Henan Oceanus Import & Export OC-1000 User manual

OC-1000

Gas and dust particle detector

Operating Manual

Henan Oceanus Import & Export Co., Ltd.

1

Catalogue

Notice ………………………………………………………2◆

Description ◆ ………………………………………………………4

Feature ◆ …………………………………………………4

Parameter ◆ ……………………………………………………5

Structure ◆ ……………………………………………………7

Operation◆ instruction ……………………………………………7

Operation interface◆ …………………………………………………9

Remarks ◆ …………………………………………………12

Fault&Treatment ◆ ………………………………………………13

Data logger funct◆ion …………………………………………14

2

Notice:

Key instruction① :

Total seven keys:▲、▼、Back、OK、run/stop、 and Print.

Three interfaces:Testing interface、Menu interface、Setting interface

Seven keys will have different function in the three interfaces as the

following:

Testing interface Menu interface Setting interface

▲ ---- move to left or up move to left or up /data plus

▼ ---- move to right or down

move to right or down/ data minus

Back ---- back back

OK main menu(Press 5s)

enter the sub menu Select/save

run/stop pump switch — —

on/off(Press 5s) on/off(Press 5s) on/off(Press 5s)

Print Print real-time data ----- ------

Attentions:OC-1000 portable gas detector only avaible to detect the gas

concentration when the pump on.

Treatment for the over measuring range. ②

Please avoid use the device in concentration which exceeds the

measurement range. It will shorten the life of the sensor or damage the

sensor.

If user used the device under the high concentration gas exceeds the

measurement range, please take the device leave the environment at once,

and put the device in clean air for about half an hour to observe if the

displayed concentration value goes lower. If the value keep decreased,

please wait it decrease to zero, then power off. If the displayed value can

3

not decrease to zero in clean air, please send it back to manufacturer of

distributor.

Remarks: If use the detector under the exceed range, this is not

provided the free repair service.

Calibrate service③

We promise all detector in our company be calibrated with normal gas

before leaving our factory, once bought from our company without need to

calibrate, and must under the professional tenical guidance.

Warranty is 12months from the date leaving our factory, for the

accessory within 3months providing free repairments, and for the detector

providing the free calibration service once in a year.

About the Backlight instruction④

OC-1000 with the electricity saver procedure,when the device without

any operation within 30s, the detector will turn on the electricity saver

procedure automatically, then the screen will become dark, and press any

keys will become light again.

Fast operation instruction⑤

Mute:When the detector under the alarming, short press ▲ or ▼ will

be muted.

Manual storage:When the storage mode under the manual storage, on

the testing interface long press the ▲, then after the

“beep”, will keep the measuring data.

Menu entrance:Under the testing interface, long press “ok” for 5s

then will enter the menu.

Parameter revise instruction⑥

All parameter for OC-1000 could be revised with the “Back”,

“OK”,▲,▼.

4

1.Description

OC-1000 series multi gas and dust particle detector, can be used for

multi gas and dust, at most for 5 sensors. With the imported sensor and

micro control technology, respond quikly, high accuracy and stability, good

repeatability. With the rechargeable 4000mA lithium battery, continuous

working for longer time. With the 3.5 inch industrial grade color screen,

displaying the each parameter and gas concentration, with the function of

detecting the temperature and humidity, also with the data logger.

2.Feature

◆ With semiconductor technology of ultra low power 32 bit

microprocessor, 24 bit ADC acquisition chip.

◆ 2.4 inch IPS industrial grade color screen, displaying each parameter.

◆ It is able to select gas concentration unit of PPM、%VOL、mg/m3.

◆ For 1~5 gas detecting, supporting PM2.5 dust particle sensor and

temperature sensor, humidity sensor.

◆ With data logger, about 100000 group of detecting data, could be

transmitted to computer.

◆ The various modes can be adjusted: detection model, storage model,

display model, pump model, print model.

◆ With the data printing function, could be equiped with the micro-printer(optional).

◆ The powerful pump, can be used in the micro vacuum environment.

◆The full auto calibration software, sensor can be adjusted up to six point

to ensure the accuracy and linearity of the measurement, also the

function of data recovery.

◆With overvoltage protection, overcharge protection, anti-static, anti

magnetic interference interference function

5

◆ Support Chinese or English operation menu.

◆ With the function of temperature compensation, water-proof and

dust-proof, equiped with the dust filter.

◆ With the temperature and humidity detection.

3.Technical parameter

Product: Multi gas and dust particle detector

Measuring

range: Reffering to the gas list

Resolution:

Reffering to the gas list

Gas type: At most for 5 sensors, the gas type will be according to your requirements.

Temperature

and

humidity:

Temperature:-40 ~ 120℃,Humidity:0-100%RH

Testing

mode:

Pump-sunction,inner pump, adjustable flow rage(500-1000mL L/min), workable for

the vacuum environment.

Accuracy: ≤±3%F.S Linearity: ≤±1%F.S

Response

time: ≤20s(T90) Zero drift: ≤±1%

(F.S/year)

Recovery

time: ≤20s Repeatability: ≤±1%F.S

Testing

mode: Realtime detecting or Timing detecting is adjustable.

Data

Storage:

Automatic storage or manual storage is adjustable; About 100000 group of data

capacity.

6

Explosion-Pr

oof grade: ExdII CT6 Case Material : ABS+PC

Protection

grade: IP66 Working

temperature:

-30 ~

60℃

Working

power: 4000mA rechargeable lithium battery Working humidity:

≤95%RH(no

n-condensin

g)

Size and

weight:

220*85*55 mm(L×W×H)

0.5 Kg(Net weight) Working pressure: -30Kpa ~

100Kpa

Accessory:

Dust filter,box, instruction, USB charger, data line,calibration cap

Target Gas List(Some gas not list,if need, pls contact manufacturer)

Gas Range Accuracy Resolution Reponse time

Ex 0~100%LEL ≤±3%F.S 0.1%LEL ≤20s

CH4 0~100%LEL ≤±3%F.S 0.1%LEL ≤20s

O2 0~30%VOL ≤±3%F.S 0.01%VOL ≤20s

CO 0~1000PPM ≤±3%F.S 1PPM ≤20s

CO2 0~5000PPM ≤±3%F.S 1PPM ≤20s

O3 0~50PPM ≤±3%F.S 0.01PPM ≤20s

H2S 0~100PPM ≤±3%F.S 0.1PPM ≤20s

SO2 0~20PPM ≤±3%F.S 0.01PPM ≤20s

NO 0~100PPM ≤±3%F.S 0.1PPM ≤20s

NO2 0~20PPM ≤±3%F.S 0.01PPM ≤20s

Cl2 0~50PPM ≤±3%F.S 0.01PPM ≤20s

NH3 0~100PPM ≤±3%F.S 0.1PPM ≤20s

PH3 0~20PPM ≤±3%F.S 0.01PPM ≤20s

ETO 0~100PPM ≤±3%F.S 0.1PPM ≤20s

HF 0~10PPM ≤±3%F.S 0.01PPM ≤20s

7

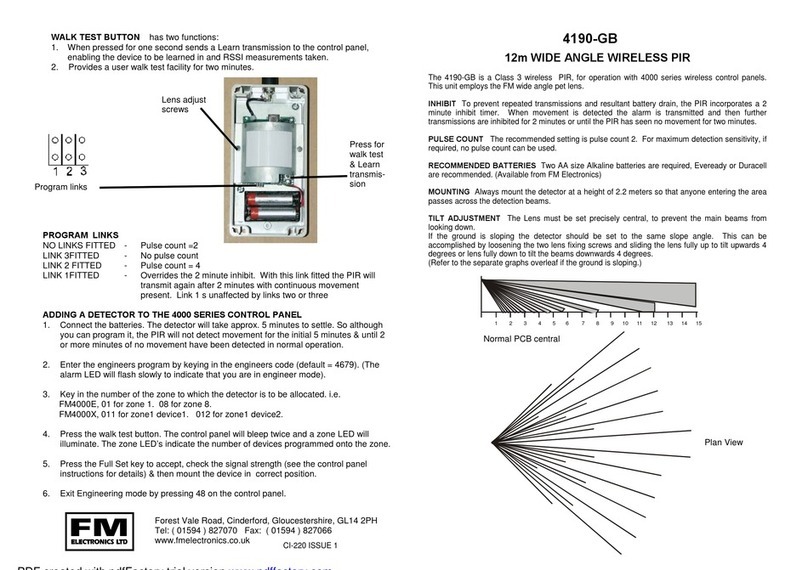

4.Structure

5.Operation instruction

5.1 Keys

Total seven keys:▲、▼、Back、OK、run/stop、 and print.

Three interfaces:Testing interface、Menu interface、Setting interface

8

Seven keys will have different function in the three interfaces as the

following:

Testing interface Menu interface Setting interface

▲ ---- move to left or up move to left or up /data plus

▼ ---- move to right or down

move to right or down/ data minus

Back ---- back back

OK main menu(Press 5s)

enter the sub menu Select/save

run/stop pump switch — —

on/off(Press 5s) on/off(Press 5s) on/off(Press 5s)

Print Print real-time data ----- -----

Attentions:OC-1000 portable gas detector only avaible to detect the gas

concentration when the pump on.

5.2 Power on

When power off, long press key for 5s to activate the backlight

and red indicator, then “beep”, then the detector power on. Then the

display will be sensor testing(3s), sensor information(1s), preheating for

60s with the pump on. After the start-up, then will enter the Testing

interface.

5.3 Power off

In noraml working status, long press key for 5s, it will power off with

a buzzer tone.

9

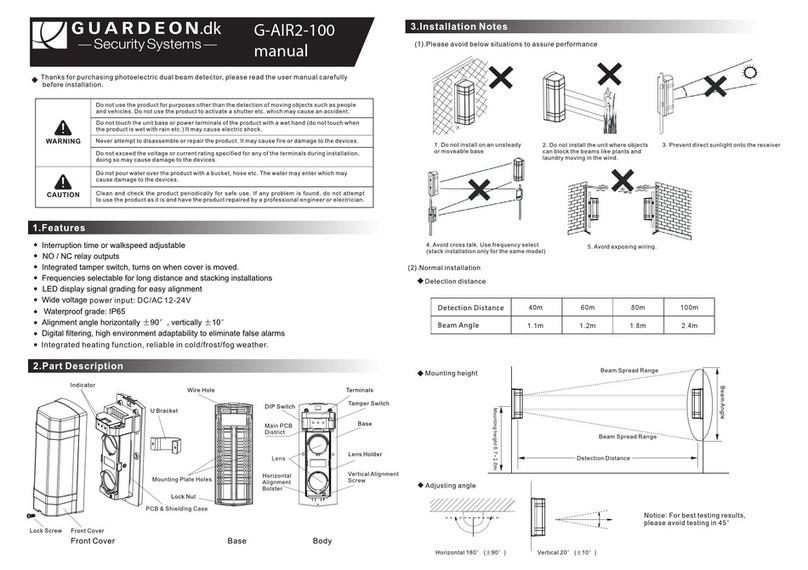

6.Operation interface

6.1 Testing interface display

After enter into the testing interface, for different gas quantity, will

display different interface:as the following picture, displaying one gas, two

gas, three gas, four gas orderly.

As the above displaying, time, temperature, pump running, battery

and humidity. Take A for example, for O3, CO, CH2O, Ex, for each gas

with the gas concentration; Once some up to the alarming value, it will

appear the alarming symbol, such as the CH2O alarming.

10

6.2 Function menu instruction

Long press “OK” key for 5s, will enter to the menu, then will display

nine sub menu: Basic set, History data, Data analyse, Zero cali, Range

calibration, Alarm param, Detection /Storage/Print , Date time, Reset

factory. On this menu by “▲” or “▼” the can move to different sub menu,

then short press the “OK” key will enter the sub menu, pressing the “back”

will back to normal detecting interface.

6.2.1 Settings

Enter into setting menu, then display each parameter, by “▲” or “▼”,

“ok” key, user can revise different parameter. With the “Range/unit setting”

option, user can check and revise different measuring range and

concentration unit(ppm、mg/m³、VOL% is selectable); With the “Channel

setting”, can turn on or off some one or more channel gas.

With the “Pump flow rate ” can adjust the pump flow rate (only need to

setting under vaccum enviroment, default is 30); With “Temperature

correction” and “Humidity correction” can adjust the device display of

temperature and humidity; With “Language setting” can choose the

Chinese or English.

6.2.2 History data

User can check the previous measuring data, after entering into the

“History data”, then will display “Check” or “Delete” the data. If choose to

check the history data, move the cursor to “Check”, then press “OK”key,

and by “▲” or “▼” will change into the export status, then press twice “ok”

key will find the previous concentration data.

6.2.3 Data analysis

This function record the average concentration and largest

concentration of each gas type in the process of usage. TWA is the average

concentration, STEL is the largest concentration.

6.2.4 Zero Calibrate

11

If the zero drift of the sensor is larger, ueser can do the zero

calibration, this will make the default of target gas concentration as “0”.

Attention: zero calibration must be in the clean air.

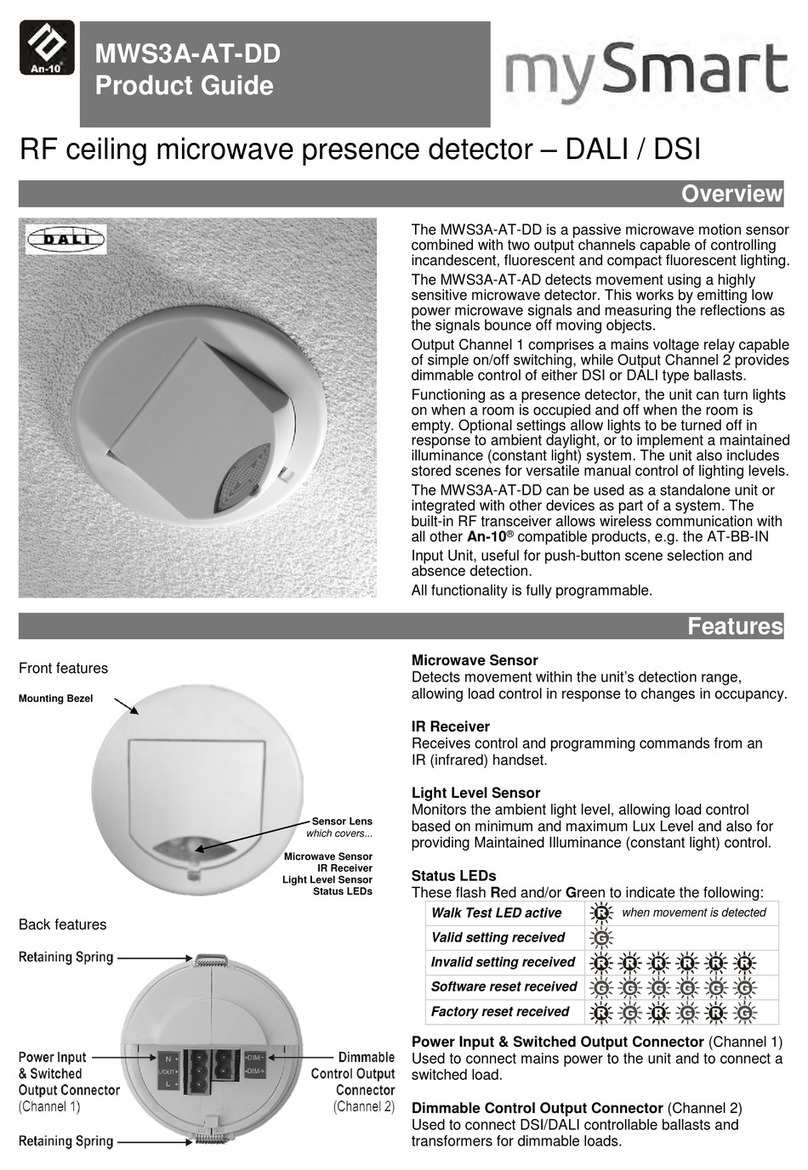

6.2.5 Target Calibrate(Only professionl engineer operation allowed)

OC-1000 multi gas and dust particle detector can make the six level

target concentration calibration for the detecting gas, as the picture shows,

this must with the standard concentration gas,

pressure relief valve, flowmeter, calibration cap, and

good connection of gas, or will be prohibited.

Operation details: Connecting the device as the

picture, enter into the target gas calibration interface,

slowly turn on the calibrate gas and control the flow

rate within 500ml/min, observing the detector gas

concentration(now should be rising), when the value

up to the peak value and keep stable, then choose a

non-calibrated option(“√” means been calibrated,

“×” means non-calibrated): firstly input the calibrate

gas concentration, then press the “calibrate”. After completing the target

point calibration, the target gas concentration of detector will be the

calibrate gas concentration.

6.2.6 Alarming setting

OC-1000 with two adjustable alarm threshold values, high alarming

value and low alarming value. When set the low alarming, gas

concentration lower than the set value will alarm; when set the high

alarming , gas concentration higher than the set value will alarm.

12

Operation details: user move the cursor to “Alarming mode”, press

“ok”, by “▲” or “▼” can change the alarming mode, after switch then

press “ok” will save the setting.

6.2.7 Detection storage

With this function user can set the detecting mode, storage mode,

print mode, the detecting mode including the realtime detecting and timing

detecting, storage mode including the manual save , auto save and

close(not save), print mode including hand, auto, close.

If realtime detecting, the detector will display the realtime

concentration of each channel, then user can set the storage mode and print

mode, also can set the storage and print cycle. If timing detecting mode,

will display and print the average concentration is this period, can set the

timing cycle and round cycle(time between the twice timing detecting).

Setting the timing detection, need to back to the Detecting interface to

press the “Run/stop”key, turn on the countdown to begin timing detection,

if not turn on the round detecting, when the countdown over, the detector

will stop pump detecting automaticly; if turn on the round detection, after

several seconds, it will begin the timing detecting again automaticly.

6.2.8 Date

Setting the date related with the detecting gas concentration data.

6.2.9 Factory reset

Once mistake operation, user can use this function to recover the

initial configuration.

7.Remarks

◆Befor use the detector, please read the instruction carefully.

◆Prohibit open the detector and replace the accessories privately.

◆Install ,setting must be operated by professional guidance.

◆Regularly check the device and change the sensor.

13

◆Prohibit drop from high space.

◆Under the high temperature or pressure is not allowed to use, if high

humidity, then need to add the device to decrese the humidity.

◆Human damage is not free repairment.

◆Befor enter into dangerous area, people need to be electrostatic

discharged, then bring the detector into the working place.

◆Using the special charger for this detector.

8.Common faults and treatments

◆ Value display not stable, up and down

Reason:some electrochemical sensor easily effected by other gas,

maybe is colorless and odorless.

Solution:Bring the detector into clean air, then the data will decrease to

normal value; If still not normal, then zero calibrate in clean air.

◆Response weak

Reason:Lower level of oxygen:<5%VOL;

High pressure, pump not work;

The sensor useful life end, or other faults;

Solution :If the Electrochemical sensor, Catalytic combustion

sensor,Semiconductor sensor,need oxygen to work, so the

level of oxygen should more than 5%VOL,pressure range

is:-30Kpa ~ 100Kpa,If user have calibrate gas, can

import the gas to test and target point calibrate. If oxygen

and pressure both normal, then maybe other faults, need to

send back to manufacturer.

◆After access the detecting gas, the data cann’t stable for a long time, up

and down

Reason:Maybe the too low content of oxygen in the detecting gas, or

the change of the detecting gas.

Solution:Increasing the oxygen level and keep stable flow rate, or

14

change the higher oxygen calibrate gas.

◆Pump weak, lack strength

Reason:Pump have suction many particle and gas, the entrance

blocked.

Solution:Send back to manufacturer to change a new pump, adding the

dust filter in the later usage.

◆Turn on fails

Reason:No power.

Solution:After charge, if still cann’t turn on it, then send back to

manufacturer.

◆ Charged fails

Reason :Charger problems or wrong model charger

(Usually5-5.5VDC,1-2A)

Solution:Check the charger output voltage if is 5V,if not, then need to

change the charger, if is 5V, then need to send back to

manufacturer for testing.

9.Data logger

OC-1000 with the data logger function, the charging port is the

data output port, the operation steps as the following:

1、Install the export software on the computer.

2、Turn on the detector, after the 60s preheating over, connectted

with the computer.

3、After install the drive of communication line, open the software,

and confirm the computer COM port, then click the “Open

port”, now the lower left corner will display the “Port

Open ”(Baud rate default is 115200)

4、Enter into the history data menu interface, export the gas

concentration data, if complete will appear the cues.

15

5、On the software,set the detector address and channel

number(same with the “address setting”and “channel

setting”in the “Setting”), start time and deadline(The save

time of history data should be in this period range).

6、Click the “search”can find the above period gas concentration

for the according channel gas,the data also could be saved

as the EXCEL form by click the “Read Data”

Remark: Data transmission line is the USB connection line.

Henan Oceanus Import & Export Co., Ltd.

Address: NO.709, Xiehe Building, Nanyang Road, Zhengzhou, China

Tel: 0086-15981942832

Email:oceanussales@outlook.com

Table of contents

Popular Security Sensor manuals by other brands

PCB Piezotronics

PCB Piezotronics 132B38/010PH Installation and operating manual

careium

careium Enzo Pendant Technical guide

VS LIGHTING SOLUTIONS

VS LIGHTING SOLUTIONS Blu2Light 187212 manual

hager

hager TRC321B quick start guide

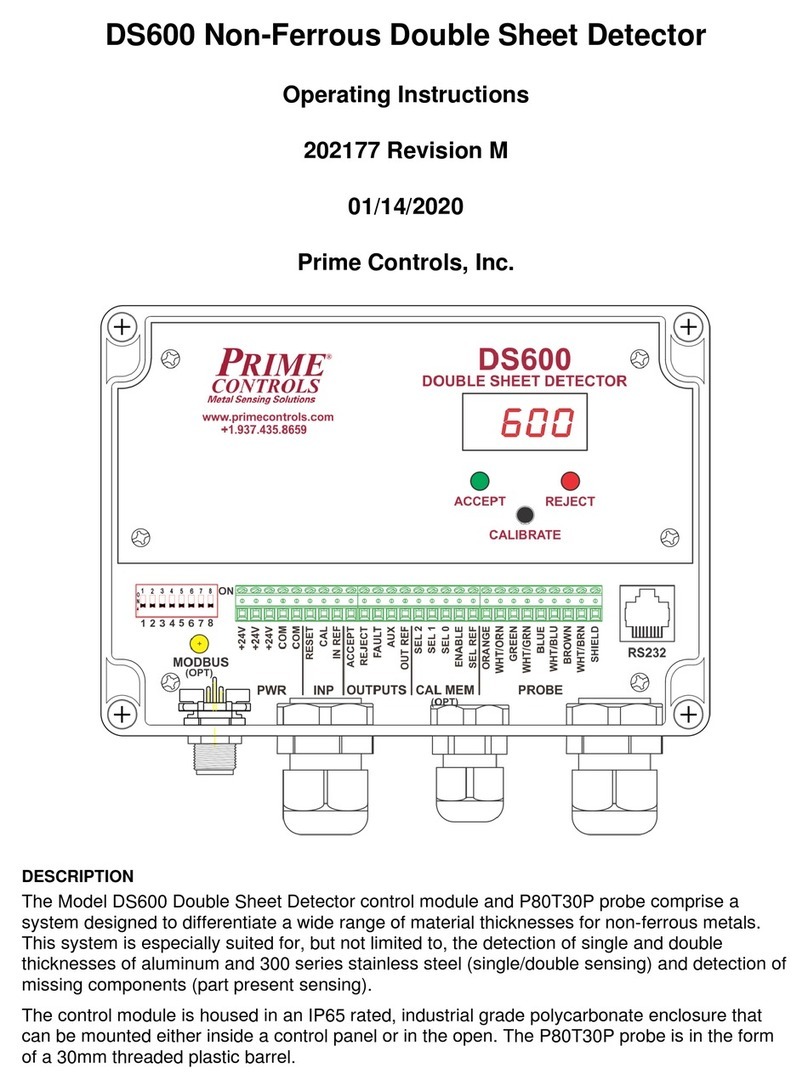

Prime Controls

Prime Controls DS600 operating instructions

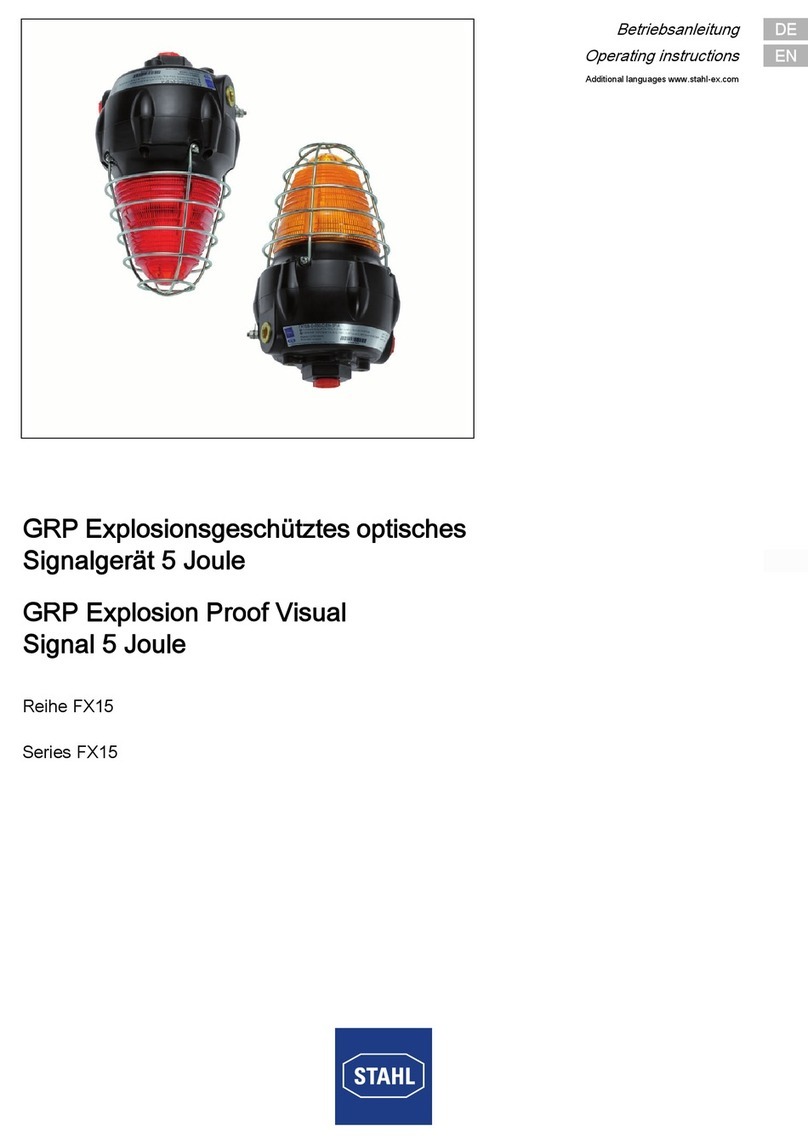

Stahl

Stahl FX15 Series operating instructions