Henkovac COMPACT ECO Series User manual

Art. no. 96.06.5.0705/05.07

User manual

COMPACT ECO-RANGE

Manufactured by:

Het Sterrenbeeld 36, 5215 ML ‘s-Hertogenbosch The Netherlands

P.O.Box 2261, 5202 CG ’s-Hertogenbosch The Netherlands

tel: +31(0)73-6271271, fax: +31(0)73-6271200

II User manual Compact Eco-range

2007 HFE vacuum systems b.v.

All rights reserved.

No part of this document may be reproduced and/or published by means of printing, photocopy, microfilm or any other method, without

the prior written permission of the manufacturer. This also applies for the accompanying illustrations and/or diagrams and schematics.

The information in this document is based on the general data associated with the construction, material qualities and working methods,

known at the moment of publication, so that we reserve the right to make changes without giving prior notice.

This document is applicable to the indicated models of the Henkovac packing machine in the version supplied. The manufacturer

therefore does accept any liability for any form of damage or injury resulting from deviating from the specifications of these machines as

supplied to you.

All possible care was taken when creating this document, but the manufacturer accepts no liability for mistakes or any consequences

thereof.

TAKE THE TIME TO READ THIS DOCUMENT THOROUGHLY TO ACQUAINT YOU WITH THE CORRECT

AND APPROPRIATE USE OF THE HENKOVAC VACUUM PACKING MACHINES.

2007-05

Contents

User manual Compact Eco-range III

CONTENTS

SAFETY AND WARNING NOTICES ............................................................................................... 4

1

INSTALLATION ........................................................................................................................... 5

2

OPERATION ................................................................................................................................ 6

2.1

Warm up ............................................................................................................................................... 7

2.2

Vacuuming and Sealing........................................................................................................................ 7

2.2.1

Vacuuming.................................................................................................................................................. 7

2.2.2

Sealing ........................................................................................................................................................ 7

2.3

Packing ................................................................................................................................................. 7

3

MAINTENANCE........................................................................................................................... 8

3.1

Warnings............................................................................................................................................... 8

3.2

Clean Daily............................................................................................................................................ 8

3.3

Weekly maintenance ............................................................................................................................ 8

3.4

Monthly maintenance............................................................................................................................ 8

3.5

Annual maintenance ............................................................................................................................. 8

3.6

Oil.......................................................................................................................................................... 9

4

SEAL BAR ................................................................................................................................. 10

4.1

Replacing the sealing wire and Teflon tape........................................................................................ 10

4.2

Replacing the sealing wires ................................................................................................................ 11

4.3

Replacing the Teflon tape................................................................................................................... 11

4.4

Replacing the silicone in the counter bar............................................................................................ 11

4.5

Maintenance of the silicone gasket in the lid ...................................................................................... 11

4.6

Replacing silicone gasket in the lid..................................................................................................... 11

5

TECHNICAL DATA.................................................................................................................... 12

6

PROBLEMS AND SOLUTIONS ................................................................................................ 14

Safety and warning notices

4 User manual Compact Eco-range

SAFETY AND WARNING NOTICES

The manufacturer accepts no liability whatsoever for damage or injury caused by not (strictly) following the

safety directions and instructions in this manual, or carelessness during the installation, use, maintenance

and repair of the machines identified on the front of this document and any accompanying options.

The owner of the machine is responsible at all times for observing the locally applicable safety

regulations and guidelines.

Obey all safety instructions and guidelines as given in this manual.

Users manual

•Every user should be informed of the contents of this manual and follow the instructions in it carefully.

Management must train personnel on the basis of this manual and obey all directions and indications.

•Never change the order of the actions to be taken.

•Always keep the manual in the proximity of the machine.

•This manual is intended as a reference for users and technicians, who can install, use and maintain the

machine(s) stated on the front of this document in a safe way.

Installation

User manual Compact Eco-range 5

1 INSTALLATION

The vacuum machines are solid and safe. For your own safety and optimal maintenance of the

machine, the following instructions must be obeyed.

•Make sure the machine is level and has been placed on a solid surface.

•To ensure easy access for maintenance and sufficient ventilation, the machine must not be closed

in and is easily accessed from all sides.

•Before connecting the machine to the mains make sure that the voltage stated on the specifications

plate is the same as that of the mains supply and that the connection is properly earthen.

•The standard machine must be connected to 230 Volt - 1 phase - 50 Hertz (depending on the

country).

•Check the oil level.

•The temperature in the workspace should not be lower than 10°C (or 50º F), as the oil in the

vacuum pump will thicken and prevent the smooth operation of the pump.

•Always remove the power plug from the socket during repair and maintenance work!!!

•Never clean the machine with a high-pressure cleaner. Water jets may penetrate and damage the

electronics.

•The machine must be switched of immediately in case of a damage in the gas springs. Contact

your dealer as soon as possible!!

•Always have a recognised HFE-dealer carry out maintenance and repairs.

•Don’t just start vacuuming sauces or other liquid products. When vacuuming sauces or soups, the

pressure in the vacuum chamber must be carefully monitored, because the boiling point of liquids

is lower as the vacuum percentage goes up. As soon as the boiling point has been reached, you

can see the gas bubbles in the product.

Operation

6 User manual Compact Eco-range

2 OPERATION

The Compact is a machine that functions automatically. When the filled vacuum pouch has been put in

the vacuum chamber and the lid is closed the operation will start automatically. The machine will

automatically follow the entered program from vacuuming to sealing. After the sealing has been

completed the vacuum pump will turn off, the chamber aerates and the lid will automatically open.

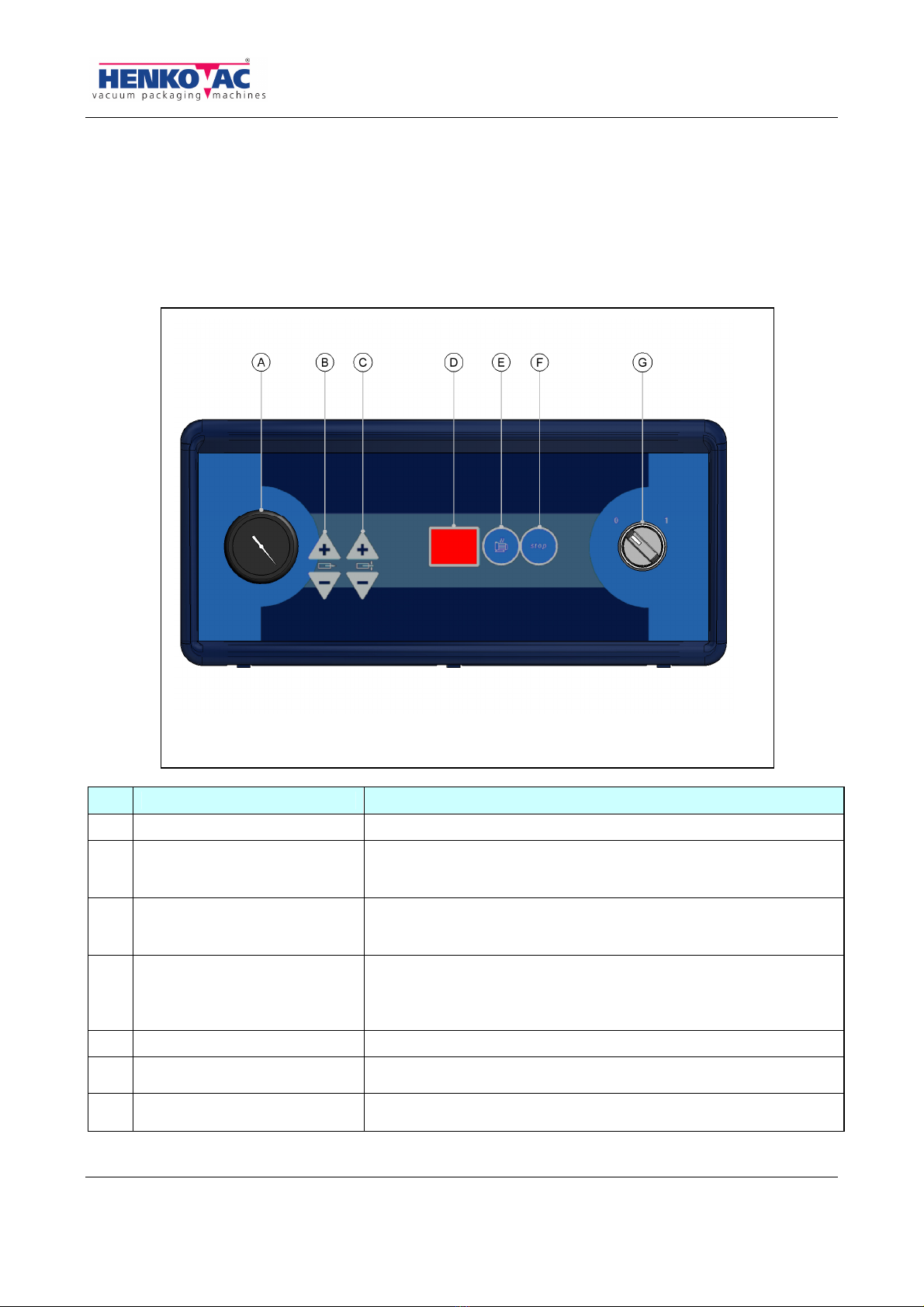

Pos

Description Function

A Vacuum gauge Indicates the reached vacuum in the chamber

B Buttons to adjust Vacuum time

•Press +to increase the vacuum time. Maximum = 99 sec.

•Press -to decrease the vacuum time. Minimum = 0 sec.

•Adjustable per 1 second

C Buttons to adjust Seal time

•Press +to increase the seal time. Maximum = 6,0 sec.

•Press -to decrease the seal time. Minimum = 0 sec.

•Adjustable per 0,1 second

D Display

•Shows ‘on’ in stand-by mode

•Shows ‘spinning’ zero when in warm-up mode

•Shows time left when vacuuming

•Shows time left when sealing

E Button to warm up pump Starts function to warm the pump

F STOP button If pressed at any time, this key stops the active function and

start the next function when necessary.

G Off / On switch •At position 0, turns the machine OFF.

•At position 1, turns the machine ON.

Fig. 2-1

Operation

User manual Compact Eco-range 7

2.1 Warm up

If the machine has been switched off for a period of time we recommend that the machine is “warmed

up”. The machine vacuums a certain time, aerates a short time and then starts vacuuming again.

These cycles will be repeated for certain times.

1. Turn on the machine with the Off/On switch (G) and press button (E). The display shows a

‘rolling’ or ‘spinning’ zero.

2. Close the lid. The machine now starts to vacuum and the display shows the number of cycles to

go.

3. After the last cycle the machine aerates totally, the lid opens and returns to the stand-by mode.

4. The machine is ready to use.

2.2 Vacuuming and Sealing

The vacuum chamber contains filler plates. When the vacuum pouches are filled, a number of the filler

plates must be removed so that the vacuum pouch lies directly on the sealing bar. The vacuum

pouches should never stick out of the machine!!

2.2.1 Vacuuming

Depending on the desired vacuum, the vacuum time can be set by pressing buttons (B).

With OPEN lid, press the + to increase or – to decrease the vacuum time. The range is between 0 and

99 seconds and adjustable per 1 second.

Only when vacuuming, the attained vacuum can be seen on the vacuum gauge (A). It is important that

the vacuum time for products with enclosed air is extended.

2.2.2 Sealing

Depending on the desired seal, the seal time can be set by pressing buttons (C).

With OPEN lid, press the + to increase or – to decrease the seal time. The range is between 0 and 6

seconds, and adjustable per 0.1 second.

If the sealing time is too long (scorching the bag), set to a lower value; if the sealing time is too short

(the sealed product easily opens), set to a higher value.

2.3 Packing

1. Turn on the machine with the Off/On switch (G).

2. The display shows ‘on’, to indicate that the machine is ready to use.

3. Put the vacuum bag with your product in it in the vacuum chamber.

4. Be sure that the open side of the bag lays smoothly over the seal bar but not OUTER the

chamber. The bag must be inside the chamber.

5. Close the lid. The machine now starts to run and the display shows the vacuum time to go.

6. After the reached vacuum time the machine begins to seal. The display shows the seal time to

go.

7. After sealing, the machine aerates automatically and the lid opens.

8. Check the quality of the package and adjust the vacuum or seal time if necessary before

continuing.

Maintenance

8 User manual Compact Eco-range

3 MAINTENANCE

Regular and thorough maintenance prevents breakdowns, prolongs the machine’s operational life and

guarantees optimum hygiene.

3.1 Warnings

•Always unplug the machine when carrying out maintenance or repairs.

•Never use high-pressure water to clean the machine as this can cause irreparable damage to the

machine and to the electronics.

•Use a wet cloth with a solution of soap for cleaning the machine. Clean the control panel with a dry

cloth.

•Never use chemicals to clean the machine.

•The gas springs may NOT show any damages. In this case to prevent accidents the gas springs

must be replaced.

•Switch off the machine in case of damage of the springs and contact your dealer.

3.2 Clean Daily

Vacuum chamber and insert plates

Clean the lid, insert plates, bottom and walls of the vacuum chamber with a damp cloth, pay particular

attention tot the silicon strip in the lid.

Do not clean the transparent lid with synthetic cleaning agent as this weakens the acrylic

material.

Warming up vacuum pump

In order to prevent oxidation in the pump, the vacuum pump must run for about 5 minutes after

cleaning, to allow the condensed water in the oil can evaporate. For this place the main switch on the

“warm up” stand.

3.3 Weekly maintenance

•Oil reservoir

Check the oil, add oil if necessary. Use the correct oil: you can buy this by your dealer. The

vacuum pump as well as the vacuum machine requires less maintenance. For the pump it is

important to check the oil and to replace it.

•Seal bars

Check the condition of the bars; replace if damaged.

•Rubber of the cover

Check the rubber; replace if damaged.

3.4 Monthly maintenance

•Oil

Check the condition of the oil.

Note: Replace the oil after 160 hours of operation. If the machine is not used frequently, change the

oil every 6 months.

3.5 Annual maintenance

•Vacuum hoses and pipes

Check the condition of the vacuum hoses and pipes and replace them if necessary.

•Silicone strip of the counter bar

Check the condition of the silicone strip of the counter bar and replace if necessary.

•Gas springs in the lid

Check the condition of the gas springs in the lid and replace them if necessary.

Maintenance

User manual Compact Eco-range 9

3.6 Oil

Check oil:

1 time a week. If necessary fill till the correct level.

Replace oil

By normal use after 160 running hours; by incidental use at least 1 time a year.

POS Description

A Cap

B Oil filler plug

C Oil gauge

D Oil drain plug

1. Drain the oil off only by a warm pump. (see Paragraph 2.1).

2. Switch the pump of and remove the power cable from the socket.

3. Use a tray for catching the oil.

4. Remove CAP (A)

5. Loosening the oil filler plug (B).

6. Loosening the oil drain plug (D).

7. Make sure the oil will completely flow away. Take time to let flow the oil completely. Wait at least 5

minutes before taking the next step.

8. Tighten the drain plug again.

9. Fill the oil with the correct quantity of oil.

10. Tighten the oil filler plug again.

11. Place the back the cap

Recommended oil: See Technical Data.

Fig. 3-1 COMPACT ECO MINI

Seal bar

10 User manual Compact Eco-range

4 SEAL BAR

•Clean the sealing and counter bars daily to ensure optimum sealing of the packaging material. Use

a dry cloth for this purpose.

•Check the condition of the sealing wires regularly. They should be free of kinks and should be

tightly strung on the sealing bar. For flawless operation the Teflon tape must be free of damage.

•If the sealing wires or the Teflon tape are damaged, replace them immediately.

•Check the counter bar. This is made of silicone which generally has a long operational life and

therefore does not need replacing often. However, if parts of the beam are scorched, replace the

silicone strip immediately.

•Ensure that spare sealing wires and Teflon tape are always kept in stock.

4.1 Replacing the seal wire and teflon tape

Removing of old materials

1. Remove the seal bars by pulling these up.

2. Remove the old teflon tape (5).

3. Unscrew the hexagon socket screws (4)

4. Check if the tightening springs (2 & 3) at the end of the bars are present. The tightening springs are

necessary to catch up the expansion of the wires during the heating process.

5. Remove the seal wire (6)

POS Description

1 Beam

2 Spring

3 Screw

4 Hexagon socket screw

5 Teflon tape

6 Seal wire

Fig. 4-1

Seal bar

User manual Compact Eco-range 11

4.2 Replacing the seal wire

1. Ensure that the two tension spring (2) and screw (3) assembly are in place in either end of the

seal bar.

2. Fold over 50mm of the end of the new seal wire (6), push this end into the slot (underneath the

seal bar) so that it extends beyond the (hole) position where the electrical pin contacts in the

chamber fit. Clamp this end of the wire into place with the hexagon socket screw (4).

3. Run the remaining length of the wire along the top of the bar, fold over the end and fit similarly at

this opposite end as the first, ensure that both screws (6) are tightly secured.

4.3 Replacing the Teflon tape

Remove the protective paper backing strip and stick the tape onto the bar

4.4 Replacing the silicone in the counter bar

Replacement of the rubber is done as follows:

1. Pull the rubber out of the counter beam.

2. Clean the groove.

3. Push a new rubber evenly into the groove. Make sure that it does not stick out at the ends of the

counter beam.

4.5 Maintenance of the silicone gasket in the lid

Clean the silicone gasket with a damp cloth. Never use synthetic cleaning agents. Treat the rubber

eventually with talcum powder in order to prevent that it will stick to the bar.

4.6 Replacing silicone gasket in the lid

Replacement of the cover rubber is done as follows:

1. Pull the cover rubber out of the groove

2. Clean the groove.

3. Push the new cover rubber evenly and without tension into the groove. Put the rubber ends tightly

against each other. This will prevent a leak, by which the chamber is not vacuuming very well.

Technical data

12 User manual Compact Eco-range

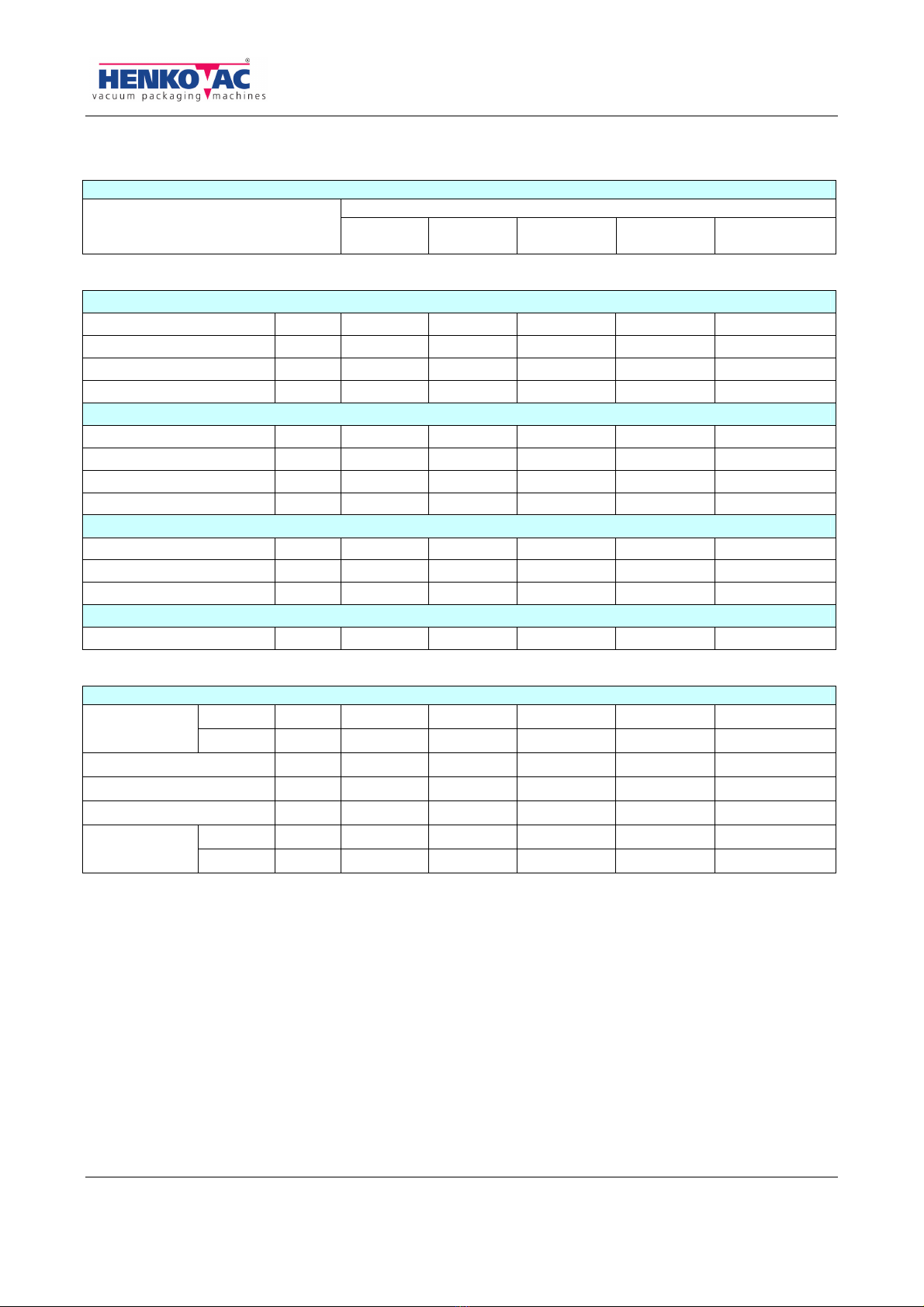

5 TECHNICAL DATA

Data per machine

COMPACTType

MINI ECO

MAXI ECO

Gastrovac

ECO

Gastrovac

PRO ECO

Size and weight of the machine

Height mm 310 310 475 480

Width mm 340 340 465 535

Depth mm 520 520 560 580

Weight Kg 30 40 55 65

Size and weight of the packed machine

Length mm 550 550 670 670

Width mm 470 470 670 710

Depth mm 670 670 660 660

Weight Kg 36 46 65 80

Size of the vacuum chamber

Length mm 365 365 385 420

Width mm 280 280 360 460

Depth mm 95 95 140 170

Sealing configuration Net sealing length

1 x sealing beam mm 270 270 320 420

Vacuum pump

50 Hz m³/h 4 8 16 16

Capacity 60 Hz m³/h 4.8 9.6 19 19

Final pressure mBar 15 2 2 2

Oil quantity Ltr 0,06 0,25 0,3 0,3

Weight vacuum pump Kg 5.1 10.3 18 18

50 Hz Db(A) 59 59 60 60

Noise 60 Hz Db(A) 59 59 64 64

Technical data

User manual Compact Eco-range 13

General data

Maximum leakage 1 mbar/s

Recommend oil Ambient temperature

VM 068 5 - 12º C

VM 100 12 - 30º C

VS 100 or VC 101 30 - 40º C

Electrical connections

Tension, power, frequency See the identification

Maximum permissible voltage variance - 10% to + 10%

Ambient conditions

Ambient temperature + 5 to + 30º C

Transportation temperature - 25 to + 55º C

Humidity 30 % to 95 % (without condensation)

Positioning Inside, level, free of walls, etc,

•Voltage data was not included in this summary because these are dependent on the electricity supply of

the country that the machine is intended for. The voltage data are given on the machine identification plate.

•The useful space in the vacuum chamber depends on the number of seal beam and their positioning. Each

beam lessens the useful space by about 50 mm.

•Sizes and weights are mentioned for standard machines.

Problems and solutions

14 User manual Compact Eco-range

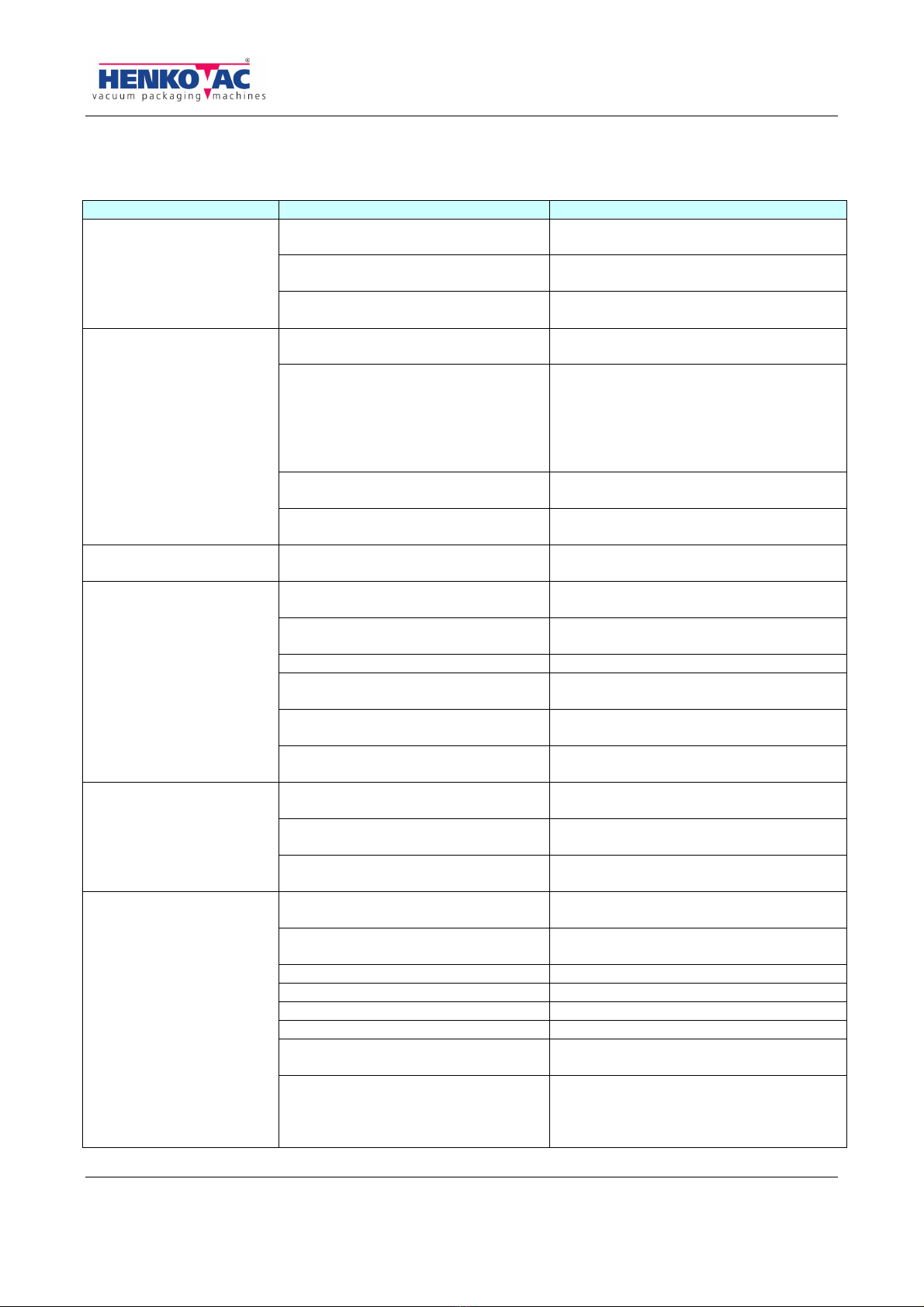

6 PROBLEMS AND SOLUTIONS

If the machine indicates a fault, use the following table to check whether you can solve the problem.

Problem Cause Solution

• The plug is not inserted in the

socket correctly.

• Push the plug into the socket correct.

• The On/Off switch is in the ‘OFF’

position.

• Put the switch in the ‘ON’ position.

Machine does not work.

• A fuse in the machine is ruptured. • Contact your authorized service

representative.

• The lid micro switch is damaged • Contact your authorized service

representative.

• The thermal safeguard has

switched the machine off due to

overheat.

• Check if the ventilation openings are

free from obstructions.

-Let the machine cool down and switch.

on again.

Contact your dealer if the machine will

be switched off again after a short time.

• A fuse could have ruptured.

• Contact your authorized service

representative

The machine does not

work, but the lights are on.

• There is an internal malfunction. • Contact your authorized service

representative.

The vacuum pump is not

functioning correctly.

• The oil is too thick, the temperature

is too low.

• Let the pump warm up. (see “Warm up”

procedure).

• The value entered for the vacuum

function is too low.

• Increase the value of the vacuum

function.

• There is not enough oil in the

pump.

Replenish the oil.

• The oil is dirty. • Change the oil.

• The suction filter is blocked. • Contact your authorized service

representative.

• The pump’s spray filter is blocked. • Contact your authorized service

representative.

There is insufficient

vacuum.

• The lid’s silicone gasket is

damaged.

• Replace the silicone gasket.

• The vacuum pouch is of inferior

quality.

• Select vacuum pouches of a better

quality.

• The product has damaged the

pouch.

• Use a new pouch.

Insufficient vacuum in the

bag.

• There is insufficient room between

the seal bar and the counter bar.

• Check the position of the sealing bar.

• The vacuum pouch is incorrectly

placed on the seal bar.

• Place the opening of the vacuum

pouch over the sealing bar correctly.

• The sealing time is not set

correctly.

• Adjust the sealing time value.

• There is a break in the seal wire. • Replace the seal wire.

• The seal bars are dirty. • Clean the seal bars.

• The Teflon tape is worn. • Replace the Teflon strip

• The counter bar is damaged. • Replace the silicon strip.

• The vacuum pouches are of

inferior quality.

• Select better quality vacuum pouches.

The vacuum pouch is

incorrectly sealed.

• The opening of the vacuum pouch

is contaminated.

• Remove any obstructions from the

opening of the pouch. Make sure the

opening of the package remains clean

while filling. or replace the bag.

CE

D

ECLARATION OF CONFORMANCE

(according to annex IIA of the machine guideline)

We, HFE vacuum systems B.V.

Het Sterrenbeeld 36, 5215 ML 's-Hertogenbosch

The Netherlands,

declare totally on our own responsibility that the products:

Henkovac Vacuum packing machines:

Compact MINI, Compact MAXI,

Compact Gastrovac and Compact Gastrovac Pro.

to which this declaration refers, comply with the following standards:

•EN 60204-1: 1997;

•EN 60335-1: 1994;

•EN 55014, EN 60555-2 and EN 60555-3;

•EN 55014-2 carried out using the values of the EN 50082-2

according to the determinations of:

•the machine guideline 89/392/EEG, amended by the guidelines 91/368/EEG, 93/44/EEG,

93/68/EEG;

•the low voltage guideline 73/23/EEC, amended by the guideline 93/68/EEG;

•the EMC-guideline 89/336/EEC, amended by the guidelines 92/31/EEG, 93/68/EEG.

A.P.J.M. van der Velden

Managing Director

The Netherlands, 's-Hertogenbosch, may 2007

This manual suits for next models

4

Table of contents

Other Henkovac Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Gaggia Milano

Gaggia Milano MAGENTA operating instructions

Tricity Bendix

Tricity Bendix SB411 Operating and installation instructions

KitchenAid

KitchenAid KSM45-KSM200 Series manual

Caple

Caple WI6141 instruction manual

Gallet

Gallet MAH 302 Dijon instruction manual

Univex

Univex 9512 MAX Series instruction manual

R.G.V.

R.G.V. Ausonia Smarty 170 instruction manual

ZANOLLI

ZANOLLI CITIZEN Series Installation, use and maintenance manual

Great Northern Popcorn

Great Northern Popcorn 6251 SS TWISTER STOVE TOP POPPER Assembly instructions

Speidel

Speidel 47014 operating instructions

Kaboodle

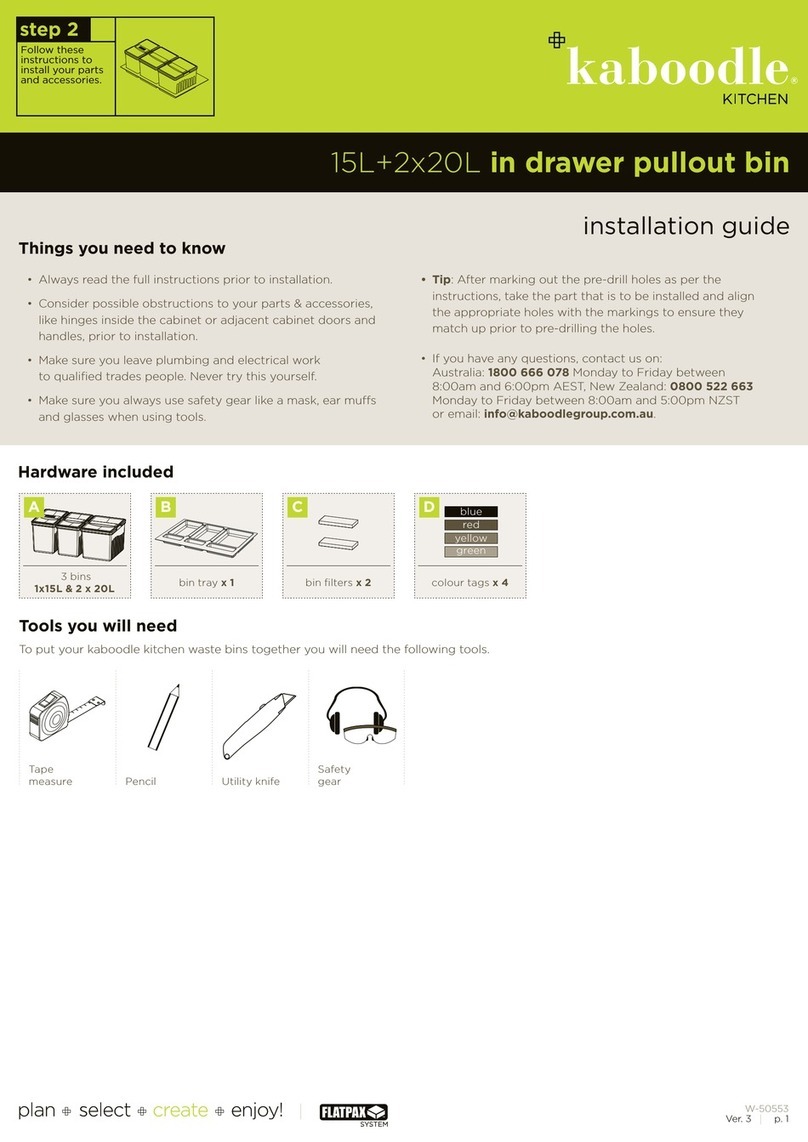

Kaboodle W-50553 installation guide

ACME

ACME BA200 user manual