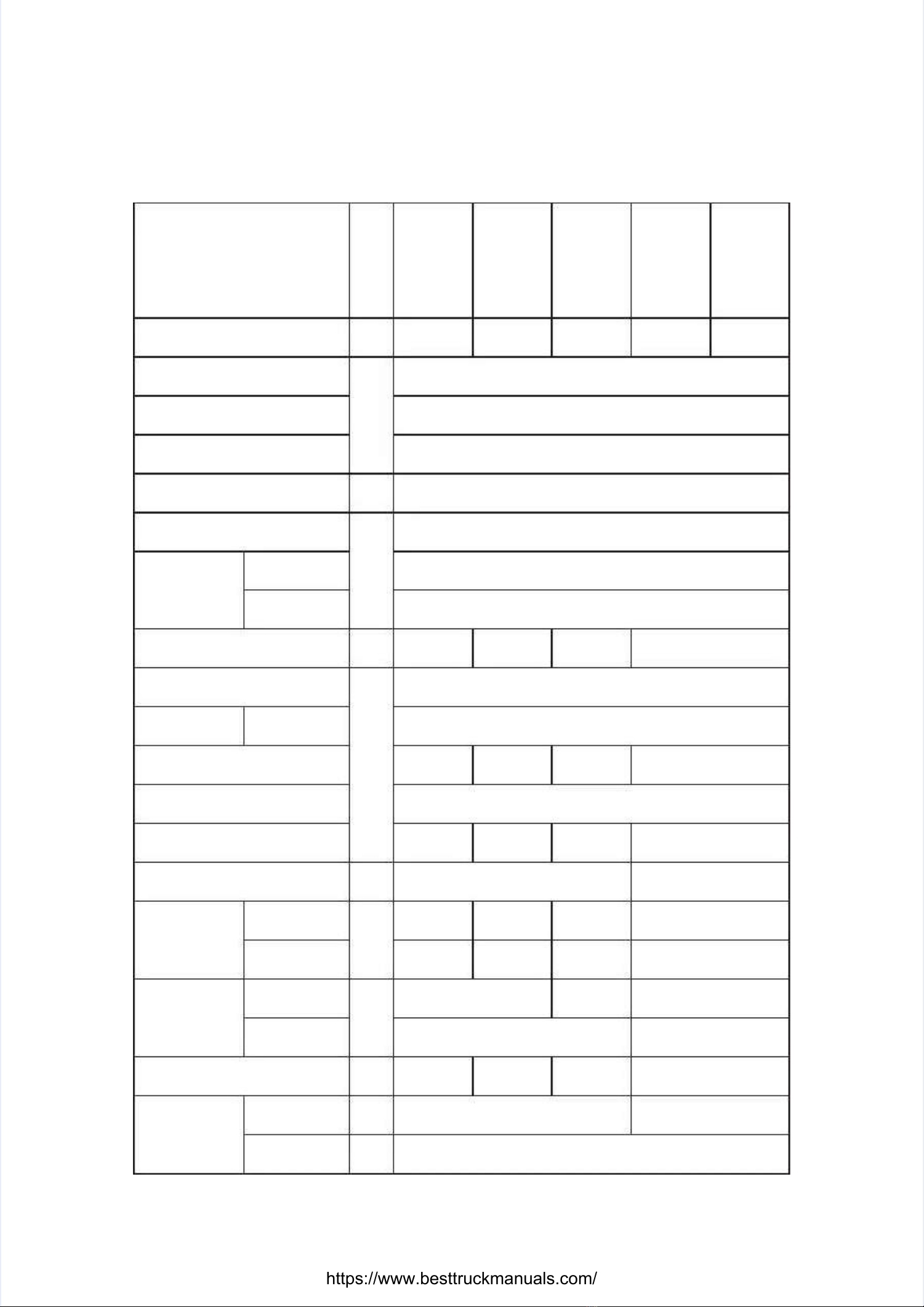

5. Arrangement sketch of instruments and controls

5. Arrangement sketch of instruments and controls

-3-3 --

1. Fuel gauge1. Fuel gauge

2. Monitor2. Monitor

3. Water temp.meter3. Water temp.meter

4. Hour meter4. Hour meter

5. Ignition switch5. Ignition switch

6. Lamp switch6. Lamp switch

7. Horn button7. Horn button

8. Turn signal switch8. Turn signal switch

9. Steering handwheel9. Steering handwheel

13. Lift lever13. Lift lever

14. Tilt lever14. Tilt lever

15. Parking brake lever15. Parking brake lever

16. Forward-reverse lever16. Forward-reverse lever

17. Inching pedal17. Inching pedal

20. Brake pedal20. Brake pedal

21. Accelerator pedal21. Accelerator pedal

22. Cable of cover22. Cable of cover

23. Cable of extinguish23. Cable of extinguish

https://www.besttruckmanuals.com/

6. Daily maintenance of forklift truck

6. Daily maintenance of forklift truck

6.1 Caution for starting6.1 Caution for starting

(1) The amount of hydraulic oil:The oil level should be at the middle position between(1) The amount of hydraulic oil:The oil level should be at the middle position between

the upper and lower scale marks of oil level meter.the upper and lower scale marks of oil level meter.

(2) Check if any leak or (2) Check if any leak or damage found on the piping joints,pumpdamage found on the piping joints,pumps and valves.s and valves.

(3) Check the travelling brakes:(3) Check the travelling brakes:

A)A)The free travel of brake pedaThe free travel of brake pedal should be within the range of 40mm.l should be within the range of 40mm.

B)B)The clearancThe clearance between the front floe between the front floor and the pedal should be bigger than 20mm.or and the pedal should be bigger than 20mm.

(4) Often check the parking brake.The laden truck can park on the 20% grade(4) Often check the parking brake.The laden truck can park on the 20% grade

ramp,whramp,when the parking lever is pulled to the en the parking lever is pulled to the bottombottom..

(5) Check the meters,lights,switches and electric wirings to see if they are properly in(5) Check the meters,lights,switches and electric wirings to see if they are properly in

operation or not.operation or not.

6.2 Fuel and lubrication used in forklift truck.6.2 Fuel and lubrication used in forklift truck.

-4-4 --

NameName

GasolineGasoline

DieselDiesel

Gear oilGear oil

(gasoline,SF)(gasoline,SF)

ElectricElectric

injection(SG)injection(SG)

Gear oilGear oil

(diesel,CD)(diesel,CD)

Hydraulic oilHydraulic oil

TorqueTorque

converter oilconverter oil

Brake fluidBrake fluid

Lubricating oilLubricating oil

Gear oil ofGear oil of

heavy-ladenheavy-laden

vehiclevehicle

Antifreeze fluidAntifreeze fluid

Brand and temp. of usingBrand and temp. of using

93# or 97#93# or 97#

Brand(diesel)Brand(diesel)

Temp. of usingTemp. of using

Sticky gradeSticky grade

Temp. of usingTemp. of using

Sticky gradeSticky grade

Temp.of usingTemp.of using

Sticky gradeSticky grade

Temp. of usingTemp. of using

6# Tor-con oil6# Tor-con oil

4604 compound brake fluid GB12981 HZY44604 compound brake fluid GB12981 HZY4

3# lithium 3# lithium base grease(-20℃~+120℃)base grease(-20℃~+120℃)

Sticky gradeSticky grade

Temp. of usingTemp. of using

NumberNumber

Temp. of usingTemp. of using

Chang chengChang cheng

Chang chengChang cheng

Chang chengChang cheng

Hai paiHai pai

Chong qingChong qing

yi pingyi ping

Hai paiHai pai

Hai paiHai pai

Jin baiJin bai

0#0#

≥4≥4

5W/305W/30

-30~+30-30~+30

5W/305W/30

-30~+30-30~+30

L-HM32 wearableL-HM32 wearable

hydraulic oilhydraulic oil

≥-5≥-5

85W/90GL-585W/90GL-5

-15~+49-15~+49

FD-1FD-1

≥-25≥-25

-10#-10#

≥-5≥-5

10W/4010W/40

-25~+40-25~+40

10W/3010W/30

-25~+30-25~+30

FD-2FD-2

≥-35≥-35

-20#-20#

≥-5~-14≥-5~-14

10W/3010W/30

-25~+30-25~+30

15W/4015W/40

-20~+40-20~+40

FD-2AFD-2A

≥-45≥-45

-35#-35#

≥-14~-29≥-14~-29

15W/4015W/40

-20~+40-20~+40

20W/5020W/50

-15~+50-15~+50

FD-3FD-3

≥-50≥-50

80W/90GL-580W/90GL-5

-25~+49-25~+49

L-HV32 low temp.L-HV32 low temp.

wearable oilwearable oil

≥-20(cold region)≥-20(cold region)

https://www.besttruckmanuals.com/

6.3

6.3 Cautions Cautions on cooling on cooling systemsystem

(1) During operation, if the radiator of forklift “boils” or the (1) During operation, if the radiator of forklift “boils” or the temperature of coolingtemperature of cooling

liquid is too high, do not open the cover of liquid is too high, do not open the cover of radiator immediately. If the cover needs to beradiator immediately. If the cover needs to be

removed to find out the cause removed to find out the cause for it, reduce the rotational speed of for it, reduce the rotational speed of engine to the moderate,engine to the moderate,

slowly rotate the cover and not remove it very soon so as to prevent operators from beingslowly rotate the cover and not remove it very soon so as to prevent operators from being

scalded by the splashing liquid. When recovering the scalded by the splashing liquid. When recovering the radiator, it must be screwed tightly,radiator, it must be screwed tightly,

otherwise, the system may not otherwise, the system may not be well enclosed and the system be well enclosed and the system pressure stipulated cannotpressure stipulated cannot

be formed.be formed.

(2) There is a compensation can on the left of engine.The letter”FULL”and(2) There is a compensation can on the left of engine.The letter”FULL”and

“LOW”are marked on the upper and lower of “LOW”are marked on the upper and lower of the can wall.Correct antifreeze agent levelthe can wall.Correct antifreeze agent level

should be between letters. Antifreeze liquid of same type should be replenished after theshould be between letters. Antifreeze liquid of same type should be replenished after the

liquid leaks or evaporates. which is not changed around the year, regardless of summer orliquid leaks or evaporates. which is not changed around the year, regardless of summer or

winter. Generally, after being used for one year, it should be let out for filtration andwinter. Generally, after being used for one year, it should be let out for filtration and

purificpurification and then put to ation and then put to use again.use again.

(3) Based on (3) Based on diffedifferent working conditrent working conditionsions, , regulregularly clean the arly clean the outer surfaouter surface ce of theof the

radiator with detergent, compressed air or high-pressure water (no high than 4kg/cm ).radiator with detergent, compressed air or high-pressure water (no high than 4kg/cm ).

22

-5-5 --

https://www.besttruckmanuals.com/

6.4

6.4 Lubrication Lubrication system system tabletable

-6-6 --

https://www.besttruckmanuals.com/

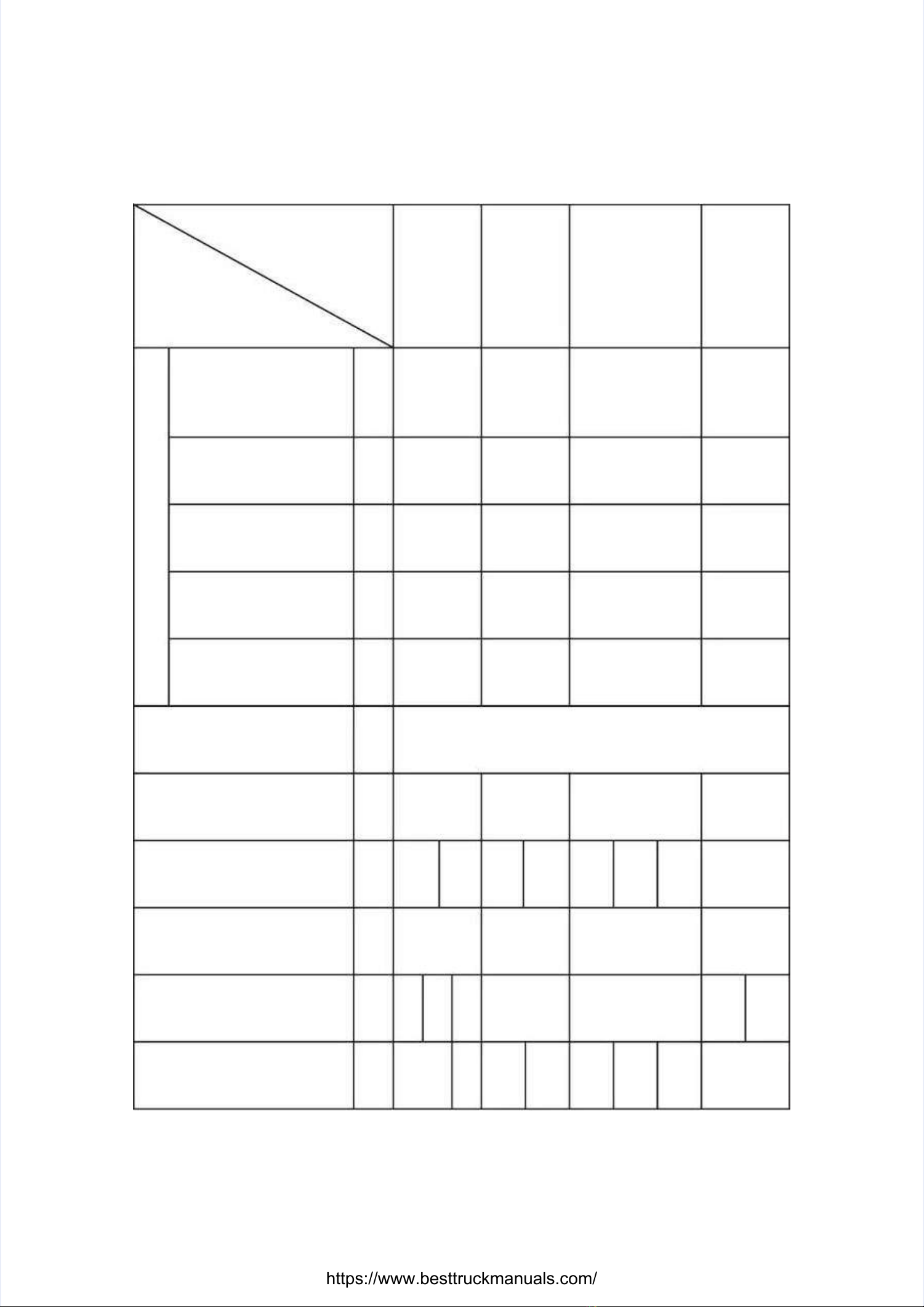

Ⅱ. Primary Technic Parameter of Forklift

Ⅱ. Primary Technic Parameter of Forklift

-7-7 --

Rated loadRated load

Load centerLoad center

Max.lift height(STD.)BMax.lift height(STD.)B

Free lift height(STD.)EFree lift height(STD.)E

Tilt angle Y/YTilt angle Y/Y

Min. turning radius WMin. turning radius W

Min.intersectinMin.intersecting g aisle aisle XX

Min.under clearance GMin.under clearance G

Wheelbase LWheelbase L

Tread Fwd/bwd S/TTread Fwd/bwd S/T

Overhang Fwd/bwd K/MOverhang Fwd/bwd K/M

Overall length HOverall length H

Overall width QOverall width Q

Mast CMast C

OverheadOverhead

gguuaarrd d PP

Height as fork liftingHeight as fork lifting

((WWiitth h bbaacckkrreesstt) ) AA

Length JLength J

Width(U)Width(U)

thickness(F)thickness(F)

Fork adjustable spaceFork adjustable space

((ououttsisiddes es of of ffororkk) ) RR

Truck weightTruck weight

LoadenLoaden

(fwd/bwd)(fwd/bwd)

UnloadenUnloaden

(fwd/bwd)(fwd/bwd)

Front 4Front 4

Rear 2Rear 2

Battery (voltage/capacity)Battery (voltage/capacity)

OverallOverall

heightheight

ForkFork

Axle loadAxle load

TyreTyre

kgkg

mmmm

mmmm

kgkg

V/AhV/Ah

5t5t 6t6t 7t7t 88t t 1100tt

5500000 0 66000000 7 700000 0 8800000 0 1100000000

600600

30003000

11995 5 220000205205 2 2000 0 221100

6 /126 /12

32503250 3 333000 0 3333770 0 3377000 0 33990000

2299660 0 3300000 0 3300440 0 3333110 0 33554400

200200 22550 0 224455

2222550 0 22550000 2800 2800

11447700//1177000 0 11660000//11770000

559900//66000 0 559900//66775 5 559900//77440 0 770000//77440 0 771188//774400

46604660 4735 4735 4800 4800 5 511660 0 55448800

19951995 2211665 25 2224455

2255000 0 22662255 2700 2700 2850 2850

2244550 0 22558855

4444220 0 44333300

12201220

115500XX555 5 115500XX660 0 115500XX6655 170X70 170X70 175X80 175X80

300 300 17017000~~ 340~1944 340~1944 410~2140 410~2140

79807980 8 866440 0 9933550 0 1100996600 12510 12510

11660/1320 13050/1590 14570/1780 17000/1950 20380/213011660/1320 13050/1590 14570/1780 17000/1950 20380/2130

4010/39704010/3970 388 3880/40/4760 760 3863860/50/549490 0 484840/40/6126120 0 5705700/60/6810810

8.25-15-14PR8.25-15-14PR 9.00-20-14PR 9.00-20-14PR

8.25-15-14PR8.25-15-14PR 9.00-20-14PR 9.00-20-14PR

24/8024/80

https://www.besttruckmanuals.com/

-8

-8 --

IItteem m UUnniitt

CC

PP

CC

DD

55

00

--

WW

XX

CC

PP

CC

DD

66

00

--

WW

XX

CC

PP

CC

DD

77

00

--

WW

XX

CC

PP

CC

DD

55

00

--

CC

11

00

CC

PP

CC

DD

66

00

--

CC

11

00

kgkg

mmmm

dedegg

mmmm

kgkg

mmmm

Km/hKm/h

mm/smm/s

knkn

Max.ratedMax.rated

Load centerLoad center

Max.lift heightMax.lift height

Free lift heightFree lift height

Tilt angle Fwd/BwdTilt angle Fwd/Bwd

Wheel baseWheel base

FrontFront

RearRear

Truck weightTruck weight

(With water and oil)(With water and oil)

Overall widthOverall width

At mastAt mast

Overall lengthOverall length

Min. under clearanceMin. under clearance

Min. turning radiusMin. turning radius

Max.traveling speedMax.traveling speed

laden/unladenladen/unladen

LadenLaden

UnladenUnladen

LadenLaden

UnladenUnladen

Gradeability ladenGradeability laden

Front 4Front 4

TreadTread

OverallOverall

heightheight

Lift speedLift speed

Max.tractionMax.traction

forceforce

TyreTyre

5500000 0 66000000 7000 7000 5 500000 0 66000000

606000

30003000

202055

6 6 //1122

22502250

14701470

17001700

79807980 8866440 0 9933550 0 88664400

19951995

25002500

4466660 0 447733554488000 0 44880022

202000

32503250 3 333000 0 33337700 3250 3250

2299//332 2 2266//2288

44000 0 44000 0 33000 0 443300

44110 0 44110 0 441100505000

442 2 441 1 5544

2222

2525%% 2 222% % 2200%%1515%%

88..2255--1155--1144PPR R 88..2255--2200--1144PPRR

Rear 2Rear 2 8.25-15-14PR 8.25-15-14PR

https://www.besttruckmanuals.com/

-9

-9 --

IItteem m UUnniitt

kgkg

mmmm

dedegg

mmmm

kgkg

mmmm

Km/hKm/h

mm/smm/s

knkn

Max.ratedMax.rated

Load centerLoad center

Max.lift heightMax.lift height

Free lift heightFree lift height

Tilt angle Fwd/BwdTilt angle Fwd/Bwd

Wheel baseWheel base

FrontFront

RearRear

Truck weightTruck weight

(With water and oil)(With water and oil)

Overall widthOverall width

At mastAt mast

Overall lengthOverall length

Min. under clearanceMin. under clearance

Min. turning radiusMin. turning radius

Max.traveling speedMax.traveling speed

laden/unladenladen/unladen

LadenLaden

UnladenUnladen

LadenLaden

UnladenUnladen

Gradeability ladenGradeability laden

Front 4Front 4

TreadTread

OverallOverall

heightheight

Lift speedLift speed

Max.tractionMax.traction

forceforce

TyreTyre

Rear 2Rear 2

CCPP

CC

DD

55

00

--

CC

UU

11

CCPP

CC

DD

66

00

--

CC

UU

11

CCPP

CC

DD

77

00

--

CC

UU

11

CCPP

CC

DD

88

00

--

CC

UU

CCPP

CC

DD

11

00

00

--

CC

UU

5500000 0 66000000 7 700000 0 8800000 0 1100000000

606000

30003000

202055

6 6 //1122

2222550 0 22550000 2800 2800

14701470 1600 1600

1177000 0 11770000

79807980 8866440 0 9933550 0 110099660 0 1122551100

1199995 5 22224455

25002500 2700 2700 2850 2850

4466660 0 44773355 4800 4800 5 511660 0 55448800

202000242455

32503250 3 333000 0 3333770 0 3377000 0 33990000

26/3026/30

373700 3 3550 0 228855444400363600

44000 0 33000 0 44770 0 338800

442 2 440 0 440 0 660 0 5588

222 2 222 2 22773131

2233% % 2200% % 2200% % 2277% % 2222%%

8.25-15-14PR8.25-15-14PR 9.00-20-14PR 9.00-20-14PR

8.25-15-14PR8.25-15-14PR 9.00-20-14PR 9.00-20-14PR

https://www.besttruckmanuals.com/

-10-

-10-

ModelModel

ItemItem

TypeType

Cyl.Number-Cyl.Number-

BoBore re ststrorokeke

Rated output/speedRated output/speed

Max.torque/speedMax.torque/speed

Min.fuel consumptionMin.fuel consumption

2-Speed gear Fwd/Bwd2-Speed gear Fwd/Bwd

BrakeBrake

Lifting speed laden/unladenLifting speed laden/unladen

Max.travel speedMax.travel speed

laden/unladenladen/unladen

Max.gradeabilityMax.gradeability

Max.traction force(laden)Max.traction force(laden)

mmmm

KwKw//

rprpmm

NmNm//

rprpmm

G/G/

kwkwhh

mm/smm/s

Km/hKm/h

%%

knkn

EE

nn

gg

ii

nn

ee

CC

PP

CC

DD

55

00

~~

77

00

--

WW

22

CC

PP

CC

DD

55

00

~~

77

00

--

CC

66

CC

PP

CC

DD

55

00

~~

77

00

--

XX

ss

CC

PP

CC

DD

55

00

~~

66

00

--

WW

FF

22

ISUZUISUZU

(diesel)(diesel)

A-6BG1QCA-6BG1QC

ChaoyangChaoyang

(diesel)(diesel)

6102BG6102BG

Komatsu(diesel)Komatsu(diesel)

S4D95LES4D95LE

WeifangWeifang

(diesel)(diesel)

R4105G32R4105G32

66--11005 5 11225656--11002 2 11118 8 44--995 5 11115 5 44--11005 5 112255

8822..33//2200000 80 811//2255000 0 6611//2244000 0 5599//22440000

416/416/

1400~16001400~1600 335533//1166550 0 229911//11660000 270/ 270/

1400~16001400~1600

22333 3 223311 221.5 221.5 243243

Power shiftPower shift

Power brakePower brake

VacuumVacuum

assistant orassistant or

power brakepower brake Power brakePower brake Vacuum Vacuum

assistantassistant

500/500/

550550

460/460/

500500

460/460/

600600

400/400/

600600

370/370/

550550

350/350/

500500

300/300/

380380

330/480 330/480

2266//330 0 2266//228 8 2244//228 8 2266//3300

35/35/

1919

32/32/

1919

30/30/

1919 20/15 20/15 22/20 22/20 26/26/

2323

22/22/

2020

554 4 553 53 53 3 5522 4 42 2 444 4 4411 41.45 41.45

https://www.besttruckmanuals.com/

Model

Model

ItemItem

TypeType

Cyl.Number-Cyl.Number-

BoBore re ststrorokeke

Rated output/speedRated output/speed

Max.torque/speedMax.torque/speed

Min.fuel consumptionMin.fuel consumption

2-Speed gear Fwd/Bwd2-Speed gear Fwd/Bwd

BrakeBrake

Lifting speed laden/unladenLifting speed laden/unladen

Max.travel speedMax.travel speed

laden/unladenladen/unladen

Max.gradeabilityMax.gradeability

Max.traction force(laden)Max.traction force(laden)

mmmm

KwKw//

rprpmm

NmNm//

rprpmm

G/G/

kwkwhh

mm/smm/s

Km/hKm/h

%%

knkn

EE

nn

gg

ii

nn

ee

CC

PP

CC

DD

88

00

--

WW

44

CC

PP

CC

DD

11

00

00

--

WW

44

CC

PP

CC

DD

88

00

--

CC

33

CC

PP

CC

DD

11

00

00

--

CC

33

ISUZU(diesel)ISUZU(diesel)

A-6BG1QCA-6BG1QC Chaoyang Chaoyang (diesel) (diesel) 6102BG6102BG

66--11005 5 11225 5 44--11002 2 111188

8822..33//2200000 0 8811//22550000

441166//11440000~~1166000 0 335533//11665500

22333 3 223311

Power shiftPower shift

Power brake-pedal brakePower brake-pedal brake

380/410380/410 310/350 310/350 3 39900//44880 0 331100//339900

26/3026/30

2211//221 1 2211//221 1 2200//1155

6633..2 2 558 8 551 1 5577

-11--11-

https://www.besttruckmanuals.com/

Specification

Specification

ModelModel

TypeType

Cyl.NCyl.Numberumber-Bore -Bore StrokStrokee

Total displacementTotal displacement

Compression RatioCompression Ratio

Rated speedRated speed

Rated outputRated output

Max.torqueMax.torque

Max.speed (unladen)Max.speed (unladen)

Min.speed(unladen)Min.speed(unladen)

Min.fuel consumptionMin.fuel consumption

(laden)(laden)

EE

nn

gg

ii

nn

ee

UnitUnit

mmmm

ll

R/minR/min

kwkw

Nm/rpmNm/rpm

rpmrpm

rpmrpm

G/kwhG/kwh

CPCD50~70-WXCPCD50~70-WX

CA4110CA4110

In line 4-cylinder,In line 4-cylinder,

4-cycle, water-cooled,4-cycle, water-cooled,

direct injectiondirect injection

4-110 1254-110 125

4.7524.752

17:117:1

23002300

6464

305/1400~1600305/1400~1600

25302530

700700

230230

CPCD50~60-C10CPCD50~60-C10

6102GB-A6B6102GB-A6B

In line 6-cylinder,In line 6-cylinder,

4-cycle,water-cooled,4-cycle,water-cooled,

direct injectiondirect injection

6-102 1186-102 118

6.4946.494

1717

22002200

7373

353/1650353/1650

-12--12-

https://www.besttruckmanuals.com/

Specification

Specification

ModelModel

TypeType

Cyl.NCyl.Numberumber-Bore -Bore StrokStrokee

Total displacementTotal displacement

Compression RatioCompression Ratio

Rated speedRated speed

Rated outputRated output

Max.torqueMax.torque

Max.speed (unladen)Max.speed (unladen)

Min.speed(unladen)Min.speed(unladen)

Min.fuel consumptionMin.fuel consumption

(laden)(laden)

EE

nn

gg

ii

nn

ee

UnitUnit

mmmm

ll

R/minR/min

kwkw

Nm/rpmNm/rpm

rpmrpm

rpmrpm

G/kwhG/kwh

CPCPCDCD5050~7~70-0-CUCU1 1 CPCPCDCD8080~1~10000-C-CUU

BB33..33--CC880 0 44BBTTAAAA33..99--CC111100

In line In line 4-cylinder,4-cyc4-cylinder,4-cycle,water-cooled, directle,water-cooled, direct

injectioninjection

44--995 5 11115 5 44--11002 2 112200

3.263.26 3.93.9

17.5:117.5:1 18:1 18:1

2222000 0 22220000

6060 8282

291/1600291/1600 468/1500 468/1500

2244550 0 22445500

800800 850850

22117 7 221166

-13--13-

https://www.besttruckmanuals.com/

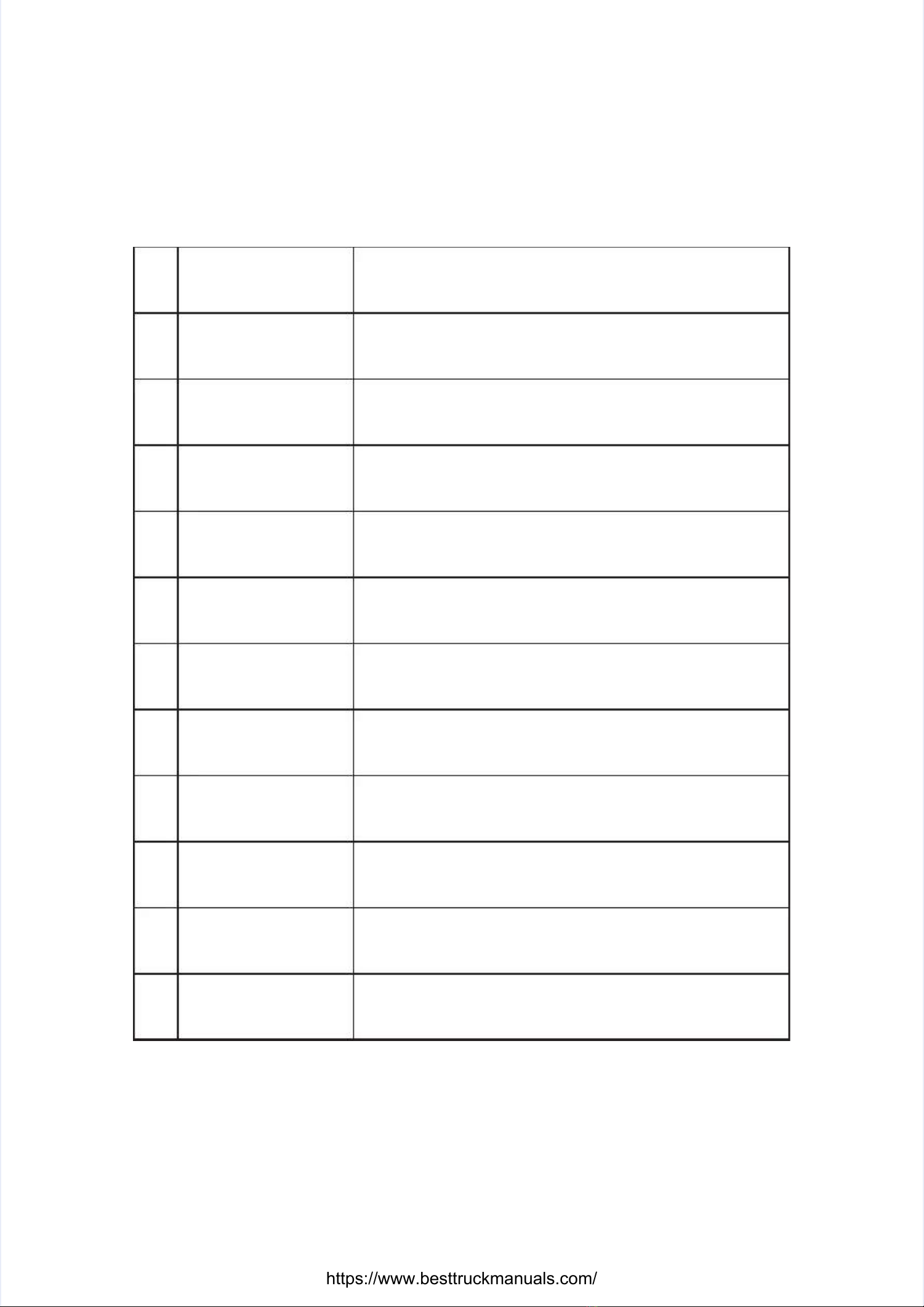

Ⅲ.

Ⅲ.

Primary Assembly of Forklift TruckPrimary Assembly of Forklift Truck

Primary Assembly of Forklift TruckPrimary Assembly of Forklift Truck

NoNo..

0101

0202

0303

0404

0505

0606

0707

0808

0909

1010

1111

NameName

Engine SystemEngine System

Transmission SystemTransmission System

Drive AxleDrive Axle

Steering SystemSteering System

Steering AxleSteering Axle

Hoist SystemHoist System

Frame SystemFrame System

Operation systemOperation system

Hydraulic systemHydraulic system

Electric systemElectric system

Overhead guardOverhead guard

Includes engine mounting,fuel system,exhaust system,Includes engine mounting,fuel system,exhaust system,

cooling system(torque converter pipelines)etc.cooling system(torque converter pipelines)etc.

Includes transmission, tor-con, transmission shaftIncludes transmission, tor-con, transmission shaft

control linkages etc.control linkages etc.

Includes axle house, half shafts, differential,Includes axle house, half shafts, differential,

hub reduction, brake, front wheel etc.hub reduction, brake, front wheel etc.

Includes powered steering unit, redirector etc.Includes powered steering unit, redirector etc.

Includes axle box, steering cylinder,rear wheel etc.Includes axle box, steering cylinder,rear wheel etc.

Includes outer & inner mast, lift bracket, backrest, fork,Includes outer & inner mast, lift bracket, backrest, fork,

tilt cylinder, lift cylinder, end roller, side roller, sheave,tilt cylinder, lift cylinder, end roller, side roller, sheave,

chain etc.chain etc.

Includes frame, cabinet,tank in frame, hood, floor,Includes frame, cabinet,tank in frame, hood, floor,

counterweight, seat,cover of radiator etc.counterweight, seat,cover of radiator etc.

Includes operation series of brake & inching control,Includes operation series of brake & inching control,

parking brake and accelerator etc.parking brake and accelerator etc.

Includes pump,valve,high & low pressure oil pipe,Includes pump,valve,high & low pressure oil pipe,

connecter,etc.connecter,etc.

Includes lights,battery,instruments harness,meter etc.Includes lights,battery,instruments harness,meter etc.

Overhead guard(cab is option)Overhead guard(cab is option)

ContentsContents

-14--14-

https://www.besttruckmanuals.com/

Ⅳ. The structure, principle, adjustment and maintenance of forklift

Ⅳ. The structure, principle, adjustment and maintenance of forklift

1. Dynamic system1. Dynamic system

(1) Brief introduction(1) Brief introduction

The dynamic system includes the engine, air inlet system, cooling system and exhaustThe dynamic system includes the engine, air inlet system, cooling system and exhaust

system, etc. The engine is linked to transmissystem, etc. The engine is linked to transmission device. The holder of engine is connectesion device. The holder of engine is connectedd

with the frame of the forklift with the frame of the forklift through a rubber cushion to reduce vibration. The engine isthrough a rubber cushion to reduce vibration. The engine is

connected to the tor-con,the transmission,transmission shaft and drive axle,see followingconnected to the tor-con,the transmission,transmission shaft and drive axle,see following

figure:figure:

Fig.1.1 Engine mountedFig.1.1 Engine mounted

(2) The engine and its (2) The engine and its accessoaccessoriesries

T hT he e p op owewer r o f o f 5 -5 -7 t 7 t f of or kr kl il if t f t t rt ru cu ck k is is p rp ro vo vi di de d ed b y b y d id iese se l e l ene ng ig in e n e I SI SU ZU ZUU

(6BG1),KOMATSU(S4D95LE) imported from Japan. The homeland diesel engine includes(6BG1),KOMATSU(S4D95LE) imported from Japan. The homeland diesel engine includes

Chaoyang(6102GB7),Weifang(R4105G32).Chaoyang(6102GB7),Weifang(R4105G32).

The power of 8-10t forklift truck is provided by diesel engine ISUZU (6BG1),The power of 8-10t forklift truck is provided by diesel engine ISUZU (6BG1),

imported from Japan. The homeland diesel engine imported from Japan. The homeland diesel engine includes Chaoyang(6102GB7). Refer toincludes Chaoyang(6102GB7). Refer to

relrelevaevant manuant manual l for the detaifor the details of ls of opeoperatration and maintion and maintenaenancences s for the for the engengineine. . ThThee

structure figure of ISUZU(6BG1) engine as following:structure figure of ISUZU(6BG1) engine as following:

Transmission shaftTransmission shaft

Drive axleDrive axle

TransmissionTransmission

-15--15-

https://www.besttruckmanuals.com/

Fig.1.2 A-6BG1QC diesel engine

Fig.1.2 A-6BG1QC diesel engine

Fuel filterFuel filter Generator Generator

GreaseGrease

compress SW.compress SW.

Grease fdterGrease fdter

Oil injection holeOil injection hole

Start motorStart motor

NameName

TypeType

Cyl.nCyl.numbeumber-borr-bore e strokstrokee

Total displacement (L)Total displacement (L)

Compression ratioCompression ratio

PerformancePerformance

Rated speed (rpm)Rated speed (rpm)

Rated output (kw)Rated output (kw)

Max.torque (N-m/rpm)Max.torque (N-m/rpm)

Full-load fuel rate (g/kwh)Full-load fuel rate (g/kwh)

Idle(rpm)Idle(rpm)

Weight(kg)Weight(kg)

Measure(mm)Measure(mm)

Ignition orderIgnition order

Rotating directionRotating direction

A6BG1QCA6BG1QC

6-6-10105m5mm m 12125m5mmm

6.4946.494

1717

20002000

82.382.3

416/1400-1600416/1400-1600

232333

707000

454500

11112929.5 .5 67672.2.0 0 86860.0.00

1-5-3-6-2-41-5-3-6-2-4

ClockwiseClockwise

4-cycle,water-cooled, in line,overhead4-cycle,water-cooled, in line,overhead

valve systemvalve system

-16--16-

https://www.besttruckmanuals.com/

Table of contents

Other HELI Forklift manuals