INSTRUCTIONS FOR

COMPRESSOR AUTODRAIN - TIMED

Model Nos: AD1 & AD2

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY

AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

AD1 & AD2 - 1105 - (1) - 120700

1.1. ELECTRICAL SAFETY

p

p

p

WARNING! It is the users responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply

leads, plugs and all electrical connections for wear and damage. You must ensure the risk of electric shock is minimised by

the installation of appropriate safety devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main

distribution board. We also recommend that an RCD (Residual Current Device) is used with all electrical products. If in doubt

consult a qualified electrician. You may obtain a Residual Current Device by contacting your Sealey dealer. You must also

read and understand the following instructions concerning electrical safety.

1.1.1. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the

appliance and the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.1.2. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power supply.

1.1.3. Ensure that cables are always protected against short circuit and overload.

1.1.4. Regularly inspect power supply, leads, plugs for wear and damage and all electrical connections for looseness.

1.1.5. Important: Ensure the voltage marked on the product is the same as the electrical power supply to be used, and check that the

correct capacity fuse is fitted. This product is intended for hard wiring and requires a 3 amp fuse.

1.2. GENERAL SAFETY INSTRUCTIONS

Familiarise yourself with the application and limitations of the drain valve.

Ensure the drain valve is in good order and condition before use. If in any doubt do not use the unit and contact an electrician or service agent.

p

p

p

WARNING! Drain valve must only be serviced by an authorised agent..

Before removing, or carrying out maintaining on, the drain valve ensure it is disconnected from the mains supply and that the air

tank pressure has been vented or isolated.

Use only recommended attachments and parts. To use non-recommended items may be dangerous and will invalidate your warranty.

Ensure that the maximum pressure (safety valve setting) of the system does not exceed the maximum working pressure of the drain valve.

Ensure that the air tank is fully vented before commencing fitment of drain valve.

Keep children and unauthorised persons away from the working area.

DO NOT operate in the vicinity of flammable liquids or gases.

DO NOT dis-assemble the drain valve for any reason. The unit must be checked by qualified personnel only.

DO NOT use this product to perform a task for which it is not designed.

p

p

p

WARNING! If an electrical fuse blows, ensure it is replaced with an identical fuse type and rating.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & SPECIFICATION

AD1 & AD2

Power Supply . . . . . . . . . . . . . . . . .230V 1ph 50Hz

Required Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . .3A

Power Consumption - Standby . . . . . . . . . . . .0.2VA

Power Consumption - Operating . . . . . . . . . . .6.2VA

Operating Pressure Range . . . . . . . . . . .0.2 - 12 bar

Maximum Pressure . . . . . . . . . . . . . . . . . . . .16 bar

Condensate Temp. Range . . . . . . . . . . . . . .1 - 80OC

Suitable for small and medium compressed air systems the AD1 and AD2 Timed Drain Valves are installed in place of drain cocks and

automatically open at preset time intervals to drain condensate. The drain valves are adjustable to suit the volume of condensate being

generated thus minimising the loss of compressed air.

AD1 AD2

Drain Capacity . . . . .0.05 - 5l/h . . . . . . . .0.2 - 20l/h

Ambient Temp. Range . . . . . . . . . . . . . . . . .1 - 60OC

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ø10mm

Cable Gland . . . . . . . . . . . . . . . . . . . . . . . .1/4BSP

IP Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.2kg

3. INSTALLATION

p

p

p

WARNING! Ensure you read and understand the safety instructions in Section 1 before proceeding.

3.1. Electrical

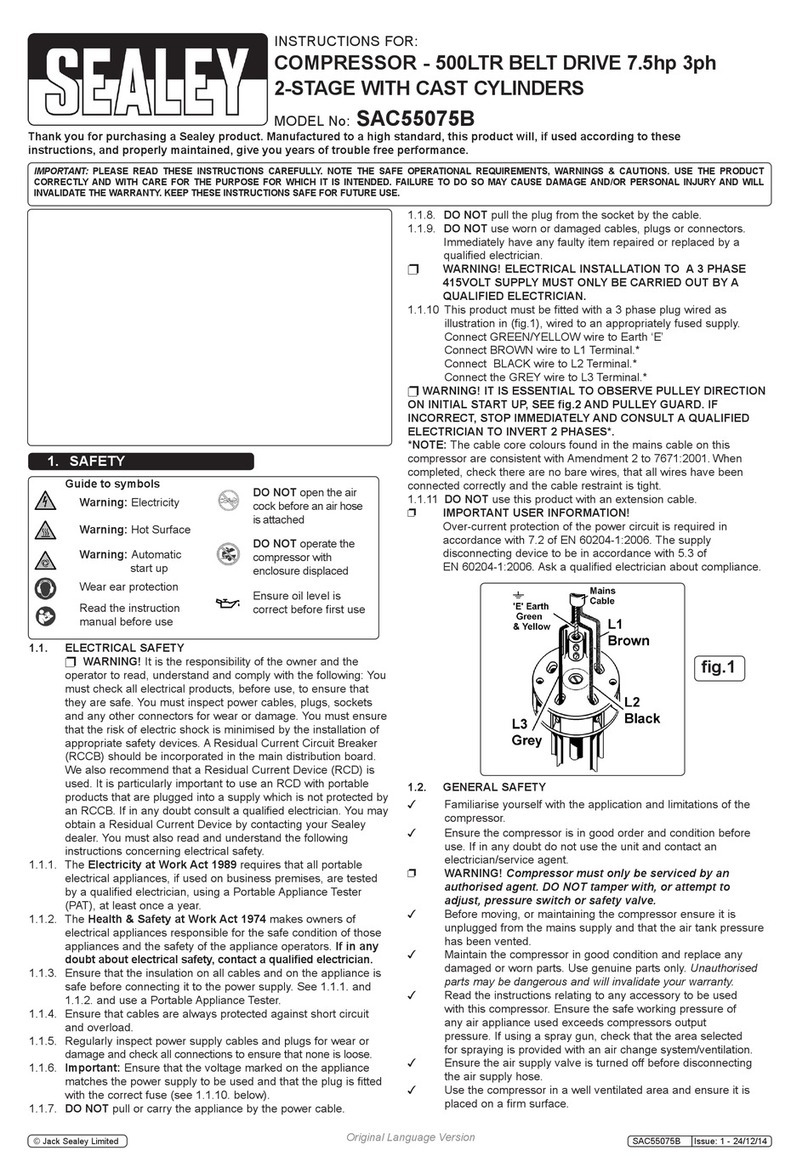

3.1.1. Remove securing screw and lift off terminal cover and terminal block (fig.2.A), note seal.

3.1.2. Gently prise terminal block from cover.

3.1.3. Pass two core cable through terminal cover and connect to terminal block (terminals 1 and 2). Note that earth terminal is

unused as unit is double insulated.

3.1.4. Press terminal block back into terminal cover then onto connecting pins and replace retaining screw. DO NOT omit seal.

3.1.5. Ensure cable outer insulation has passed through the gland seal and then tighten gland (fig.2.B) to grip and seal cable.

INSTRUCTIONS FOR

COMPRESSOR AUTODRAIN - TIMED

Model Nos: AD1 & AD2

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY

AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

AD1 & AD2 - 1105 - (1) - 120700

1.1. ELECTRICAL SAFETY

p

p

p

WARNING! It is the users responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply

leads, plugs and all electrical connections for wear and damage. You must ensure the risk of electric shock is minimised by

the installation of appropriate safety devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main

distribution board. We also recommend that an RCD (Residual Current Device) is used with all electrical products. If in doubt

consult a qualified electrician. You may obtain a Residual Current Device by contacting your Sealey dealer. You must also

read and understand the following instructions concerning electrical safety.

1.1.1. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the

appliance and the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.1.2. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power supply.

1.1.3. Ensure that cables are always protected against short circuit and overload.

1.1.4. Regularly inspect power supply, leads, plugs for wear and damage and all electrical connections for looseness.

1.1.5. Important: Ensure the voltage marked on the product is the same as the electrical power supply to be used, and check that the

correct capacity fuse is fitted. This product is intended for hard wiring and requires a 3 amp fuse.

1.2. GENERAL SAFETY INSTRUCTIONS

Familiarise yourself with the application and limitations of the drain valve.

Ensure the drain valve is in good order and condition before use. If in any doubt do not use the unit and contact an electrician or service agent.

p

p

p

WARNING! Drain valve must only be serviced by an authorised agent..

Before removing, or carrying out maintaining on, the drain valve ensure it is disconnected from the mains supply and that the air

tank pressure has been vented or isolated.

Use only recommended attachments and parts. To use non-recommended items may be dangerous and will invalidate your warranty.

Ensure that the maximum pressure (safety valve setting) of the system does not exceed the maximum working pressure of the drain valve.

Ensure that the air tank is fully vented before commencing fitment of drain valve.

Keep children and unauthorised persons away from the working area.

DO NOT operate in the vicinity of flammable liquids or gases.

DO NOT dis-assemble the drain valve for any reason. The unit must be checked by qualified personnel only.

DO NOT use this product to perform a task for which it is not designed.

p

p

p

WARNING! If an electrical fuse blows, ensure it is replaced with an identical fuse type and rating.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & SPECIFICATION

AD1 & AD2

Power Supply . . . . . . . . . . . . . . . . .230V 1ph 50Hz

Required Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . .3A

Power Consumption - Standby . . . . . . . . . . . .0.2VA

Power Consumption - Operating . . . . . . . . . . .6.2VA

Operating Pressure Range . . . . . . . . . . .0.2 - 12 bar

Maximum Pressure . . . . . . . . . . . . . . . . . . . .16 bar

Condensate Temp. Range . . . . . . . . . . . . . .1 - 80OC

Suitable for small and medium compressed air systems the AD1 and AD2 Timed Drain Valves are installed in place of drain cocks and

automatically open at preset time intervals to drain condensate. The drain valves are adjustable to suit the volume of condensate being

generated thus minimising the loss of compressed air.

AD1 AD2

Drain Capacity . . . . .0.05 - 5l/h . . . . . . . .0.2 - 20l/h

Ambient Temp. Range . . . . . . . . . . . . . . . . .1 - 60OC

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3/8BSP

Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ø10mm

Cable Gland . . . . . . . . . . . . . . . . . . . . . . . .1/4BSP

IP Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.2kg

3. INSTALLATION

p

p

p

WARNING! Ensure you read and understand the safety instructions in Section 1 before proceeding.

3.1. Electrical

3.1.1. Remove securing screw and lift off terminal cover and terminal block (fig.2.A), note seal.

3.1.2. Gently prise terminal block from cover.

3.1.3. Pass two core cable through terminal cover and connect to terminal block (terminals 1 and 2). Note that earth terminal is

unused as unit is double insulated.

3.1.4. Press terminal block back into terminal cover then onto connecting pins and replace retaining screw. DO NOT omit seal.

3.1.5. Ensure cable outer insulation has passed through the gland seal and then tighten gland (fig.2.B) to grip and seal cable.