Heliodyne GOBI 406 001 User manual

EXCELLENCE

BY DESIGN

INSTALLATION

GUIDE

HPAK SYSTEMS

SOLAR HOT WATER

TABLE OF CONTENTS

1. PREPARATIONS 3-9

GOBI INSTALLATION

10-11

2.

12-13

14-16

20

21

17-19

3. HPAK INSTALLATION

4. PIPING

5. COMMISSIONING

6. O & M

NOTES 3

SOLAR HOT WATER

1. PREPARATIONS

1.0. General Notes

1.0.0. Safety Guidelines

Carefully review all instructions in this manual for installation and use. Do not modify Gobi

Collectors or Helio-Pak under any circumstances; use only as designed. This manual and

its content are integral parts of both the Helio-Pak and Gobi Solar Collector warranties.

Noncompliance with these guidelines will void all warranties.

Follow all local building codes and regulations, as well as these industry accepted

guidelines and standards:

IAPMO USEC, UBC, UPC

ASHRAE Solar Energy Equipment

NFPA 70 National Electric Code

ASCE 7-05 Minimum Design Loads for Buildings and Other Structures

Select an installation location that is easily accessible for maintenance and servicing.

1.0.1. Collector Storage and Handling

Keep collectors covered when storing.

Avoid lifting collectors by the headers. Take care not to scratch the tempered solar glass;

follow the glass breakage guidelines at the end of this manual in case of breakage.

Gobi collectors nest and lock into each other for horizontal transportation. Do not

transport Gobi upside down or standing on a side.

1.0.2. Collector Installation

Make a site visit prior to installation to verify adequate installation conditions:

Collector sun exposure, especially during crucial solar hours of 10AM• – 2PM.

Take into consideration deciduous tree shading, structures, chimneys, etc.

Use a minimum tilt of 10• ° in mild areas and 30° in areas with snow.

Orient collectors within 20° of true South (in North latitudes); use internet maps•

rather than compass readings for verification.

Ideal collector tilt for hot water production is equal to site latitude. For space•

heating combination systems, use tilt equal to latitude plus 15°. Heliodyne

recommends a standard of 35° for hot water and 45° for space heating,

regardless of location. Use racks only when necessary, as variation up to 15°

can have only small effects on performance.

Avoid banking• of snow and ice below or on the collectors.

Never mount Gobi collectors horizontally in a drainback system.•

• Heliodyne recommends 6-12” of flex tubing before any rigid copper lines to allow

for thermal expansion in the copper tubing.

1.0.3. Minimum Heat Storage

A minimum of 1.5 – 2.0 gallons of liquid heat storage per square foot of Gobi collector

(e.g., 60 – 80 gallons per Gobi 410) is recommended.

Minimize stagnation (no load, no flow) conditions on peak output days by using

appropriate system sizing and maximizing year round usage. For design assistance,

contact Heliodyne.

Ensure the backup heating capacity is properly sized to produce hot water for installation

site on days of little or no solar energy production. Use only ASHRAE 90.2 compliant

storage tanks and heaters with R-16 or higher.

1.0.4. Equipment for Installation

For a complete and functional SHW system, ensure the following equipment is ready for

installation at the job site:

Gobi Solar Collectors•

Rack or Flush mount hardware kit•

Appropriate roof penetration hardware and sealant•

Copper tubing, type M or L for collector / heat transfer appliance connections,•

adapters, elbows and fittings.

96/4 Tin/Silver solder•

Non-rubber based insulation (Armaflex); 1/2” wall / R2.6l minimum•

UV resistant covering or coating for outdoor exposed insulation•

Helio-Pak heat transfer appliance (HPAK)•

Isolation valves, tempering valve, air vent•

Storage tank with adequate volume for collectors installed•

Connections for storage tank (flexible or otherwise)•

Dyn-O-Flo HD high temperature propylene glycol or equal•

Pipe hangers or supports installed per code requirement installed without•

compromising any insulation.

1.0.5. Tools

Heliodyne collectors and heat transfer appliances do not require any special tools. Never

use plumbing wrenches on hex connections. Always tighten the bolts rather than the

nuts. Aside from using the standard plumbing tools (torch, pipe cutter, etc.) the following

tools and sizes are used in Heliodyne equipment:

9/16” wrench / socket for 3/8”- 16 bolts and nuts•

3/4” wrench / socket for 1/2” - 13 hanger bolts and nuts•

Adjustable hex wrench for 1.25” thru 1.875” hex sizes•

Phillips screw driver (for tank sensor installation)•

1/4” drill bit for 3/8” lag screws•

3/8” drill bit for 1/2” lag screws•

1.0.6. Safety Equipment

Working on roof tops and other elevated collector installation sites as well as using

flames can be dangerous; use extreme caution and follow all local codes and good safety

practices when installing. Heliodyne is not responsible for job safety nor any accidents

that may occur, and always recommends:

Safety glasses•

Roof harness•

Scaffolding rather than ladders•

Solder in well ventilated areas

•

1.0.7. Heliodyne OG-300 Certified Systems and SRCC Numbers

Installers: check box next to OG-300 system installed (if applicable)

HPAK 016 1 408 G 65 ACS 300-1992-010A

HPAK 016 1 410 G 80 ACS 300-1992-010B

HPAK 016 2 408 G 120 ACS 300-1992-010C

HPAK 016 1 406 G 50 ACS 300-1992-010J

HPAK 016 1 406 G 80 ACS 300-1992-010K

HPAK 016 2 406 G 80 ACS 300-1992-010L

HPAK 016 2 406 G 120 ACS 300-1992-010M

HPAK 016 1 408 G 80 ACS 300-1992-010N

HPAK 016 2 410 G 120 ACS 300-1992-010O

HPAK 016 1 410 G 65 ACD 300-1992-013A

HPAK 016 2 408 G 80 ACD 300-1992-013B

HPAK 016 2 408 G 120 ACD 300-1992-013C

HPAK 016 2 410 G 120 ACD 300-1992-013D

HPAK 016 1 408 G 65 ACD 300-1992-013F

HPAK 016 1 406 G 80 ACD 300-1992-013G

HPAK 016 2 406 G 80 ACD 300-1992-013H

HPAK 016 1 408 G 80 ACD 300-1992-013I

HPAK 016 1 410 G 80 ACD 300-1992-013J

HPAK 016 1 410 G 80 ACD Z 300-1998-001A

HPAK 016 2 408 G 80 ACD Z 300-1998-001B

HPAK 016 2 408 G 120 ACD Z 300-1998-001C

HPAK 016 2 410 G 120 ACD Z 300-1998-001D

HPAK 016 1 408 G 65 ACD Z 300-1998-001F

HPAK 016 1 406 G 80 ACD Z 300-1998-001G

HPAK 016 2 406 G 80 ACD Z 300-1998-001H

HPAK 016 1 408 G 80 ACD Z 300-1998-001I

The solar energy system described in this Manual, when properly installed

and maintained, meets or exceeds the minimum standards established by

the SRCC. This certification does not imply endorsement or warranty of this

product by SRCC.

Contact Heliodyne for service in your area: 1.888.878.8750

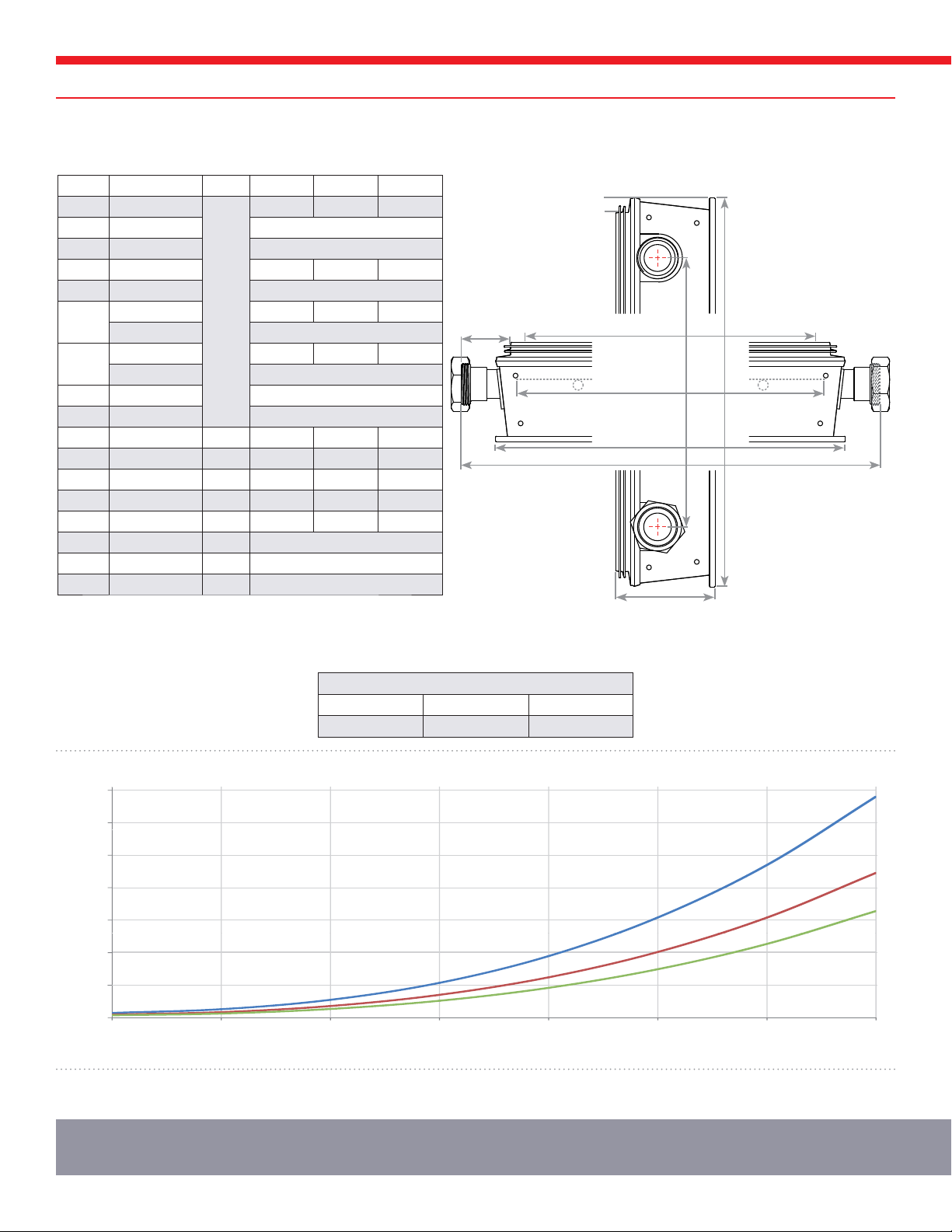

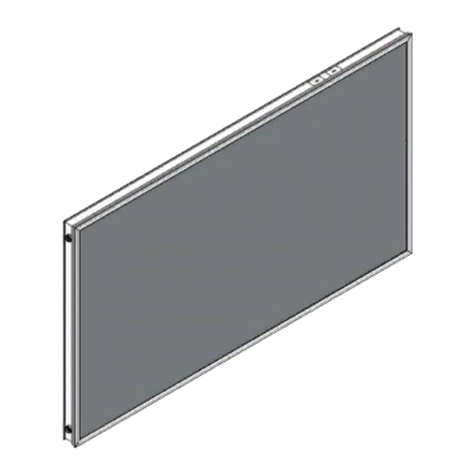

COLLECTOR SPECIFICATIONS

1.1. Technical Specifications for Gobi

DIM DESCRIPTION UNITS GOBI 406 GOBI 408 GOBI 410

L Length

inch

81.56 97.56 121.56

W Width 47.56

T Thickness 3.90

H Header Length 76.88 92.88 116.88

M Header Width 50.25

A

Aperture Length 79.25 95.25 119.25

Aperture Width 45.25

P

Plate Length 78.0 94.0 118.0

Plate Width 46.25

D Flashing Base 0.61

F Flashing Header 1.93

L x W Gross Area ft226.94 32.22 40.15

ALx AWNet Area ft224.90 29.93 37.47

g Dry Weight lb. 97 110 128

G Full Weight lb. 103.2 116.9 135.8

V Volume Gal. 0.75 0.83 0.95

- Max Pressure PSI 150 (10 Bar)

- Test Pressure PSI 300 (20 Bar)

- Stag. Temp. °F 397.6 (203 °C)

A

F

D

P

W

M

T

LH

1.2. Flow and Pressure Loss1

RECOMMENDED DESIGN FLOW RATES WITH GLYCOL2

GOBI 406 GOBI 408 GOBI 410

0.85 Gal / min 1.0 Gal / min 1.25 Gal / min

PRESSURE DROP PLOT

1. Losses calculated at recommended Gobi design flow rates for 50/50 propylene glycol / water solution.

2. Minimum flow rates shown. Do not exceed recommended flow rates by more than (3) times.

Number of Gobi in Array (8 Max)

ΔP (Inches H20)

1

0

10

20

30

40

50

60

70

2345678

Gobi 410

Gobi 408

Gobi 406

COLLECTOR ORIENTATION AND PLUMBING 5

SOLAR HOT WATER

1.3. Gobi Orientation and Plumbing

OR

OR

Figure 1.3.-2 Two DOS-Discs Per Vertical ArrayFigure 1.3.-1 DOS-Disc Assembly (p/n: 50013) Figure 1.3.-3 Two DOS-Discs Per Horizontal Collector

S

15° 15°

+ / - 15°

Helio-Pak

Helio-Flo

Drain Back

Helio-Pak

Helio-Flo

Drain Back

Combi DHW:

DHW / Pool:

45°

35°

2x

66

67

47 *001 Models Only

*032 Shown

*Optional

2

14

3

16 13

5

717

11 12

25 26

1

24

5

8

45

4

61

62

63

65

64

15 13

9

20 21

13

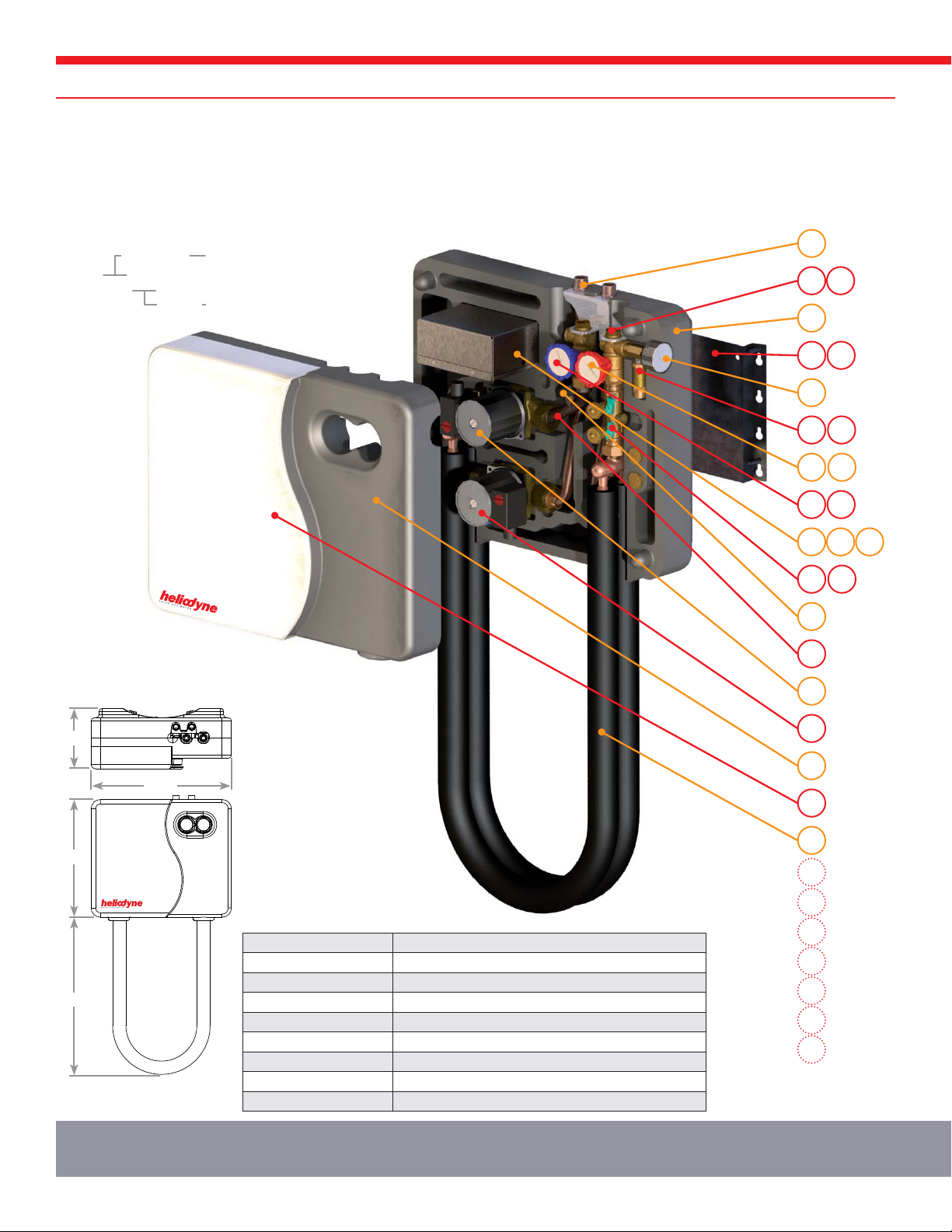

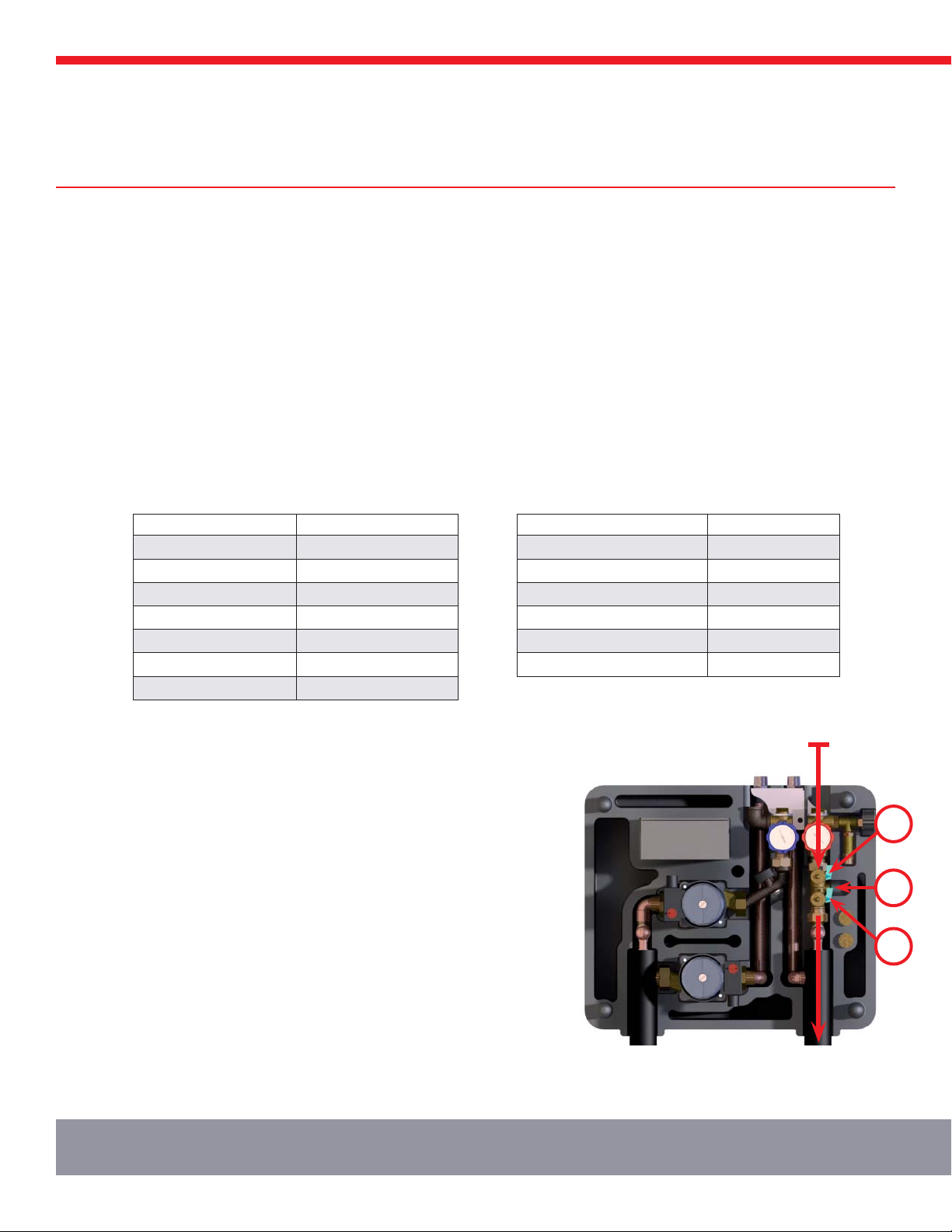

HPAK SPECIFICATIONS

1.4. Helio-Pak Heat Transfer Appliance HPAK

Insulated solar hot water system, closed loop glycol / water, double wall heat exchanger with visual leak detection, control and sensors, filling

valve and hot / cold temperature and pressure indication.

*HPAK 032 shown.

024 & 048 HX’s measure 43”

25.0”*

18.9”

9.7”

22.5”

Figure 1B-1: HPAK Dimensions

HPAK 0XX 00X

Heat Exch.

000 Std

001 Pro

016 ,000 Btu/hr

024 ,000 Btu/hr

032 ,000 Btu/hr

048 ,000 Btu/hr

Control

1.5. Technical Specifications

Maximum Operating Conditions 150 psig / 275 °F

Heat Transfer Fluid 40-50% Dyn-O-Flo HD and Water

Solar Loop Connections Compression fittings for 3/4” Type M or L Copper, 7/8” OD (ASTM B88)

Domestic Water Connections 3/4” Male NPT Fittings

Pressure Relief Barbed Hose Connection (For 1/4” ID Hose)

Gaskets EPDM

Domestic Water Contact Material Type M or L Copper & Bronze (Pump)

Insulation EPP Foam (Casing), Armaflex (HX)

Thermal Conductivity 0.25 Btu·in / hr·ft2·°F (0.036 W/m·K)

Item

Numbers

HPAK SPARE PARTS LIST 7

SOLAR HOT WATER

1.6. HPAK Replacement Parts

1.6.0. HPAK Spare Parts Table

ITEM CODE PART NUMBER DESCRIPTION QUANTITY

1

HPAK 16 DW

HPAK 24 DW

HPAK 32 DW

HPAK 48 DW

40020

40095

40096

40097

Pre insulated double wall HPAK U Tube

Heat Exchanger with visual leak detection (IAPMO Listed) 1

2 EPP Foam Front 21250 Front insulation casing 1

3 EPP Foam Back 21251 Back insulation casing 1

4 Acrylic Cover 21254 Front white acrylic cover with logo 1

5a UPS 15-58 Cil2 23098 PPG Volute 3-Speed circulation pump (HPAK 016 Models) 2

5b UPS 15-78 Cil2 23299 PPG Volute 3-Speed circulation pump (HPAK 024-048 Models) 2

7 PRV 23001 150 psig, 1/4” NPT pressure only relief vavle 1

8 PGauge 21214 Back entry pressure gauge, 0–160 psi 1

9 2-40FloCast 21199

21202

Bronze flow casting, with flow meter input, Pro models only

Bronze flow casting, without flow meter input 1

11 Comp. Nut 21191 7/8” OD copper tube brass compression nut 2

12 Comp. Ring 21192 7/8” OD copper tube brass compression ring 2

13 Combo Gasket 21186 EPDM gasket for combo valves 3

14 Combo Valve: Hot 23090 Hot combination valve: check, ball, temperature 1

15 Combo Valve: Cold 23091 Cold combination valve: check, ball, temperature 1

16 Combo Valve: Fill 23092 Filling combination valve 1

17 EX-2

EX-5

23030

23031

2-gallon bladder type expansion tank

5-gallon bladder type expansion tank 1

20 Tank Bracket 21204 Tank mounting bracket 1

22 Mtg Screws 21194 1/4 - 20 x 1” Self-tapping screws for tank mount 8

24 HP Elec. Box - bot 21198 HPAK electrical box - bottom 1

25 HP Elec. Box - top 21197 HPAK electrical box - top 1

26 Delta- T 21153

21270

Delta - T Control Board

Delta - T Pro Control Board, Pro models only 1

29 SENS 000 001 23029 10,000 Ohm Thermistor Sensors 2

45 HPAK - DHW Tube 40029 DHW pump inlet tube, flanged, 3/4” Type M 1

47 Grundfos VFS 2-40 23086 Grundfos vortex flow and temperature sensor, Pro models only 1

Optional Equipment (Not Included in HPAK Package)

61 ZZZZ 000 003 23020 Tempering valve, 3/4” sweat 1

62 AV700 23021 Air vent for filling, 1/2” Male NPT 1

63 SENS 000 002 23025 Sensor wire -

64 DFLO 001 000 23040 Dyn-O-Flo HD propylene glycol concentrate -

65 ZZZZ 000 005 23023 Tank bypass valve 1

66 ITLS 000 002 50064 Collector loop filling station -

67 ITLS 000 001 50078 Propylene glycol test kit -

HPAK SYSTEM COMPONENTS OVERVIEW

1.6.3. Operation of Combo Valves

The combo valves are integrated check and ball valves, with temperature gauges. Cracking pressure (minimum fluid flow pressure)

of the check valves is 0.30 psi. The valves can be operated by turning the plastic handles clockwise, with note taken of the position

of the slots on the handles, indicating valve position as pictured in figures 1.6.3.-1 – 3 below. To ensure proper compression fitting

seals, clean and round copper tubing must be used. Use a counter wrench on the hex provided to fully torque compression nut

fittings. Bush up or down as necessary for proper flow rates.

1.6.1. Tempering Valve

Install a tempering valve to prevent scalding; the solar storage may reach 180°F. Some areas may require a rated Anti-Scald

valve.

For dual tank systems with a gas backup, install the tempering valve before the gas water heater and after installing the solar

storage tank, to avoid a service call for high limit fuse replacement. For dual tank systems with an electric tank, the tempering

valve may be installed before or after the tank. For instantaneous water heaters as backup, consult the manufacturer for the

recommended method of tempering or bypass of solar heated water into the heater.

1.6.2. System Overheat Protection and Operation of Pressure Relief Valve and Expansion Tank

The HPAK comes with a preinstalled pressure only relief valve, nonadjustable and pre-set at 150 psig. A 1/4“ barbed hose fitting is

supplied for routing relief fluid to a drain or retaining vessel.

In addition, the system comes with a pre-sized bladder type expansion tank. The acceptance volume of the expansion tank

should be large enough to store up to 17 – 20% of the total collector system fluid volume.

With these safety precautions, and high temperature Dyn-O-Flo HD propylene glycol, the system can stagnate for short periods.

If extended periods (2 weeks or more) are expected, install a Delta-T Pro with the proper vacation setting. Additionally, the

system should never have less than 1.5 gallons of storage for each square foot of collector surface area.

1.6.4. Operation of Filling Valve

The filling valve integrates three gate valves into one.

The green handles operate the inlet and outlet of the

valve, while the drain fitting on the side enables either

filling or system operation. Always fill the system in the

direction of the flow path.

If not using a Heliodyne filling station, hose adapters

are set into the HPAK foam to the right of the fill

valve.

16

14

15

61

7

17

Figure 1.6.4.-1: Drain Fitting Open

(Operation Position)

Figure 1.6.4.-2: Drain Fitting Closed

(Fluid Servicing)

Figure 1.6.3.-1: Ball Valves Open

(Operation Position)

Figure 1.6.3.-2: Check Valves Open

(Fluid Servicing)

Figure 1.6.3.-3: Ball Valves Closed

(HPAK Servicing)

Item

Numbers

HPAK SYSTEM COMPONENTS OVERVIEW 9

SOLAR HOT WATER

1.6.7. 3-Speed Pump Operation

The DHW and collector circulation pumps are identical bronze volute pumps; they come prewired, set at speed 2. Depending on

Gobi surface area installed, the speed may need to be adjusted by rotating the red knob to desired speed. Use Table 1.6.7.-1 for

pipe size, collector surface and speed reference. Table 1.6.7.-2 shows the pump performance.

UPS 15-58 Cil2 Power Ratings:

Speed 1: 55 Watts

Speed 2: 65 Watts

Speed 3: 75 Watts

1.6.5. Solar Control and HPAK electrical

THE ELECTRICAL INSTALLATION SHOULD BE PERFORMED BY AN AUTHORIZED PROFESSIONAL. FOLLOW ALL LOCAL REGULATIONS AND

CODES WHEN INSTALLING WIRE, FUSES, GROUNDING, ETC. PROTECT THE HPAK FROM OVERCURRENT. BEFORE ANY ELECTRICAL WORK

IS DONE, ENSURE THE HPAK LINE CORD IS DISCONNECTED FROM THE ELECTRICAL SOURCE.

Both the HPAK 000 and 001 come with the basic internal electrical wiring already completed. For simple DHW operation, the

installer only needs to plug in the HPAK line cord into a nearby 120 VAC, 60 Hz grounded wall outlet and wire the storage and

collector sensor appropriately. The control comes prewired with two sensor lines. Use 22 AWG or larger cable if the sensor lines

need to be extended. Connect the sensors to wire using non-metal wirenuts, or other corrosion resistant connection method. Ensure

the control high limit is set at or below the tank manufacturer’s recommended limit.

If attaching additional sensors or wiring, such as for the Pro models, remove the top cover for the electrical box and make the

appropriate connections. See the Delta-T or Delta-T Pro manual for controller installation.

1.6.6. Flow Sensor: 001 Models

The HPAK pro models come with a digital vortex flow and temperature sensor preinstalled and wired to the Delta-T pro control. No

adjustment is necessary. See the Delta-T Pro Manual for in-depth explanation.

25

26

24

5

5

47

Table 1.6.7.-1: HPAK Piping Recommendations

HPAK HEAT EXCHANGER 016 024 032 048

Recommended Flow Rate (GPM) 3 4 6 9

Max Gobi Surface Area (Ft2) 96 144 192 288

Recommended Pump Speed 1 2 2 3

Max Piping Resistance (Ft H20)2567

Item

Numbers

Figure 1.6.7.-1: Grundfos UPS 15-58 CiL2 Pump

16

18

6

8

10

12

14

0

2

4

02468101214

40

50

60

70

80

40

02468101214

Table 1.6.7.-2: UPS 15-58 CiL2 Performance

Q [US GPM]

SPEED

H [ft]P [W]

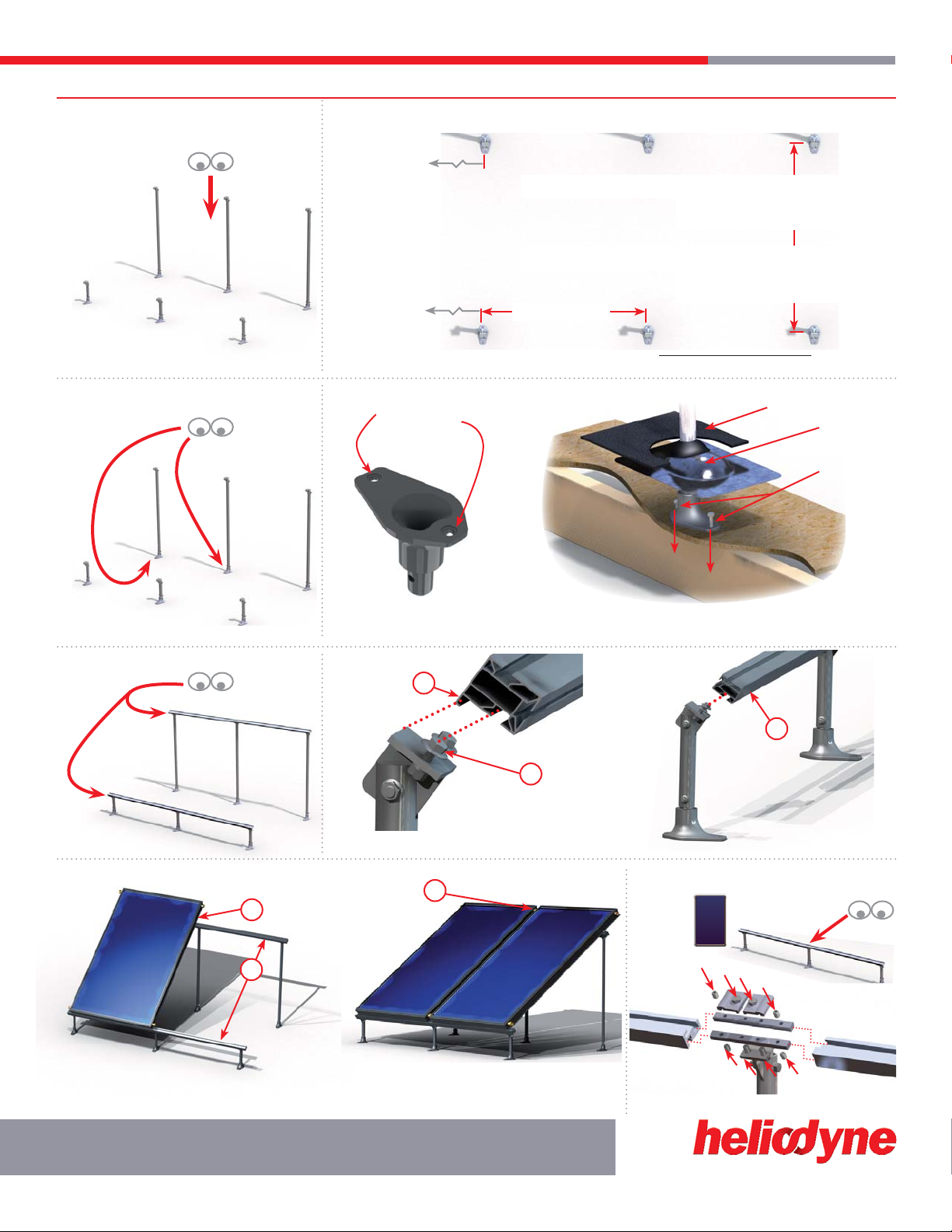

2. MOUNTING HARDWARE

2

1

3*002 Shown

RACK 000 000: 4.00”

RACK 000 001: 6.40”

RACK 000 002: 10.70”

2.0.0. RACK 000 00X Components and Leg Assembly

2.0. Rack Mounting Overview

B

A

C

D

D

C

E

3/8-16 x 1” SS Bolt

With Flat Washer

Lock Washer

3/8-16 SS Nut

3/8-16 x 1-3/4 SS Bolt

001 & 002:

3/8-16 x 1-3/4 SS Bolt

000:

3/8-16 x 2 SS Bolt

3/8-16 SS Serrated Flange Nut

Rail T - Foot

F

E

RACK 000 000: 47.30”

RACK 000 001: 49.40”

RACK 000 002: 49.40

2.0.1. RACK Replacement Parts

ITEM CODE PART NUMBER DESCRIPTION QUANTITY

1 CLIP 000 000 40082 Gobi Rail Clamp, 3/8-16 x 1” SS Bolt, Flange Nut (set of 4) 1 / Gobi

2 RAIL 002 000 40090 2x102.0” Gobi Mounting Rail, 2xCLIP 000 000 set See Note 1

3

RACK 000 000

RACK 000 001

RACK 000 002

40080

40081

40083

Commercial Mount, 4” Front Leg, 47” Rear Leg

Flat Roof Rack Mount, 4” Front Leg, 47” Rear Leg

Flat Roof Rack Mount, 8” Front Leg, 47” Rear Leg

# Gobi + 1

4 RAIL 000 001 40089 Splice Kit for Joining Rails (Includes 2 for upper and 2 for lower rail) 1 Kit

1. Order minimum quantity of rails that will accommodate number of collectors in array.

2. RACK 000 00X Kits require field assembly.

3. 47” Rear tilt leg is not for tilts greater than 45° on 408 or 410 collectors

RACK MOUNTING INSTALLATION

45-50.25” MAX

2 X

3/8 x 3-1/2” Lag*

OATEY®

1-1/4” – 1-1/2” DIA

Shingle

(Cutout not required)

Gobi Tilt = 45°

Gobi Tilt = 35°

RACK 000 000: 43.0”

RACK 000 001: 43.3”

RACK 000 002: 38.7”

RACK 000 000: 61.8”

RACK 000 001: 61.4”

RACK 000 002: 55.3”

OR

2.1. Rack Installation

2.1.0. Rack Leg Spacing

2.1.1. Rack Foot Mounting

2.1.2. Rail Mounting

2.1.3. Collector Mounting 2.1.4. Rail Splice (optional)

a

a

a

a

b

b

>2x

b

b2

3

4

5

1

1

1. Note rail orientation

2. Insert bolt head and flat washer into rail channel, lock washers and nuts compressing rail foot

1. Spacing for tilt is independent of collector size.

2. For other tilts the distance between front and rear mounting points =

(Rear Leg Height - Front Leg Height)

Tan (Gobi Tilt Angle)

3. Brace rails for first collector

4. Place first collector and install all (4) Helio-Clips.

Tighten bolts on Helio-Clips to engage locking serrated flange nut.

Roof Sealant

RACK MOUNTING INSTALLATION 11

SOLAR HOT WATER

5. Insert O-rings, tighten Unions. Take care not to crimp O-ring.

Do not use thread lock or sealants

*While lag screws are provided with most kits, consult the American Wood Council NDS 2005 for proper lag

screw specifications, or verify with a certified structural engineer, for each specific roof site. Heliodyne is not

responsible for mounting anchor integrity.

Heliodyne

recommends using

a long lasting thread

locker, such as Loctite

277, on rail splice kits.

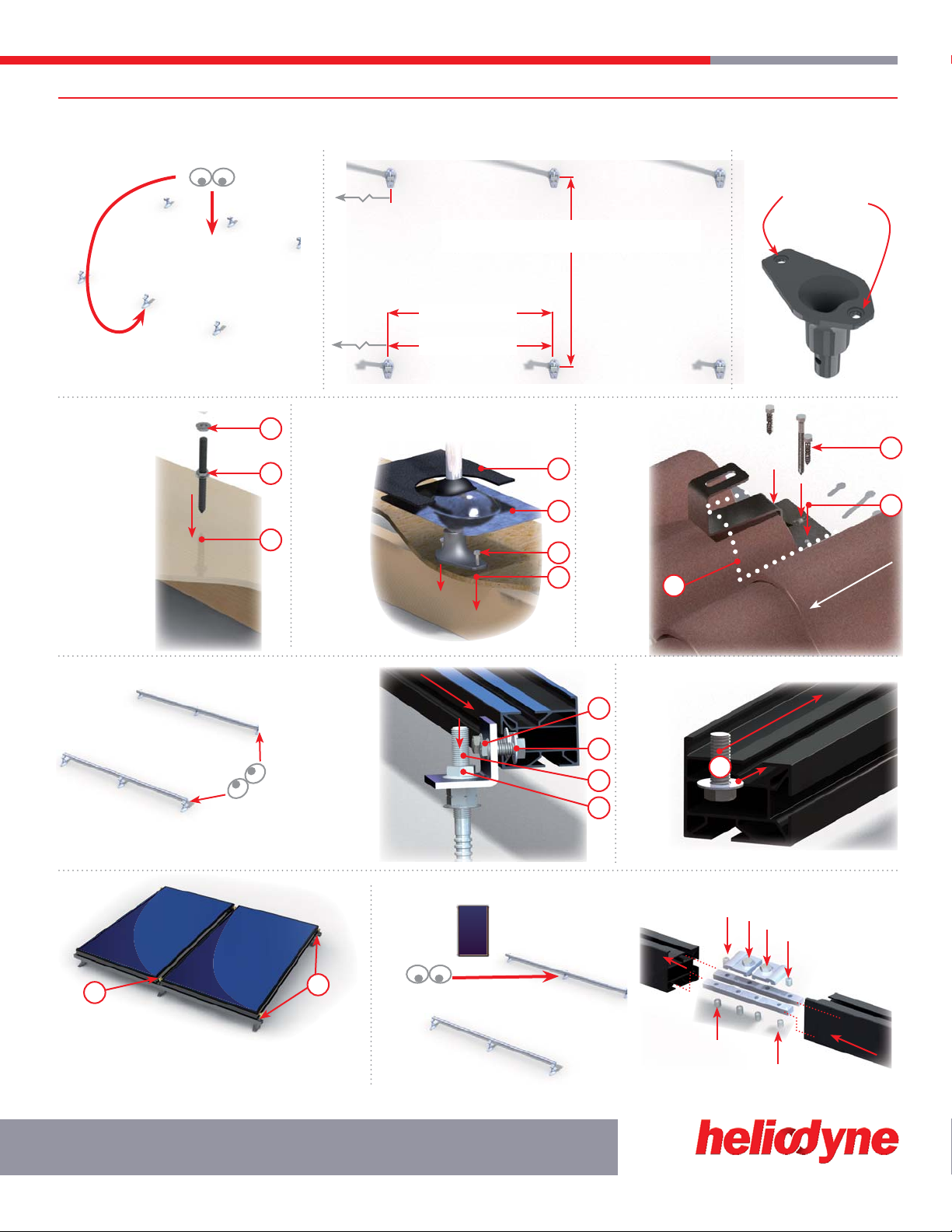

FLUSH MOUNTING INSTALLATION

2

1

3

*000 001 Shown

2.2.0. FLSH Kit Components

2.2. Flush Mounting Overview

2.2.1. Flush Replacement Parts

ITEM CODE PART NUMBER DESCRIPTION QUANTITY

1 CLIP 000 000 40082 Helio-Clamp, 3/8-16 x 3/4 SS Bolt, Flange Nut (set of 4) 1 / Gobi

2RAIL 001 000

RAIL 002 000

40092

40090

2 x 1 Collector Mounting Rail - 51”, 1 x CLIP 000 000 set

2 x 2 Collector Mounting Rail - 102”, 2 x CLIP 000 000 set See Note 1

3

FLSH 001 000

FLSH 000 000

FLSH 000 001

FLSH 000 002

40087

40084

40085

40086

1 Collector Mounting Kit

Shingle Mount Hanger Bolt Kit

Shingle Mount Flange Kit

Tile Mount Kit

# Gobi + 1

4 RAIL 000 001 40089 Splice Kit for Joining Rails 1 Kit

E

F

H

G

N

D

3/8” - 16 x 1 SS Bolt11/2”- 13 SS Flange Nut 3/8” - 16 SS Flange Nut 1/2” - 13 x 1.25” SS Bolt

3/8” SS Flat Washer11/2”-13 x 6 SS Hanger Bolt Flush Mount Flange 3/8” x 4 SS Lag ScrewTile Bracket

Gobi Collector Clip Rail “L” Bracket 1/2” SS Flat Washer 3/8” x 2 SS Lag Screw

A D G

B E H LN

C F J

K

M

BD B

G

J

G

J

F

A D

C

A

A

K

M

L

B

FLSH 001 000

Single Collector Kit - No rail

FLSH 000 000

Shingle - Hanger Bolt Kit

FLSH 000 001

Shingle - Flashing Flange Kit

FLSH 000 002

Domed Terra-cotta Tile Kit

1May be substituted with integrated washer head bolt without notice

>2x

FLUSH MOUNTING INSTALLATION 13

SOLAR HOT WATER

36-50.25” MAX

36-45” MAX

Roof Sealant

75-90% Gobi Length

2.3. Flush Installation

2.3.0. Flush Foot Spacing

2.3.1. Hanger Bolt Mounting2

2.3.4. Rail Mounting 2.3.5. Collector Mounting

Roof Slope

2.3.6. Rail Splice (optional)

2.3.2. Flange Mounting22.3.3. Tile Mounting2

a

ab

b

3

2

1

1

1

1

2

3

3

1

2

2

2

3

3

3

4

2. Place collectors. Insert O-rings, tighten Unions. Take care not

to crimp O-ring. Do not use thread lock or sealants.

3. Place Helio-Clamps, and thread flanged nuts on exposed bolts

and tighten securely.

Heliodyne recommends using a

long lasting thread locker, such as

Loctite 277, on rail splice kits.

Locate a1.

rafter and drill

a 3/8” hole for

lag portion add

roof sealant; use

two flange nuts

backed against

each other to lag

bolt into roof

Use one2.

flange nut

face down for

compression seal.

Thread on3.

2nd nut with

flange upwards,

then Clip or “L”

bracket, then third

flange nut and

tighten.

Locate1.

a rafter and

use flange as

template to drill

two 3/8” holes

for lag screws;

add roof sealant

to holes and

flange.

Lag in2.

screws.

Place3.

OATEY 1-1/4”

flashing over

flange.

Replace4.

shingle over

flashing; follow

best roofing

practices to

ensure seal.

Remove1.

tiles. Locate a

rafter and use

tile bracket as

template to

drill three 3/8”

holes for lag

screws; add

roof sealant to

holes.

Lag in2.

screws.

Replace3.

tiles over

bracket; follow

best roofing

practices to

ensure seal.

With bolts, flange1.

nuts and washers

installed, slide all “L”

brackets onto each

rail into approximate

position of hanger

bolts, flash flange or

tile bracket; ensure the

washer is on the inside

of the rail flange for

proper strength.

Insert “L” bracket2.

onto each mount.

Tighten all nuts3.

and bolts for proper

strength.

Before1.

placing

collectors,

slide all

clamp

bolts and

washers into

approximate

position

on rails.

Ensure

washer is

inside the

rail channel

for proper

strength.

FLSH 001 000:

OTHERS:

2While lag screws are provided with most kits, consult the American Wood Council NDS 2005 for proper lag screw specifications, or verify with a certified structural

engineer, for each specific roof site. Heliodyne is not responsible for mounting anchor integrity.

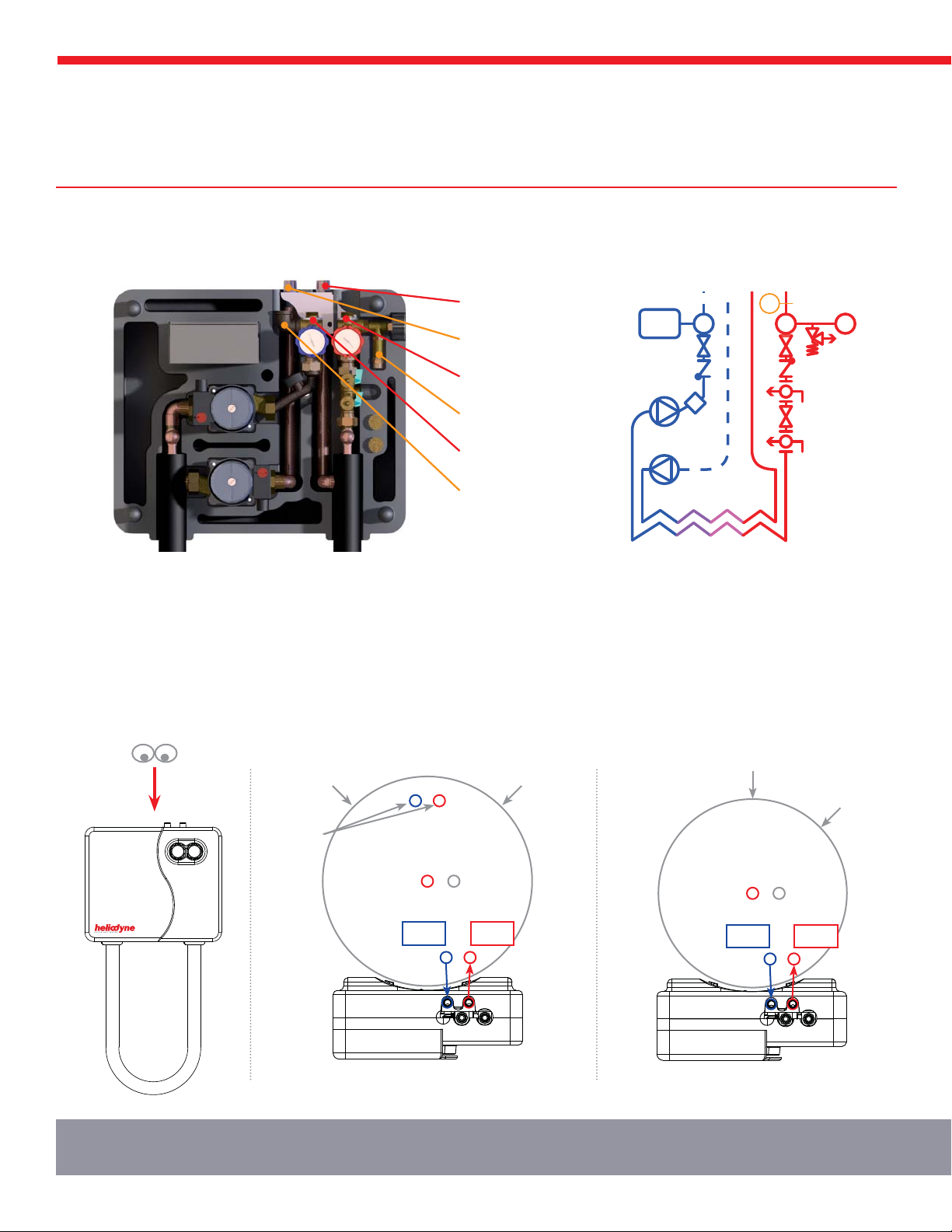

HPAK INSTALLATION INSTRUCTIONS

3. HELIO-PAK INSTALLATION

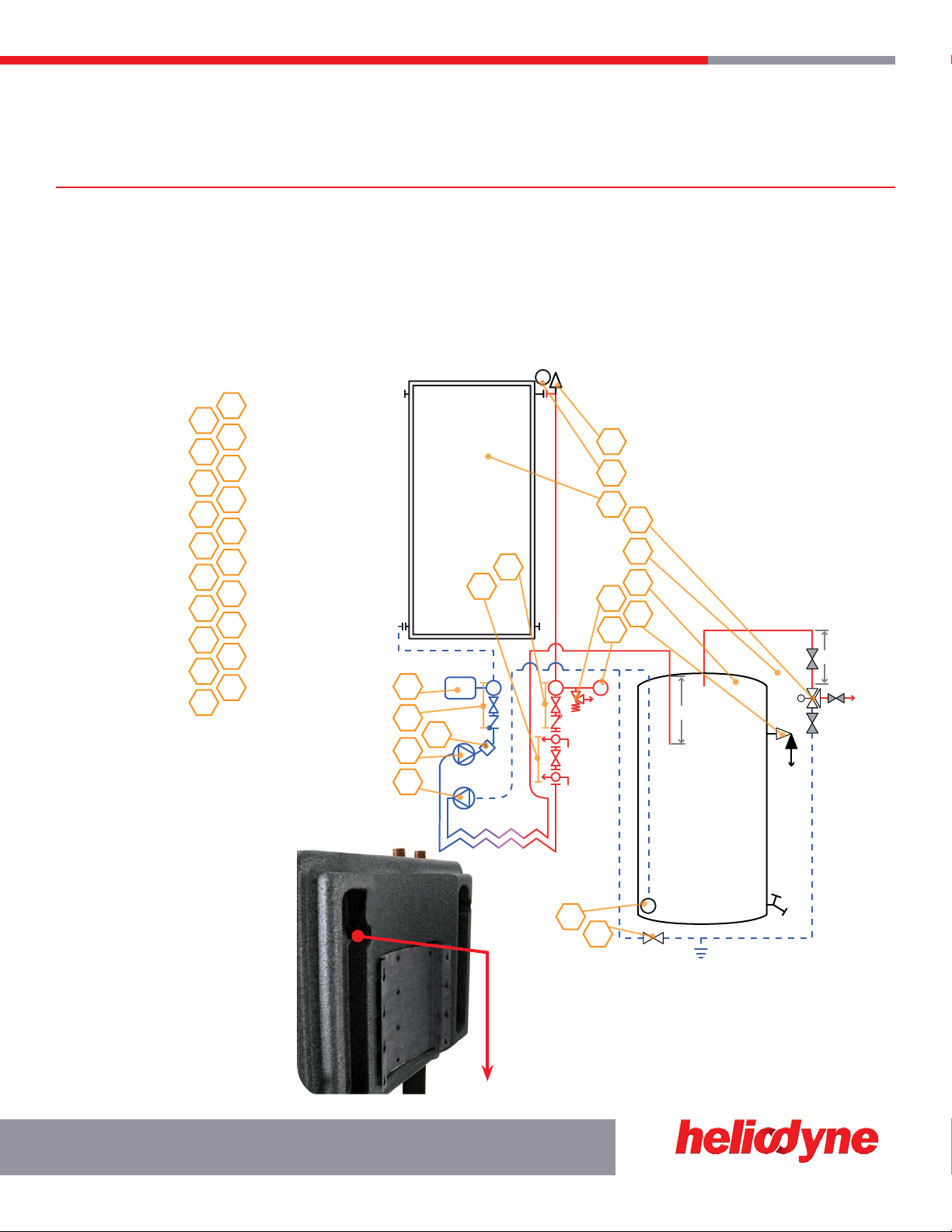

3.0. Helio-Pak Connections and Hydraulic Schematic

DHW Out (To Tank)

DHW In (From Tank)

Solar In (From Gobi)

PRV (Back Exit)

Solar Out (To Gobi)

Expansion Tank

T&P

T&P

DRAIN

SHWM

LONG

DIPTUBE

LONG

DIPTUBE SHORT

DIPTUBE

SHORT

DIPTUBE

Helio-Tank 119 Helio-Tank 80

DRAIN

Figure 3.0.-1: HPAK Connections Figure 3.0.-2: HPAK Hydraulic

Figure 3.1.-1: HPAK and Helio-Tank 119 Connections Figure 3.1.-2: HPAK and Helio-Tank 80 Connections

3.1. Tank Orientation

If using a Helio-Tank for installation, orient the proper solar connections in line with the HPAK connections to eliminate piping. On all tanks:

ensure proper dip tube length by inspection.

TT

P

M

T4

3.3.0. Storage Sensor Panel Removal and Installation 3.3.1. Collector

Sensor Installation

HPAK INSTALLATION INSTRUCTIONS 15

SOLAR HOT WATER

Helio-Tank 119

Tank Interconnect

CTOR 000 000

Helio-Tank 119

Standard Solar 119

Collector Sensor

Figure 3.2.-1: HPAK with Multiple Helio-Tank 119 Figure 3.2.-2: HPAK with Multiple Standard Solar Tanks

3.3. Sensor Installation

HPAK’s come with the necessary sensors pre-wired into the control; for more information see the separate control manual. The controls

require at least one tank sensor: on the bottom of the storage tank; the top tank sensor is optional. Most solar storage tanks have a stud near

the bottom for placement; the Helio-Tanks have studs for both top and bottom. If a specific area is not available, attach to a metal drain,

disconnected lower element, or use the cold in for lower tank sensor; use the hot out for a top tank sensor. The collector sensor must go on

the outlet header of the array.

For Pro models: the energy production is default set to calculate via the collector outlet sensor and the pre-installed flow meter temperature and flow sensor. For greater accuracy, install

an additional thermistor sensor just above the inlet to the heat exchanger and connect to T4 at the Delta-T Pro. See the hydraulic schematic on the opposite page for T4 position.

3.2. Plumbing Multiple Tanks

If using multiple tanks to achieve proper storage ratio, always use reverse return plumbing with the cold lines the longest, to ensure least

heat loss, and that each tank gets the same amount of circulation. For Helio-Tanks, use the 119 and connect all 2” side ports for increased

layering and higher performance.

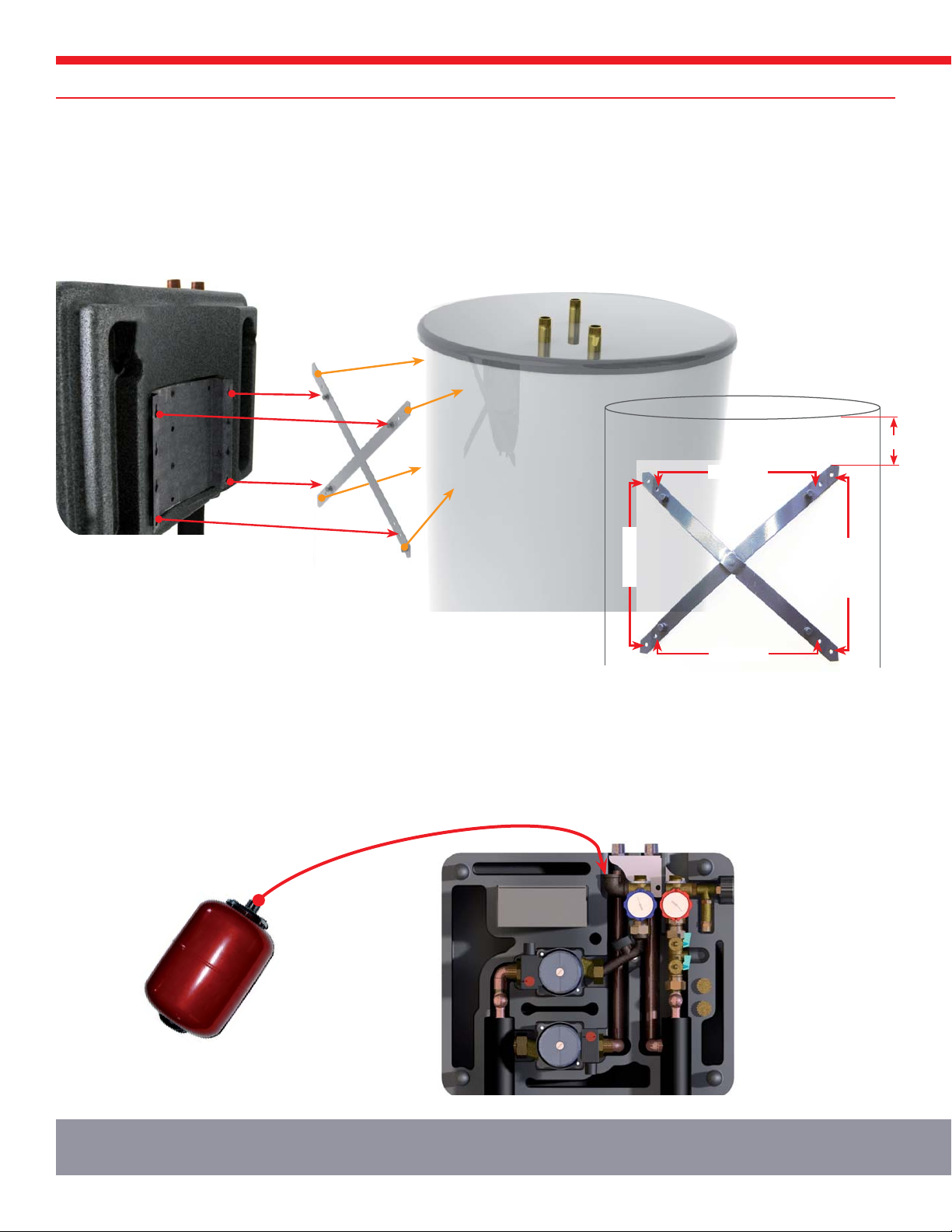

HPAK INSTALLATION INSTRUCTIONS

Figure 3.4.-1: HPAK Tank Mounting

6”

Wall Mount

Wall Mount

Tank Mount

Tank Mount

3.4. Helio-Pak Tank Mounting

Choose the mounting location for the HPAK. Using the X-Bracket supplied with the HPAK, measure and level a spot 6” down from the

desired position of the top of the HPAK foam. With the 4 self - tapping screws provided with the HPAK; on a tank use the inner mounting

holes on the curved part of the X, on a wall, use the outer mounting holes on the flattened part of the X. Align the top and bottom lugs on

the X with the top and bottom mating holes on the HPAK pre-mounted bracket and hang. Pull the HPAK down to lock in the lugs with the

HPAK bracket holes.

3.5. Expansion Tank Mounting

Helio-Paks come with a pre-sized expansion tank of bladder type. If the shipped expansion tank volume is less than 1/5th of the total

collector system fluid volume, contact Heliodyne to purchase the appropriate additional expansion.

Orientation of the bladder type tanks does not matter; any location using the expansion tank port and flex hose provided with the HPAK

is acceptable.

PLUMBING THE HPAK

4. PIPING

1

2

13

7

8

17

4

5

15

10

19

3

14

9

18

6

16

12

11

20

Figure 4.0.-1: Typical HPAK Installation Schematic

S

12"

18"

S

TT

P

M

M

4

12

5

13

6

14

15

16

7

18

9

8

17

10

11

3

2

1

S

S

M

M

P

Air Vent

Tempering Valve

Collector Sensor

Expansion Tank

Gobi Collector

Combo Valve: Cold

Filling Valve

Flow & Temp Meter

Combo Valve: Hot

Collector Pump

150 psi PRV

Storage Pump

Pressure Gauge

Tank Sensor

P & T Valve

Normally Open Valve

HSTG Solar Storage

Normally Closed Valve

Optional Isolation Valve

Bypass Valve

17

SOLAR HOT WATER

4.0. Connect the HPAK to the Tank

Insulate all hot water piping, as well as the final five feet of cold water storage inlet piping to a minimum R2.6. To enable backup heat

during solar system maintenance, isolation and shut off valves must be installed as recommended in installation schematics below. Use

dielectric unions when connecting piping to the storage tank nipples. When using the Helio-Tank, appropriately sized flex hoses can be

purchased from Heliodyne to avoid rigid copper plumbing. In the case of standard storage tanks, Heliodyne Gas Tank, or multiple tanks,

this is unavoidable.

When using the Helio-Tank, the DHW Cold is shared with the HPAK Cold. NEVER share the hot DHW and HPAK to prevent cold water

entering the hot line.

4.1. Connect the PRV to

Hose for Drain

The PRV comes with a barbed hose

fitting to attached a 1/4” ID hose for

funneling glycol to a bucket or drain, in

the rare even of release. Since this is

not part of a pressurized system, there

is no need to use expensive copper;

PEX or other high temperature suitable

plastics are okay here only.

In the even of a pressure release,

contact Heliodyne to discuss expansion

tank sizing.

*A combo valve is an integrated temperature gauge,

ball and check valve. The ball valve can be operated

as described in the components section 1.6.3 above

and is normally open.

12"

M

FLUID PLUMBING SCHEMATIC AND GUIDELINES

S

12"

S

18" 12"

12"

S

18"

M

M

M

HPAK

HPAK

From

Solar

Storage

To

Solar

Storage

From

Mains

HPAK HPAK

12"

Tank 115 VAC

Supply to

Delta-T Pro @

R3

M

T3

T2

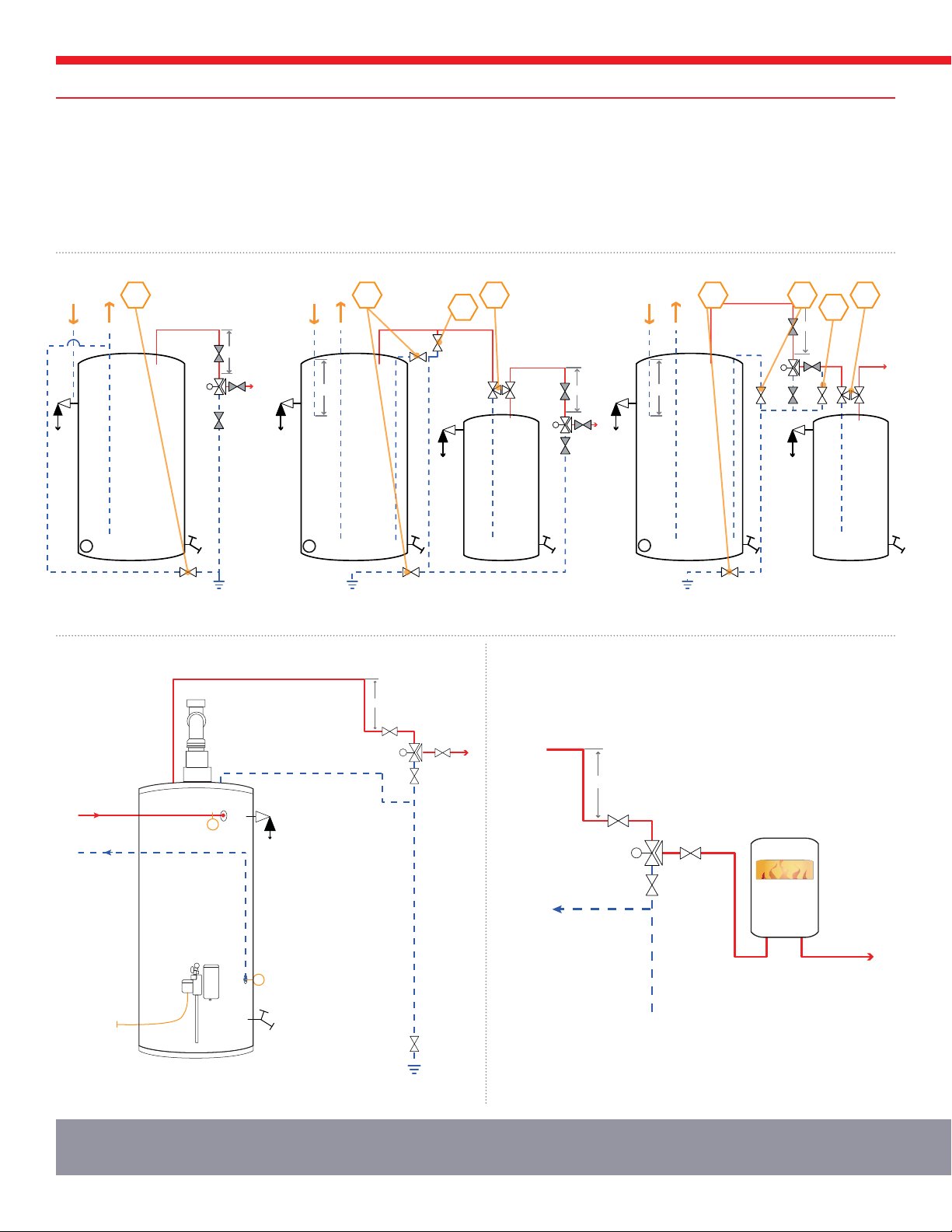

Figure 4.2.-1: Single Standard Tank Figure 4.2.-2: Dual Tank: Electric Backup Figure 4.2.-3: Dual Tank: Gas Backup

Figure 4.2.-4: HPAK PRO and Gas Figure 4.2.-5: Flow Thru Connection

4.2. Different Tank Schematics

If your tank is not here, contact Heliodyne with questions. Refer to the valve descriptions on the previous page. In accordance

with SRCC standard OG-300, all piping and valves must be labeled. Attach the waterproofed labels provided with this manual

to the appropriate components using zip-ties.

NOTE: For single tank electric systems: disconnect lower element for proper operation.

NOTE: For single tank gas systems: tanks with electric pilot and HP Pro ONLY

18 18 19 20 18 19

18 20

COLLECTOR FLUID PIPING

SOLAR HOT WATER

19

4.3. Gobi Collector Plumbing

Use only copper piping on the collector loop, solder to appropriate conditions in technical specifications. Always plumb in reverse return with

the longest line the cold, or use automatic balancing valves. Insulate piping for least losses; use rubber based insulation with environment

protection or Solar Pipe from Heliodyne. Gobi collectors can be put in portrait arrays of up to eight. Install bleed vents for filling at local high

points. Install a flexible arm or line on either side of the inlet and outlet to allow for header expansion.

4.3.0. Portrait Single Collector or Array 4.3.1. Single Horizontal Collector

4.3.2. Multiple Horizontal Collectors 4.3.3. Multiple Vertically Aligned Portrait Arrays

4.3.3. Multiple Horizontally Aligned Portrait Arrays

Min. Distance = Gobi Length * Sin (Tilt from Horiz.)

0.577

SYSTEM FILL AND STARTUP

5. COMMISSIONING

2

Flow Direction

1

3

5.0. Pressure Test and Clean Collector Loop

Before filling the collector loop with Dyn-O-Flo HD solution, pressure test the collector loop to check for soldering leaks. Remove the expansion

tank and cap off the exposed port, then fill the collector loop with water using the site hose and pressurize up to mains pressure 60 – 80 psig.

The filling station can also be used.

Monitor the pressure gauge for drops in pressure, inspect all joints. Turn the collector loop pump on to clean out residue; a 2% TSP solution

can be used. Fully drain the system to ensure correct glycol concentration upon final fill.

5.1. Calculate System Fluid Volume and Necessary Glycol Concentration

Find the total fluid capacity by adding in the volume of the collectors, HPAK and supply and return lines. With the total volume, use the

equation below to find out necessary gallons of glycol. Glycol concentration should be 40 – 60% for proper inhibitor concentration, regardless

of required freeze protection. A higher concentration than is required for freeze protection is recommended in case of errors in fluid

calculation.

5.2. Fill System

The system can be filled easily with a filling pump from Heliodyne or manually. Consult

the manual with the filling pump for operation. Take care to use mineral spring water or

good quality tap water and only fill system when collector is cold. See installation notes

at the end of this manual for water requirements. Air vents or bleed vents at the high

points in the system help rid the system of air during filling only. If using any type of

automatic air vent, close vent after filling is complete as vents are not suitable for glycol

systems, or systems without continuously replaced fluids.

For use with a pump, connect pump supply hose to position 3 at right, and return hose

to position 2. Turn 1 so slot is horizontal, forcing return fluid out of 2. Turn on pump

to begin filling. After fluid begins to return back into tank from 2, close off valve at 2

and open 1. System will pressurize rapidly; monitor gauge and close off valve at 3 when

system reaches 40 – 60 psi. Turn off pump. Close off any bleed or air vents and run

system throughout the day. Check after a day cycle to ensure the cold pressure of the

system is at around 30 psig when cold. If further pressurization is necessary, hook up

pump supply to 3, turn pump on, open valve and pressurize back up.

For manual fill, pour in proper glycol and water mixture with a funnel into the top unused

header connection of Gobi. Pressurize with house water using the valve at position 3;

follow pressure guidelines as above. Hose nipples are provided, pre-set into the foam

next to the fill valve.

SYSTEM COMPONENT FLUID CAPACITY (GAL.)

GOBI 406 001 & 002 0.75

GOBI 408 001 & 002 0.83

GOBI 410 001 & 002 0.95

HPAK 016 000 & 001 0.80

HPAK 024 000 & 001 0.95

HPAK 032 000 & 001 1.00

HPAK 048 000 & 001 1.25

ASTM B88 COPPER TUBING GALLONS / 100’

Type M 1/2” (5/8” OD) 1.32

Type M 3/4” (7/8” OD) 2.68

Type M 1” (1-1/8” OD) 4.54

Type M 1-1/4” (1-3/8” OD) 6.80

Type M 1-1/2” (1-5/8” OD) 9.51

Type M 2” (2-1/8” OD) 16.5

Gallons of Dyn-O-Flo HD = Desired Concentration (%) * Total System Fluid (gal.) / 100

This manual suits for next models

13

Popular Solar Panel manuals by other brands

Battery Doctor

Battery Doctor 23140 instruction manual

oventrop

oventrop OKF-MQ25 Installation and operating instructions

Viessmann

Viessmann VITOVOLT Operating Instructions for the System User

esotec

esotec 101812 operating manual

Solimpeks

Solimpeks Wunder CLS 2510 instruction manual

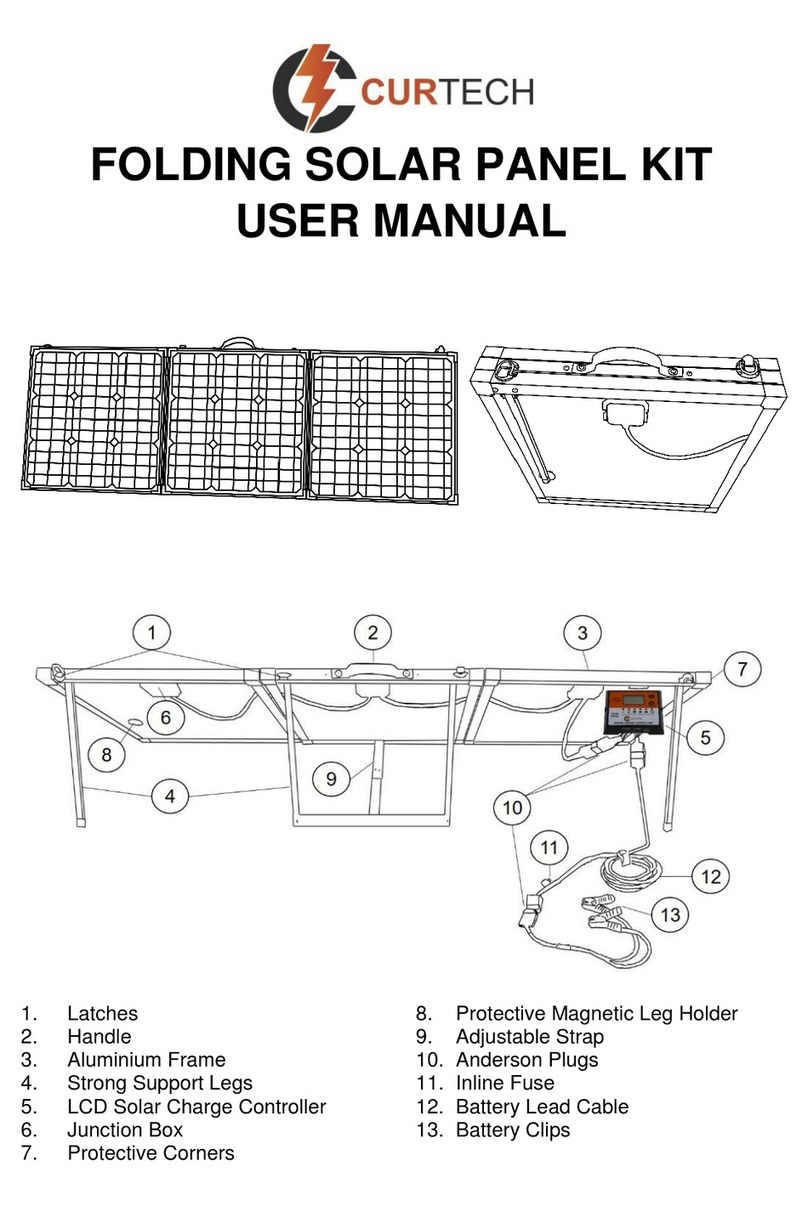

Curtech

Curtech CT-K140 user manual