Henkel Loctite 97102 User manual

22121

97102

135550

2

3

Contents

1

Please observe the following...........................................................4

1.1

Emphasized Sections...................................................................................................4

1.2

Items Supplied .............................................................................................................4

1.3

For your Safety.............................................................................................................5

1.4

Field of Application (Intended Use)...............................................................................5

2

Description......................................................................................5

2.1

Theory of Operation .....................................................................................................5

2.2

Displays, Operating Elements and Connections...........................................................6

3

Technical Data................................................................................9

3.1

Energy Requirements...................................................................................................9

3.1.1

Electrics .......................................................................................................................9

3.1.2

Pneumatics..................................................................................................................9

3.2

Connections and Dimensions.......................................................................................9

3.3

Other Data ...................................................................................................................9

4

Installation.....................................................................................10

4.1

Environmental and Operating Conditions...................................................................10

4.2

Dimensions................................................................................................................10

4.3

Basic Settings of the Unit ...........................................................................................10

4.4

Connecting the Unit....................................................................................................10

5

Dispensing....................................................................................11

5.1

First Operation ...........................................................................................................11

5.1.1

Priming the Feed Line................................................................................................11

5.1.2

Adjusting the Dispensed Quantity...............................................................................12

5.1.2.1

Time Controlled Mode................................................................................................12

5.1.2.2

Continuous Mode.......................................................................................................13

5.2

Refilling the Product Reservoir...................................................................................14

5.3

Shutdown...................................................................................................................15

5.4

Returning to Operation...............................................................................................15

6

Maintenance and Service..............................................................15

7

Troubleshooting............................................................................ 17

8

Pin Assignment.............................................................................17

8.1

XS1: Start via Footswitch ...........................................................................................17

8.2

XS1: External Start.....................................................................................................18

8.3

XS1: Start via Promixity Switch ..................................................................................18

8.4

XS2: Digital Level Sensor Reservoir (Empty Signal)...................................................19

8.5

XS2: Automatic Reservoir 97106 / 97108...................................................................19

9

Declaration of Conformity..............................................................20

4

1

Please observe the following

Before installing the system: For safe and successful operation of the unit, read these

instructions completely. If instructions are not observed, the manufacturer will not accept

any liability.

Be sure to keep the manual close at hand for further reference.

The WEEE symbol on this equipment indicates that this product may not be treated as

household waste. By ensuring this product is disposed of correctly you will help prevent

potential negative consequences for the environment. For more information about where

you can drop off your waste equipment for recycling, please contact your local city office

or your waste disposal service.

1.1

Emphasized Sections

Danger!

Refers to safety regulations and requires safety measures that protect the equipment

operator or other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property shall not be

damaged.

Note!

Gives recommendations for better handling of the unit during operation or adjustment as

well as for service activities.

The numbers printed in bold in the text refer to the corresponding position numbers in the

illustration on pages 6 –7.

–The dash emphasizes a list.

●The point emphasizes an instruction step.

Instruction steps in the illustrations are

indicated with arrows.

The shading of the arrows have the

following meaning:

Black arrow = 1st step

Grey arrow = 2nd step

White arrow = 3rd step

1.2

Items Supplied

1 Semi-Automatic Controller 97102, Order No. 135550

1 Power Cord

1 Pneumatic Tube 6 x 1, 2 m

1 Instruction Manual 97102

Note!

As a result of technical development, the illustrations and descriptions in this operating

manual may deviate in detail from the actual unit delivered.

5

1

Please observe the following

1.3

For your Safety

Please refer also to the relevant Technical Data Sheet for the adhesive to be processed.

Download from www.loctite.com or request the Technical Data Sheet and the Safety

Data Sheet from your Henkel Technical Service.

INSTRUCTIONS given in these data sheets must be followed scrupulously at all times!

While under warranty, the unit may be repaired by an authorized Henkel service

representative only.

Danger!

Improper handling of chemicals may result in potential health hazards!

Observe general safety regulations for the handling of chemicals!

Always wear goggles when working with compressed air!

Before starting operation, check the dispensing system for visible damage and make

sure that it is operated only when in perfect working order!

Any defects found must be reported immediately! Remedy any defects immediately!

Use only original substitute and spare parts. We cannot be held responsible for damage

or injury of any kind because of failure to observe the instructions in this Operating

Manual.

1.4

Field of Application (Intended Use)

The Semi-Automatic Controller 97102 controls the exact application of LOCTITE

Products from a product reservoir by means of a dispensing valve.

It can be combined with the following LOCTITE Units to from a dispensing system:

1 Product reservoir (product tank or cartridge reservoir emptying unit with or without low

level and empty sensor).

1 Pneumatic dispensing valve.

Depending on the combination of components, it is possible to dispense the following

products:

–Anaerobic curing adhesives

–UV light curing adhesives

–Humidity curing cyanacrylate adhesives

2

Description

2.1

Theory of Operation

The Semi-Automatic Controller 97102 controls the selected dispensing pressure in the

product reservoir and the pneumatic opening of the dispensing valve according to the

selected dispensing time.

The start signal for dispensing is provided by an external Footswitch.

Error messages are shown on the digital display and are accompanied by a beeping tone

(see Section 8).

When a product reservoir is connected, the pressurization or depressurization of the

automatic reservoir is automatically controlled when the control unit is switched on or off.

When an empty signal is received, the automatic reservoir 97106 / 97108 is

automatically depressurized.

The control unit indicates that the automatic reservoir was refilled. By acknowledging this

message with button the automatic reservoir is again pressurized.

6

2

Description

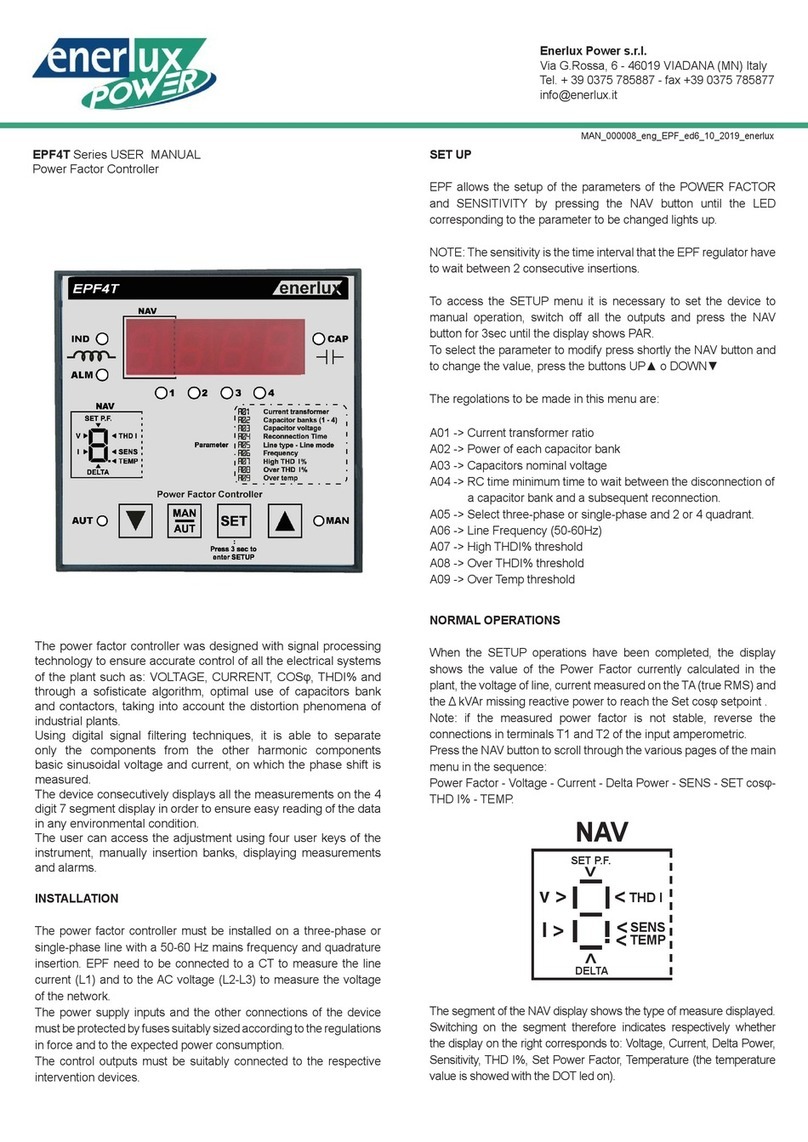

2.2

Displays, Operating Elements and Connections

1

Digital Display

Display of the dispensing time [s] for a dispensing sequence.

–During dispensing in time controlled mode, the dispensing time remaining is

indicated.

–During dispensing in continuous mode, the elapsed dispensing time is indicated.

Display of the dispensing pressure [bar] or [psi] set on the pressure regulator 8.

Display of error messages (see Chapter 7).

2

Buttons and

Buttons for changing the dispensing time for a dispensing sequence.

When button or is pressed, the display of the dispensing time [s] in the

digital display begins to blink. The dispensing time indicated is increased with

button and decreased with button .

The dispensing time is adjustable from 0.01 to 99.9 s.

7

2

Description

3

Button

Button for the storage of the new values set for the dispensing time [s] and the

dispensing pressure [bar] or [psi].

When the indication of the dispensing time [s] in the digital display blinks, the

indicated dispensing time is stored by pressing button and the display stops

blinking.

For an error message „ Press. 0.83 NOK“ with beeping, the error message is

acknowledged by pressing button . The value 0.83 [bar/psi] is only an

example for the indication of a dispensing pressure (see Chapter 7).

If the error message „ PRESS ENTER; >Tank Inactive< “ appears, the automatic

reservoir ( Tank) is pressurized by pressing ( PRESS) button ( ENTER) (see

Section 5.2.1).

4

Button

Button for filling the product line (see Section 5.1.1).

The LED lights as long as button is pressed.

When button is pressed in time-controlled mode, the dispensing time is not

changed.

The product is dispensed as long as button is pressed.

When button in pressed in continuous mode, the dispensing time is changed

(see Section 2.3)

5

Button

Button for switching the measuring units for the dispensing pressure in the digital

display.

After each pressing of button the indication of the selected dispensing

pressure in the digital display changes to the other measuring unit [bar] or [psi]

with the corresponding value.

6

Button

Button for switching from time controlled mode to continuous mode.

The lighting of the LED in button indicates continuous mode (see Section

5.2.2.2).

By pressing button the indication of the dispensing time in the digital display is

set to 0.00 s and blinks. During dispensing, the elapsed dispensing time is

indicated in the digital display beginning each time with 0.00 s. The last

dispensing time remains displayed until the next start.

–Switching back to time controlled mode without storage of the dispensing time

by renewed pressing of button . The LED in button extinguishes. In the

digital display, the dispensing time previously stored for the time controlled

mode reappears.

–Switching back to time controlled mode with storage of the dispensing time by

pressing button . The LED in button extinguishes. The indicated

dispensing time is stored and the display stops blinking.

7

Power Switch I/O (ON/OFF)

The control unit is switched on and off with the power switch.

When a product reservoir is connected, the following also applies:

Position I (ON) –The reservoir is automatically pressurized with the dispensing

pressure set on the precision pressure regulator.

Position O (OFF) –The reservoir is automatically depressurized.

8

2

Description

8

Precision Pressure Regulator

Precision regulator for adjusting the dispensing pressure.

By turning the regulator knob, the dispensing pressure is adjusted in the range

from 0.00 to 7.00 bar (0.00 to 100 psi).

If the error message „Press. 0.83 NOK“ appears with beeping, the dispensing

pressure was changed more than ± 10 %. The value 0.83 [bar/psi] is only an

example for the displayed dispensing pressure (see Chapter 7).

By pressing button ENTER the indicated dispensing pressure is stored as the new

comparison value for automatic pressure monitoring. The error message and

beeping is eliminated.

9

Control Air Connection (Dispensing Valve), dispensing valve open.

The single pneumatic hose to the dispensing valve is connected here (for

connections, see Section 8.2).

10

Control Air Connection (Dispensing Valve), dispensing valve closed.

The single pneumatic hose to the dispensing valve is connected here (for

connections, see Section 8.2). If a dispensing valve is used with single-acting

actuator, this plug must be closed with a blind plug.

11

a

P in - Main air connector

2 - 10 bar (30 PSI - 145 PSI) for air hose OD Ø 6 mm , ID Ø 4 mm

11

b

P out - Pneumatic Connection Reservoir

Regulated air pressure supply (0 - 7 bar, 0 –100 PSI) to the reservoir, for

air hose OD Ø 6 mm , ID Ø 4 mm.

12

Power Fuse

Caution!

Removing, jumpering or putting out of operation of the safety devices can result in

damage to the unit and is therefore prohibited!

13

Power Cord

14

Power Supply Socket

15

Footswitch (Accessory to be ordered separately!)

Signalling device for starting the dispensing sequence.

The dispensing time in time-controlled mode corresponds to the value on the

digital display and is independent of the length of time that the Footswitch is

depressed (see Section 2.3.1). In continuous mode, the product is dispensed as

long as the Footswitch is depressed (see Section 2.3.2).

16

Socket XS1: Start

The Footswitch 15 is connected here. A "Ready" signal is provided at Pin 3 and 4.

17

Socket XS2: Reservoir

The product reservoir is connected here.

+ 0.05

–0.10

+ 0.05

–0.10

9

3

Technical Data

3.1

Energy Requirements

3.1.1

Electrics

Power supply

90 –260 VAC; 47 –63 Hz

Power consumption

Approx. 40 W

Power protection

Glass tube, fine wire fuse, 2 AM

Internal control voltages

5 VDC; 12 VDC; 24 VDC

3.1.2

Pneumatics

Compressed air supply

min. 2 bar (29 psi); max. 12 bar (174 psi)

Quality

If the required quality is not

achieved, install a Loctite® 97120

filter regulator.

filtered 10 µm, oil-free, non-condensing

Order No. 88649

Regulation range of the pressure regulator

0.00 –7.00 bar (0.00 –100 psi)

Pressure indication

0.00 –7.00 bar (0.00 –100 psi)

3.2

Connections and Dimensions

Pneumatic hose, control air connection

O.D.

6 mm

Pneumatic hose, Dispensing Valve O.D.

4 mm

Pneumatic hose, Reservoir O.D.

6 mm

Dimensions

W x H x D: 145 x 230 x 260 mm

3.3

Other Data

Storage temperature

-10°C to +60°C (+14°F to +140°F),

dry/dust-free

Operating temperature

+10°C to +40°C (+50°F to +104°F)

Weight

~ 2.8 kg

Continuous sound pressure level

< 70 dB(A)

+0.05

-0.10

+0.05

-0.10

+0.05

-0.10

10

ve

4

Installation

4.1

Environmental and Operating Conditions

–Avoid kinking of the pressure hoses.

–Typically, the pressure hose should be no longer than 1 m.

–Carefully tighten all fittings.

–The equipment should be installed in a dry, dust-free place, no splash water!

4.2

Dimensions

4.3

Basic Settings of the Unit

4.4

Connecting the Unit

11

5

Dispensing

5.1

First Operation

5.1.1.

Priming the Feed Line

●Check that the product reservoir, the dispensing valve and the footswitch are

connected correctly according to their operating manuals.

●To avoid air bubbles during dispensing, the product line must be filled and then purged

of air.

●Position the dispensing valve as specified in its instruction manual to ensure bubble-

free filling of the product line.

Caution!

Place a container under the dispensing valve since the product will flow out.

●Switch the power switch 7 to the position I (ON).

●With the pressure regulator 8 set the

dispensing pressure to 0.50 bar

(approx. 7 psi).

●Press button until the product flows

free of bubbles from the dispensing

needle.

●For viscous products, increase the

pressure slowly in steps until the

product flows out.

Caution!

Hold the dispensing valve pointing downward to prevent uncontrolled squirting out of the

product.

12

5

Dispensing

5.1.2

Adjusting the Dispensed Quantity

5.1.2.1

Time Controlled Mode

This mode of operation is used for spot shaped wetting or drop dispensing.

●With buttons or set the dispensing

time to 0.50 s (factory setting). The

indication of the dispensing time in the

digital display begins blinking.

●With the pressure regulator 8 set the

dispensing pressure to 0.50 bar (approx.

7 psi). An error message „ Press. 0.83

NOK “ with beeping is possible. The

value 0.83 [bar/psi] is only an example

for the indicated dispensing pressure

(see Chapter 7).

●Press button to store the dispensing

pressure setting as the comparison

value for automatic pressure monitoring.

The error message with beeping is

eliminated.

●Press the Footswitch 15 to check the

dispensed quantity.

If the dispensed quantity is too small:

●Increase the dispensing pressure and store. Check the dispensed quantity again.

Repeat this sequence until the desired dispensed quantity is roughly achieved.

When the desired dispensed quantity is roughly achieved:

●Set the exact dispensed quantity by changing the dispensing time with button or .

●Press the Footswitch 15 to check the dispensed quantity.

Storing of the dispensed quantity setting for subsequent dispensings:

●Press button . The indication of the dispensing time in the digital display stops

blinking.

If the desired dispensed quantity is not achieved:

●With a larger (or smaller) dispensing needle, repeat the steps of Section 5.1.2.1.

13

5

Dispensing

5.1.2.2

Continuous Mode

This mode of operation is used for wettings of varying lengths or for the application of

beads.

●With the pressure regulator 8 set the

dispensing pressure to 0.50 bar (approx.

7 psi). An error message „ Press. 0.83

NOK “ with beeping is possible. The

value 0.83 [bar/psi] is only an example

for the indicated dispensing pressure

(see Chapter 7).

●Press button to store the dispensing

pressure setting as the comparison

value for automatic pressure monitoring.

The error message with beeping is

eliminated.

●Press button . The lighting of the LED

in button indicates continuous mode.

The indication of the dispensing time in

the digital display is set to 0.00 s and

blinks.

●Press the Footswitch 15 until the

dispensed quantity is roughly achieved.

If the dispensed quantity is too small:

●Increase the dispensing pressure and store. Check the dispensed quantity again.

Repeat this sequence until the desired dispensed quantity is roughly achieved.

–Switching back to time controlled mode without storage of the dispensing time by

renewed pressing of button . The LED in button extinguishes. In the digital

display, the dispensing time previously stored for the time controlled mode reappears.

–Switching back to time controlled mode with storage of the dispensing time by

pressing button . The LED in button extinguishes. The indicated dispensing time

is stored and the display stops blinking.

If the desired dispensed quantity is not achieved:

●With a larger (or smaller) dispensing needle, repeat the steps of Section 5.1.2.1.

14

5

Dispensing

5.2

Refilling the Product Reservoir

Error message „ --- Refill ---“

(see Chapter 7):

The error message display blinks.

●Prepare product for refilling.

Error message „ --- Empty ---“ with

beeping:

The error message display blinks. The

dispensing sequence is interrupted and no

further dispensing sequence can be

started.

●Press the button to stop the beeping.

The reservoir is automatically depressurized following the empty message.

●Refill the reservoir according to its instruction manual and reconnect.

Error message „ PRESS ENTER>Tank

Inactive< “(product reservoir (Tank) not

pressurized):

●Press button once (PRESS ENTER).

The reservoir is pressurized.

The error message „Press. 0.83 NOK“ (Press.= Dispensing pressure) blinks in the

digital display with beeping. The value 0.83[bar/psi] is only an example for the indication

of the dispensing pressure (see Chapter 7).

The error message „Press 0.83 NOK“ with beeping disappears by itself when the

dispensing pressure in the product reservoir does not deviate more than 10 % from the

stored comparison value of the automatic pressure control.

After the error message „ Press. 0.83 NOK “ with beeping has disappeared:

●Continue dispensing with the stored values for dispensing time and pressure.

15

5

Dispensing

5.3

Shutdown

●Switch the power switch 7 to the position O (OFF).

Shutdown for Longer Periods of Non-use

Caution!

For pauses in the work of longer than 14 days, place the system out of operation to

prevent curing of the product.

●Switch the power switch 7 to the position O (OFF).

●Put the product reservoir and dispensing valve out of operation according to their

instructions manuals.

5.4

Returning to Operation

●Switch the power switch 7 to the position I (ON).

●Continue dispensing with the stored values or readjust the dispensed quantity

according to Section 5.1.2.

Returning to Operation after Longer Periods of Non-use

●Check the installation according to Chapter 4.

●Return to operation according to Section 5.1.

6

Maintenance and Service

The unit requires no special care and maintenance.

16

7

Troubleshooting

Malfunction/Fault signal

Possible Cause

Corrective Action

The digital display does

not light.

–No power voltage present.

–Power switch 7 in position O (OFF).

–Power fuse 12 is defect.

–Power cord 13 is defect.

–Control unit is defect.

●Check the power voltage.

●Switch power switch 7 to position I

(ON).

●Check/replace fuse 12.

●Replace power cord 13.

●Henkel Service.

No change in the value on

the digital display

–No air pressure present.

–Product reservoir not switched on or

defect.

–Control unit is defect.

●Check pneumatic supply.

●Check product reservoir (see

operating manual for product

reservoir).

●Henkel Service

The error message (with

beeping) blinks in the

digital display:

Press.

=Dispensing pressure

0.83 [bar/psi]

=Example for the

indication of dispensing

pressure.

NOK

= Not O.K

–The unit was switched off and the

pressure regulator 8 in now

adjusting to the dispensing pressure

setting. The indicated dispensing

pressure is increased continuously.

–Pressure regulator 8 was

unintentionally changed by more

than ±10 %.

–Dispensing pressure was set to a

new value of more than ±10 %.

–Leak in the system

●Wait until the pressure regulator 8

has adjusted the dispensing

pressure.

●The error message and beeping are

eliminated when the indicated

dispensing pressure is within -10 %

of the stored comparison value.

●Adjust pressure regulator 8 until the

error message and beeping are

eliminated.

●Press button to store the

indicated dispensing pressure as the

new comparison value for the

automatic pressure monitoring. This

eliminates the error message and

beeping.

●Check system for leakage.

●Henkel Service.

The desired pressure is

not achieved.

–Supply pressure inadequate.

●Increase the supply pressure.

No product, too little or too

much product.

–Dispensing pressure not set

correctly.

–Pressure hose not properly

connected.

–Dispensing needle is clogged, too

small or too large.

–Dispensing valve not correctly

connected or defect.

–Product reservoir not switched on or

defect.

–Controller is defect.

●Adjust dispensing pressure setting.

●Connect air pressure hose correctly.

●Replace the dispensing needle.

●Check the dispensing valve (see

operating manual for dispensing

valve).

●Check product reservoir (see

operating manual for product

reservoir).

●Henkel Service.

LED in button or

does not light.

–LED defect.

–Button defect.

–Control unit is defect.

●Henkel Service.

●When the button I operational

(check by means of the digital

display), the unit can be used until

repaired by Henkel Service.

●Henkel Service.

●Henkel Service.

17

7

Troubleshooting

Malfunction/Fault signal

Possible Cause

Corrective Action

No start signal.

–Reservoir is empty.

The error message (with beeping)

blinks in the digital display:

–Automatic reservoir refilled but not

yet pressurized. The error message

blinks in the digital display:

Tank = Reservoir.

Inactive = Not pressurized.

–Plug on the socket XS1: Start 16 is

loose.

–Footswitch 15 defect.

–Control unit is defect.

●Refill reservoir (see Section 5.2).

The error message appears

previously in the digital display:

●Pressurize the automatic reservoir.

●Press button . The automatic

reservoir is pressurized.

●Switch the power switch 7 to the

position O (OFF).

●Tighten the screws of the plug.

●Switch the power switch 7 to the

position I (ON).

●Replace the Footswitch 15.

●Henkel Service.

8

Pin Assignment

Caution!

Never connect any external voltage on pin 9 of XS1 or XS2!

8.1

XS1: Start via Footswitch

18

8

Pin Assignment

8.2

XS1: External Start

8.3

XS1: Start via Promixity Switch

19

8

Pin Assignment

8.4

XS2: Digital Level Sensor Reservoir (Empty Signal)

8.5

XS2: Automatic Reservoir 97106 / 97108

20

9

Declaration of Conformity

This manual suits for next models

1

Table of contents

Languages:

Other Henkel Controllers manuals

Popular Controllers manuals by other brands

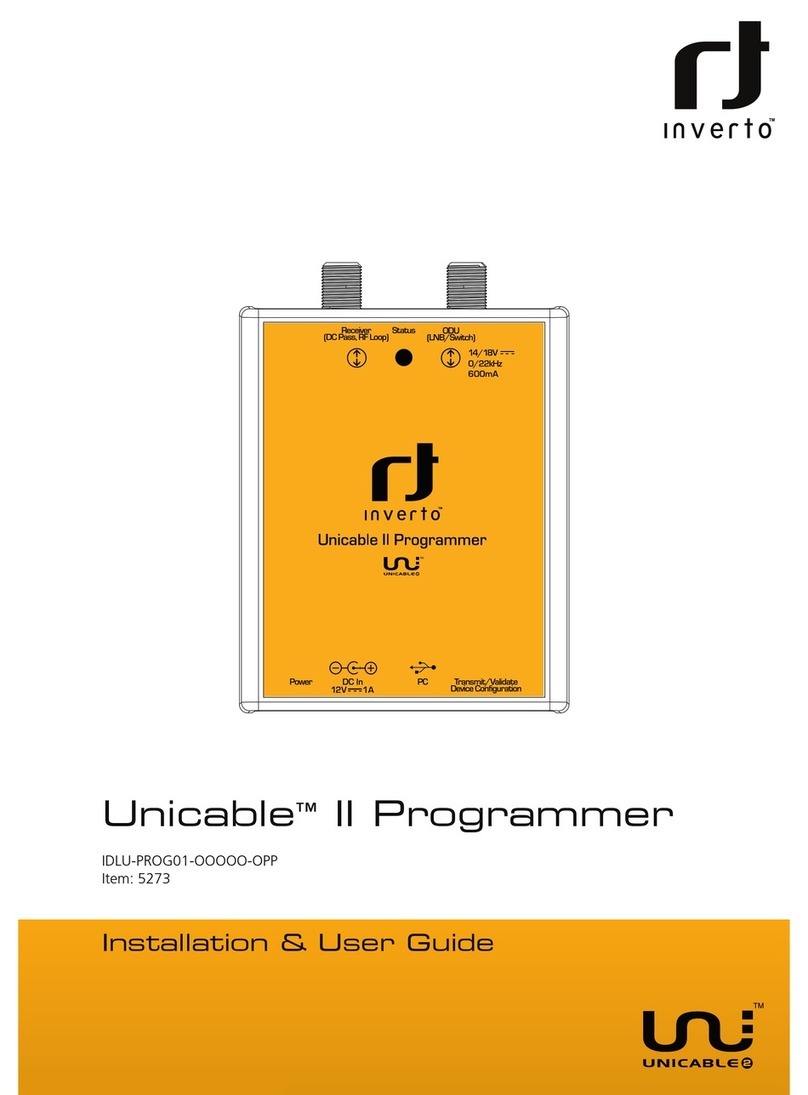

Inverto

Inverto Unicable II Installation & user guide

HydroStat

HydroStat 3200-Plus Installation instructions and operating manual

Pioneer

Pioneer DDJ-RB Service manual

Woodward

Woodward GCP-30 Series manual

Allen-Bradley

Allen-Bradley controllogix 1756-L61 Programming manual

TOPP

TOPP TOPP Installation and use instructions