Henry Schein PowerSpin 112-6907 User manual

PowerSpinLX Centrifuge

with Variable Speed and Timer

Item # 112-6907 with 6 place rotor

Item # 112-6909 with 6 place rotor

OPERATION MANUAL

Revision Date 2014/03

Distributed by (in US only):

(manufacturer)

HENRY SCHEIN INC.

135 Duryea Road

Melville, NY 11747 USA

Henry Schein U.K. Holdings Ltd.

Medcare House, Centurion Close

Gillingham Business Park

Gillingham ME8 0SB U.K.

2

CAUTION

Read this manual before operating Power-Spin™ LX centrifuge

Introduction

Henry Schein, Inc. has been a long standing provider of quality laboratory equipment for

the medical, veterinary, and educational market. With a range of bench top centrifuges

designed to meet today’s stringent lab needs, as well as a full range of microscopes, Henry

Schein is constantly searching for newer and better technology. The Power Spin™ LX

Centrifuge offers the protection needed in the fast growing medical and health care

industries.

Description/Intended Use

The HENRY SCHEIN PowerSpin™LX centrifuge with variable speed control and timer

are specially designed to run for years of demanding laboratory work in clinical labs,

physician’s offices as well as in any chemical, industrial or biological labs where

separation for blood or other materials are desirable.

Features

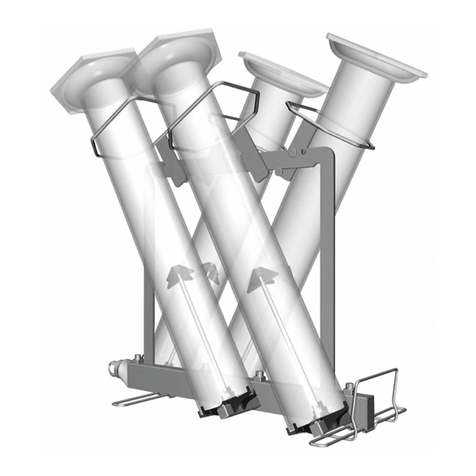

Six/eight place rotor for use with standard 5-10 ml tubes.

Note: Can spin up to three 15 ml tubes.

Can spin 2 ml and 4-5 ml tubes with available adapters.

Linear speed control allows use from 500 rpm- 4,000 rpm.

Dependable mechanical 30-minute timer with bell signal at end of run.

High impact plastic housing for years of dependable use.

Safety switch in lid shuts off motor when lid is unlatched. Latch release located on the

right front side of unit.

Power indicator light tells when unit is powered on.

1 year warranty, parts and labor.

Construction

The enclosures of the HENRY SCHEIN PowerSpin™LX Centrifuges are made of high

impact plastic, which is acid and reagent resistant. The internal chamber is made of

stainless steel. A safety switch is built into the lid and disconnects the power to the motor

whenever the lid is unlatched. The motor is mounted on rubber mounts to provide quieter

running and less vibration. The rotor chamber can be easily cleaned and disinfected.

Performance

Maximum speed depends on the number and size of the test tubes being spun.

PowerSpin™LX is variable speed unit, with 6 or 8 place rotor. The maximum speed is

4,000 rpm.

Accessories

Adapters are available to accommodate various tube sizes. Contact Henry Schein for

details.

3

Unpacking and Installation

The centrifuge is first packed in a styrofoam and then put in a carton box for shipping.

Please examine the shipment upon receipt and retain all packing until the unit has been

tested. The warranty excludes any damage caused by shipping.

Inspect for any possible shipping damage. If you note any damage, please contact

HENRY SCHEIN. Save the original packaging. If it becomes necessary to return the

instrument to us, we ask that it be returned in the original packaging.

Unpack the shipping carton carefully and verify that the shipment is complete. It should

include the following items:

PowerSpin™ centrifuge (LX) 1 unit

Power cord 1 pc.

Operation manual (LX version) 1 pc.

No on-site installation is required. Follow simple procedures below to set the centrifuge

up:

Take the centrifuge from the styrofoam and place it on a sturdy flat surface.

Press the lid latch release button located on the right side and open the centrifuge

cover. A special packing styrofoam disc is packed inside the lid of the centrifuge to

prevent the rotor or shields from moving during shipping. REMOVE THIS

PACKING DISC PRIOR TO OPERATION OF THE CENTRIFUGE

The centrifuge rotor is pre-installed. No rotor installation and calibration is required.

The power inlet is located in the back of the centrifuge. Plug in one end of the power

cord to the inlet and the other end to a power outlet.

Turn the speed control counterclockwise to “0” rpm.

CAUTION: Make sure the voltage of the power source matches the voltage input of

centrifuge.

Operation

1. Set the timer control to “off”.

2. Plug the centrifuge into a power source outlet. Make sure the voltage is correct.

3. Turn the power rocker switch in rear of unit to “on” position.

4. Open the lid by pressing the lid-opening button.

5. Place the specimen tubes into the tube shields of the rotor.

CAUTION: Make sure that the specimen tubes are balanced; see safety

section below.

6. Close the lid firmly.

7. Set the speed control knob at or close to “0” rmp.

8. Set the timer clockwise to the desired time.

9. Rotate the speed control knob slowly to the appropriate speed.

For example, Blood at 3,400 or Urine at 2,000- 2200 rpm.

4

10. After the centrifuge rotor has come to a complete stop (following the end of

the run bell), open the lid.

Safety

Your PowerSpin™LX centrifuge is a carefully designed and built instrument. When

operated properly, it presents no safety hazards. However, please take note of these safety

precautions.

Lid NEVER OPEN THE LID UNTIL THE ROTOR HAS COME TO A

COMPLETE STOP!

Load Balance Always make sure that the load is balanced before operating

the instrument.

It is very important that test tubes with equal loads are placed opposite each other in the

rotor. Also, when spinning a single specimen tube, another specimen tube of the same

size filled with water must be installed directly across from the specimen tube to maintain

balance. If the centrifuge is not properly balanced, damage could occur. If excessive

noise or vibration is noticed during a run, stop the centrifuge and recheck the balance.

Maintenance

This centrifuge is designed to be relatively maintenance free. The motor is a brushless

type and has permanently sealed bearings so oiling is not necessary. A surface cleaner

such as Formula 409 can be used to clean the outside of the instrument. The rotor

chamber and cover can be disinfected with a mild solution of bleach or other disinfecting

liquid and allowed to dry. Do not drench or immerse the unit in any liquid! Be sure to

disconnect the power before attempting to clean.

Routine Rotor Inspection and Maintenance

All centrifuge rotors should be removed and inspected for damage, defects or other

problems:

-Before initial use.

-Each time the rotor is removed for cleaning.

-At least every 6 months.

Plastic rotors and tube shields should be replaced every 12 months (once each year).

What to do if your inspection finds rotor or tube shield damage, defects or other

problems? If you detect any problems or damage, or defects in your centrifuge rotor or

tube shields discontinue use of the centrifuge and rotor immediately! Do not under any

circumstances continue to use a rotor that you think has damage as it could create a

safety problem.

Contact support at HENRY SCHEIN immediately at 800-588-9776 or 732-274-1155.

Please be prepared with the serial # (found on the rear of the machine near the electrical

plug) and any information you may have about where and when it was purchased.

5

Calibration

According to Code of Federal Regulations Title 21, centrifuges require verification or

calibration as follows:

1) Before initial use; 2) after repair or adjustments; and 3) 6 month after use. The

centrifuge timer, however, should be checked for accuracy at least every 3 month.

2) The speed should fall within ±100 rpm of the speed display.

3) The timer is a mechanical one and designed to be accurate to 5 min ± 30 sec.

Electrical Shock Hazard

Do not attempt to operate this instrument near water or liquid spill. Unplug the unit

before cleaning or repairing. Periodically check the condition of the power cord for cuts

or damage. Do not operate with a damaged cord.

Biohazard

If a tube breaks, a biological hazard may exist. Unplug the instrument. Clean using

approved laboratory procedures. Always wear the proper protective clothing and gloves.

Use a suitable disinfectant and dispose of the sample properly. Refer to the guidelines set

forth by OSHA, CLIA, etc.

Service

If you feel that your centrifuge needs factory service, please call support at HENRY

SCHEIN at 800-588-9776 or 732-274-1155 to determine the nature of the problem.

REPAIRS OR MODIFICATIONS MADE TO THE CENTRIFUGE BY AN

UNAUTHORIZED PARTY WILL VOID THE WARRANTY.

Problem Solving

1. Centrifuge does not start.

a) Check to determine if centrifuge is plugged in.

b) Check that timer has been set.

c) Check that lid is closed and latched.

Speed is checked using

UNICO digital tachometer.

Order part# C800-75

6

d) Check that Power rocker switch in rear of unit is in the “on” position.

e) Check that the Power indicator light (on front panel) is lit. A failure of the

power light to illuminate could indicate a need for a new fuse when the unit is

properly plugged in turned on and the lid closed.

2. Excessive noise when running. If the noise is irregular or different in tone, be

sure that there is no paper or debris in the rotor or rotor chamber. Make sure

that the load is balanced.

3. Indicator light fails to light.

a) Unit is not turned on

b) Lamp needs to be replaced

c) Fuse is blown

4. Fuse Replacement:

CAUTION: DISCONNECT THE POWER CORD BEFORE REPLACING FUSE.

Follow the procedures below to replace the fuse:

a) Unplug the power cord. Turn the on/off switch to “off”

b) Remove the power cord from the power inlet on the back of the centrifuge.

c) Locate the fuse holder. The fuse holder is a part of the power inlet.

On/off switch Inlet

Fuse Holder

d) Use a Philip type screwdriver to take the snap-in type holder cover off.

Remove the blown fuse and replace it with the same type and rating fuse

which is: 250V 3A.

e) Put the snap-in fuse holder back.

5. Intermittent motor operation; or no operation.

Call support at HENRY SCHEIN: 800-588-9776 or 732-274-1155.

O

7

Specifications

Speed________________________________500 –4,000 rpm

Speed accuracy ± 100 rpm @ 3000 RPM

Width________________________________10.2 inches

Depth________________________________11.8 inches

Height________________________________8 inches

Weight________________________________18 lbs

This manual suits for next models

1

Table of contents

Other Henry Schein Laboratory Equipment manuals