Helvi PC EVO 66 User manual

MANUALE D’ISTRUZIONEMANUALE D’ISTRUZIONE

ITIT

3PH PLASMA CUTTING UNIT3PH PLASMA CUTTING UNIT

UNITÁ DI TAGLIO AL PLASMA 3PHUNITÁ DI TAGLIO AL PLASMA 3PH

UNITÉ DE COUPE PLASMA 3PHUNITÉ DE COUPE PLASMA 3PH

3PH PLASMASCHNEIDANLAGE3PH PLASMASCHNEIDANLAGE

UNIDAD DE CORTE DE PLASMA 3PHUNIDAD DE CORTE DE PLASMA 3PH

UNIDADE DE CORTE PLASMA 3PHUNIDADE DE CORTE PLASMA 3PH

INSTRUCTION MANUALINSTRUCTION MANUAL

MANUEL D’INSTRUCTIONSMANUEL D’INSTRUCTIONSFRFR

ENEN

PC EVO 66PC EVO 66

MANUAL DE INSTRUCCIONESMANUAL DE INSTRUCCIONES

ESES

BEDIENUNGSANLEITUNGBEDIENUNGSANLEITUNG

MANUAL DE INSTRUÇÕESMANUAL DE INSTRUÇÕESPP

DD

II

INDEX

FOREWORD EN-1

SAFETY EN-1

WARNINGS EN-1

PERSONAL PROTECTION EN-2

LIGHT RADIATIONS EN-2

WORKING AREA EN-2

ELECTRIC SYSTEM EN-4

FIRE PREVENTION EN-4

PROTECTION GAS EN-5

NOISE EN-5

FIRST AID EN-5

ELECTROMAGNETIC COMPATIBILITY EN-5

GENERAL INFORMATION EN-6

TECHNICAL INFORMATION EN-6

INSTALLATION EN-6

LOCATION EN-6

MAIN SUPPLY VOLTAGE REQUIREMENTS EN-6

SAFETY INSTRUCTIONS EN-6

CONNECTION TO GROUND CABLE EN-7

TORCH CONNECTION EN-7

TORCH CONSUMABLE PARTS MOUNTING EN-7

COMPRESSED AIR EN-7

PURGE EN-7

CONNECTION OF THE MACHINE TO

THE CNC EN-8

ARC VOLTAGE SIGNAL EN-8

FUNCTIONS EN-9

CUTTING OPERATION EN-10

PRELIMINARIES EN-10

CUTTING EN-11

MAINTENANCE EN-13

OPERATING FAULTS EN-14

TROUBLESHOOTING EN-14

TORCH CONSUMABLES A÷B

INDICE

PREMESSA IT-1

SICUREZZA IT-1

AVVERTENZE IT-1

PROTEZIONE PERSONALE IT-2

RADIAZIONI LUMINOSE IT-2

AREA OPERATIVA IT-2

IMPIANTO ELETTRICO IT-4

PREVENZIONE D’ INCENDIO IT-4

GAS DI PROTEZIONE IT-5

RUMORE IT-5

PRONTO SOCCORSO IT-5

EMC IT-5

GENERALITA’ IT-6

DATI TECNICI IT-6

INSTALLAZIONE IT-6

COLLOCAZIONE IT-6

REQUISITI DELLA TENSIONE DI RETE IT-6

ISTRUZIONI PER LA SICUREZZA IT-7

COLLEGAMENTO DEL CAVO DI MASSA IT-7

COLLEGAMENTO DELLA TORCIA IT-7

MONTAGGIO CONSUMABILI TORCIA IT-7

ALLACCIAMENTO ARIA COMPRESSA IT-7

SPURGO IT-7

COLLEGAMENTO A SISTEMI DI

TAGLIO AUTOMATICI IT-8

SEGNALE DI TENSIONE DELL’ARCO IT-8

FUNZIONI IT-9

OPERAZIONI DI TAGLIO IT-10

PRELIMINARI IT-10

TAGLIO IT-11

MANUTENZIONE IT-13

DIFETTI DI TAGLIO IT-14

RICERCA GUASTI IT-14

CONSUMABILI TORCIA A÷B

CONTENU

AVANT-PROPOS FR-1

SÉCURITÉ FR-1

AVERTISSEMENT FR-1

PROTECTION PERSONNELLE FR-2

RADIATIONS LUMINEUSES FR-2

CIRCUIT ÉLECTRIQUE FR-4

PRÉVENTION D’INCENDIE FR-4

GAZ DE PROTECTION FR-5

BRUIT FR-5

PREMIERS SECOURS FR-5

EMC FR-5

GÉNÉRALITÉS FR-6

DONNÉES TECHNIQUES FR-6

INSTALLATION FR-6

MISE EN PLACE FR-6

CONDITIONS REQUISES POUR LA TENSION

DU RESEAU FR-6

INSTRUCTIONS POUR LA SÉCURITÉ FR-7

BRANCHEMENT DU CABLE DE MASSE FR-7

BRANCHEMENT DU CHALUMEAU POUR LE

COUPE PLASMA FR-7

MONTAGE DES PIÈCES CONSOMMABLES

DE CHALUMEAU FR-7

BRANCHEMENT DE L’AIR COMPRIMÉ FR-8

PURGE FR-8

CONNEXION DE LUNITÉ A SYSTÈMES DE

COUPE AUTOMATIQUE FR-8

SIGNAL DE TENSION D’ARC FR-8

DISPOSITIFS DE CONTROLE, SIGNALISATION

ET SECURITÉ FR-9

OPÉRATIONS DE COUPE FR-10

PRÈLIMINAIRE FR-10

COUPE FR-11

ENTRETIEN FR-13

DISFONCTIONNEMENTS HABITUELS FR-14

DÉPANNAGE FR-14

CONSOMMABLES DE CHALUMEAU A÷B

INHALT

VORWORT D-1

SICHERHEIT D-1

HINWEISE D-1

PERSÖNLICHE SCHUTZAUSRÜSTUNG D-2

LICHTSTRAHLEN D-2

ARBEITSBEREICH D-2

ELEKTRISCHE ANLAGE D-4

BRANDVERHÜTUNG D-4

SCHUTZGAS D-5

GERÄUSCHENTWICKLUNG D-5

ERSTE HILFE D-5

EMV (ELEKTROMAGNETISCHE

VERTRÄGLICHKEITS-RICHTLINIE) D-5

III

ALLGEMEINE INFORMATIONEN D-6

TECHNISCHE DATEN D-6

INSTALLATION D-6

PLATZIERUNG D-6

NETZSPANNUNG – ALLGEMEINE

BEDINGUNGEN D-6

SICHERHEITSVORSCHRIFTEN D-7

ANSCHLUSS DES MASSEKABELS D-7

ANSCHLUSS DES SCHNEIDBRENNERS D-7

MONTAGE DER D-7

BRENNERVERSCHLEISSTEILE D-7

DRUCKLUFTVERSORGUNG D-8

ENTLEERUNG D-8

CNC SCHNITTSTELLE D-8

SIGNAL LICHTBOGENSPANNUNG D-8

FUNKTIONEN D-9

SCHNEIDVORGANG D-10

VORBEREITENDE MASSNAHMEN D-10

SCHNEIDEN D-11

INSTANDHALTUNG D-13

BEDIENUNGSFEHLER D-14

HINWEISE ZUR FEHLER BEHEBUNG D-14

BRENNERVERSCHLEISSTEILE A÷B

CONTENIDO

PREÁMBULO ES-1

SEGURIDAD ES-1

ADVERTENCIAS ES-1

PROTECCIÓN PERSONAL ES-2

RADIACIONES LUMINOSAS ES-2

AREA OPERATIVA ES-2

INSTALACIÓN ELÉCTRICA ES-4

PREVENCIÓN DE INCENDIOS ES-4

GAS DE PROTECCIÓN ES-5

RUIDO ES-5

PRIMEROS AUXILIOS ES-5

EMC ES-5

DATOS GENERALES ES-6

DATOS TÉCNICOS ES-6

INSTALACIÓN ES-6

COLOCACIÓN ES-6

REQUISITOS DE LA TENSIÓN DE

LA RED ELÉCTRICA ES-6

INSTRUCCIONES PARA LA SEGURIDAD ES-7

CONEXION AL CABLE DE TIERRA ES-7

CONEXION DE LA ANTORCHA DE CORTE ES-7

MONTAJE DE LOS CONSUMIBLES DE LA

ANTORCHA ES-7

CONEXION DEL AIRE COMPRIMIDO ES-8

SISTEMA DE PURGA ES-8

CONEXIÓN A SISTEMAS AUTOMÁTICOS DE

CORTE ES-8

SEÑAL DE TENSIÓN DE ARCO ES-8

FUNCIONES ES-9

OPERACIONES DE CORTE ES-10

PRELIMINARES ES-10

CORTE ES-11

MANTENIMIENTO ES-13

ERRORES DE CORTE MAS COMUNES ES-14

BUSQUEDA DE AVERIAS ES-14

CONSUMIBLES DE LA ANTORCHA A÷B

ÍNDICE

INTRODUÇÃO P-1

SEGURANÇA P-1

ADVERTÊNCIAS P-1

PROTECÇÃO PESSOAL P-2

RADIAÇÕES LUMINOSOS P-2

ÁREA OPERACIONAL P-2

CIRCUITO ELÉCTRICO P-4

PREVENÇÃO DE INCÊNDIO P-4

GÁS DE PROTECÇÃO P-5

RUÍDOS P-5

PRIMEIROS SOCORROS P-5

EMC (COMPATIBILIDADE ELECTROMAGNÉTICA) P-5

INFORMAÇÕES GERAIS P-6

DADOS TÉCNICOS P-6

INSTALAÇÃO P-6

COLOCAÇÃO P-6

REQUISITOS DA TENSÃO DE REDE P-6

INSTRUÇÕES PARA SEGURANÇA P-7

CONEXÃO DO CABO DE TERRA P-7

CONEXÃO DA TOCHA P-7

MONTAGEM DOS CONSUMÍVEIS DA TOCHA P-7

CONEXÃO DE AR COMPRIMIDO P-8

PURGA P-8

CONEXÃO AOS SISTEMAS DE CORTES

AUTOMÁTICOS P-8

SINAL DE TENSÃO DO ARCO P-8

FUNÇÕES P-9

OPERAÇÕES DE CORTE P-10

PRELIMINARES P-10

CORTE P-11

MANUTENÇÃO P-13

DEFEITOS DE CORTE P-14

RESOLUÇÃO DE PROBLEMAS P-14

CONSUMÍVEIS DA TOCHA A÷B

TORCH CONSUMABLES

H.70 A

HM.70 B

EN-1

Thank you for purchasing our products. When

assembled and used correctly, our welding gene-

rators are reliable and long-lasting and will help

increase the productivity of your business with

minimum maintenance costs.

All these appliances were designed, manufactured

and tested entirely in Italy, in full accordance with

the European Directives of Low Voltage (2006/95/

EC) and EMC (2004/108/EC), by applying norms

EN 60974.1 (safety rules for electric material, Part 1:

source of welding current) and EN 60974-10 (EMC

Electromagnetic Compatibility) and are identified as

Class A products.

Class A appliances were not designed for use in

domestic environments in which power is supplied

through a public low-voltage grid; it is therefore po-

tentially difficult to ensure the electromagnetic com-

patibility of Class A appliances in such environments,

due to radiated and conduced disturbances.

These professional electric appliances must therefore

only be used in industrial environments, connected

to private power distribution cabins.

These generators are therefore not subject to the

European/International EN/IEC regulation 61000-

3-12 which defines the maximum levels of harmonic

distortion induced in the public grid of low-voltage

power distribution.

The installer or the user (if necessary, contact your

power distributor) is responsible for ensuring that

these appliances can be connected to a public low-

voltage grid.

Warning: the manufacturer refuses all re-

sponsibility in the event of unauthorized mo-

difications performed on its products.

FOREWORD

These power generators must only be used for the

cutting procedures described in this manual; they

must never be employed to recharge batteries, for the

thawing of water pipes, for the heating of buildings

by means of added resistances etc.

Compliance to RoHS Directive: We hereby declare

that this range of generators 3Ph described in this

manual is in accordance with RoHS EU Regulations

2011/65/UE of 8 June 2011 regarding the restriction

of the use of certain substances harmful for human

health present in Electric and Electronic Equipment

(EEE).

This symbol, applied to the welding generator

or to its packaging, indicates that, at the end

of its useful life, the product must not be tre-

ated as ordinary waste, but must be collected

separately from other waste and in accordan-

ce with European Directive 2012/19/UE of 4

July 2012 regarding the disposal of waste

electrical and electronic equipment (WEEE).

These must be collected separately and di-

sposed of in an environmentally compatible

way.

As owner of an EEE product (Electrical Electronic

Equipment), you are responsible for contacting your

area dealers for information on authorized collectors.

Applying the above mentioned European Directive

improves the environment and our own health.

Warning: Welding, cutting and similar tech-

niques may be dangerous operations for

the worker and for anyone near the wor-

king area. Please carefully read the SAFE-

TY chapter below in order to reduce risks.

SAFETY

WARNINGS

This manual contains instructions for the proper in-

stallation of the Electric Electronic Equipment (EEE)

you have just purchased.

The owner of an EEE must make sure that this

document is read and understood by welding tech-

nicians and their assistants and by maintenance

technicians.

Warning: Even when the ON/OFF switch of

the EEE is at “O”, voltage from the power grid

is still present within the generator and in the

power cable. Prior to any internal inspection,

make sure the appliance has been discon-

nected from the power source (this means ta-

king a series of steps in order to separate the

appliance from the power source and to keep

it free from voltage).

Electrical electronic appliances may never be used

without their panels and covers, as this may be

dangerous for the workers involved. Using the ap-

pliances without these protections may cause serious

damage to the appliances themselves.

These generators may be supplied by an electricity

generator, which must absolutely be equipped with

a diesel engine with a power higher than the power

required by the generator (see technical data table)

and output voltage of 400Vac +/- 10% - 3Ph –

50/60Hz.

SMALTIMENTO DI APPARECCHI DA ROTTAMARE DA PARTE DI PRIVATI NELL’UNIONE EUROPEA

Questo simbolo che appare sul prodotto o sulla confezione indica che il prodotto non deve essere smaltito assieme agli altri rifiuti domesti-

ci. Gli utenti devono provvedere allo smaltimento delle apparecchiature da rottamare portandole al luogo di raccolta indicato per il riciclag-

gio delle apparecchiature elettriche ed elettroniche. La raccolta ed il riciclaggio separati delle apparecchiature da rottamare in fase di smal-

timento favoriscono la conservazione delle risorse naturali e garantiscono che tali apparecchiature vengano rottamate nel rispetto dell’am-

biente e della tutela della salute. Per ulteriori informazioni sui punti di raccolta delle apparecchiature da rottamare, contattare il proprio comu-

ne di residenza, il servizio di smaltimento dei rifiuti locale o il negozio presso il quale è stato acquistato il prodotto.

DISPOSAL OF WASTE EQUIPMENT BY USERS IN PRIVATE HOUSEHOLDS IN THE EUROPEAN UNION

This symbol on the product or on its packaging indicates that this product must not be disposed of with your other household waste. Instead,

it is yr responsibility to dispose of yr waste equipment by handing it over to a designated collection point for the recycling of waste electri-

cal and electronic equipment. The separate collection and recycling of yr waste equipment at the time of disposal will help to conserve natu-

ral resources and ensure that it is recycled in a manner that protects human health and the environment. For more information about where

you can drop off yr waste equipment for recycling, please contact yr local city office, yr household waste disposal service or the shop where

you purchased the product.

EVACUATION DES ÉQUIPEMENTS USAGÉS PAR LES UTILISATEURS DANS LES FOYERS PRIVÉS AU

SEIN DE L’UNION EUROPÉENNE

La présence de ce symbole sur le produit ou sur son emballage indique que vous ne pouvez pas vous débarrasser de ce produit de la même

façon que vos déchets courants. Au contraire, vous êtes responsable de l’évacuation de vos équipements usagés et à cet effet, vous êtes tenu

de les remettre à un point de collecte agréé pour le recyclage des équipements électriques et électroniques usagés. Le tri, l’évacuation et le

recyclage séparés de vos équipements usagés permettent de préserver les ressources naturelles et de s’assurer que ces équipements sont recy-

clés dans le respect de la santé humaine et de l’environnement. Pour plus d’informations sur les lieux de collecte des équipements usagés,

veuillez contacter votre mairie, votre service de traitement des déchets ménagers ou le magasin où vous avez acheté le produit.

ENTSORGUNG VON ELEKTROGERÄTEN DURCH BENUTZER IN PRIVATEN HAUSHALTEN IN DER EU

Dieses Symbol auf dem Produkt oder dessen Verpackung gibt an, dass das Produkt nicht zusammen mit dem Restmüll entsorgt werden darf.

Es obliegt daher Ihrer Verantwortung, das Gerät an einer entsprechenden Stelle für die Entsorgung oder Wiederverwertung von

Elektrogeräten aller Art abzugeben (z.B. ein Wertstoffhof). Die separate Sammlung und das Recyceln Ihrer alten Elektrogeräte zum

Zeitpunkt ihrer Entsorgung trägt zum Schutz der Umwelt bei und gewährleistet, dass sie auf eine Art und Weise recycelt werden, die keine

Gefährdung für die Gesundheit des Menschen und der Umwelt darstellt. Weitere Informationen darüber, wo Sie alte Elektrogeräte zum

Recyceln abgeben können, erhalten Sie bei den örtlichen Behörden, Wertstoffhöfen oder dort, wo Sie das Gerät erworben haben.

ELIMINACIÓN DE RESIDUOS DE APARATOS ELÉCTRICOS Y ELECTRÓNICOS POR PARTE DE

USUARIOS DOMÉSTICOS EN LA UNIÓN EUROPEA

Este símbolo en el producto o en el embalaje indica que no se puede desechar el producto junto con los residuos domésticos. Por el contra-

rio, si debe eliminar este tipo de residuo, es responsabilidad de usuario entregarlo en un punto de recolección designado de reciclado de apa-

ratos electrónicos y eléctricos. El reciclaje y la recolección por separado de estos residuos en el momento de la eliminación ayudarán a pre-

servar recursos naturales y a garantizar que el reciclaje proteja la salud y el medio ambiente. Si desea información adicional sobre los luga-

res donde puede dejar estos residuos para su reciclado, póngase en contacto con las autoridades locales de su ciudad, con el servicio de

gestión de residuos domésticos o con la tienda donde adquirió el producto.

DESCARTE DE EQUIPAMENTOS POR USUÁRIOS EM RESIDÊNCIAS DA UNIÃO EUROPEIA

Este símbolo no produto ou na embalagem indica que o produto não pode ser descartado junto com o lixo doméstico. No entanto, é sua respon-

sabilidade levar os equipamentos a serem descartados a um ponto de colecta designado para a reciclagem de equipamentos eletro-eletrônicos.

A colecta separada e a reciclagem dos equipamentos no momento do descarte ajudam na conservação dos recursos naturais e garantem que os

equipamentos serão reciclados de forma a proteger a saúde das pessoas e o meio ambiente. Para obter mais informações sobre onde descartar

equipamentos para reciclagem, entre em contacto com o escritório local de sua cidade, o serviço de limpeza pública de seu bairro ou a loja em

que adquiriu o produto.

EN-2

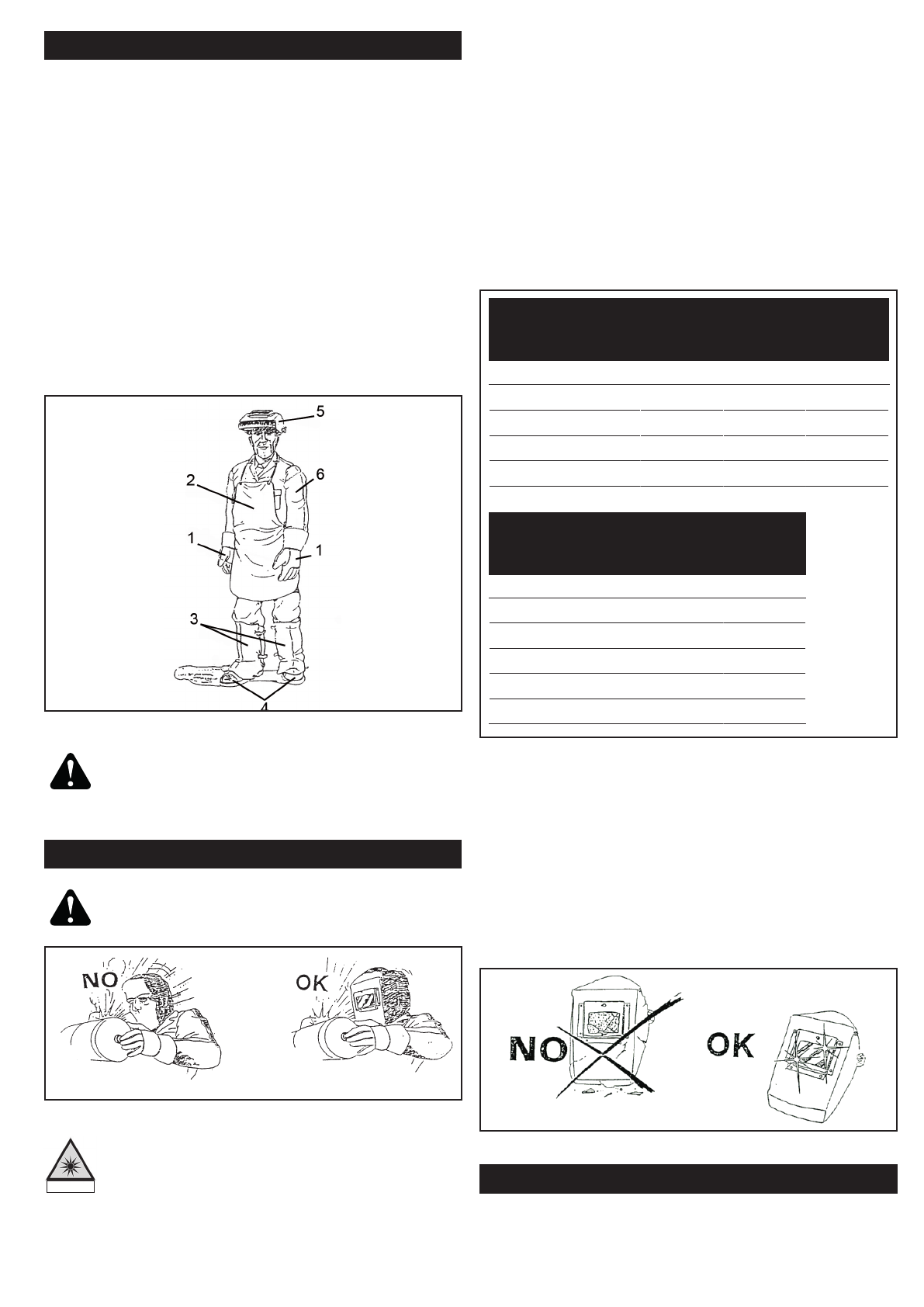

PERSONAL PROTECTION

• Workers and their assistants must protect

themselves by wearing closed, non-flamma-

ble protection coveralls, without pockets or

rolled sleeves or legs. Any residue of oil or

grease must be cleaned from the garments

before wearing them. Only wear CE marked

garments suitable for arc welding and cutting

(Fig. 1):

1. Gloves;

2. Apron or jacket made of crust leather;

3. Gaiters to protect the shoes and the bottoms

of the trousers;

4. Protection shoes with steel toes and rubber soles;

5. Mask (please consult the paragraph on light

radiations);

6. Crust leather sleeves to protect the arms.

• Users must wear fireproof helmet or mask,

designed in such a manner as to offer protec-

tion to the neck and face (including the sides)

against the light of the electric arc (glare from

the visible light and infrared and ultraviolet

radiations). The helmet or the mask must be

equipped with a protector whose degree of

opacity will depend on the welding or cutting

procedure and on the value of the electric arc

current, according to the values contained in

Table 1 (EN 169).

Figure 1

Caution: Make sure all protection gar-

ments are in good conditions and replace

them regularly in order to ensure perfect

personal protection.

LIGHT RADIATIONS

Warning: Never stare at an electric arc wi-

thout suitable eye protection (Fig. 2).

Figure 2

According to the requirements in 2006/25/

EC Directive and EN 12198 Standard, the

equipment is a category 2. It makes com-

pulsory the adoption of Personal Protective

Equipment (PPE) having filter with a pro-

tection degree up to a maximum of 15, as

required by EN169 Standard.

• The colored filter (inactinic filter) must be kept

clean at all times. Should it break or dete-

riorate (Fig. 3), replace it with a new filter,

with the same degree of opacity. The colored

filter must be protected against impact and

welding or cutting projections by means of a

transparent glass positioned on the anterior

part of the mask. This transparent glass must

be replaced whenever visibility is reduced du-

ring welding.

DIN Taglio

Plasma Elettrodi

Rivestiti

Elettrodi

Carbonio

Arc/Air TIG

9 20 - 39A 5 - 19A

10 40 - 79A 125 - 174A 20 - 39A

11 50 - 149A 80 - 174A 175 - 224A 40 - 99A

12 150 - 249A 175 - 299A 225 - 274A 100 - 174A

13 250 - 400A 300 - 499 275 - 349A 175 - 249A

14 500A 350 - 449A 250 - 400A

DIN MIG per

Leghe

Leggere

MIG per

Pezzi d’Ac-

ciaio MAG

9

10 80 - 99A 80 - 99A 40 - 79A

11 100 - 174A 100 - 174A 80 - 124A

12 175 - 249A 175 - 299A 125 - 274A

13 250 - 349A 300 - 499A 275 - 349A

14 350 - 499A 500 - 550A 350 - 449A

Table 1

Figure 3

WORKING AREA

Welding or cutting operations must be carried out

in a sufficiently ventilated place, isolated from other

working areas. If this is not possible, anyone near

the person operating the welding machine and

their assistants must be protected by curtains and

Optical Radiation Emission

Category 2

(EN 12198)

EN-3

• Prior to any welding or cutting operation, cle-

ar the working area from all chlorine solvents,

which are normally used to clean or degrea-

se the working material. The fumes of these

solvents, when submitted to the radiations of

an electric arc, even from afar, may, in some

cases, transform into toxic gases. Make sure

all the pieces which are to be welded or cut

are absolutely dry.

Warning: When the welding operator is in

a closed space, the use of chlorine solvents

is absolutely forbidden in the presence of

electric arcs.

• During the grinding, brushing and hamme-

ring operations involving the welded pieces,

always wear protection goggles with transpa-

rent lens to prevent projected chips and any

other foreign particles from hurting your eyes

(Fig. 5).

transparent opaque screens, self-extinguishable and

in accordance with regulation in force (the color of

the screen will depend on the welding process and

on the value of the currents used), anti-UV goggles

and, if necessary, masks with suitable protection

filter (Fig. 4).

Figure 4

Figure 6

Figure 5

Unhealthy or dangerous gases or fumes must be

collected (as they are produced) as close and effi-

ciently as possible to the source of emission, in such

a manner that the concentration of pollutants does

not exceed the permitted limits (Fig. 6). In addition,

all welding operations must be carried out on metal

surfaces devoid of rust and paint, to avoid the

formation of hazardous fumes.

Any symptom of discomfort or pain in the eyes, nose

or throat may be caused by inadequate ventilation;

if this is the case, immediately interrupt work and

ventilate the area.

Do not weld or cut metals or painted metals contai-

ning zinc, lead, cadmium or beryllium, unless the

operator and the persons nearby are using breathing

apparatuses or wearing helmets with oxygen cylinder.

Should welding or cutting operations be carried out

in conditions different from the usual working condi-

tions, with an increased risk of electric shock (reduced

or damp working area), additional precautions must

be taken, such as:

• Using power generators marked “S”;

• Placing the power generator out of the wor-

king area;

• Reinforcing personal protection devices,

ground insulation and insulation between the

piece to be welded and the operator (Fig. 7).

Figure 7

Workers and their assistances must never allow

any parts of their bodies to come into contact with

metallic materials at high temperatures or which are

moving (Fig. 8).

EN-4

Figure 8

Using the arc welding and cutting equipment requires

strict respect for safety conditions regarding electric

currents. Make sure that no metallic parts accessible

to the operators may come into direct or indirect

contact with a phase conductor or with the neutral

of the power grid.

All electrode holders and torches used must be in

good conditions. Do not coil the cables around your

body and never point the torchs to other people

(Fig. 9).

Figure 9

Make sure that no power cables from other ap-

pliances, control lines or phone cables are near the

generators.

Any other electric equipment in the welding or cutting

area must be in conformity with the corresponding

EMC regulation.

Caution: Access to the the working area

and near the welding/cutting operation

generators is forbidden to anyone wearing

pacemakers or other such electric devices.

At least once every 6 months make sure that all

electric appliances and accessories are well insulated.

Contact your supplier for more information on the

maintenance and repair of such equipment.

Warning: Never touch the welding cable or

the electrode and the piece which is being

welded at the same time.

ELECTRIC SYSTEM

Any intervention on electrical and electronic

equipment must be entrusted to qualified technicians

capable of performing such operations.

Prior to connecting your appliance to the power grid,

make sure that the counter, the overload and short-

circuit protection devices, the sockets, the plugs and

the electric system as a whole are compatible with

the maximum power of the appliance and its voltage

(please check the information on the plate) and in

conformity with the norms and regulations in force.

The ground single-phase or three-phase connection

(yellow/green cable) must be protected by a medium

or high-intensity differential-residual current device

(sensitivity between 1 and 30 mA).

If the cable is connected, the earth cable (when

present) must not be interrupted by the protection

device against electric shock. The switch, if present,

must be at “O”; the power cable, if not supplied,

must be of the harmonized type.

Ground all metal parts near the operator, using

cables that are thicker or as thick as the welding

cables.

The protection class of the appliance is IP22S, which

means it prevents:

- manual contact with internal parts in high tempe-

rature, which are moving or live;

- the introduction of solid bodies with more than 12

mm of diameter;

- protection against rain with maximum inclination

of 15°.

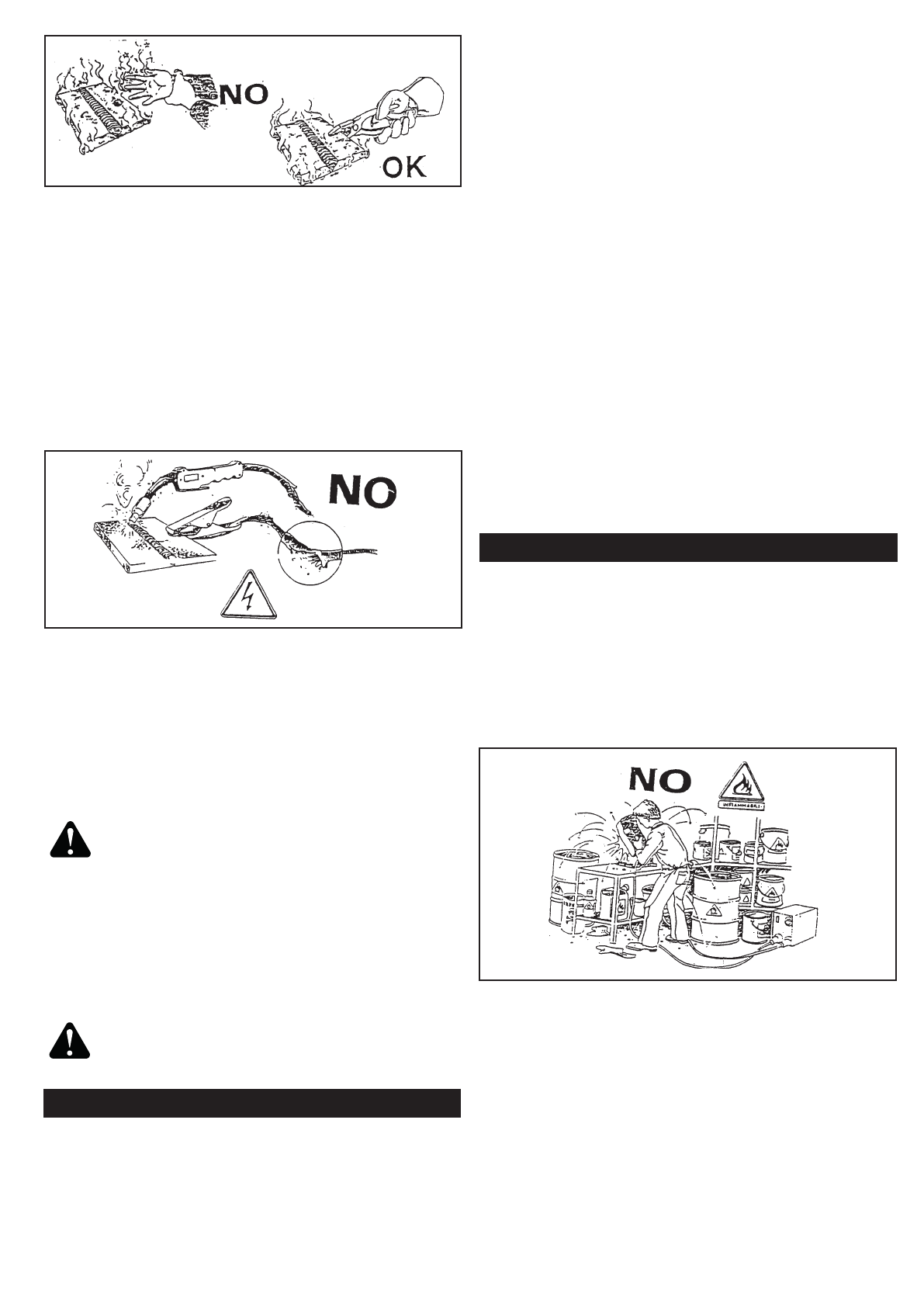

FIRE PREVENTION

The working area must be in conformity with safety

regulations. This means that fire extinguishers must

be installed, compatible with the type of fire which

may happen.

The ceiling, the floor and the doors must be non-

flammable. All combustible material must be moved

away from the workplace (Fig. 10). If this is not

possible, cover it with a fireproof cover.

Figure 10

Before you start welding or cutting, ventilate all areas

that are potentially flammable.

Do not use the equipment in places with significant

concentrations of dust, flammable gas or combusti-

ble liquid vapor.

The generator must be placed on solid, smooth floor,

and should never lean against walls.

Do not weld or cut containers filled with gasoline,

lubricant or other flammable substances.

EN-5

Under normal work conditions, the noise emitted by

a welding/cutting generator does not exceed 80 dBA;

should it be necessary to emit noise above 85 dBA,

the worker involved must be equipped with suitable

protections, such as helmet and ear plugs, and be

informed by suitable signaling.

FIRST AID

Each country specifies the minimum personal pro-

tection equipment that employers must provide their

first aid team with, for immediate help in the event of

electric shock, suffocation, burns of different types,

eye burns etc.

Beware of electric shock and electric burns:

the workplace may be dangerous; do not

attempt to help the patient if the power

source is still active. Cut off the appliance

from the power source and remove all po-

wer cables from the victim using a piece of

dry wood or any other insulating material.

ELECTROMAGNETIC COMPATIBILITY

Before installing your welder, carry out an inspection

of the surrounding area, observing the following

guidelines:

• Make sure that there are no other power sup-

ply cables, control lines, telephone leads or

other equipment near the unit.

• Make sure that there are no radio receivers,

television appliances, computers or other

control systems near the unit.

• People with pace-maker or hearing-prosthe-

sis should keep far from the power source.

! In particular cases special protection

measures may be required.

Interference can be reduced by following these sug-

gestions:

• If there is interference in the power source

line, an E.M.T. filter can be mounted between

the power supply and the power source;

• The output cables of the power source should

be not too uch long, kept together and con-

nected to ground;

• After the maintenance all the panels of the po-

wer source must be securely fastened in place.

Do not weld or cut near ventilation ducts, gas ducts

or any other installation which could accelerate the

spreading of a fire.

After concluding the welding or cutting operation,

always make sure that no incandescent or burning

material has been left in the area.

Make sure the earth connection is good; a defective

ground connection may result in an electric arc which

can become the cause of a fire.

PROTECTION GAS

Strictly follow all instructions of use and handling

provided by the gas supplier. In particular: the areas

of storage and use must be open and ventilated,

sufficiently away from the working area and from

sources of heat (< 50°C). Fix the cylinders, protect

them from impact and from any technical accident.

Make sure the cylinder and the pressure gauge corre-

spond to the gas required for the welding operation.

Never lubricate the cylinder taps and do not forget

to remove all gas from the same before connecting

the pressure gauge.

The protection gases must be dispensed at the

pressures recommended for the different welding/

cutting procedures.

Periodically inspect the ducts and rubber tubes to

make sure they are properly sealed. Never use

a source of flame/fire to detect gas leaks; use a

suitable detector or brush the suspected area with

soapy water.

Warning: Improper use of the gas, in par-

ticular in small spaces (cargo holds, tanks,

reservoirs, silos etc), will expose the user to

the following risks:

1. Suffocation or intoxication with gas and gassy

mixtures containing less than 20% of carbon

dioxide (these gases replace oxygen in the

air);

2. Fire and explosion with gassy mixtures con-

taining hydrogen (hydrogen is light and flam-

mable; it accumulates beneath ceilings or in

nooks, resulting in risk of fire and explosion).

NOISE

The safety prescriptions regarding workers’ pro-

tection against the risks derived from exposure to

noise are treated by European Directive 2003/10/

CE of 6 February 2003, which describes the need

to adopt measures to promote safety, hygiene and

good health in the workplace.

The noise emitted by the welding and cutting gene-

rators depends on the intensity of the welding/cutting

current, on the procedure used (MIG, pulsed MIG,

TIG etc), on the work environment (size of the area,

reverberation of the walls etc).

EN-6

PLASMA ARC AND BASIC PRINCIPLES

FOR THE PERFORMANCE OF PLASMA

CUTTING

• Plasma is a gas that is heated to an extremely

high temperature and ionised so that it beco-

mes a conductor of electricity.

• This cutting procedure utilises the plasma to

transfer the electric arc to the metal workpiece,

which is melted by the heatand then separated.

• The torch uses compressed air from a single

source, for both the plasma and cooling and

protective gas.

• The start of the cycle is determided by an arc,

called the pilot arc, which is struck between

the mobile electrode(negative polarity) and

the torch nozzle (positive polarity) due to the

short circuit between these two elements.

• When the torch is brought into direct contact

with the workpiece to be cut (connetcted to

the positive polarity of the power source) the

pilot arc is transfered between the electrode

and the workpiece itself thus striking a pla-

sma arc, also called cutting arc.

• The duration of the pilot arc is set in the fat-

cory at 3 seconds; if the transfer has not been

made within this time, the cycle is automati-

cally stopped except for the cooling air which

is kept on.

TECHNICAL INFORMATION

The data in the following table may differ

from the values on the data plates on the

rear panel of the generators.

The data may also vary according to the

torch that is gonna be used with the gene-

rator.

GENERAL INFORMATION

INSTALLATION

Be sure to locate the welder according

to the following guidelines.

• In areas, free from moisture and dust;

• Ambient temperature between 0° to 40°C;

• In areas, free from oil, steam and corrosive

gases;

• In areas, not subjected to abnormal vibration

or shock;

• In areas, not exposed to direct sunlight or rain;

• Make sure that obstacles do not prevent the

cooling air flow out of front and rear ope-

nings of the machine.

• Arrange an open space of at least 5m around

the machine.

• In the case the machine has to be moved,

always disconnect the plug from the outlet

and gather the cables and pipes so as not to

damage them.

Since the inhalation of welding fumes

can be harmful, ensure that the welding

area is effectively ventilated.

MAIN SUPPLY VOLTAGE REQUIREMENTS

Before you make any electrical connection,

check that supply voltage and frequency avai-

lable at site are those stated in the ratings la-

bel of your generator.

The main supply voltage should be within ±10% of

the rated main supply voltage. Too low a voltage

may cause poor welding performance. Too high a

supply voltage will cause components to overheat

and possibly fail. The welder Power Source must be:

• Correctly installed, if necessary, by a qualified

electrician;

• Correctly grounded (electrically) in accordan-

ce with local regulations;

• Connected to the correct size electric circuit.

LOCATION

PC 66 EVO

EN-7

In case the supply cable is not fitted with a plug,

connect a standardized plug (3P+T) to the supply

cable (in some models the supply cable is supplied

with plug).

To connect the plug to the supply cable, follow these

instructions:

• the brown (phase) wire must be connected to

the terminal identified by the letter L1

• the blue or grey wire must be connected to

the terminal identified by the letter L2

• the black or grey wire must be connected to

the terminal identified by the letter L3

• the yellow/green (ground) wire must be con-

nected to the terminal identified by the letter

PE or by the symbol .

In any case, the connection of the yellow/green wire

to the PE terminal must be done in order that in

the event of tearing of the power supply cable from

the plug, the yellow/green wire should be the last

one to be disconnected.

The outlet should be protected by the proper

protection fuses or automatic switches.

Notes:

• Periodically inspect supply cable for any

cracks or exposed wires. If it is not in good

conditions, have it repaired by a Service Cen-

tre.

• Do not pull violently the input power cable to

disconnect it from supply.

• Do not squash the supply cable with other ma-

chines, it could be damaged and cause electric

shock.

• Keep the supply cable away from heat sorces,

oils, solvents or sharp edges.

• In case you are using an extension cord, try to

keep it well straight and avoid its heating up.

SAFETY INSTRUCTIONS

For your safety, before connecting the power source

to the line, closely follow these instructions:

• An adequate switch must be inserted before

the mains outlet; this switch must be equip-

ped with time-delay fuses;

• The connection with ground must be made

with a plug compatible with the above men-

tioned socket;

• When working in a confined space, the power

source must be kept outside the welding area

and the ground cable should be fixed to the

workpiece. Never work in a damp or wet area,

in these conditions.

• Do not use damaged input or welding cables

• The welding torch should never be pointed at

the operator’s or at other persons’ body;

• The power source must never be operated

without its panels; this could cause serious

injury to the operator and could damage the

equipment.

CONNECTION TO GROUND CABLE

Connect the plug to the socket and the work cable

clamp to the piece to be cut or to the metallic

workbench. Take following precautions:

• Verify that there is a good electrical contact

particularly if insulated or oxidated coated

sheets are cut.

• Make ground connections as close as possi-

ble to the cutting area. The use of the metallic

structures which are not part of the workpie-

ce, such as the return cable of the cutting

current, may endanger the safety system and

give poor cutting results.

• Do not make a ground connection on the pie-

ce which has to be removed.

TORCH CONNECTION

Ensure unit is off and unpluged from the power

receptacle.

Figure 11

Supplied torch, manual or automatic, has a quick

connection system called “H Fit” . Correctly align the

“H Fit” pins and connect it to the connector on the

front panel of the unit by handscrewing the plastic

ring.

WARNING!: Before starting the cutting

operations verify that the parts are pro-

perly assembled by inspecting the head of

the torch as described on paragraph “Torch

Maintenance”.

TORCH CONSUMABLE PARTS MOUNTING

Position the torch with the outside protection nozzle

facing upward to prevent these parts from falling out

when the nozzle is removed.

WARNING: Wait the torch has completely

cooled before replacing torch parts to avoid

any damage to the torch head.

To change the torch consumable parts use the

following procedure:

1. Unscrew and remove the shield cup from the

Torch Head Assembly.

2. Remove the tip, gas distributor, and electrode.

3. Install the electrode, gas distributor, and tip.

Choose the correct consumable parts, refer

to the paragraph “Torch consumable parts

selection”.

4. Hand tighten the shield cup until it is seated

on the torch head. If resistance is felt when

installing the cup, check the threads before

proceeding.

5. if necessary, install also the spacer.

EN-8

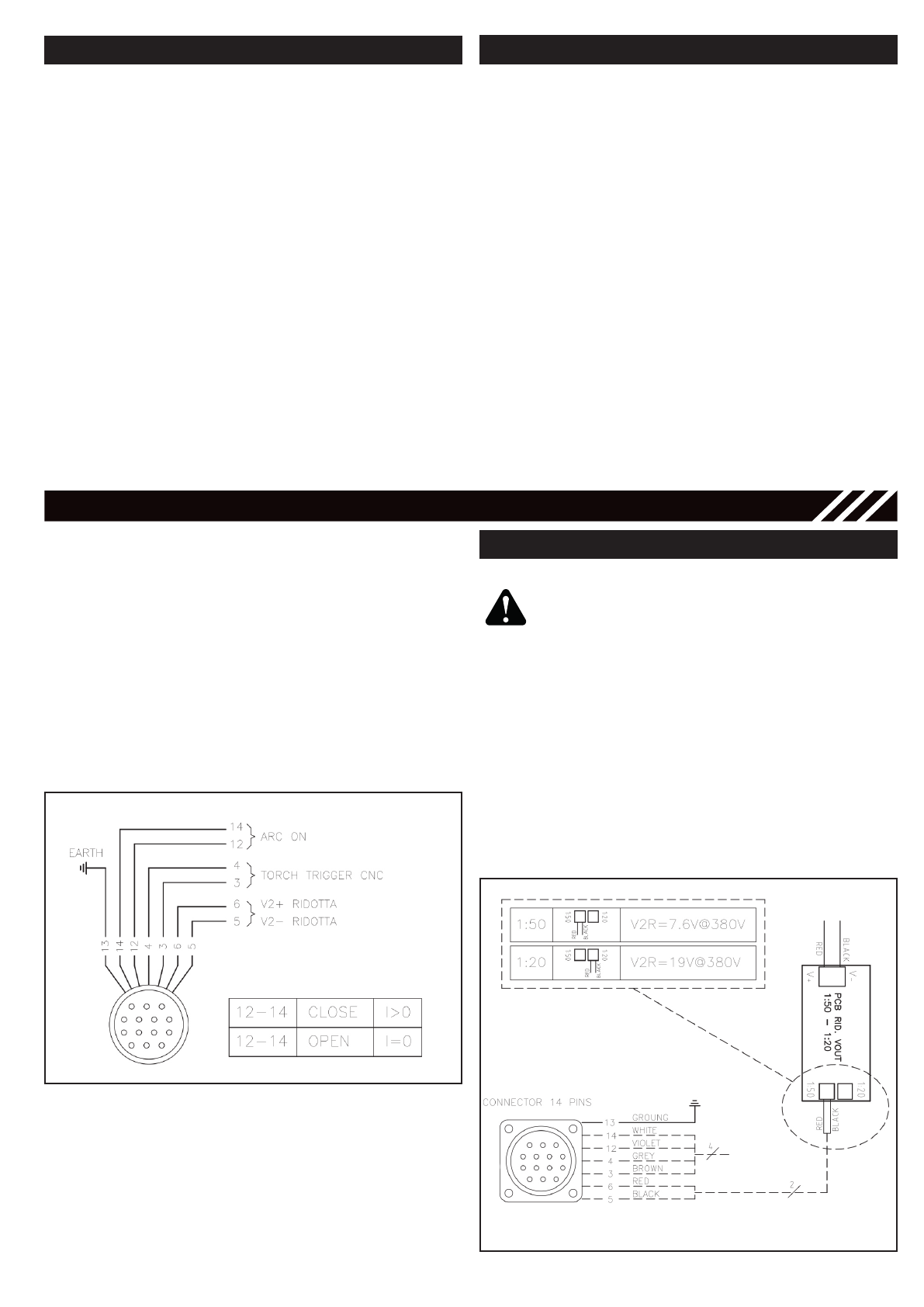

CONNECTION OF THE MACHINE TO THE CNC

The machine is ready for the connection to

the robotic machines.

• Ensure unit is off and unpluged from the po-

wer receptacle.

• The machine is provided of a 14-pin male

connector located on the back panel. Con-

nect the power contact of the robotic machine

to a 14-pin female connector suitable for the

connector mounted on the machine by fol-

lowing the here shown diagram.

• Connect the male connector to the machine.

Figure 12

Figure 13

ARC VOLTAGE SIGNAL

AUTION! ELECTRIC SHOCK CAN KILL

Following operation should be carried out

by trained personnel who are aware of the

risks caused by the high voltage.

Carefully read the instructions and speci-

fications of the CNC machine before pro-

ceeding.

By default, the reduction of the output voltage is

equal to 1:50. In the case that the cutting table to be

connected requires a different voltage, it is possible

to set a 1:20 reduction. FIG. 13

• Remove the connector on PS1: 50.

• Install the connector into PS1: 20

COMPRESSED AIR

A source of clean, dry air or nitrogen must be

supplied to your plasma cutting unit.

The supply pressure must be between 6 and 8 bar.

The flow rate is approximately 240 l/min for H.70

torch.

Failure to observe these precautions could

result in excessive operating temperatures

or damage to the torch.

An air regulator is included with the unit with

optimum pressure setting set to 5.5 Bar.

Note: the regulator should never be

set above 8 bar.

Note: LEDs on the front panel of the unit

will show if the input air pressure is not

correctly adjusted.

PURGE

Oil in the air is a severe problem and must be

avoided.

The unit is also equipped with an air filter which

captures water and oil vapor.

The vapor collected can be drained out turning the

drain knob located on the air filter.

The knob has two positions:

1. Open

The drain knob should not be left in this

position during the cutting operations.

2. Closed

EN-9

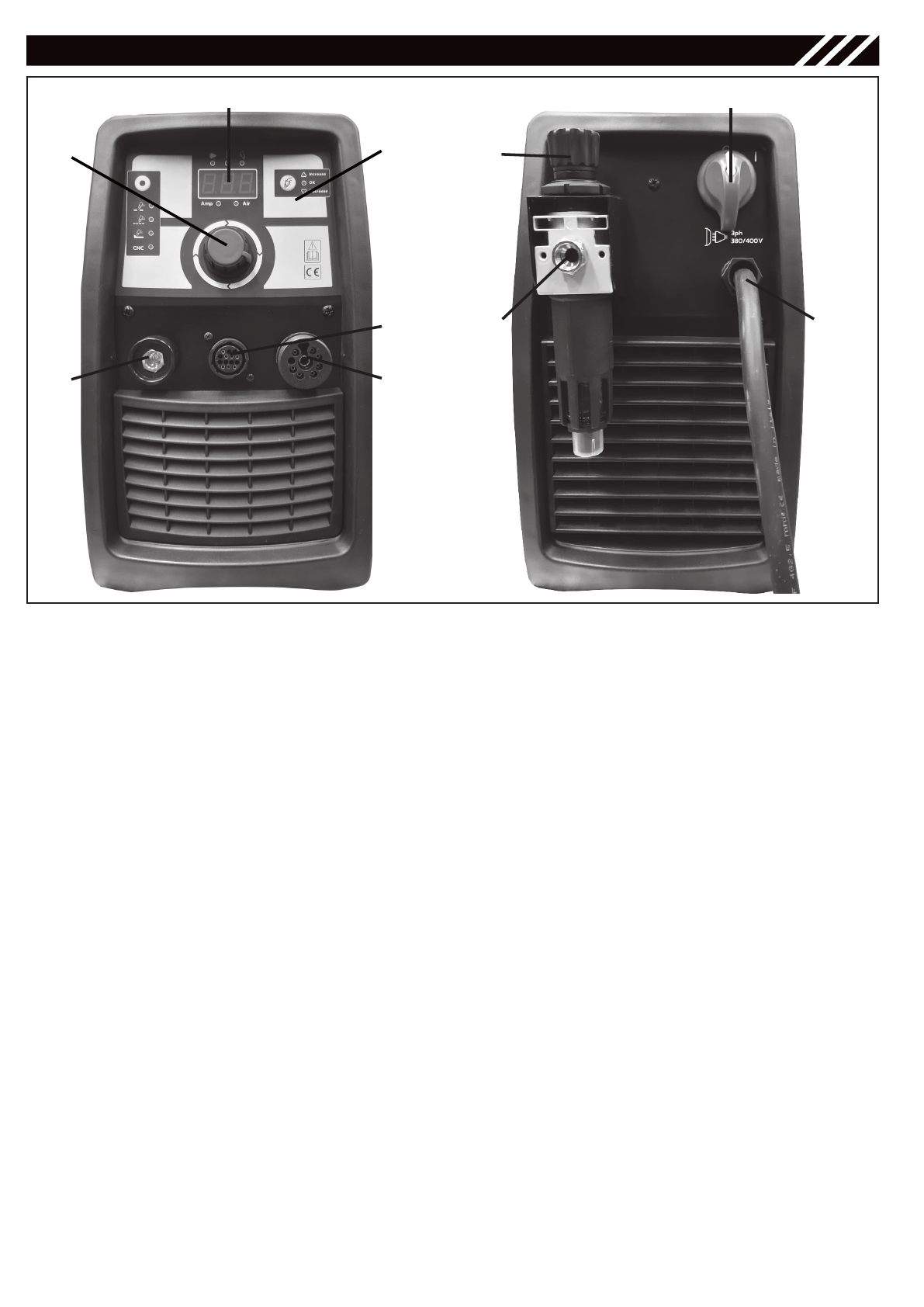

FUNCTIONS

1. ON/FF Switch

In the ON position the machine is ready for normal

operation. All system control circuits are activated.

OFF position deactivates control circuits.

2. Output Current Knob (2)

Adjusts the cutting current supplied by the machine

according to application (thickness of material/

speed).

3. Display

It views the set cutting current when unit is on, during

pilot arc time views the pilot arc current and during

cutting views the cutting current.

It views the adjusted air pressure (bar) by pushing

the air drain key (B).

4. Control Panel

5. Air Regulator

It adjusts the input air pressure - pull outwards to

unlock. Note: push torch air purge key before acting

on the air regulator to get the air pressure displayed.

6. Earth cable connection (6)

7. Torch connection

8. Power cable

9. 14-Pin Male Connector

10. Compressed Air Connector

Figure 14

2

3

4

7

9

6

1

8

5

10

EN-10

CUTTING OPERATION

PRELIMINARIES

WARNING

unplug the unit from the power supply

before assemble or disassemble piled

parts, single parts, parts of the torch,

torch assemblies or cables.

• Check and follow instructions as foreseen in

the paragraphs “Safety and Installation” of

the present instructions manual.

A. Operation Mode Selection Key

•Non-continuous pilot arc. Cuts or pierces

metal plate. Standard setting for normal

cutting.

•Automatic pilot arc. Cuts expanded metal or

grate.

•Gouge. Gouges metal plate.

•Cutting with CNC

B. Torch Air Purge Key

It allows to remove any condensation that may have

accumulated in the torch and leads while the system

was shut down, to get the pressure set thru the air

regulator (5) viewed on the display and to select and

set the secondary parameters.

C. Air Pressure Indication LEDs

• Green LED “OK” ON = correct air pressure

Figure 15

• Red LED “Increase” ON = too low air pres-

sure

• Red LED “Decrease” ON = too high air pres-

sure

D. Cutting Current LED

when on it means that the display is viewing the

adjusted or the effective cutting current.

E. BAR LED

when on it means that the display is viewing the

adjusted pressure.

F. Green LED

It is on when power is applied to the unit. It blinks

by overvoltage, low voltage o missing of one phase.

G. Yellow LED

It is on by overtemperature.

H. Red LED

It is on when pilot arc or cutting arc is started.

PARTS OF THE TORCH

• Check the torch for proper assembly (refer

to Section called Torch Consumable Parts

Mounting).

• Install proper torch parts for the desired ap-

plication (refer to Section called Torch Consu-

mable Parts Selection).

INPUT POWER

• Check the power source for proper input vol-

tage.

• Plug unit in and close main disconnect switch

A

B CED HGF

EN-11

INITIAL SETUP

• Once unit is powered on, the display will show

“set” for a few seconds. In this time press the

left Selection key (A) to view the adjustable

parameters.

• Use the central knob (2) and the right selec-

tion key (B) to adjust the parameter:

- Pre-air safety.

Off = Arc starts immediately

On = Pre-air before the arc starts

On CNC cutting this safety can not be acti-

vated (off).

• Use the right selection key to confirm the pa-

rameter adjustment and return to the pre-

vious menù.

• To reset the parameters press and hold the

right selection key (B).

• Use the left selection key to exit.

CUTTING

CUTTING WITH A HAND TORCH

• Select the non-continuous pilot arc mode with

the selection key (A) in the control panel.

• The torch can be comfortably held in one

hand or steadied with two hands. Choose the

technique that feels most comfortable and

allows good control and movement. Position

the index finger or thumb to press the control

switch on the torch handle.

• For edge starts, hold the torch perpendicular

to the workpiece with the front of the tip on

the edge of the workpiece at the point where

the cut is to start - Fig. 16.

Figure 16

to supply primary power to the system.

GROUND CABLE

• Check for a solid ground cable connection to

the workpiece.

AUTOMATIC PURGE SYSTEM

• Place the ON/OFF switch to the ON position.

Activate the torch button to initiate 3s gas

purge (pre-flow) to remove any condensation

that may have accumulated in the torch and

leads while the system was shut down. When

the gas purge is complete, pilot arc will be

initiated. To cool torch handle or to further

remove condensation in the torch and leads

push the torch gas purge button (B) on the

front panel of the unit.

WARNING

Do not initiate pilot arc during adjustment.

CHECKING AIR QUALITY

• To check air quality, deactivate the torch (post-

flow) and place filter lens in front of the torch.

Any oil or moisture in the air will be visible

on the lens. DO NOT initiate pilot arc while

checking air quality.

OPERATION MODE SELECTION

• Select the desired operation mode with the

selection key (A) in the control panel.

AIR PRESSURE REGULATION

• Adjust the air pressure by pushing the air purge

button (B) and by acting on the air regulator (5).

• Adjust the correct air pressure for each ope-

ration mode.

Torch 6m H.70

Manaul cutting 3,5-4,5bar

Grid cutting 3,5-4,5bar

Gouging 2,5-4,0bar

CNC 3,5-4,5bar

For different torch length consider the following

pressure increases :

Torch Length H.70

10/12m +0bar

20m +0,4bar

30m +0,7bar

• The display shows the adjusted air pressure in

bars. If air pressure is correctly adjusted the

LED “OK” is on. If the LEDs “Increase” or “De-

crease” are on, adjust again the air pressure

until these get off and LED “OK” lights on.

CUTTING CURRENT REGULATION

• Adjust the cutting current by acting on the ou-

tput current knob (2).

• With the torch in starting position, press the

control switch. After an initial gas purge (pre-

air), the pilot arc will come on and remain on

for 3 seconds until the cutting arc starts.

• Once on, the main arc remains on as long

as the control switch is held down, unless the

torch is withdrawn from the work or torch

motion is too slow. Keep moving while cut-

ting. Cut at a steady speed without pausing.

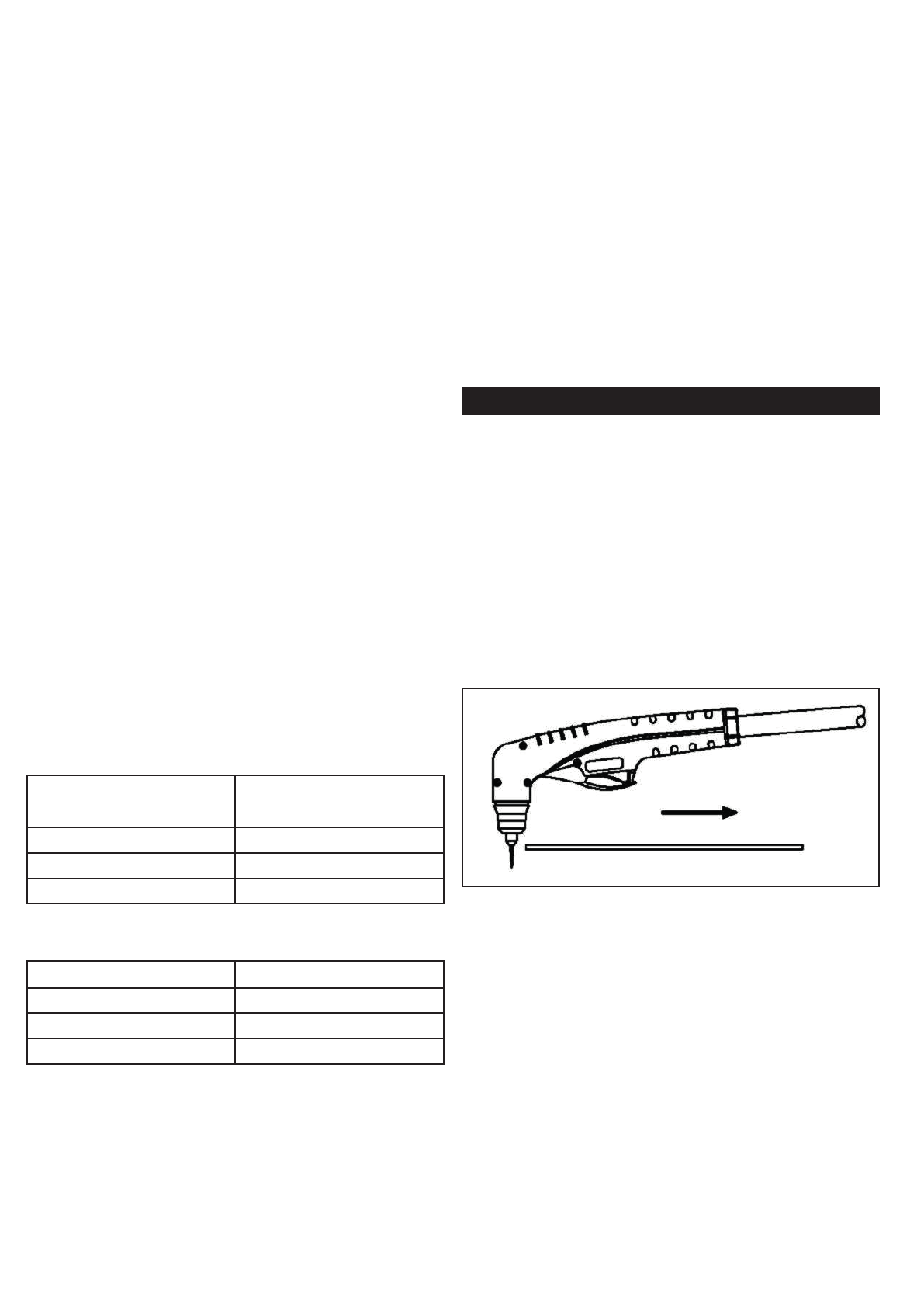

Maintain the cutting speed so that the arc lag

is about 30° behind the travel direction. Fig.

17. If the cutting arc is interrupted, and the

torch trigger is still pressed, the pilot arc co-

mes back on automatically for 3 seconds.

• To shut off the torch simply release the control

switch. When the switch is released a post-

flow will occur. If the torch trigger is pressed

during the post-flow, the pilot arc will restart.

EN-12

Figure 17

• Hold the torch at a 45° angle with the

workpiece. Press the trigger to obtain a pilot

arc. Transfer the arc to the workpiece.

• Pull the torch back by keeping a 45° angle

with the workpiece and a certain distance

between the torch tip and the molten metal to

avoid consumable life reduction or damage

to the torch.

Changing the torch’s angle change the di-

mensions of the gouge.

• The gouge profile may vary in accordance with:

1. speed of the torch over the workpiece

2. the torch-to-work standoff distance

3. the angle of the torch to the workpiece

4. the adjusted current output.

• To increase width:

- Increase the standoff and/or the current.

- Decrease the speed and/or the angle.

• To decrease width:

- Increase the speed and/or the angle.

- Decrease the standoff and/or the current

• To increase depth:

- Decrease the speed and/or standoff.

- Increase the current and/or the angle.

• To decrease depth:

- Decrease the current and/or the angle.

- Increase the speed and/or standoff.

CUTTING WITH CNC

• Select the CNC mode with the selection key

(A) in the control panel.

• Follow indications at paragraph “Connection

of the machine to a CNC”

• Since the equipment with mechanized torch

can be used with different cutting tables, for the

operations in such configuration it is necessary

to consult the manufacturer’s instructions.

WARNING

Disconnect primary power at the source

and wait that the torch has cooled before

disassembling the torch or torch leads.

Frequently review the Important Safety

Precautions at the front of this Manual. Be

sure the operator is equipped with proper

gloves, clothing, eye and ear protection.

Make sure no part of the operator’s body

comes into contact with the work piece

while the torch is activated.

CAUTION

Sparks from the cutting process can cause

damage to coated, painted, and other sur-

faces such as glass, plastic and metal.

NOTE

Handle torch leads with care and protect

them from damage.

Figure 19

PIERCING WITH A HAND TORCH

Note: Recommended maximum piercing

capacity depends on the torch and on the

cutting current of the cutting unit. Refer to

the torch specification sheet provided with

the cuttig unit. If necessary to make a cut

on a metal sheet with a tickness more than

the maximum piercing capacity without

an edge start, make a hole ø 6mm at least

using an electric drill to start cutting.

• When piercing with a hand torch, tip the torch

slightly.

Figure 18

• Complete the pierce off the cutting line and

then continue the cut onto the line. Hold the

torch perpendicular to the workpiece after the

cut is complete. Fig.19

• Clean spatter and scale from the shield cup

and the tip as soon as possible.

GRATES CUTTING

• Select the automatic pilot arc mode with the

selection key (A) in the control panel.

GOUGE

• Select the gouge mode with the selection key

(A) in the control panel.

• Hold the torch with torch tip within 1.5 mm

from the workpiece.

EN-13

MAINTENANCE

Maintenance can only be carried out on the unit if the

person in charge of this operation has the necessary

technical knowledge and the correct tools. If this is

not the case, contact your nearest service centre.

CAUTION!

Never access inside the machine (panel re-

moval) or touch the torch (disassemblage)

without having disconnected power plug.

Any inspection performed under voltage

inside the machine or inside the torch may

cause severe electric shocks caused by di-

rect contact with parts under voltage.

UNIT

Keep the cutting or gouging area and the area

around the machine clean and free of combustible

materials. No debris should be allowed to collect ,

this could obstruct air flow to the machine.

Inspect the unit every 3-4 months (depending on

how often the unit is used) and use compressed air

to remove any dust deposits.

CAUTION!

Only use dry compressed air for cleaning.

Do not point the jet of air at the electronic

circuits.

TORCH

Periodically, according to its use or to cutting faults

verify wear of the parts connected to plasma arc:

Shield Cup:

Unscrew manually from head of the torch. Clean

throughly abd replace if damaged (burns, distortions

or cracks). Verify integrity of superior metal sector

(actuator torch safety).

Tip:

Check wear of plasma arc hole and of inner and

outer surfaces. If the hole is widened compared to

its original width or if it is damaged, replace tip. If

surfaces are particularly oxidated clean them with

extra fine abrasive paper.

Air Distributor:

Verify the are no burns or cracks or that airflow holes

are not obstructed. If damaged, replace immediately.

Electrode:

Replace electrode when crater settling on emitting

surface is about 2mm.

WARNING!

• Before making any operation to the torch let

it cool at least all along the “postgas” period.

• Except for particular cases it is advisable to

replace electrode and tip AT THE SAME TIME.

• Respect assembly order of torch parts (reser-

ved compared to disassemblage).

• Be carefull that distributing is assembled pro-

perly.

• Reassemble shield cup screwing tightly and

manually.

• Never assemble shield cup without having

assembled electrode distributing ring and tip

beforehand.

• Timely and appropriate control procedures

on torch parts are essential for safety and

functionality of the cutting system.

TORCH BODY, HANDLE AND CABLE

• These parts usually need no particular main-

tenance with the exception of a periodic in-

spection and an accurate cleaning to be

made WITHOUT THE USE OF SOLVENTS.

• In case of damages to the insulation such as

breaks, cracks and burns or even a loosening

of electric coonductors, the torch CANNOT

BE USED FURTHER SINCE SAFETY CONDI-

TIONS HAVE NOT BEEN RESPECTED.

• IN THIS CASE, REPAIRING (EXTRAORDINA-

RY MAINTENANCE) CANNOT BE MADE ON

SITE BUT NEEDS TO BE DELEGATED TO A

SERVICE CENTER TO MAKE SPECIAL REST

TRIALS AFTER REPAIRING HAS BEEN EXECU-

TED.

In order to keep the torch and the cable efficient it

is necessary to follow these precautions:

• DO NOT touch torch and cable with warm

or hot parts.

• DO NOT strain the cable.

• DO NOT move the cable on sharp edges or

abrasive surfaces.

• gather the cable in regular coils if it is too

long.

• DO NOT step on the cable.

COMPRESSED AIR FILTER

The unit is also equipped with an air filter which

captures water and oil vapor.

Water contained in the glass can be drained through

a knob located on the bottom of the air filter. See

Purge Section.

EN-14

OPERATING FAULTS

During cutting operations performance faults may

arise which are not caused by plant malfunctioning

but by other operational faults such as:

• Insufficient penetration:

too high cutting speed;

torch is too tilted;

piece is too thick;

cutting current too low;

torch parts are worn out;

non-genuine Manufacturer’s parts;

• Interruption of the cutting arc:

cutting speed too slow;

excessive distance between torch and workpiece;

AC line too low - reduce output current;

torch parts are worn out;

non-genuine Manufacturer’s parts;

work cable is disconnected;

• Excessive scoria settlement:

too low cutting speed (bottom dross);

too high cutting speed (top dross);

excessive distance between torch and workpie-

ce;

cutting current too low;

torch parts are worn out;

non-genuine Manufacturer’s parts;

• Tilted cutting (not perpendicular):

torch position not correct;

asymmetric wear of nozzle hole and/or

wrong; assemblage of the torch parts;

• Excessive wear of nozzle and electrodes:

air pressure too low;

exceeding system capability (material too

thick);

contaminated air (humidity-oil);

excessive pilot arc arc ignitions in the air;

Improperly assembled torch;

torch tip contacting workpiece;

damaged or loose torch head components;

non-genuine Manufacturer’s parts.

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

Power Led OFF, Fan not operating.

No Input Power. Open breaker. Plug unit into 380/400V outlet.

Reset Breaker.

Power LED ON, Overtemperature

LED ON

The display views

Unit is overheated. Make sure the unit has not been

operated beyond duty cycle limits.

Air Flow obstructed. Ensure at least 0.5m of free space

around the unit.

Power LED ON, “Increase” or

“Decrease” LEDs ON Air pressure not correct Check that there is a correct air

pressure for the selected operation

mode.

Air line blocked Check that air line and torch leads

are free of twists and kinks

Power LED blinking

The display views

Too low input voltage

Check power supply for correct

line voltage. As soon as the

voltage falls within the parame-

ters allowed by the generator

the power LED is turned on and

the machine restarts normal

operation. If unit doesn’t restart,

contact a Service Center.

Power LED blinking

The display views

Too high input voltage

Power LED blinking

The display views

Missing phase

EN-15

Power LED ON, “OK” air pressure

LED ON

The display views

Consumables not properly

installed on torch. Wait 30 ‘’ for the restart of the unit or

alternatively press the mode selection

key (A).

Check that the consumables are

correct and properly installed on the

head of the torch.

If the unit does not work again it will

be necessary to repair / replace it.

Faulty Main PC Board

Faulty torch

Power LED ON, “Increase” air

pressure LED ON

The display views

Air pressure not correct Check that there is a correct air

pressure for the selected operation

mode.

Power LED ON, “OK” air pressure

LED ON, no air flow once torch

trigger is pressed

Faulty torch trigger Refer to Maintenance paragraph.

Faulty Main PC Board Repair / Replace Power Supply.

Power LED ON, “OK” air pressure

LED ON, air flows once torch

trigger is pressed. Torch doesn’t

strike the arc.

Faulty torch parts Inspect torch parts and replace if

necessary.

Faulty Main PC Board Repair / Replace Power Supply.

Torch has pilot arc but does not

cut. Work lead not connected. Make sure work lead is connected

securely to bare metal.

AC input power too low Use extension cords as short as

possible.

Faulty Main PC Board Repair / Replace Power Supply.

Power LED blinking

The display views

PCB Input Voltage Problem Check power supply for correct

line voltage. As soon as the

voltage falls within the parame-

ters allowed by the generator

the power LED is turned on and

the machine restarts normal

operation. If unit doesn’t restart,

contact a Service Center

Faulty Control PC Board

Faulty Auxiliary Transformer

IT-1

Vi ringraziamo della fiducia accordataci con l’acqui-

sto di uno o più apparecchi riportati nel presente

libretto. Questi prodotti se correttamente montati

e utilizzati sono dei generatori di taglio affidabili

e durevoli che aumenteranno la produttività della

vostra attività con minimi costi di manutenzione.

Questi apparecchi sono stati tutti progettati, costruiti

e testati interamente in ITALIA nel pieno rispetto delle

Direttive Europee Bassa Tensione (2006/95/EC) e

EMC (2004/108/EC) mediante l’applicazione delle

rispettive norme EN 60974.1 (regole di sicurezza per

il materiale elettrico, Parte 1: sorgente di corrente di

saldatura) ed EN 60974-10 (Compatibilità Elettro-

magnetica EMC) e sono identificati come prodotti

di Classe A.

Le apparecchiature di Classe A non sono progetta-

te per l’utilizzo in aree domestiche, dove l’energia

elettrica è fornita da una rete pubblica a bassa

tensione, quindi è potenzialmente difficile assicurare

la compatibilità elettromagnetica di apparecchiature

di Classe A in queste aree, a causa di disturbi radiati

e condotti. Questi apparecchi elettrici professiona-

li vanno quindi utilizzati in ambienti industriali e

connessi a cabine private di distribuzione. Su questi

generatori non è quindi applicabile la normativa

Europea/Internazionale EN/IEC 61000-3-12 che

definisce i livelli massimi di distorsione armonica

indotti sulla rete pubblica di distribuzione a bassa

tensione.

E’ responsabilità dell’installatore o dell’utilizzatore

(se necessario consultare il distributore dell’energia

elettrica) assicurarsi che queste apparecchiature

possono essere collegate ad una rete pubblica in

bassa tensione.

Attenzione: la ditta produttrice viene sollevata da ogni

responsabilità in caso di modifiche non autorizzate sui

PREMESSA

propri prodotti, Questi generatori di corrente vanno

utilizzati unicamente per i procedimenti di taglio sopra

riportati; quindi non possono tassativamente essere

utilizzati per la ricarica delle batterie, lo scongelamen-

to delle condotte d’ acqua, il riscaldamento di locali

con l’aggiunta di resistenze, ecc……

Conformità alla Direttiva RoHS: si dichiara qui di

seguito che la gamma di questi generatori 3Ph trattati

nel presente manuale rispettano la Normativa Co-

munitaria RoHS 2011/65/UE dell’8 Giugno 2011

sulla restrizione d’uso di determinate sostanze pe-

ricolose alla salute umana presenti nelle Apparec-

chiature Elettriche ed Elettroniche (AEE).

Questo simbolo riportato sul generatore di

taglio o sull’ imballo indica che al momen-

to della rottamazione, lo stesso “non dovrà”

essere smaltito come un rifiuto ordinario, ma

dovrà essere trattato in modo specifico e in

conformità alla Direttiva Europea 2012/19/

UE del 4 Luglio 2012 relativa allo smaltimen-

to dei Rifiuti di Apparecchiature Elettriche ed

Elettroniche (RAEE) che devono essere raccolti

separatamente e sottoposti ad un riciclo ri-

spettoso dell’ambiente.

In veste di proprietario di un prodotto AEE (Appa-

recchiature Elettriche Elettroniche), dovrà informarsi

sui sistemi di raccolta autorizzati presso i nostri

rappresentanti di zona. L’applicazione della sopra

menzionata Direttiva Europea migliorerà l’ambiente

e la nostra salute.

Attenzione: i procedimenti di saldatura, ta-

glio e tecniche affini possono essere peri-

colosi per l’operatore e per le persone che

si trovano in prossimità dell’area di lavoro;

di conseguenza leggete con attenzione il

capitolo “SICUREZZA” di seguito riportato.

SICUREZZA

AVVERTENZE

Questo manuale contiene le istruzioni per una

corretta installazione dell’ Apparecchiatura Elettrica

Elettronica (AEE) da Voi acquistata.

Il proprietario di un prodotto AEE deve assicurarsi

che il presente documento venga letto e capito dagli

operatori in saldatura e taglio, dai loro assistenti e

dal personale tecnico addetto alla manutenzione.

Attenzione: anche con l’interruttore ON/OFF

dell’apparecchiatura elettrica elettronica in

posizione “0” la tensione di rete è presen-

te all’interno del generatore e sul cavo

di alimentazione, quindi prima di qualsiasi

verifica interna dovete assicurarvi che l’appa-

recchio sia separato dall’impianto elettrico di

distribuzione dell’energia elettrica median-

te interdizione (con il termine interdizione si

intende un insieme di operazioni destinate a

separare ed a mantenere l’apparecchio fuori

tensione).

Un apparecchio elettrico elettronico non dovrà mai

essere utilizzato privo di pannelli e copertura, poiché

pericoloso per il personale operativo. Un simile

utilizzo potrebbe causare gravi danni all’ apparec-

chiatura stessa.

Questi generatori possono essere alimentati da

un gruppo elettrogeno; quest’ultimo dovrà tassa-

tivamente essere equipaggiato di motore diesel di

potenza superiore alla potenza richiesta dal gene-

ratore (fare riferimento alla tabella dati tecnici) e

con tensione di uscita di 400Vac +/- 10% - 3Ph

– 50/60Hz.

SMALTIMENTO DI APPARECCHI DA ROTTAMARE DA PARTE DI PRIVATI NELL’UNIONE EUROPEA

Questo simbolo che appare sul prodotto o sulla confezione indica che il prodotto non deve essere smaltito assieme agli altri rifiuti domesti-

ci. Gli utenti devono provvedere allo smaltimento delle apparecchiature da rottamare portandole al luogo di raccolta indicato per il riciclag-

gio delle apparecchiature elettriche ed elettroniche. La raccolta ed il riciclaggio separati delle apparecchiature da rottamare in fase di smal-

timento favoriscono la conservazione delle risorse naturali e garantiscono che tali apparecchiature vengano rottamate nel rispetto dell’am-

biente e della tutela della salute. Per ulteriori informazioni sui punti di raccolta delle apparecchiature da rottamare, contattare il proprio comu-

ne di residenza, il servizio di smaltimento dei rifiuti locale o il negozio presso il quale è stato acquistato il prodotto.

DISPOSAL OF WASTE EQUIPMENT BY USERS IN PRIVATE HOUSEHOLDS IN THE EUROPEAN UNION

This symbol on the product or on its packaging indicates that this product must not be disposed of with your other household waste. Instead,

it is yr responsibility to dispose of yr waste equipment by handing it over to a designated collection point for the recycling of waste electri-

cal and electronic equipment. The separate collection and recycling of yr waste equipment at the time of disposal will help to conserve natu-

ral resources and ensure that it is recycled in a manner that protects human health and the environment. For more information about where

you can drop off yr waste equipment for recycling, please contact yr local city office, yr household waste disposal service or the shop where

you purchased the product.

EVACUATION DES ÉQUIPEMENTS USAGÉS PAR LES UTILISATEURS DANS LES FOYERS PRIVÉS AU

SEIN DE L’UNION EUROPÉENNE

La présence de ce symbole sur le produit ou sur son emballage indique que vous ne pouvez pas vous débarrasser de ce produit de la même

façon que vos déchets courants. Au contraire, vous êtes responsable de l’évacuation de vos équipements usagés et à cet effet, vous êtes tenu

de les remettre à un point de collecte agréé pour le recyclage des équipements électriques et électroniques usagés. Le tri, l’évacuation et le

recyclage séparés de vos équipements usagés permettent de préserver les ressources naturelles et de s’assurer que ces équipements sont recy-

clés dans le respect de la santé humaine et de l’environnement. Pour plus d’informations sur les lieux de collecte des équipements usagés,

veuillez contacter votre mairie, votre service de traitement des déchets ménagers ou le magasin où vous avez acheté le produit.

ENTSORGUNG VON ELEKTROGERÄTEN DURCH BENUTZER IN PRIVATEN HAUSHALTEN IN DER EU

Dieses Symbol auf dem Produkt oder dessen Verpackung gibt an, dass das Produkt nicht zusammen mit dem Restmüll entsorgt werden darf.

Es obliegt daher Ihrer Verantwortung, das Gerät an einer entsprechenden Stelle für die Entsorgung oder Wiederverwertung von

Elektrogeräten aller Art abzugeben (z.B. ein Wertstoffhof). Die separate Sammlung und das Recyceln Ihrer alten Elektrogeräte zum

Zeitpunkt ihrer Entsorgung trägt zum Schutz der Umwelt bei und gewährleistet, dass sie auf eine Art und Weise recycelt werden, die keine

Gefährdung für die Gesundheit des Menschen und der Umwelt darstellt. Weitere Informationen darüber, wo Sie alte Elektrogeräte zum

Recyceln abgeben können, erhalten Sie bei den örtlichen Behörden, Wertstoffhöfen oder dort, wo Sie das Gerät erworben haben.

ELIMINACIÓN DE RESIDUOS DE APARATOS ELÉCTRICOS Y ELECTRÓNICOS POR PARTE DE

USUARIOS DOMÉSTICOS EN LA UNIÓN EUROPEA

Este símbolo en el producto o en el embalaje indica que no se puede desechar el producto junto con los residuos domésticos. Por el contra-

rio, si debe eliminar este tipo de residuo, es responsabilidad de usuario entregarlo en un punto de recolección designado de reciclado de apa-

ratos electrónicos y eléctricos. El reciclaje y la recolección por separado de estos residuos en el momento de la eliminación ayudarán a pre-

servar recursos naturales y a garantizar que el reciclaje proteja la salud y el medio ambiente. Si desea información adicional sobre los luga-

res donde puede dejar estos residuos para su reciclado, póngase en contacto con las autoridades locales de su ciudad, con el servicio de

gestión de residuos domésticos o con la tienda donde adquirió el producto.

DESCARTE DE EQUIPAMENTOS POR USUÁRIOS EM RESIDÊNCIAS DA UNIÃO EUROPEIA

Este símbolo no produto ou na embalagem indica que o produto não pode ser descartado junto com o lixo doméstico. No entanto, é sua respon-

sabilidade levar os equipamentos a serem descartados a um ponto de colecta designado para a reciclagem de equipamentos eletro-eletrônicos.

A colecta separada e a reciclagem dos equipamentos no momento do descarte ajudam na conservação dos recursos naturais e garantem que os

equipamentos serão reciclados de forma a proteger a saúde das pessoas e o meio ambiente. Para obter mais informações sobre onde descartar

equipamentos para reciclagem, entre em contacto com o escritório local de sua cidade, o serviço de limpeza pública de seu bairro ou a loja em

que adquiriu o produto.

IT-2

PROTEZIONE PERSONALE

• Gli operatori e loro assistenti devono pro-

teggere il proprio corpo indossando tute di

protezione chiuse e non infiammabili, sen-

za tasche o risvolti. Eventuali tracce di olio

o grasso devono essere rimosse da tutti gli

indumenti prima di indossarli. Indossare solo

indumenti marchiati CE e idonei per la salda-

tura ad arco e il taglio (Fig. 1):

1. Guanti,

2. Grembiule o giacca in cuoio di crosta,

3. Ghette a protezione delle calzature e del fon-

do pantaloni,

4. Scarpe di sicurezza con puntali in acciaio e

suole di gomma,

5. Maschera (ved. paragrafo radiazioni luminose)

6. Maniche in cuoio di crosta a protezione delle

braccia.

tro fino ad un massimo di 15, secondo

quanto prescritto dalla Norma EN169.

• Gli operatori devono indossare casco o ma-

schera ignifughi, progettati in modo da pro-

teggere il collo e il viso (anche lateralmente)

dalla luminosità dell’arco elettrico (abbaglia-

mento dell’arco da luce visibile e da radia-

zioni infrarosse e ultraviolette). Il casco o la

maschera devono essere dotati di un filtro

protettore il cui grado di opacità dipende dal

procedimento di saldatura o taglio e dal va-

lore della corrente dell’arco elettrico secondo

i valori riportati in Tab. 1 (Norma EN 169).

Figura 1

Attenzione: assicuratevi del buon stato

degli indumenti di protezione, sostituiteli

regolarmente onde ottenere una perfetta

protezione personale.

RADIAZIONI LUMINOSE

Attenzione: non guardare mai un arco

elettrico senza un’ adatta protezione agli

occhi (Fig. 2).

Figura 2

• Occorre mantenere sempre pulito il filtro co-

lorato (vetro inattinico); se rotto o deteriorato

(Fig.3) va sostituito con un filtro dello stesso

grado di opacità. Il filtro colorato deve essere

protetto contro gli urti e le proiezioni di sal-

datura e taglio mediante un vetro trasparente

situato sulla parte anteriore della maschera;

quest’ ultimo va sostituito ogni qualvolta si

constata una ridotta visibilità in saldatura o

taglio.

DIN Taglio

Plasma Elettrodi

Rivestiti

Elettrodi

Carbonio

Arc/Air TIG

9 20 - 39A 5 - 19A

10 40 - 79A 125 - 174A 20 - 39A

11 50 - 149A 80 - 174A 175 - 224A 40 - 99A

12 150 - 249A 175 - 299A 225 - 274A 100 - 174A

13 250 - 400A 300 - 499 275 - 349A 175 - 249A

14 500A 350 - 449A 250 - 400A

DIN MIG per

Leghe

Leggere

MIG per

Pezzi d’Ac-

ciaio MAG

9

10 80 - 99A 80 - 99A 40 - 79A

11 100 - 174A 100 - 174A 80 - 124A

12 175 - 249A 175 - 299A 125 - 274A

13 250 - 349A 300 - 499A 275 - 349A

14 350 - 499A 500 - 550A 350 - 449A

Tabella 1

Figura 3

AREA OPERATIVA

Le operazioni di saldatura e taglio devono essere

eseguite in un ambiente sufficientemente ventilato e

isolato rispetto alle altre zone di lavoro, se ciò non

Optical Radiation Emission

Category 2

(EN 12198)

Conformemente a quanto prescritto nel-

la Direttiva 2006/25/CE e alla norma

EN 12198, l’apparecchiatura è di cate-

goria 2. Si rende obbligatoria l’adozione

di Dispositivi di Protezione Individuale

(DPI) con grado di protezione del fil-

This manual suits for next models

1

Table of contents

Languages:

Popular Cutter manuals by other brands

Wolfcraft

Wolfcraft VLC 800 Translation of the original operating instructions

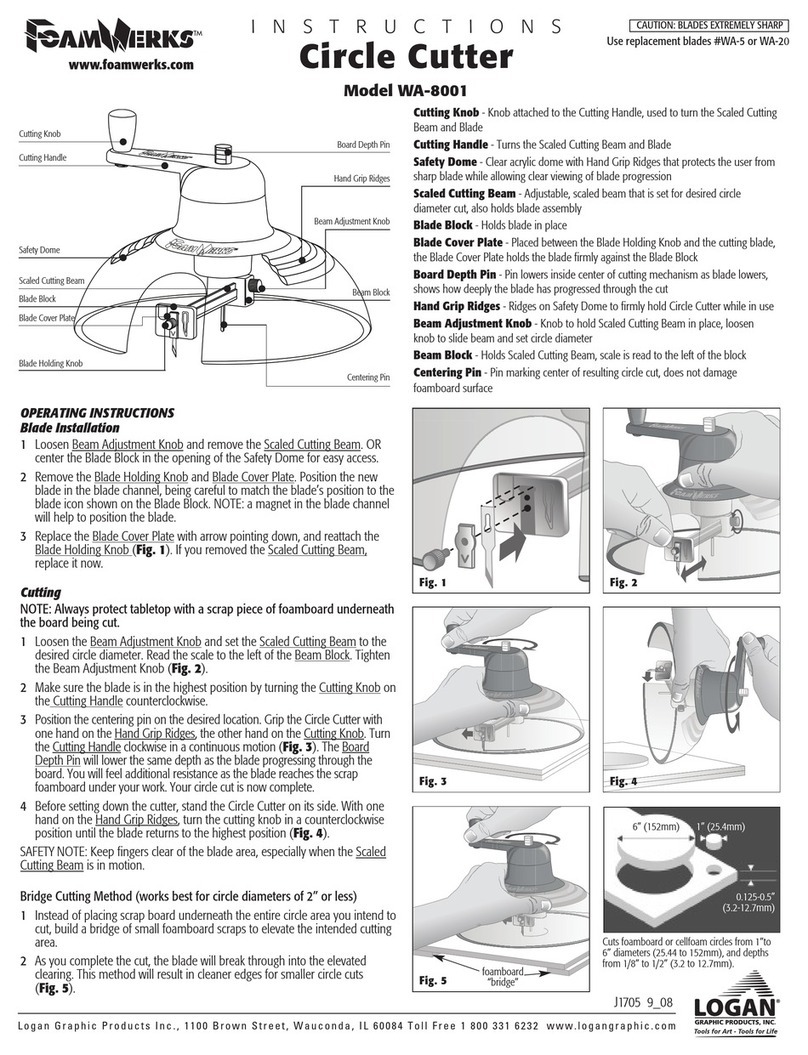

Logan Graphic Products

Logan Graphic Products FoamWerks WA-8001 instructions

Huskie Tools

Huskie Tools REC-54ACM Operation manual

EINHELL

EINHELL TPR 200/2 operating instructions

Schiller

Schiller Classen SCHV-18/5.5 Operator's manual

Evolution

Evolution 110V Original instructions