Henkel Loctite EQ CL25 HP User manual

44

2

Contents

English.............................................................................................................2 - 43

Deutsch........................................................................................................44 - 85

1

Please observe the following...........................................................................4

1.1

Emphasized sections...................................................................................................4

1.2

Items supplied..............................................................................................................5

1.3

Risk Group Measurement............................................................................................6

1.4

For your safety.............................................................................................................6

1.5

General Instructions.....................................................................................................7

1.6

Special Instructions......................................................................................................8

1.7

Features ......................................................................................................................8

1.8

Field of Application (Intended Use)..............................................................................9

2

Description...........................................................................................................10

2.1

Displays, Operating Elements and Connections ........................................................10

2.2

Theory of Operation...................................................................................................13

2.3

Operation Modes .......................................................................................................13

2.3.1

Time Controlled Mode................................................................................................13

2.3.2

Continuous Mode.......................................................................................................13

3

Technical Data...................................................................................................14

4

Installation............................................................................................................15

4.1

Environmental and Operating Conditions...................................................................15

4.2

Connections...............................................................................................................15

5

Operation..............................................................................................................17

5.1

First Start-up..............................................................................................................17

5.2

Shut down..................................................................................................................17

5.3

Start-up......................................................................................................................17

5.4

Indication of several Displays.....................................................................................17

5.4.1

LEDs..........................................................................................................................17

5.4.2

START/STOP Indication............................................................................................17

5.5

Setup the System ......................................................................................................18

5.5.1

Making Adjustments...................................................................................................18

5.5.2

Default Settings .........................................................................................................18

5.5.3

Restore Default Settings............................................................................................18

5.5.4

Set UV Intensity Level and Curing Time.....................................................................19

5.5.4.1

Setting Irradiation Intensity.........................................................................................19

5.5.4.2

Setting Curing Time and Continuous Mode................................................................19

5.5.5

Display of Head Temperature and Lifetime Information .............................................20

5.5.5.1

Display of Head Temperature ....................................................................................20

5.5.5.2

Display of Lifetime Information...................................................................................20

5.5.5.3

Resetting head lifetime and cumulative irradiation time values ..................................20

5.5.5.4

Operating Panel Lock ................................................................................................20

5.5.6

Setting of UV Intensity Measurement/Calibration.......................................................21

3

Contents

5.7

Operating the System.................................................................................................22

5.7.1

Time Controlled Mode................................................................................................22

5.7.1.1

Requirements for the READY signal to be on.............................................................22

5.7.1.2

Irradiation start...........................................................................................................22

5.7.2

Continuous Mode.......................................................................................................24

5.7.2.1

Requirements for the READY signal to be on.............................................................24

5.7.2.2

Irradiation start...........................................................................................................24

5.7.3

Emergency Stop (Stop during irradiation)...................................................................25

5.8

External Control .........................................................................................................26

5.8.1

RS232........................................................................................................................26

5.8.2

PC..............................................................................................................................28

5.8.2.1

Connect the Unit to the PC.........................................................................................28

5.8.2.2

General......................................................................................................................28

5.8.2.3

Setup of the software .................................................................................................29

5.8.2.4

Set 97079...................................................................................................................31

5.8.2.5

Using the “TYPE Setting” screen................................................................................32

5.8.2.6

Using the “UV.CHK” screen........................................................................................33

6

Maintenance and Service...............................................................................34

7

7...............................................................................................................................34

7.1

Warning Displays .......................................................................................................34

7.1.1

Temperature Warning ................................................................................................34

7.1.2

Time Warning.............................................................................................................35

7.2

Error Messages..........................................................................................................35

7.3

Malfunction/Fault signal..............................................................................................36

8

Annex.....................................................................................................................37

8.1

Spare Parts................................................................................................................37

8.2

Pin Assignment..........................................................................................................38

8.2.1

Control Connector 12 pin (2x) ....................................................................................38

8.2.1.1

Control Connector INPUT...........................................................................................40

8.2.1.2

Control Connector OUTPUT.......................................................................................41

8.2.2

RS232........................................................................................................................42

8.3

Declaration of Conformity...........................................................................................43

4

1

Please observe the following

Before installing the system: For safe and successful operation of the unit, read these

instructions completely. If instructions are not observed, the manufacturer will not accept

any liability.

Be sure to keep the manual close at hand for further reference.

The WEEE symbol on this equipment indicates that this product may not be treated as

household waste. By ensuring this product is disposed of correctly you will help prevent

potential negative consequences for the environment. For more information about where

you can drop off your waste equipment for recycling, please contact your local city office

or your household waste disposal service.

1.1

Emphasized sections

Warning!

Refers to safety regulations and requires safety measures that protect the equipment

operator or other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property shall not be

damaged.

☞

Note!

Gives recommendations for better handling of the unit during operation or adjustment as

well as for service activities.

The numbers printed in bold in the text refer to the corresponding item numbers in the

illustration on pages 10-12.

●The point emphasizes an instruction step.

–The dash emphasises a list.

Numerations are indicated by bold letters and refer to the operating elements

at section 2.1.

Displayed terms and names of LED displays are indicated by italic letters.

All others by CAPITAL letters, except the term LED itself.

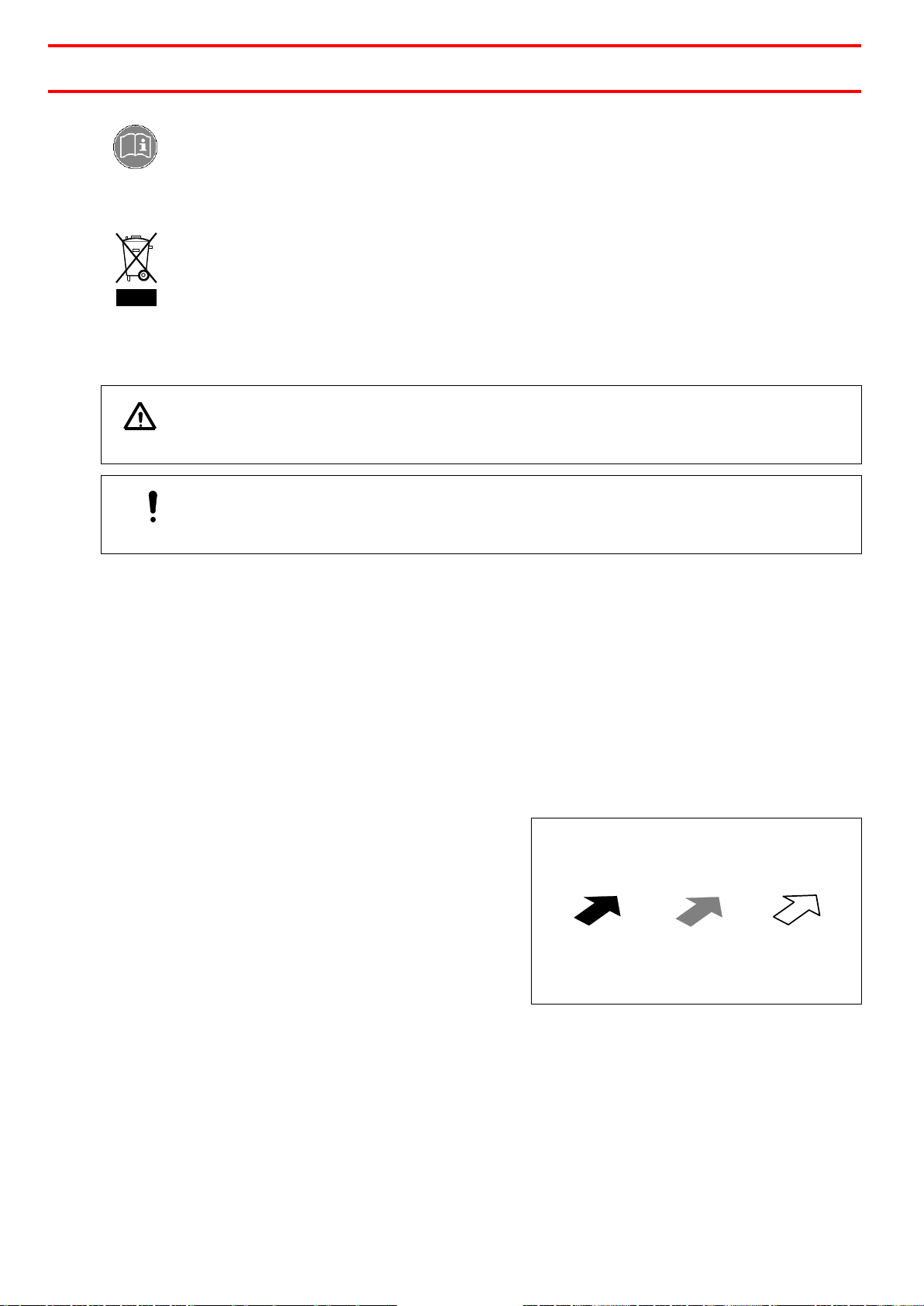

Instruction steps in the illustrations are

indicated with arrows.

Where several instruction steps are

indicated in an illustration, the colour

coding of the arrow has the following

meaning:

Black arrow = 1st step

Grey arrow = 2nd step

White arrow = 3rd step

5

1

Please observe the following

1.2

Items supplied

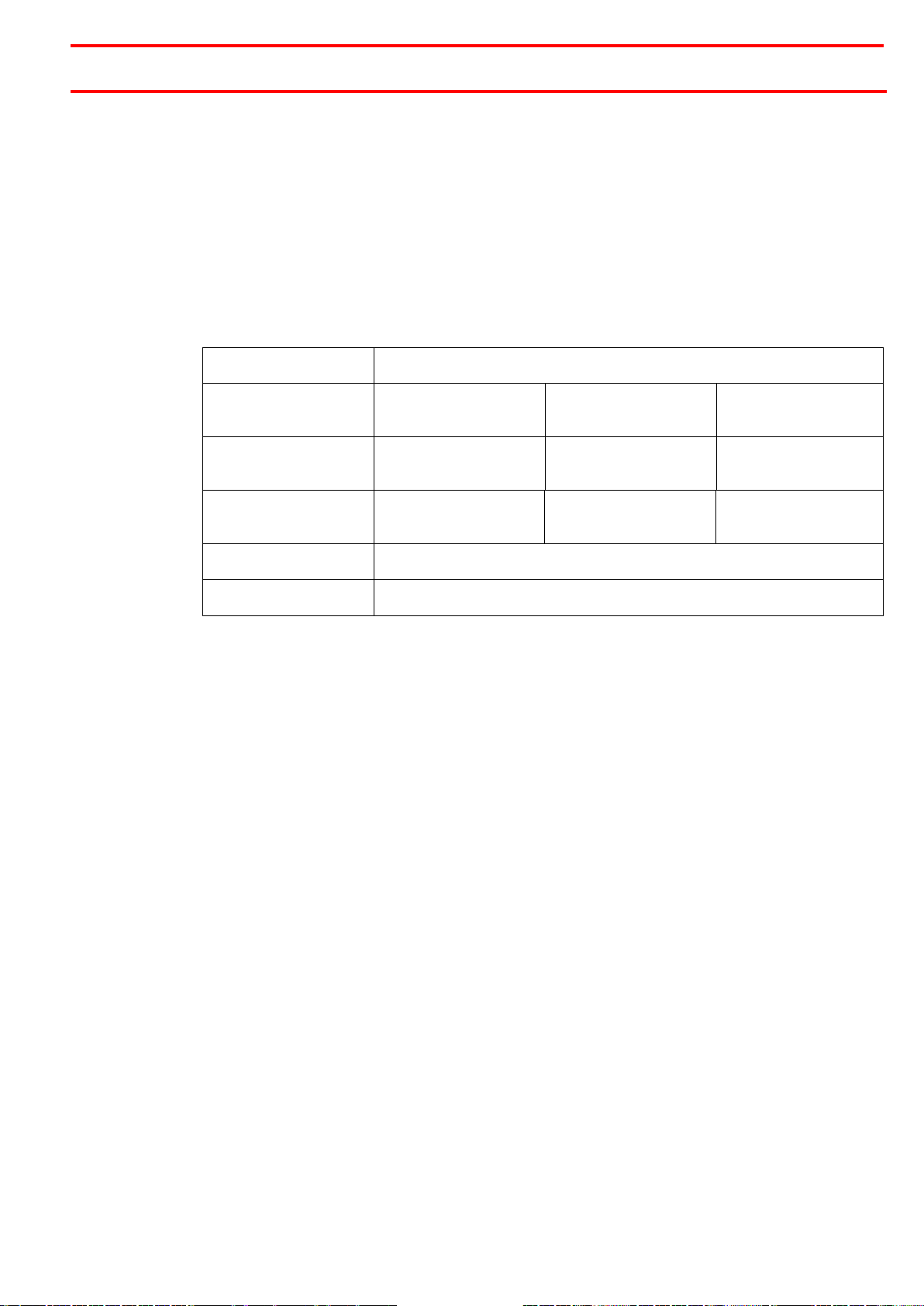

–1 pc. EQ CL25 HP LED Spot Cure Controller, former 97079, item no. 1786127,

including

–1 AC adapter 100-240 VAC

–Adapter Cord to connect Footswitch 97201

–Operating Manual

–Software on CD

–Connection cord to PC

The following parts have to be ordered separately:

Controller

EQ CL HP LED Spot Cure Controller, item no. 1786127

Lenses

3 mm

item no. 1305335

6 mm

item no. 1305333

10 mm

item no. 1305332

Connection Cords

Length 1.7 m

item no. 1305339

Length 3 m

item no. 1984961

Length 10 m

item no. 1305337

LED Heads

365 nm, short

item no. 1984957

365 nm, long

item no. 1984949

405 nm, long

item no. 2014788

Foot Switch

Item no. 88653

UV Meter

Item no. 1523721

☞

Note

As a result of technical development, the illustrations and descriptions in this operating

manual may deviate in detail from the actual unit delivered.

1.3

Risk Group Measurement

Measurement regarding the DIN EN 62471:2009-03; VDE 0837-471:2009-03 resulted in

the following risk groups:

–Lens, Diameter 3 mm RG1

–Lens, Diameter 6 mm RG3

–Lens, Diameter 10 mm RG3

–w/o Lens RG1

6

1

Please observe the following

1.4

For your safety

Please refer also to the relevant Technical Data Sheet for the adhesive to be processed.

Download from www.loctite-equipment.com or request the Technical Data Sheet and the

Safety Data Sheet (acc. to EC Directive 91/155/EC):

Henkel AG & Co. KGaA

+49 89 92 68 11 67 for the English language version of the data sheet;

089 92 68 11 22 for the German language version of the data sheet.

INSTRUCTIONS given in these data sheets must be followed scrupulously at all

times!

While under warranty, the unit may be repaired only by an authorized Henkel service

representative.

Warning!

Follow the manufacturer's instructions! Request a Safety Data Sheet for the Loctite®

product to be processed!

Controlling or calibrating this product by other than the procedures stipulated here could

cause exposure to dangerous LED radiation.

Damage to the power cord, the housing or the power adapter can result in contact with

live electrical parts.

Check the power cord and the unit before each use.

Never operate the system if the power supply unit / power cord is damaged! Replace a

damaged power supply unit / power cord with a new one.

Do not look directly at LED-UV light, or at LED-UV light reflected in a mirror or other reflective

surface. Doing so could cause eye damage.

Install the LED head in a way that humans are not exposed to LED-UV light.

Exposure could injure the skin or eyes.

Always turn off the key switch, before cleaning the LED head.

Cleaning the head while the switch is on could cause eye damage or injury to the skin.

Never disassemble this product. Disassembling this product could cause exposure to LED-

UV light, causing eye damage or injury to the skin.

If there is a risk of the LED-UV light being exposed to UV reflective light, place the product

inside a cover with proper reflectance and heat characteristics to block that reflected light.

When operating the controller, set up the system so that the path of the LED-UV light is not

at eye level.

It is strongly recommended to place a protective barrier around the product so that people

cannot approach it while it is operating.

Wear protective UV glasses and other protective clothing during operation.

Never operate this product in a manner not described in this manual. Doing so risks

exposure to LED-UV light.

Do not use any input power supply outside the specified range.

Do not use this product in a place where a large vibration or impact can be applied.

Never disassemble, repair, or modify this product in any way other than specified in this

User Manual.

We cannot be held responsible for damage or injury of any kind because of failure to

observe the instructions in this Operating Manual.

7

1

Please observe the following

1.5

General Instructions

–Do not connect this product to any power supply outside the power supply voltage and

frequency range indicated on the main unit and in this User’s Manual. Otherwise, this

product may be damaged.

–Do not place anything on the controller or block the air vents around this product to

prevent the occurrence of burns due to overheating.

–When handling the LED head, do not touch the lens or LED with bare hands. If a

foreign substance adheres to the lens or LED, it can cause the UV intensity to

decrease and the curing performance to degrade. If contaminations are applied to the

lens or LED, wipe it clean with alcohol and a lint-free cloth.

–Be careful not to drop or apply shock to the LED head. Doing so may damage this

product.

–Do not repeatedly bend the connection cables of the LED head, as this may result in

breakage. If any part of the LED head is broken, the whole LED head must be

replaced.

–Set the rubber feet of this product on a flat horizontal surface. Do not tilt this product or

put it on its side or upside down during use. The product may overheat and be

damaged.

–Do not use any other cable than the supplied connection cable to connect the LED

head to the controller.

–Ensure that the connection cable approx. 80 mm from the connector is kept free from

flexing stress and the joint between the connector and the cable is kept free from

tension. Otherwise, the cable may be broken.

–If the connection cable is longer than 2 m, or if the product is installed inside a larger

equipment, set up a display near the LED head so that the “LED radiation warning” can

be seen immediately. If you use OUTPUT terminals “+5V” (23) and “COM” (24) at the

rear of the controller, these will output a signal when the power is switched ON.

–Never connect any LED head, connection cable, AC adapter, or UV sensor to the main

unit, other than those designated by Henkel. Otherwise, any failure, loss, or damage

that may occur will not be covered under warranty.

–Never try to disassemble or modify the product, or to alter its internal settings. Any

failure or damage that occurs after disassembling or modifying the product will not be

covered under warranty.

Explanation of the Label

UV radiation hazard

warning!

To protect your

eyes, wear UV

safety glasses!

Exposure could

injure the skin or

cause other injury!

Do not operate the

unit before reading

the Operating Manual!

For actions to be taken or avoided, see section 1.3 For Your Safety.

8

1

Please observe the following

When using more than 1 Unit

When using more than one controller, do

not bundle the supplied AC adapters

together. The AC adapters may overheat

and damage the products.

Ventilation

Cooling air is drawn through ventilation slots in the side panels of the controller. Do not

obstruct any of these air vents to make sure that ventilation air circulates throughout the

system. Obstruction of these openings will cause the unit to overheat.

Explosive Zones / Earthquake Zones

This unit is not specified for operation in explosive zones.

If operated in earthquake zones, the unit must be securely fastened.

1.6

Special Instructions

How to handle the Lens

Any contamination which has not been removed, such as fingerprints on the glass, will

bake to the surface and result in premature deterioration of performance.

☞

Note!

Fingerprints can be removed with a lint free wipe and pure alcohol. Before reassembling

the lens into the unit the alcohol must have evaporated completely!

Repair and Servicing

Refer all repairs to an authorized Henkel service center.

1.7

Features

LED Lamp Life

Based on an average power-on time of 8 hours per day and normal service conditions,

the lamp has an expected service life of 20,000 hours (Total irradiation time before the

UV intensity becomes 70% of the initial value).

Power irradiation

High-power irradiation 8,000 mW/cm2is standard when a 3 mm lens is used. It is

measured with a UV dosimeter type 98787, oder no. 1390323. Usually the unit is

purchased with a 6 mm lens.

UV curing without temperature increases

A single 365-nm LED UV light source is used, which does not include infrared radiation.

This eliminates the risk of heat damage to the workpiece.

Stable UV intensity

UV intensity is kept constant, even if the ambient or LED temperature changes.

9

1

Please observe the following

Use in a Clean Room

No cooling fan construction allows the use in a clean room. There is no need to deal with

exhaust. No ozon is generated.

Programmable UV irradiation with four individually controlled heads

Each LED head can be independently controlled by one controller. The heads can also

be controlled all together or in combination. Up to 7 different operation programs can be

stored for each channel (LED head), including one program for the constant intensity

irradiation and 7 programs composed of up to 10 steps each. Each channel can be

started separately. To setup such programs it is necessary to use the software and a PC.

The start of each program is possible only with an external start signal.

Program Examples

Operation Mode for each LED head with a start via button START/STOP or connected

footswitch:

Up to 7 individual programs can be set via PC, see section 5.8.2:

1.8

Field of Application (Intended Use)

The LED Spot Cure System is a specially developed high power radiation system for

curing Loctite UV adhesives and coatings with UVA radiation.

It can be used for manual workstations as well as for integration into automatic

production lines.

10

2

Description

2.1

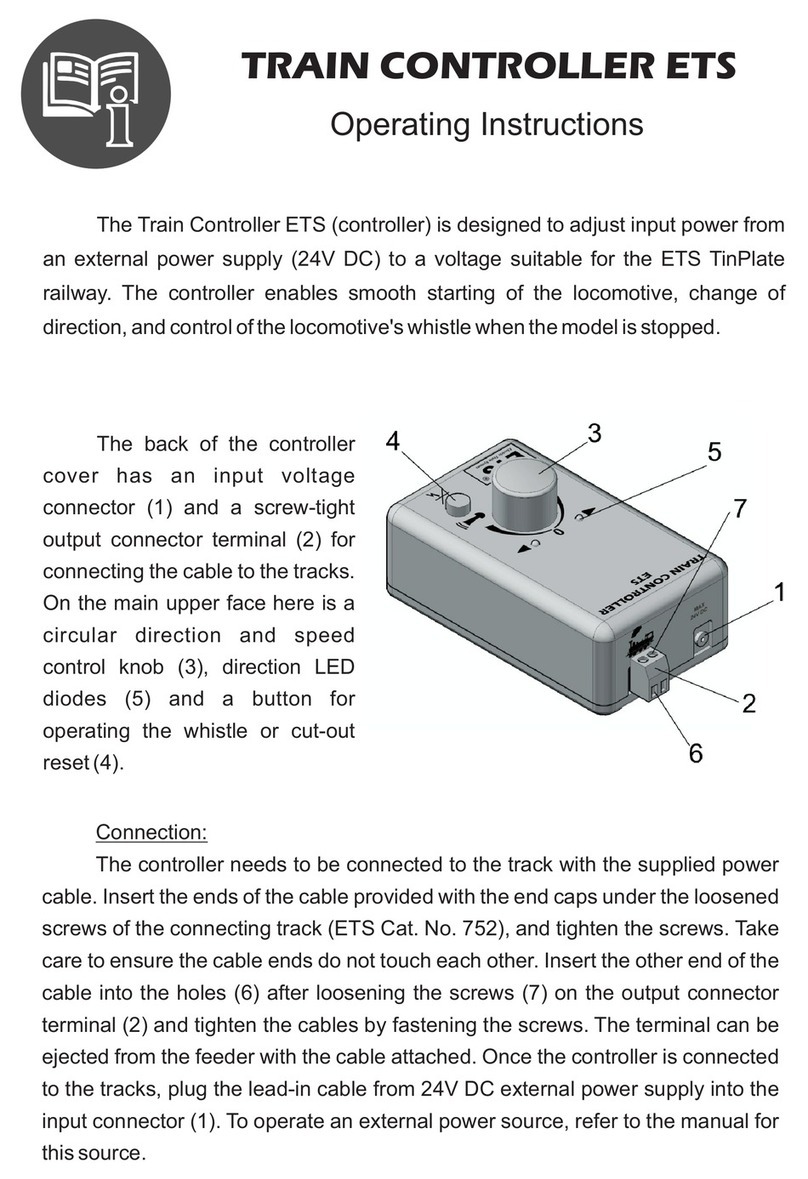

Displays, operating elements and connections

1

Button START/STOP

In AUTO mode pressing this key starts a curing cycle. Pressing during a curing

cycle aborts it. Pressing in MANU mode starts the curing cycle and stopped with

pressing a second time.

2

Ready indicator

Indicates that irradiation is ready to start.

Stays on while irradiation is ready to start.

Stays off during irradiation.

3

Display red (3 digits)

4

Indicator for

Irradiation time in sec. (Con, 0.00-999 sec.)

LED head temperature (0-999 TEMP)

Cumulative LED life time (0-999 × 100 hrs)

Error codes (E00~E99)

UV intensity measurement (0.00-49.9 W/cm2)

5

Buttons LED Channel 1 - 4

To preselect the required channel.

6

LED indicator Channel 1 –Channel 4

Indicates CH selection and active CH during irradiation. Also indicates

temperature warnings and errors. The “CH” indicators flash during irradiation:

Green: During selection

Orange: Temperature warning or error

Red: During irradiation.

7

Key operated I/O switch

The controller unit of this product is put on or off via this key switch. Ensure that

the key is removed while this product is not in use.

8

UV sensor connection port

The optional UV sensor can be connected here.

9

Button UV Monitoring

Press button to start UV monitoring. The UV meter has to be connected.

11

2

Description

10

Button PLUS

To increase the setting values.

11

Button MINUS

To decrease the setting values.

12

Key lock indicator

Settings are locked (no changes can be made).

13

Button SET/ENTER

When pressed for more then 3 sec, switches to the setting mode.

When pressed in setting mode, saves the accepted settings in memory.

14

Button MODE/ESC

When pressed,

–switches between the different settings and modes.

–leaves the menu without storing the adjusted values.

15

Indicator for Intensity level in %

16

Display green (3 digits)

UV intensity modulation (0-100%)

12

2

Description

17

LED connection cable ports

for channels 1 - 4

18

Input terminal

(Pin Nos. 1 to 12), see section 8.2.1.1.

19

Output terminal

(Pin Nos. 13 to 24), see section 8.2.1.2.

20

Connection RS232C

Serial interface for connection of a programmable logical controller (PLC) or a PC

for programming.

Connect via null modem cable, but pins 7 and 8 must not be assigned. Observe

the serial interface protocol: 9600 baud/1stop bit/no parity/8 data bits.

21

Connector

for the supplied AC adapter (6 VDC)

22

Interlock line

(Pin Nos. 11 and 12)

UV radiation can be stopped by opening INPUT terminal “EMER” on the rear of

the controller. It is shorted with a shorting bar as a factory default. It can be

replaced by a connection of an emergency stop switch.

13

2

Description

2.2

Theory of Operation

The radiation cycle can be initiated with the button “START/STOP” in the front panel,

with a footswitch (sold separately), via PLC connection with an external start signal and

also via a PC connection.

Each channel can be started separately or all simultaneously.

The UV LED Curing System EQ CL25 High Power LED Spot Cure offers the possibility

of programming of each channel with 7 programmes each containing up to 10 steps only

via PC connection.

Within the programmes the value of intensity and time can be adjusted and changed for

each step.

This can be done only via a PC (RS232).

For the possibility to check the irradiation output of the LED head an optional UV power

meter is necessary. The power meter has to be ordered separately.

The intensity of each LED head can be calibrated and monitored. If the level is below of

an adjusted value an error message is available at the output interface. It is also

displayed on the controller.

2.3

Operation Modes

2.3.1

Time Controlled Mode

In this mode the unit can be started easily with setting curing time and intensity only

2.3.2

Continuous Mode

With this curing mode the irradiation can be started with the button START/STOP 1and

stoppes by pressing the button START/STOP 1again. The channels are started

simultaneously.

14

3

Technical Data

Power supply (external adapter)

100 to 240 V AC (10%), 50/60 Hz

Power consumption

60 VA

LED head

Max. output: 660 mW; Wavelength:365 ±5 nm;

LED risk group 3

Estimated LED life time

20,000 hours (LED head temp. at +60ºC, max)

Irradiation Intensity (mW/cm2)

(100% power) w/ 3 mm lens

up to 8000 mW/cm2

Connectable LED Heads

1-4

Connectable UV sensor

1

UV irradiation

One program for Simple Mode and up to 7 user-

definable programs (up to 10 steps each)

Display

Large colour-switching seven-segment LED

display

Storage temperature

-10°C to +60°C (+14°F to +140°F), dry/dust-free

Operating temperature Controller

Operating temperature LED Head

0°C to +35°C (+32°F to +95°F)

+5°C to +35°C (+41°F to +95°F)

Relative humidity

85% RH or lower (with no condensation)

Dimensions Controller (WxHxD)

80 mm x 127 mm x 140 mm (3.15“ x 5“ x 5.5“)

Dimensions LED Head w/ Cable

OD 12 mm x 50 mm, cable length 200 mm

(OD 0.472“ x 2“, cable length 7.9“)

Weight Controller

Weight LED Head w/ 1.7 m cable

1.3 kg

0.125 kg

Dimensions

15

4

Installation

4.1

Environmental and operating conditions

–Relative humidity: Not more than 85% RH, with no condensation.

–Make sure the rubber legs are set horizontally parallel.

–In order to avoid damage due to overheating, do not use if the area around the system

is blocked.

–The minimum allowable bending radius for the LED head cord is 33 mm. Using the cord

with a curve radius of less than 33 mm could cause damage to the cable.

–Do not place items on top of the main unit, or block its air vents.

–Excessive heat could damage the unit due to overheating.

–The equipment should be installed in a dry, dust-free place.

4.2

Connections

Connect the LED Head

Connect the AC Adapter

Caution!

When using more than one controller, do not bundle the supplied AC adapters together.

The AC adapters may overheat and damage the units.

16

4

Installation

Connect the external Signal Plug

Further information see Section 8.2.1

Connect the optional UV sensor

17

5

Operation

5.1

First Start-up

●Insert the key into the I/O switch 7.

●Set key operated I/O switch to I.

When the power is turned on a beep will

sound and the display will indicate startup

status. The display will then change to

operation mode (under the default

setting).

5.2

Shut down

●Set key operated I/O switch to 0.

5.3

Start-up

●Set key operated I/O switch to I.

The program finally adjusted is active again.

5.4

Indication of several Displays

5.4.1

LEDs

LED lights:

LED flashes:

READY LED

–Lit blue to indicate that

irradiation is ready to

start.

–Stays on while irradiation

is ready to start.

–Stays off during

irradiation.

Channel

LED

CH1- CH4

–Flashes green when

displaying the data of

chosen channel

–Flashes green to show a

connected LED head and

during selection

–Flashes red during

irradiation

–Orange flashing: Indicates

a temperature warning of

the LED head.

5.4.2

START/STOP Indication

The button START/STOP 1lit red and stays on during irradiation.

18

5

Operation

5.5

Setup the System

It will always be necessary to follow all steps. The sequence of steps should be followed.

Each programming step must be confirmed and saved by pushing the button

SET/ENTER 13. For setting up the system.

●For setting up the system press button SET/ENTER 13 for more then 2 sec.

5.5.1

Making Adjustments

Adjust the required value with buttons PLUS 10 and MINUS 11 and set the channels by

pressing the corresponding channel key.

If the adjustment is not confirmed or stored by pressing button SET/ENTER 13 the

display switches back to the setting before.

5.5.2

Default Settings

The default values are Celsius (°C) for temperature display, READY, and buzzer ON.

●To adjust the default settings press down

the button MODE/ESC 14 and

simultaneously switch power to I. Hold

the button till the startup display “1” and

“C” is shown.

●Use buttons PLUS 10 or MINUS 11 to

switch between °C (Celsius) and °F

(Fahrenheit).

●Press the button SET/ENTER 13. “2” and

“b” will be displayed.

●Use buttons PLUS 10 or MINUS 11 to

switch between A=READY and b=BUSY.

When using the unit in connection with a

higher ranking controller it is

recommended to set “A =READY”. At the

output terminals 14-17 a READY signal is

available, see section 8.2.1.

●Press the button SET/ENTER 13. “3” and “On” will be displayed.

●Use buttons PLUS 10 or MINUS 11 to switch between buzzer ON and OFF.

●Press the button SET/ENTER. The 1st display will be displayed.

●Hold down the button SET/ENTER to switch to operation mode and store the settings.

5.5.3

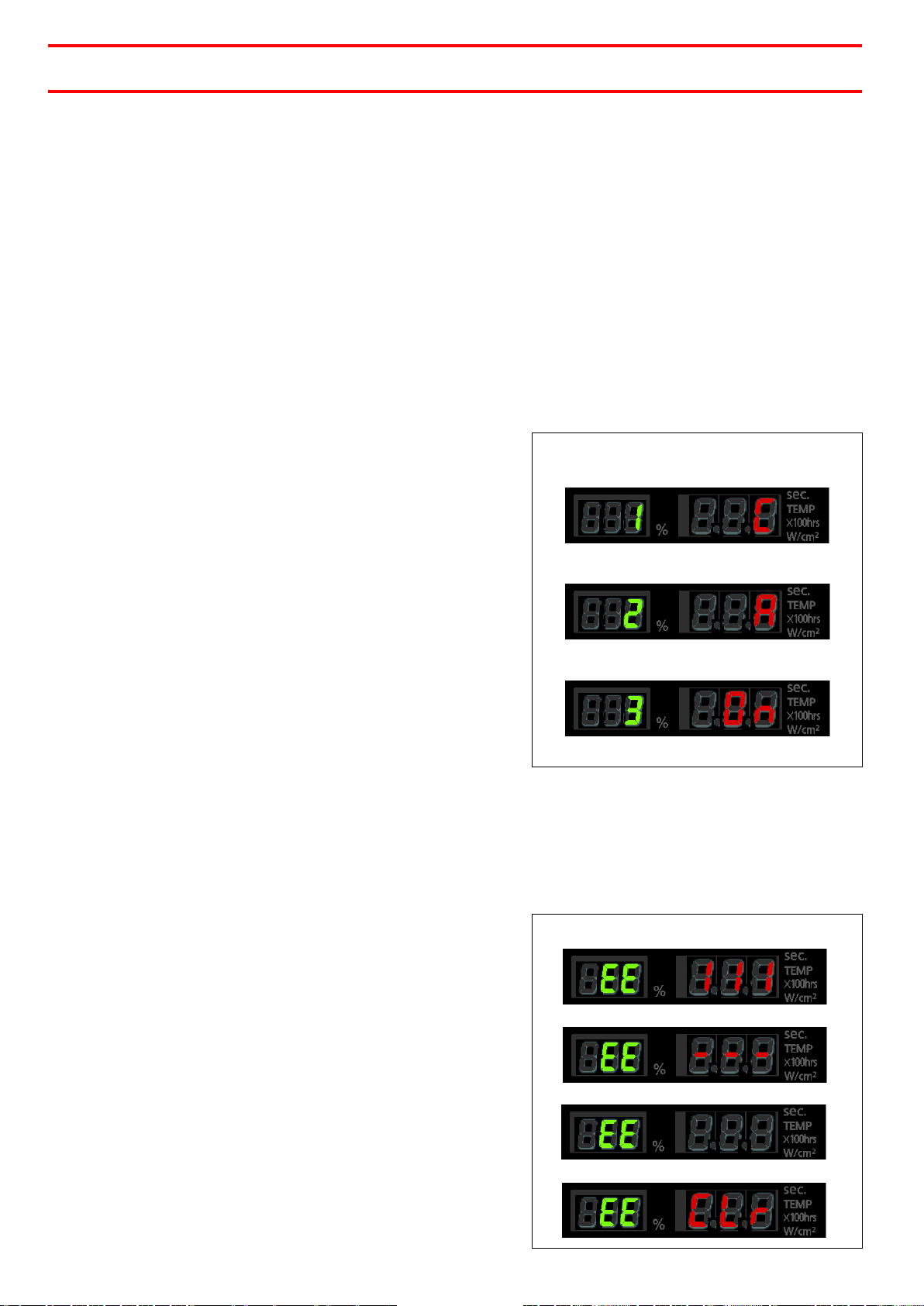

Restore Default Settings

All settings are restored to their initial default values.

●To adjust the default settings press down

the button MODE/ESC 14 and

simultaneously switch power to I. Hold

the button till the startup display “1” and

“C” is shown.

●While in default settings mode, press the

button MODE/ESC 14 till “EE III” will be

displayed.

●Hold down buttons PLUS 10 and MINUS

11 simultaneously till “EE ---“will be

displayed

●Hold down button SET/ENTER 13 as

long till “EE” is displayed.

When “EE CLr” appears all settings

have been restored to their original default

values (factory settings) and the controller

returns to operation mode.

19

5

Operation

5.5.4

Set UV Intensity Level and Curing Time

Set the irradiation intensity and curing time separately for each of CH1 to CH4.

☞

Note!

The displayed values apply to the selected and flashing channel.

●Select the channel to be set by pressing

buttons CH1 to CH4. The selected

channel is indicated by a green light

(flashing

or still).

It is not possible to select a curing channel

unless a LED head is connected to it.

5.5.4.1

Setting Irradiation Intensity

●Hold down the button SET/ENTER 13 to

select the CH to be set. (The selected

channel is indicated by a green light.)

Initially, only “%” (intensity) appears in

the green display.

●Use buttons PLUS 10 or MINUS 11 to

set the desired intensity value.

●Press button SET/ENTER 13 again to

confirm.

☞

Note!

While setting the irradiation intensity you can press the button START/STOP 1to start

UV irradiation. This makes it easy to make adjustments.

5.5.4.2

Setting Curing Time and Continuous Mode

●When you have finished setting the

intensity, the green display will

automatically display only “sec.”

●Use buttons PLUS 10 or MINUS 11 to

set the desired time value.

●Press the button SET/ENTER 13 again

to confirm.

●If you use button MINUS 11 to decrease

the setting below “0.0 sec” the display

will show “Con.” At this setting irradiation

will be continuous with no time limit.

20

5

Operation

5.5.5

Display of Head Temperature and Lifetime Information

5.5.5.1

Display of Head Temperature

●With the display showing irradiation

information, press the button

MODE/ESC 14.

●The head temperature is displayed.

●Press the Channel buttons to switch to

other channels.

5.5.5.2

Display of Lifetime Information

●With the display showing head

temperature, press the button

MODE/ESC 14.

The display shows the lifetime setting

(green) and cumulative irradiation time

(red).

●Press the Channel button to switch to

other channels.

●Press the button MODE/ESC 14 to return

to display of irradiation information.

5.5.5.3

Resetting head lifetime and cumulative irradiation time values

●With the display showing the lifetime

setting (green) and cumulative

irradiation time (red), hold down the

SET/ENTER 13 switch.

The lifetime setting (green) will be

displayed.

●Use buttons PLUS 10 or MINUS 11 to

change the lifetime setting.

●Press the SET/ENTER 13 switch.

●The cumulative irradiation time is

displayed (red).

●Hold down buttons PLUS 10 or

MINUS 11 simultaneously to reset the value to 0.

●Press the CH button to switch to other channels.●Press the button MODE/ESC 14 to

return to display of irradiation information.

●To cancel a change, press the button MOD/ESC 14. The display will return to showing

irradiation information, and the change will be lost from memory.

5.5.5.4

Operating Panel Lock

This is a way to safeguard the system

against unauthorised manipulation.

●In operation mode, hold down buttons

PLUS 10 or MINUS 11 simultaneously.

The settings will become locked and the

“LOCK” indicator will light up.

●To unlock the settings; hold down

buttons PLUS 10 or MINUS 11 again.

This manual suits for next models

1

Table of contents

Languages:

Other Henkel Controllers manuals

Popular Controllers manuals by other brands

Western Digital

Western Digital Ultrastar A2U24-S user guide

LEHMANN

LEHMANN Primary Controller operating instructions

YASKAWA

YASKAWA Lift Inverter L1000V Technical manual

ETS

ETS Train Controller ETS operating instructions

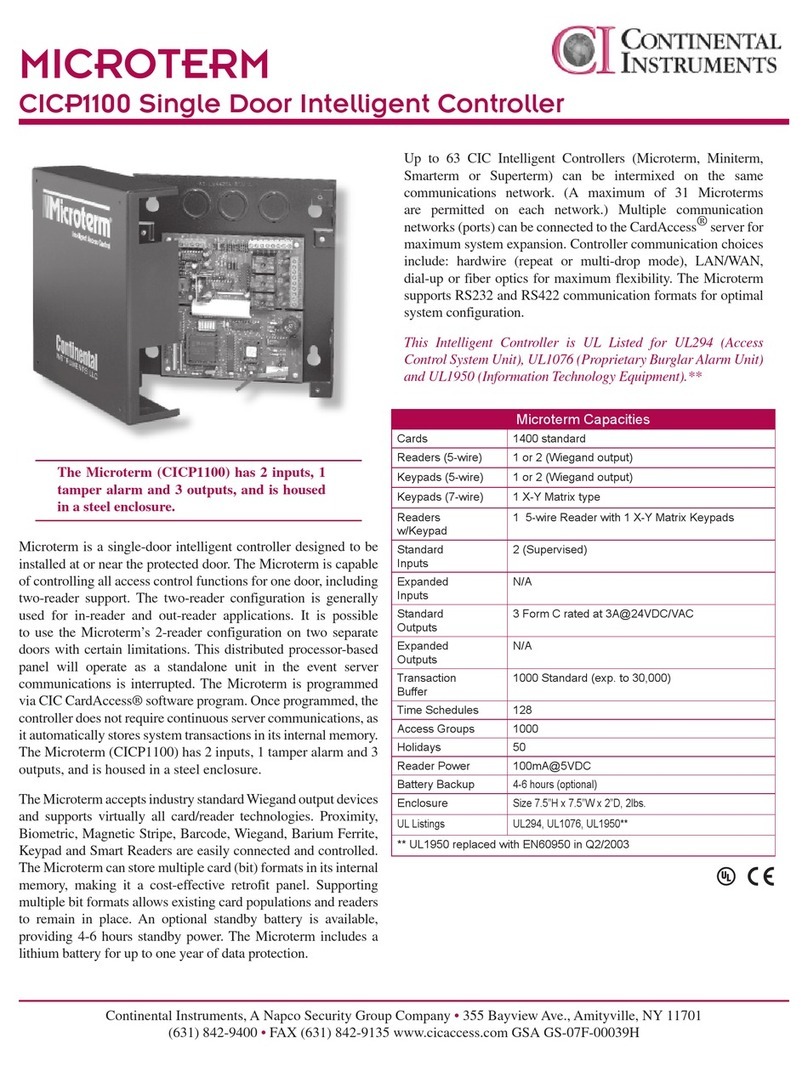

Continental Instruments

Continental Instruments CICP1100 datasheet

HP

HP Surestore Disk Array 12h - And FC60 installation guide