OTF 5000/HS/LS-001/2/3/4 Iss 4 June 2012

3

WARRANTY

The warranty relating to the instrument is outlined in our Terms and Conditions of Sale,

paragraph 6.

Warranty

1. The Seller’s manufactures are carefully inspected and submitted to its standard tests.

2. The Seller warrants all its manufactures to be free from defects in workmanship and

materials under normal conditions of use and service provided always:

3. that if any of the goods so manufactured is alleged to be defective in workmanship and

materials and is returned carriage paid, and protected against damage in transit, to the

Seller’s works, Huntingdon, within 12 months from the date of despatch and if after

examination by the Seller the goods or part of them are found to be so defective then the

Seller will repair or replace them free of charge and will return them to the Buyer, carriage

paid;

4. where any part of the goods manufactured by the Seller is repaired or replaced under the

terms of the foregoing warranty, such warranty shall thereafter be limited to a period of

six months from the date when the goods shall have been re-delivered to the Buyer;

5. this warranty does not apply to any defects caused by wear and tear, incorrect

installation, abnormal conditions of working, accident, mis-use or neglect;

6. that save as in this clause herein before expressed, the Seller shall not be under any

liability for negligence or otherwise in respect of defects in goods delivered or for any

injury, damage or loss resulting from such defects, and the Seller’s liability under this

clause shall be in lieu of any warranty or condition implied by law as to the quality or

fitness for any particular purpose of such goods;

7. this warranty is expressly in lieu of all other warranties, guarantees or liabilities expressed

or implied by any of the Seller’s Representatives or Agents.

For customers in the UK mainland please see our separate Product Warranty sheet.

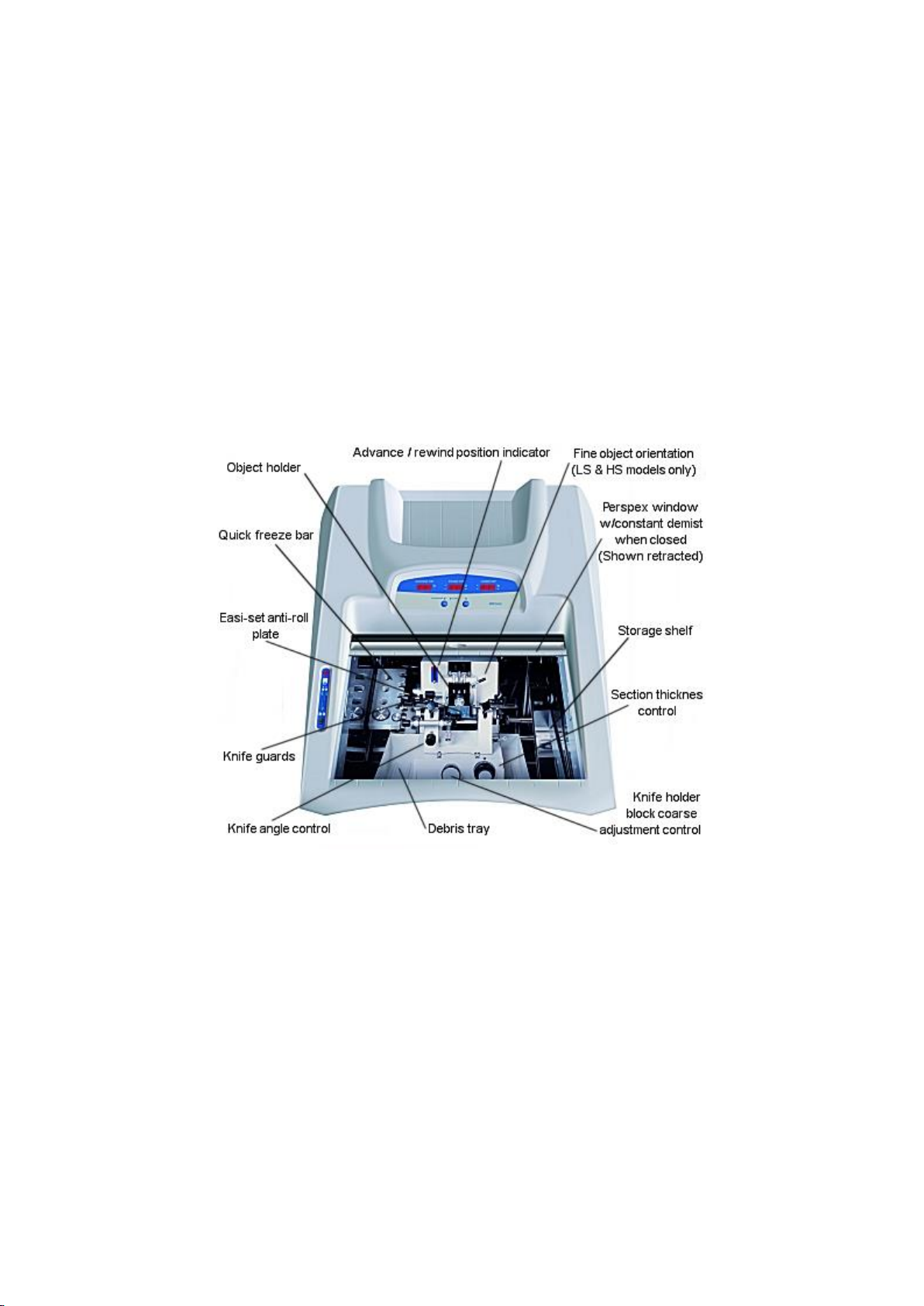

1.1 RECEIPT AND UNPACKING

This instrument received a final test and inspection prior to despatch from the factory. The

following instructions are given for the re-assembly of the instrument, adjustments and its

correct use. If the instrument is received before preparations for installation are completed; it

should be stored in a clean, dry place and not exposed to dirty or damp conditions. Do not place

or store any items on top of the carton.

1.1.1 RECEIPT

Immediately upon receipt of the instrument, make a careful examination for evidence of damage

encountered in transit. If any damage is found or suspected, notify both the carrier and Bright

Instrument Co Ltd immediately.

1.1.2 UNPACKING

All packing must be carefully removed and parts checked against the enclosed packing list. If

any damage or discrepancy is noted, please inform our agent/distributor, or Bright Instrument

Co Ltd direct, immediately. To prevent damage in transit, the handwheel and microtome have

been removed and packed in separate containers together with the accessories.