HELVAR SCENESET HES91010 User manual

page 1

Document Ref. EPD05113 (08/04/98) ENGLISH Part No. I259GB issue 5

INTRODUCTION

These instructions relate to the installation, basic connection and

setting-up of an HES91010 SCENESET Lighting Controller.

For operational instructions, please refer to the User Guide

(part no. I299GB) supplied separately.

INSTALLATION

Choosing a Suitable Location

The HES91010 is designed to be mounted vertically with the connection

points at the bottom; this is to ensure correct ventilation.

The chosen mounting surface must be flat and the location must meet the

following requirements:

·A clearance of at least 100mm on all sides is recommended to allow

for adequate ventilation.

·Sufficient clearance must be left below the unit to allow for the

connection of cables, conduits or trunking.

·The ambient temperature must be within the range 0C to 35C and the

area must be adequately ventilated.

·Humidity should be within the range of 0 to 90% (non-condensing).

DO NOT install this product in a damp location.

Fixing Method

Mounting is achieved by using the four ‘keyhole’ fixing holes on the side

flanges. The fixing screws (not supplied) must be chosen to suit the

following criteria:

·Wall Construction – suitable wall plugs must be used for masonry

construction and plasterboard partitions.

·Screw Length – must be sufficient to securely anchor the unit.

·Screw Head - round-head, pan-head or cheese-head screws must be

used. The head size should be small enough to just pass through the

large area at the centre of the fixing hole and large enough to clamp

the flange securely in the slotted portion of the hole.

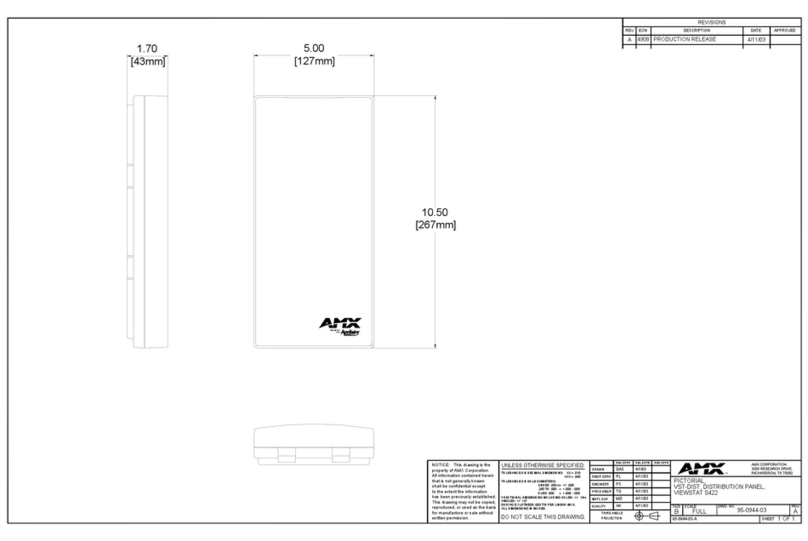

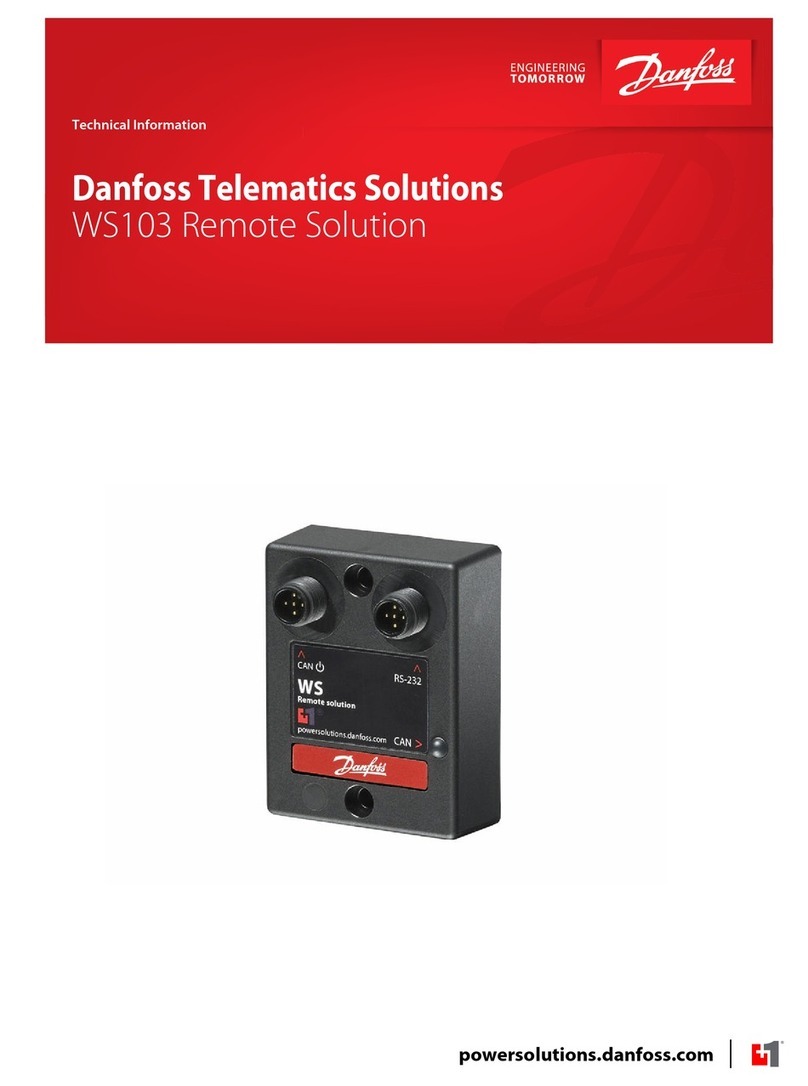

1. Mark and drill four holes to correspond with the centres of the

fixing holes (see Fig.1-1), and fit wall plugs as required. Note the

drop-down clearance of 12mm.

2. Insert the screws, and screw them in until the distance between the

wall and the underside if the screw heads is a little more than the

depth of the flange.

3. Align the centres of the flange fixing holes with the screws, then

allow

the slotted part of the holes to drop-down behind the screw heads.

If necessary, loosen the screws to ease this operation.

4. Finally, tighten all four screws sufficiently to prevent the unit from

being lifted away.

211

230

181

370

251 93

63

(ALL DIMENSIONS IN mm.)

HES91010 SCENESET – LIGHTING CONTROLLER

Ø5.0

KEYHOLE SLOTS

(4 off) for securing the unit

Ø8.0

Drop Height

= 12mm

Fig.1-1: Overall dimensions & fixing holes positions.

Cable Access

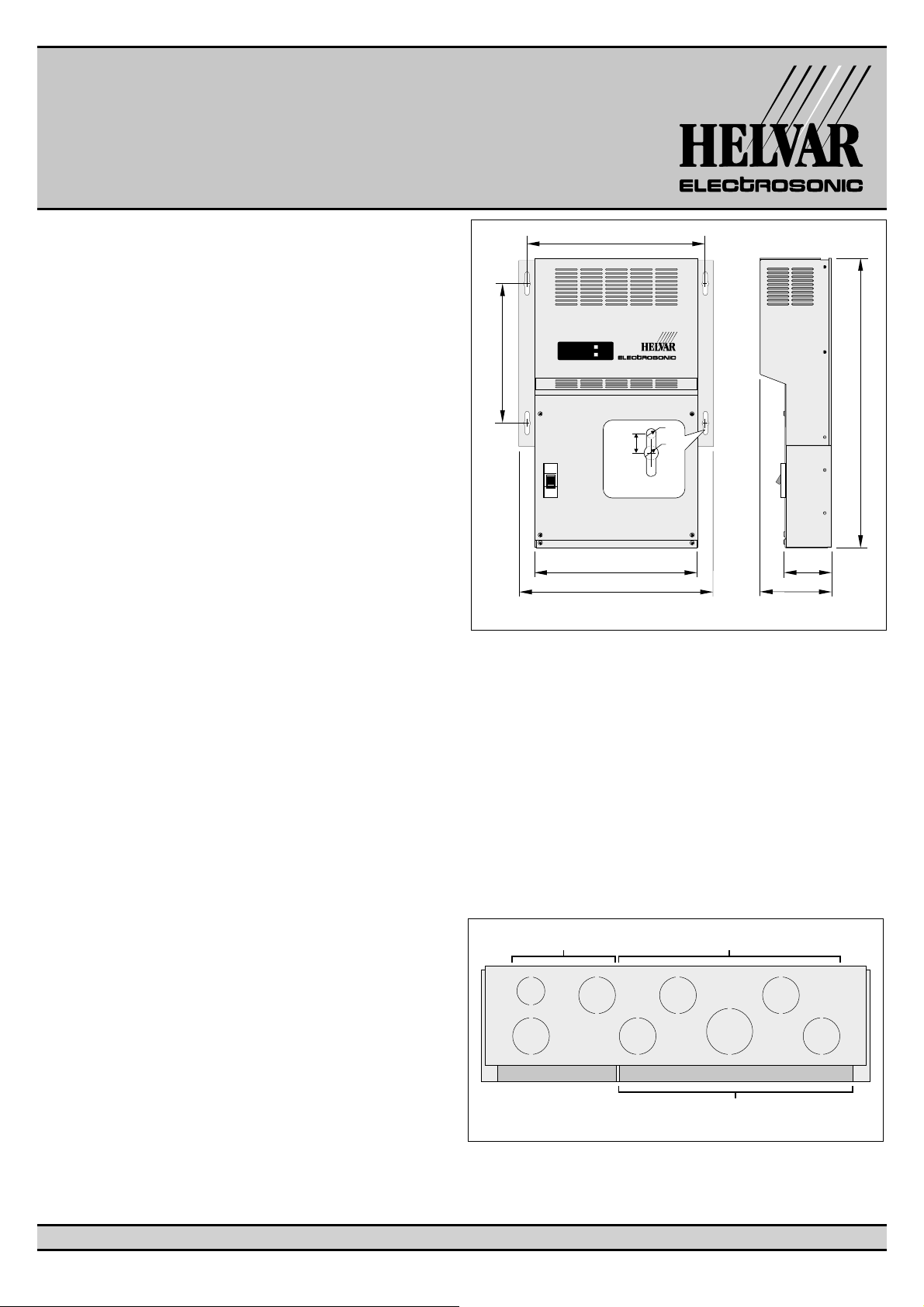

There are various ‘knock-outs’ on the base of the unit which are suitable

for 15, 20, or 25mm conduit fixings (see Fig.1-2).

These are arranged such that the three left hand positions are used

exclusively for mains cables, whilst the remainder are used for the FELV

(Functional Extra-Low Voltage) control connections.

If required, control cables which are not in conduits can enter the unit via

the slot behind the knock-outs.

MAINS CABLES LOW VOLTAGE CONTROL CABLES

Entry point for free cables

(not in conduit)

15

20

20

20 25

20 20

20

Fig.1-2: Cable entry knock-outs

Installation Instructions

SCENESET™Lighting Controller

HES91010

Document Ref. EPD05113 (22/07/03) ENGLISH Part No. I259GB issue 6

Document Ref. EPD05113 (22/07/03) ENGLISH Part No. I259GB issue 6

page 2

MAINS SUPPLY INPUT

Voltage Range

The SCENESET Lighting Controller is factory-set for use with one of the

following voltage ranges which cannot be changed by the user:

·230V a.c. (nominal); 180V – 260V a.c. (absolute).

·115V a.c. (nominal); 90V – 130V a.c. (absolute).

Check that the controller is set for the correct range for the intended power

supply by referring to the serial no./rating plate which is mounted inside

the control connection compartment (behind the right-hand access plate).

WARNING: THE MAINS INPUT MUST BE CONNECTED TO A

SINGLE-PHASE SUPPLY ONLY AND MUST BE EARTHED.

CAUTION:Connecting a supply which exceeds the maximum voltage for the

appropriate input range may cause irreparable damage to the SCENESET.

Frequency Range

The input supply frequency should be within the range 45 – 65Hz.

Supply Protection

The supply input is protected by the internal 3A MCB. No further

external supply protection is required.

Connecting the Mains Supply

Access to the mains input terminals is gained by removing the access

plate (four-screw fixing).

Cable Function Connection Point

Live Input Bottom screw terminal of the MCB

Neutral Cream coloured screw-terminal block.

Earth Green/Yellow coloured screw-terminal block.

Suitable cable type: Solid, stranded or flexible.

Cable size: 1.5mm2– 4.0mm2.

Stripping length: 12mm (for MCB)

10mm (for other terminals).

EARTH

NEUTRAL

LIVE

Fig.1-3: Mains connection terminals

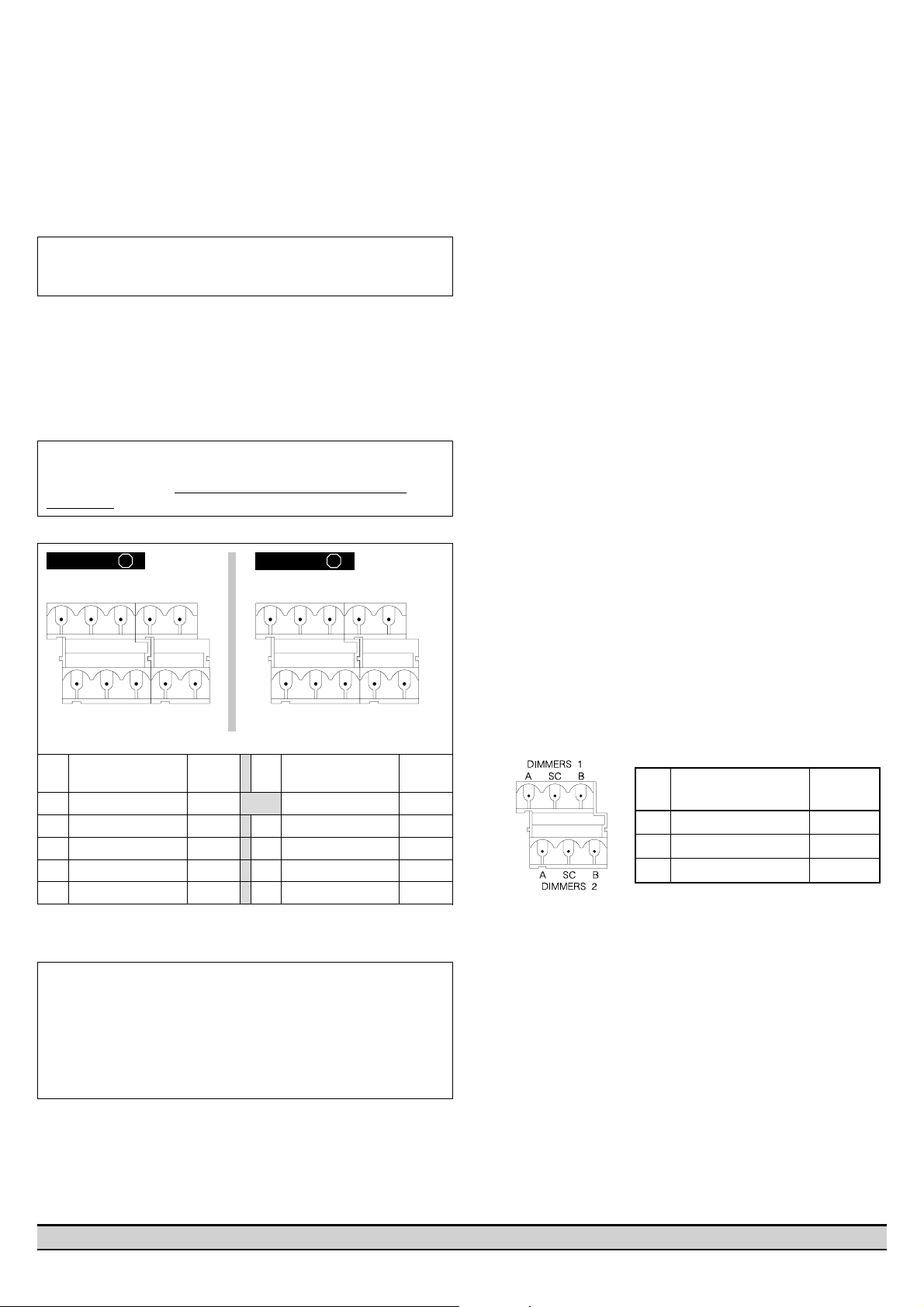

BREAKOUT MODULE

The BREAKOUT module is located behind the access plate (on the

right-hand side) and provides connection points to the various FELV

(Functional Extra-Low Voltage) data and control circuits (see Fig.1-4.).

·S-COM (external) power & data highway.

·S-COM (star) data highway.

·S-COM (internal) data highway.

·S-DIM data highways.

·SCENESET watchdog relay contacts.

·BREAKOUT module relay coil and contacts.

·DIMMER level override input.

These allow the connection of various external control input or output

devices and enable separate SCENESETs to be linked. Full details of each

connector and its function are given in the User Guide.

Suitable Cable

All of the S-COM and S-DIM data highways require a screened twisted

pair, whilst all other connections should use equipment wire. For full

details, refer to the Electrosonic Control Cable Specifications data sheet

(part no. I237GB).

Special S-COM cable is available from Helvar Electrosonic which

comprises the following conductors in an overall sleeve:

·Twisted pair with screen (for data lines).

·Two power wires (for S-COM supply).

This is ideally suited for use with the S-COM (external) line, but may also

be used on the other S-COM and S-DIM lines if the two power wires are

cut back.

Configuration Switches

A bank of eight DIL slide switches is provided on the module which are

used for the following purposes (from left to right):

·Switches1–3 Toselect different interconnections of the

SCENESET watchdog and DIMMER override circuits.

·Switches4–8 Toselect line termination on the various

data highways .

All of the configuration switches are factory-set to the ‘ON’ (up) position,

but these can be changed if required.

1

23

456

78

LEVEL RELAY SCENESET DIMMERS 1 STAR PANEL

CN1

LK1

CN10

OFF

CONFIGURATION

SWITCHES

TEMP WATCHDOG SCENESET DIMMERS 2 RELAY PA NE L

Fig.1-4: Location of BREAKOUT Module.

Document Ref. EPD05113 (22/07/03) ENGLISH Part No. I259GB issue 6

page 3

S-COM Loading

Each device that can be connected to the S-COM (external) data highway

has a Unit Loading Factor (ULF) according to its power consumption.

The total of the ULF’s for all devices connected must not exceed 15:

SCENECOMMANDER:1

SCENETIMER:1

INPUT module: 1 (using bistable inputs & LCS only).

1.5 (using LCS, analogue & bistable inputs).

LCS panels: 0.25 (via INPUT module only).

LCS infra-red unit: 0.5 (via INPUT module only).

CHANNEL COMMANDER:1

STAR DISTRIBUTION unit: 2.

The S-COM (external) line also has the capacity to support either

SCENEMAKER or SCENEPLANNER without affecting the total number of

devices permitted.

Line Termination

If the BREAKOUT module is located at one end of the data highway, set

switch 4 (‘PANEL’) to the ‘ON’ (up) position.

If the module is located along the highway, set switch 4 to ‘OFF’.

S-DIM

Two data highways are available (S-DIM #1 and S-DIM #2) which can be

used to connect various output devices (e.g. DIMMER modules, OUTPUT

modules, etc.).

Connection Details

Connection to each S-DIM highway is made via the 3-way connectors

labelled ‘DIMMERS 1’ and ‘DIMMERS 2’ (Fig.1-5). Both S-DIM highways

are functionally identical but are electrically buffered. If the BREAKOUT

module is located along either data highway, both halves of the highway

need to share the same connector.

Mating connector part no.: P9830 (3-way).

Cable size: 0.2 – 2.5mm2.

Stripping length: 7.0mm.

S-DIM Loading

Each highway can support up to 64 channels (e.g. 16 x HES99400). Thus a

total of 128 channels can be controlled when using both highways.

Line Termination

If the BREAKOUT module is located at one end of the data highway(s), or

if the connections are not used, set switch 7 (‘DIM 1’) or switch 8 (‘DIM 2’)

to the ‘ON’ position accordingly.

If the module is located at some point along the highway(s), set switches

7or8tothe‘

OFF’ position.

S-COM (external)

This data highway is used to connect the following scene-recall devices:

·SCENECOMMANDERs.

·SCENETIMER.

·INPUT Module.

·CHANNEL COMMANDER

·STAR DISTRIBUTION Unit [also requires S-COM (star) line].

Connection Details

CAUTION

Ensure that the SCENESET controller is turned-off before attempting to

connect the S-COM (external) highway.

Connection of the S-COM (external) highway is made via the 5-way

connectors labelled ‘PANEL’ (Fig.1-6). Both connectors are electrically

identical. If the BREAKOUT module is located along the data highway,

one connector should be used for each half of the highway.

Mating connector part no.: P9850 (5-way).

Cable size: 0.2 – 2.5mm2.

Stripping length: 7.0mm.

CAUTION

Please note that the power supply connections are different on issue Cand D

BREAKOUT Modules — check for correct polarity before powering the

S-COM line.

CAUTION

Incorrect connections may result in damage to the internal circuitry of the

controller and of any other devices connected to the S-COM (external)

highway.

Check that all connections are correct and that there are no short-circuits

before powering-up the SCENESET controller. In particular, ensure that the

data lines are not accidentally or deliberately connected to the supply lines.

Fig.1-5: Connection details for S-DIM#1 & S-DIM#2.

Pin Function Wire

Colour

A S-DIM data A Red

SC Power ground (0V) —

B S-DIM data B Black

B

B

+

+

–

–

A

A

SC

SC

PANEL

PANEL

B

B

–

–

+

+

A

A

SC

SC

PANEL

PANEL

PCB Issue :C

PCB Issue :C

PCB Issue :D

PCB Issue :D

Fig.1-6: Connection details for S-COM (external).

Pin Function Wire

Colour Pin Function Wire

Colour

– Power ground (0V) Grey Power supply (40V) Purple

A S-COM data A Red A S-COM data A Red

SC Screen (earth) — SC Screen (earth) —

B S-COM data B Black B S-COM data B Black

Power supply (40V) Purple – Power ground (0V) Grey

page 4

WATCHDOG/LEVEL OVERRIDE

The SCENESET watchdog and DIMMER level override circuits are

provided to allow the DIMMER outputs to be taken to a pre-defined level

if the SCENESET controller loses control (automatic watchdog). This level

override facility can also be triggered by a separate security/fire alarm

system.

These two circuits, together with a relay on the BREAKOUT module can be

interconnected by using switches 1,2&3;forfull details of other circuit

applications, refer to the User Guide. Note that although switches2&3

are separate, they are always operated as a pair (i.e. both ‘on’ or both

‘off’).

Selecting Automatic Watchdog (Switches 1,2&3)

These are factory-set to the ‘ON’ position but may be changed as

required.

With all three switches set to the ‘ON’ position (default), automatic

watchdog is enabled; with all three switches set to the ‘OFF’ position,

automatic watchdog is disabled.

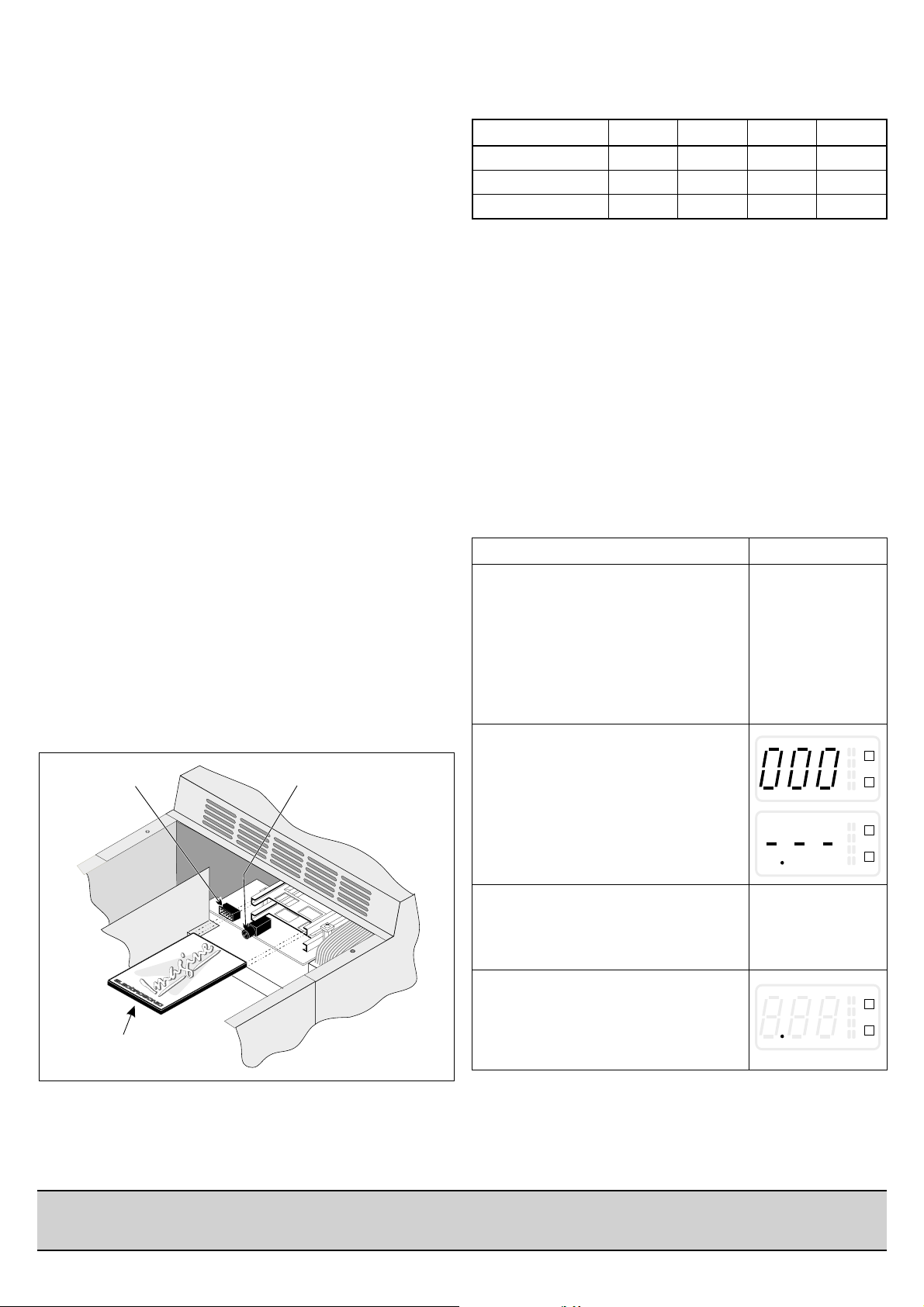

SCENESOFT CARDS

There are two slots behind the access plate (on the right-hand side)

which are used for SCENESOFT memory cards (see Fig.1-7):

The card in slot ‘A’ (which is nearest the front panel) is used by the

SCENESET controller to retrieve and store the following data:

·SCENESET address.

·DIMMER output levels for each scene.

·DIMMER parameters.

·Scene parameters (linking, fade times, re-directions, etc.).

ASCENESOFT card must be plugged into slot ‘A’ to allow the SCENESET

to function correctly. The card can either be pre-programmed or

programmed in situ by connecting a SCENEMAKER or SCENEVIEWEDITOR

to the Programming Connector.

Slot ‘B’ is used in conjunction with the SCENESET‘s ‘Copy’ function to make

a copy of the card in Slot ‘A’ (see the User Guide for further details).

Card Capacity

The number of scenes stored on the card depends on its capacity. Three

types of card are available offering different system capabilities:

Card Type/Capacity Scenes Triggers Redirects Clusters

HES90120 8K 40 10 10 2

HES90240 128K 600 150 150 15

HES91280 512K 1024 500 500 50

Choose the card type carefully to match current requirements, and also

allow for any anticipated future expansion.

Default Scene

The SCENESOFT card can be programmed to perform one of two actions

when the SCENESET controller is powered-up:

·Default to scene zero (‘000’).

·Restore the last known output levels (‘000’ is displayed but any

programmed levels for scene zero are ignored).

NOTE Whilst scene zero can be programmed in the same way as any other,

it cannot be recalled via the S-COM line (except with

SCENEPLANNER).

POWER-UP PROCEDURE

Procedure Display & Buttons

1. Remove the access plate and insert a

programmed SCENESOFT card into slot ‘A’

(nearest the front) and turn-on the mains

supply.

Note: Ensure that the card is correctly

orientated i.e. with the logo side facing

outwards and with the ‘arrowhead’ symbol

pointing towards the slot.

(see Fig.1-7)

2. After approximately one second, the

display should change to show scene zero.

If the display shows three dashes, this

indicates that the card cannot be read. This

may be caused by an unformatted card, or

if the card’s internal battery is discharged

or missing.(Refer to the User Guide).

3. The SCENESET will now perform a

‘logging-on’ process of all the devices

connected to it. This may take up to 30

seconds in a large system, during which

time the display will not change.

4. If the diagnostic flag indicator is lit

(between the first two digits), one or more

diagnostic codes are waiting to be

displayed.

Refer to the User Guide for details.

Programming

Connector

S-COM Supply

Fuse Holder

scenesoft

SceneSoft Card

(inserted into slot A)

Fig.1-7: Card slots, program connector & fuse holder.

© 1997 HELVAR ELECTROSONIC Group Part No. I259GB

Hawley Mill, Hawley Road, Dartford, Kent. DA2 7SY (U.K.) Document Ref. EPD05113

Tel: 01322 222211 Fax: 01322 282282 issue 6 (22/07/03)

Table of contents

Other HELVAR Recording Equipment manuals