HelioSphera HS Series Setup guide

10-SSI-001_rev.005_ENG Page 1of 51

SAFETY AND INSTALLATION

INSTRUCTIONS

10-SSI-001_rev.005_ENG Page 2of 51

Content Table

1. INTRODUCTION................................................................................................................. 4

2. PURPOSE OF THIS DOCUMENT...................................................................................... 5

3. GENERAL INFORMATION................................................................................................. 6

4. SAFETY INSTRUCTIONS .................................................................................................. 7

4.1 General Safety............................................................................................................. 7

4.2 Electrical Safety........................................................................................................... 8

4.3 Fire Safety................................................................................................................... 9

4.4 Hazardous Locations................................................................................................... 9

5. MECHANICAL INSTALLATION .........................................................................................10

5.1 HS Series ...................................................................................................................10

5.1.1 HS Atlas Series.......................................................................................................11

5.1.2 HS Venus Series.....................................................................................................15

5.1.3 HS Glass-Glass Series............................................................................................18

5.2 Location and Tilt Angle ...............................................................................................23

6. ELECTRICAL INSTALLATION...........................................................................................24

6.1 Grounding...................................................................................................................30

6.2 Suitable Inverters........................................................................................................30

6.3 Bypass diode..............................................................................................................31

7. MAINTENANCE.................................................................................................................32

7.1 Cleaning .....................................................................................................................32

8. IN CASE OF BREAKAGE/RECYCLING SYSTEM.............................................................33

9. PACKAGING AND TRANSPORTATION SPECIFICATIONS .............................................34

9.1 Storing........................................................................................................................34

9.2 Transportation box specifications................................................................................35

10. PHYSICAL SPECIFICATIONS...........................................................................................37

10.1 Module........................................................................................................................37

10.2 Junction Box...............................................................................................................39

10.2.1 Diode.......................................................................................................................40

10.2.2 Cables.....................................................................................................................40

10.2.3 Connectors..............................................................................................................41

11. ELECTRICAL CHARACTERISTICS...................................................................................42

12. CERTIFICATES.................................................................................................................43

12.1 Modules......................................................................................................................43

12.2 Junction boxes............................................................................................................47

12.3 Cables ........................................................................................................................48

10-SSI-001_rev.005_ENG Page 3of 51

12.4 Connectors.................................................................................................................49

12.5 Factory Inspection.......................................................................................................50

12.6 Quality Management System......................................................................................51

Edition: October 2011

10-SSI-001_rev.005_ENG Page 4of 51

1. INTRODUCTION

HelioSphera S.A. (HS) thin-film PV modules (Micromorph™ technology) are distinguished

in the marketplace by their efficacy in numerous applications, superior longevity and maximum

efficiency.

Micromorph™solar cell has a dual structure with an amorphous and microcrystalline

silicon layer. The amorphous layer is sensitive to the visible range of the solar radiation, while

the microcrystalline layer converts the infrared part of the spectrum into electricity which results

to an excellent performance in comparison with other solar cell technologies.

HS modules have unique design properties - such as a higher energy yield in low-light

conditions, a lower vulnerability to deviations of azimuth and tilt angles, and an improved

temperature coefficient which make them suitable for use both in optimal and in traditionally

non-optimal conditions.

These advantages also improve performance on partially shaded surfaces, resulting in

higher output using the lower cost production methods of thin-film modules. In crystalline solar

cells the light energy is absorbed within a thin surface layer (~10 μm) while using a total

thickness of approximately 180 μm of material. The Micromorph™ technology needs only 3 μm

to absorb a similar amount of light energy with no other silicon required. The costly cutting of the

relatively thick crystalline silicon blocks is eliminated, as micromorph silicon is deposited directly

onto the glass surface.

10-SSI-001_rev.005_ENG Page 5of 51

2. PURPOSE OF THIS DOCUMENT

The purpose of this document is to provide clear instructions on how to install HelioSphera

photovoltaic modules, in order to use them as easy and safely as possible.

HS products not installed according to guidelines will void the warranty. HelioSphera

assumes no liability for damages incurred due to non-compliance with these instructions.

Please, also read the instructions for the other components which make up the total PV system.

Due to continuous innovation, research and product development, the guidelines in this

document are subject to change without notice. No rights can be derived from the document

and HelioSphera assumes no liability whatsoever connected to or resulting from the use of any

information contained herein.

10-SSI-001_rev.005_ENG Page 6of 51

3. GENERAL INFORMATION

This Photovoltaic Module produces electricity when exposed to the sun or other light

source. Array of many modules can cause lethal shock and burn hazards. Only authorized and

trained personnel should have access to these modules. The installer assumes the risk of all

lesions that can happen during the installation, included, the risk of electric shock.

Please read the entire safety and installation instruction manual carefully prior to product

installation. Also, carefully read the module data sheet provided with this product. This guide

pertains to modules installed within the European Union only. If a module is being installed

outside of Europe, contact HelioSphera or the product distributor.

Determine local permits, installation and inspection requirements before installing

module(s).

Do not attempt to disassemble the module, and do not remove any attached nameplates

or components! Doing so will void the warranty. Do not disconnect under load! An

electrical arc could occur and pass through the fingers and body of the person holding

the two ends of the connector.

Do not use mirrors or other hardware to artificially concentrate sunlight on the module.

Under normal conditions, a solar photovoltaic module is likely to experience conditions

that produce more current and/or voltage than reported at standard test conditions.

10-SSI-001_rev.005_ENG Page 7of 51

4. SAFETY INSTRUCTIONS

4.1 General Safety

Solar modules should only be used for the purposes for which they are intended (see

module installation for further details). All works on the PV system, i.e. installation,

commissioning, servicing and repairs, should be carried out by qualified and authorized

personnel only. During installation, all local and national electrical and building regulations,

health and safety regulations and accident prevention regulations should be strictly followed.

All protective measures regarding working at heights and preventing falls specified in

national and local health and safety codes and regulations should be implemented before and

during all work on roof-mounted and other PV array structures, and all necessary scaffolding

and other protective measures applied at the site of the installation. Protective helmets, gloves

and footwear should be worn during installation work. Protective goggles should be worn when

carrying out drilling, cutting or grinding work. Safety harnesses may be required in some

situations.

Unpacking the modules and storage: Utmost care is required when handling solar electric

modules. Be careful when unpacking, transporting, and storing the modules, they are subject to

breakage if they are not properly handled and installed:

Always transport and store the modules in the shipping container provided. Transport

modules in an upright position. It is recommended not to take them out of the packaging

until the moment of the installation. During installation, never let the modules in direct

contact on ground, concrete or tiles without intersecting a soft material. Scratches or

glass breakages may occur.

Carry modules always between two workers and with both hands (Do not use the

junction box as a handle).

Do not carry more than one module at a time.

Ensure modules do not bow under their own weight and do not place modules on top of

each other.

Do not drop modules or allow objects to fall on modules.

Do not carry the module by the cables.

Avoid setting the module down hard on any surface. Pay particular attention to the glass

edges.

Don’t mark using sharp tools and keep all electrical contacts clean and dry. Do not

handle modules when they are wet unless wearing the appropriate protective equipment.

Do not install this module integral with a roof or wall without a certified integration

mounting system.

Do not wear metallic jewelry while performing mechanical or electrical installation.

10-SSI-001_rev.005_ENG Page 8of 51

Avoid application of excessive bending or twisting forces to the modules.

Mandatory use of

gloves or other hand

protection

Mandatory use of

protective footwear

Safety helmet must

be worn

Mandatory use of

safety goggles

4.2 Electrical Safety

Be familiar with the basic principles of electricity and electrical equipment. Use properly

insulated tools and appropriate protective equipment such as safety shoes and insulated gloves

as well as protection goggles. Do not remove any parts originally installed or disassemble the

module.

Short circuits on the DC side of the installation can cause arcing. This is a burn and fire

hazard. Unlike arcs occurring in conventional low voltage AC wiring, these arcs are not self

extinguishing. The high temperatures generated by these arcs can destroy contacts and

connectors. If not handled and installed according to instructions, solar modules can present a

lethal hazard.

Cover module face(s) completely with opaque material to halt the production of electricity

when working with module wiring.

Disconnect module(s) from other sources of electricity, such as batteries or inverters,

when any work on the installation is being done.

Avoid contact with terminals when modules are exposed to light.

Exercise utmost caution when working on wiring, including the inverter installation.

Do not attempt to install or use a module with broken front cover glass or a damaged

back glass. They represent a shock hazard due to leakage currents, especially when

wet.

Do not connect HS modules directly to motor loads. Variation in PV module output power

as a function of solar irradiance may damage directly connected loads.

Make sure that all electrical connections are completely dry before they are assembled.

Materials, tools and working conditions need to be clean and dry.

10-SSI-001_rev.005_ENG Page 9of 51

The modules are qualified for application class A: Hazardous voltage (IEC 61730: higher

than 50V DC: EN 61730: higher than 120V), hazardous power applications (higher than 240W)

where general contact access is anticipated (Modules qualified for safety through EN IEC

61730-1 and -2 within this application class are considered to meet the requirements for safety

class II).

Danger electric shock risk

4.3 Fire Safety

HS modules have a Class E Fire Rating and must be installed over a roof of appropriate

fire resistance. Consult your local building department to determine approved roofing materials.

Do not use modules near equipment or locations where flammable gases can be

generated or collected.

Fire codes vary widely, but in general require a minimum number of access paths so that

fire brigades can fight fires and ventilate the structure. Check with local authorities before

designing a project.

4.4 Hazardous Locations

The modules are not suitable for installation in potentially explosive or flammable

environments. The modules should not be installed at the following locations:

Near sources of flammable gases and vapors, such as gas/petrol stations, gas storage

containers, spray paint facilities.

Near open flames.

10-SSI-001_rev.005_ENG Page 10 of 51

5. MECHANICAL INSTALLATION

5.1 HS Series

Unpacking the product

Make sure the pallet is placed on a horizontal surface

Remove the modules one-by-one from each side of the box

ATTENTION: Make sure that the modules in the center of the box are the last to be removed

Fig. 1 Unpacking method

The following instructions make reference to three different certified mounting procedures.

X

10-SSI-001_rev.005_ENG Page 11 of 51

5.1.1 HS Atlas Series

The HS Atlas modules incorporate four anchors bonded to the rear glass of the modules,

showed in Fig. 2. The anchor design is shown in Chapter 5.

Front view

Rear view

Fig. 2 HS Atlas with 4 anchors

The aluminum anchors, which are shown in Fig. 3, are fixed to the rear glass of the

module using a proven adhesive from the structural glazing industry. These anchors are

designed to match perfectly with the metallic rail of the mounting substructure, see Fig. 7. No

tools are necessary for mounting the modules.

Fig. 3 View of anchors design.

10-SSI-001_rev.005_ENG Page 12 of 51

PV modules are exposed to a wide range of mechanical conditions, so that surface stress

may appear. Due to the different thermal coefficient of glass and metal structures, thermal

stress can occur as a result of the module’s outdoor exposure. During mounting the following

recommendations should be followed:

1. It is strongly recommended to install HS Atlas modules in vertical (portrait) position. For

more info see next point “6.- Electrical installation”.

2. The mounting assembly and the undercarriage must be appropriately dimensioned and

adapted to the in-site environmental conditions so that the maximum

bending/deformation admitted should not exceed a specific value related to the edge

length of the module (1300 mm, respectively 1100 mm). This value is: L/100, so the

maximum bending/deformation for both edges is 13 mm, and 11 mm respectively. No

buckling/twisting of more than 30 mm across the module diagonal! This requirement is

completely fulfilled by HS Atlas modules mounting system.

3. All direct contact of the glass/solar module with metal parts of the substructure must be

prevented. This requirement is completely fulfilled by HS Atlas modules mounting

system.

4. The solar module should be run at stress and force-free conditions. This requirement is

completely fulfilled by HS Atlas modules mounting system.

5. Accumulation of water at the solar module must be prevented; might cause corrosion

on the adhesive bonding or on the PVB foil between front and back glass.

6. The specified fixation points at the approved mounting assemblies are shown in Fig. 7

In order to place the mounting rails at the right distances, HelioSphera provides a helpful

tool with 2 hooks fixed at the same distance as the Atlas module. ( Fig. 5)

Fig. 4 Interface integrated on the metallic rail of the mounting substructure for HS Atlas modules

10-SSI-001_rev.005_ENG Page 14 of 51

Fig. 7 Mounting configuration

HelioSphera modules have been designed and tested, according to IEC 61646 paragraph

10.16, to a maximum mechanical load of 2400 Pa or 2.4 N/m2.This load can be any

combination of snow, ice or wind. In order for the solar modules to withstand this load, the

module must be supported as shown in Fig. 6.

In any roof installation, check carefully with local authorities/local building codes for

minimum mechanical means for securing the module.

10-SSI-001_rev.005_ENG Page 15 of 51

5.1.2 HS Venus Series

The HS Venus series modules are equipped with a special aluminum frame Fig. 8.

Front view

Rear view

Fig. 8 HS Venus

HS Venus modules are designed to be mounted on the substructure without using any

special tool, accelerating the whole installation procedure.

HelioSphera is aiming to provide different procedures for HS Venus modules to be valid

for different applications.

The aluminum frame, shown in Fig. 9, is attached to the rear glass of the module using a

proven adhesive from the structural glazing industry.

Fig. 9 Profile of the HS Venus frame

Bonding Area

10-SSI-001_rev.005_ENG Page 16 of 51

PV modules are exposed to a wide range of mechanical conditions, so that surface stress

may appear. Due to the different thermal coefficient of glass and metal structures, thermal

stress can occur as a result of the module’s outdoor exposure. DIN 1055 sets basics for the

planning of a structural framework regarding building structures which must be taken into

account.

During mounting the following recommendations should be followed:

1. It is strongly recommended to install HS Venus modules in vertical (portrait) position.

For more info see next point “6.- Electrical installation”

2. Modules must be set up on the lower edge (dimension 1100 mm.) and inserted linearly

at both short sides in accordance with the support structure. The mounting system is

shown in Fig. 10 & Fig. 11.

Fig. 10 Detail of how HS Venus is inserted on the profiles

Fig. 11 HS Venus mounting system

3. The solar module should be run at stress-free and force-free conditions.

10-SSI-001_rev.005_ENG Page 17 of 51

4. Accumulation of water at the solar module must be prevented; might cause corrosion

on the adhesive bonding or on the PVB foil between front and back glass.

This is a fully integrated on roof mounting system. It is composed by:

Assembly system: Model S2 PLUS, made by aluminum, EN-AW 6063.

HelioSphera modules have been designed and tested, according to IEC 61646 paragraph

10.16, to a maximum mechanical loading of 2400 Pa (2, 4 N/m2or 240 Kg/m2).This loading can

be any combination of snow, ice or wind. In order to withstand this load, the module should be

supported as shown in Fig. 12.

Fig. 12 HS Venus’ mounting instructions

For further information about the mounting elements, please, contact HelioSphera.

Any roof installation should comply with the local building regulations.

1

2

3

4

5

6

7

8

10-SSI-001_rev.005_ENG Page 18 of 51

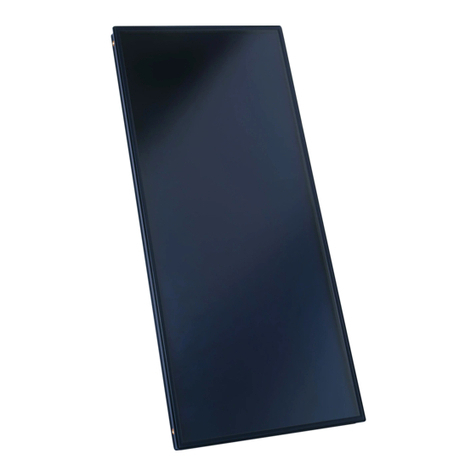

5.1.3 HS Glass-Glass Series

The HS Glass-Glass modules are HelioSphera modules without any aluminum structure

attached, Fig. 13.

Front view

Rear view

Fig. 13 HS Glass-Glass

PV modules are exposed to a wide range of mechanical conditions, so that surface stress

may appear. Due to the different thermal coefficient of glass and metal structures, thermal

stress can occur as a result of the module’s outdoor exposure. DIN 1055 sets basics for the

planning of a structural framework regarding building structures which must be taken into

account. During mounting the following recommendations should be followed:

1. It is strongly recommended to install HS modules in vertical (portrait) position. For

more info see next point “6.- Electrical installation”

2. Modules must be set up on the lower edge (dimension 1100 mm.) and fastened

linearly at both long sides in accordance with the support structure. A horizontal middle

support is placed to enable the center fastening and to prevent non-admissible

bending of the module. The horizontally positioned clamps guarantee that the module

resists high wind suction loads (Fig. 15).

3. The mounting assembly and the undercarriage must be appropriately dimensioned

and adapted to the in-site environmental conditions so that the maximum

bending/deformation admitted have not to exceed a specific value related to the edge

length of the module (1300 mm, respectively 1100 mm). This value is: L/100, so the

10-SSI-001_rev.005_ENG Page 19 of 51

maximum bending/deformation for both edges is 13 mm, and 11 mm respectively. No

buckling/twisting of more than 30 mm across the module diagonal.

4. All direct contact of the glass/solar module with metal parts of the substructure must be

prevented.

5. The clamps’ width of contact must have a maximum of 14 mm and at least 12 mm.

See clamps’ draft with all the dimensions. (Fig. 16)

6. The solar module must run at stress-free and force-free conditions.

7. Accumulation of water at the solar module must be prevented; might cause corrosion

on the adhesive bonding or on the PVB foil between front and back glass.

8. The specified fixation points at the approved mounting assemblies are shown in Fig.

14 and Fig. 17.

The approved mounting system is described in Fig. 14. In Fig. 15 the clamps are shown

as a reference; they should not be taken as standards, because other dimensions are possible,

except for the dimensions marked in the figures (all in mm), these are mandatory to fulfill

HelioSphera installation requirements mentioned above.

1100 mm

310 mm

1300 mm

650 mm

Fig. 14 Mounting configuration

310 mm

10-SSI-001_rev.005_ENG Page 20 of 51

There are two kinds of clamps:

End clamps

Middle clamps (between two modules)

(A) Support frame of the substructure

(B) Middle support frame of the substructure (horizontal)

(C) Vertical clamps.

(D) Horizontal holding clamps

Fig. 15 View on the two-sided linear fixation set-up

Both clamps dimensions are presented in Fig. 16;

It is important to note, that both clamps have mandatory dimensions to maintain HS

warranties.

This manual suits for next models

6

Table of contents

Popular Solar Panel manuals by other brands

REC

REC ALPHA Series installation instructions

SFC Energy

SFC Energy XTREMESOLAR XTR-S290P Series installation manual

BenQ

BenQ PM200M00 installation guide

Westinghouse

Westinghouse AC System installation guide

Viessmann

Viessmann Vitovolt 200 Operating Instructions for the System User

Flexopower

Flexopower SK79 instructions