1 Introduction

Conergy SunTop Trapeze Installation manual 1

ENGLISH

1 Introduction

1.1 Short description

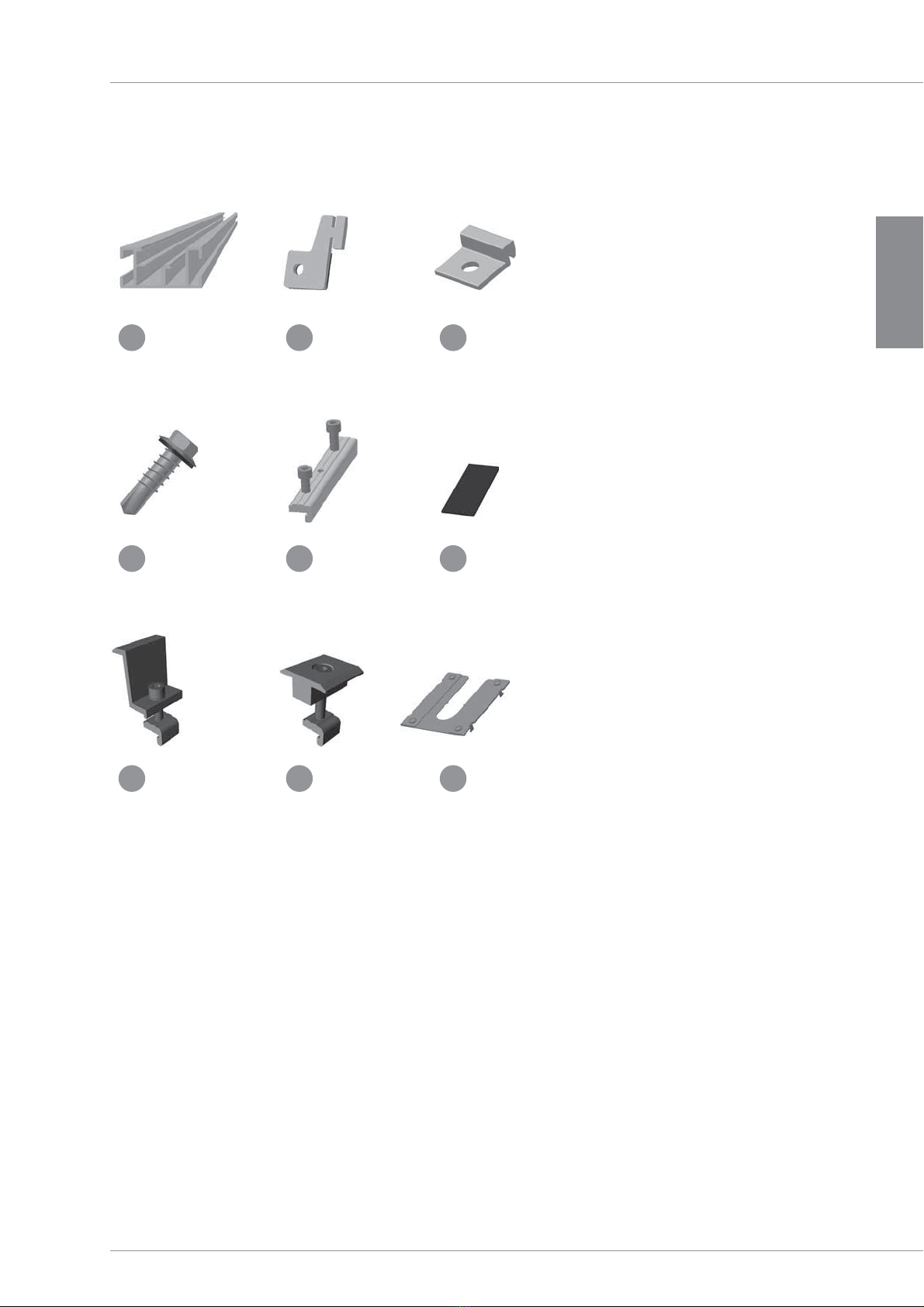

The SunTop Trapeze flat roof system is a sturdy frame sys-

tem for mounting PV modules on trapezoidal sheet metal

roofs. It consists of aluminum base rails and all necessary

small parts to install the modules to the rails and con-

necting the components to each other. Both portrait and

landscape mounting of the modules are possible.

1.2 Intended use

The on-roof system SunTop Trapeze is to be used for the

installation of PV modules only. Any other use is consid-

ered improper. Please follow the instructions in this manual

carefully. Mounting Systems is not responsible for damage

that results from improper installation. Be sure to follow the

safety and use guidelines closely.

1.3 Standards and guidelines

When planned correctly, SunTop Trapeze fulfills the follow-

ing standards and directives:

• Eurocode 9 — DIN EN 1999-1-1: Design of aluminum

structures

• Eurocode 1 — DIN 1055 — Actions on structures

• DIN 18807-3 Trapezoidal sheeting in building; trapezoidal

steel sheeting; structural analysis and design

• DIN 18807 Trapezoidal sheeting in buildings - Part 9:

Aluminium trapezoidal sheeting and their connections;

application and construction

In addition, every installation must be in compliance with

the following codes/rules:

• VDE 0100 – 712 ; IEC 64/1736. Installation of low-voltage

systems

• VDE 0185 Serie, IEC 81/335. Lightning protection

1.4 About these instructions

Subject

The purpose of this manual is to provide instructions for the

installation of the on-roof system SunTop Trapeze.

The illustrations in this manual show the installation for

framed modules in portrait orientation. The installation in

landscape orientation is dealt separately in section 8.

Users

This manual is written specifically for qualified installers

who have undergone instructions by the operator and have

basic mechanical and trade skills.

Orientation aids

The following aids will improve the readers’ understanding

when using this manual:

Symbols

Shows detail and additional information for

handling procedures.

Useful Tips

Simplifies handling procedures and contributes

to the success of the installation.