herdstar BinTrac Breeder Control User manual

Operation Manual

Version 2.0 1 Part Number MAN-000009

Breeder Control

Operation Manual

Patented

U.S. Patent No. 7,980,129, Patent No. 8,581,122, Patent No. 8,853,566

U.S. Patent No. 9,310,243, Patent No. 9,651,413, Patent No. 10,082,421

Canada Patent No. 2,822,294

Korea Patent No. 1900521

Operation Manual

Version 2.0 2 Part Number MAN-000009

1400 Madison Avenue Suite 504, Mankato, MN 56001

PH: 507-344-8005 FAX: 507-344-8009

www.herdstar.com

Table of Contents

Overview..........................................................................................................................................................................3

Components.................................................................................................................................................................3

Features .......................................................................................................................................................................3

About This Manual............................................................................................................................................................4

Configurations .............................................................................................................................................................. 4

System Settings................................................................................................................................................................7

Accessing the Setup mode...........................................................................................................................................7

Navigating Setup mode................................................................................................................................................7

Selecting an Option in Setup mode..............................................................................................................................7

Options in Setup Mode.................................................................................................................................................7

Setup and Operation.......................................................................................................................................................12

Gain-In-Weight (Load Batch Method) ........................................................................................................................12

Overview................................................................................................................................................................12

Setup Parameters..................................................................................................................................................13

System Settings in Setup Mode.............................................................................................................................13

Startup ...................................................................................................................................................................16

Operation...............................................................................................................................................................16

Wiring Diagram......................................................................................................................................................18

Loss-In-Weight (Unload Batch Method).....................................................................................................................19

Overview................................................................................................................................................................19

Setup Parameters..................................................................................................................................................20

System Settings in Setup Mode.............................................................................................................................20

Startup ...................................................................................................................................................................23

Operation...............................................................................................................................................................23

Wiring Diagram......................................................................................................................................................25

Inventory Bin with Dual Breeder Console Unloads....................................................................................................26

Overview................................................................................................................................................................26

Setup Parameters..................................................................................................................................................27

System Settings in Setup Mode - MASTER ..........................................................................................................27

System Settings in Setup Mode - REMOTE..........................................................................................................31

Startup ...................................................................................................................................................................33

Operation...............................................................................................................................................................33

Wiring Diagram......................................................................................................................................................36

Weigh Bin with Dual Breeder Consoles for Programmed Fill and Batch Configuration.............................................37

Overview................................................................................................................................................................37

Setup Parameters..................................................................................................................................................38

System Settings in Setup Mode - MASTER ..........................................................................................................38

System Settings in Setup Mode - REMOTE..........................................................................................................42

Startup ...................................................................................................................................................................44

Operation...............................................................................................................................................................44

Wiring Diagram......................................................................................................................................................47

Service............................................................................................................................................................................48

Maintenance and Repair............................................................................................................................................48

Troubleshooting..........................................................................................................................................................48

Flashing Fill............................................................................................................................................................48

Flashing Set.LC .....................................................................................................................................................48

Load Batch Does Not Start....................................................................................................................................48

BinTrac Breeder Control Blank..............................................................................................................................48

Inaccurate Weight Readings..................................................................................................................................49

Error Messages......................................................................................................................................................49

Load Cell Troubleshooting Procedures .................................................................................................................51

HerdStar BinTrac®Warranty...........................................................................................................................................52

is a trademark of HerdStar, LLC.

Copyright © 2019 HerdStar, LLC. All rights reserved.

Printed in the USA

Operation Manual

Version 2.0 3 Part Number MAN-000009

Thank you for purchasing a BinTrac Breeder Control from HerdStar, LLC.

Overview

Your BinTrac Breeder Control provides a cost-effective way to automatically monitor bin

level and batch a programmed load or unload amount.

Components

A BinTrac Breeder Control consists of a few basic components:

BinTrac Breeder Control

This is the main unit of the BinTrac system. The BinTrac Breeder Control communicates

with the Smart Summing Boxes to register the weight of material in the bins. The material

level is computed and displayed on the LED bar graph.

Load Cell Bracket

Four or more load cell brackets allow the BinTrac system to accurately measure the material weight in your bins. The

Smart Summing Box averages the signals from all brackets to minimize errors that could result from voids (holes) in

the material.

Smart Summing Box

A single Smart Summing Box per bin communicates the current reading on the leg brackets to the BinTrac Breeder

Control.

BinTrac Power Supply

This provides the power for the BinTrac Breeder Control. The power supply converts the line voltage to low voltage.

BinTrac Breeder Control Remote Display

A BinTrac Breeder Control Remote Display is a standard BinTrac Breeder Control indicator configured as a Remote

Display. A hardwire cable must connect the Remote Display to the Master BinTrac Breeder Control. Required for

dual Breeder Control configurations.

BinTrac Remote Display (Optional)

A BinTrac Remote Display is a standard BinTrac Indicator configured as a Remote Display. A hardwire cable must

connect the Remote Display to the Master BinTrac Breeder Control.

Features

Weight Display

The BinTrac Breeder Control displays the gross weight of the bin and its level.

Batch Run

The BinTrac Breeder Control features a relay to enable a load or unload system for batching a programmed amount.

Fill Events

The BinTrac Breeder Control records the net weight increase of the last four fill events.

24-Hour Usage

The BinTrac Breeder Control records the last four operational 24-hour usage amounts.

Remote Display

A BinTrac Indicator is configured as a Remote Display which will display the same updated weight information from

the host Breeder Indicator.

Operation Manual

Version 2.0 4 Part Number MAN-000009

About This Manual

The BinTrac Breeder Control Operation Manual is divided into a few different sections:

•System Settings –This section covers how to access and navigate the SETUP menu. It gives a basic

overview of what each setting is used for.

•Setup and Operation –This section covers the specific setup and operation instructions for each

configuration that is possible with the BinTrac Breeder Control. Refer to Configurations below to determine

which configuration is appropriate for your scenario.

•Service –This section covers the basic maintenance of the BinTrac Breeder Control system as well as

troubleshooting should problems arise.

Configurations

The BinTrac Breeder Control can be used in different configurations based on your needs. Before beginning the

setup of your system, determine which configuration you will be using. Below is an overview of the four different

configurations of batching. After determining the appropriate configuration, proceed to the portion of the manual for

that specific configuration by using the noted page numbers.

Gain-In-Weight (Load Batch Method)

Pages 12 - 18

The BinTrac Breeder Control System allows the user to select the amount of feed required for the day. The BinTrac

Breeder Control System controls a conveying system to deliver feed from the Inventory Bin to the Weigh Bin. The

Weigh Bin weighs the feed delivered and the BinTrac Breeder Control System stops the delivery when the required

amount of feed has been delivered to the Weigh Bin. In this configuration, the system batches into the weigh bin until

the total weight (gross weight) equals the target batch amount.

Operation Manual

Version 2.0 5 Part Number MAN-000009

Loss-In-Weight (Unload Batch Method)

Pages 19 - 25

The Loss-In-Weight (Unload Batch Method) allows the user to select the target batch amount of feed required for

the day. The BinTrac Breeder Control System will enable the hopper or feed line fill system allowing the feed line

system to transfer the feed into the house until the required amount of feed has been delivered. In this

configuration, this system batches and unloads until the batch target amount is unloaded from the bin.

Inventory Bins with Dual Breeder Console Unloads

Pages 26 - 36

Dual Breeder Consoles can be connected to a single inventory bin for programmed batching of two independent

amounts on separate delivery systems. The system can be used for both rooster (Master) and hen (Remote)

feeding by enabling/disabling the appropriate feed delivery system. The system features an auto/manual override

feature for each auger via an external switch.

Operation Manual

Version 2.0 6 Part Number MAN-000009

Weigh Bin with Dual Breeder Consoles for Programmed Fill and Batch

Pages 37 - 47

This configuration provides automated filling and batching of hen feed using a weigh bin. A Remote Breeder

Console provides automated filling of a programmed gross weight amount into a weigh bin. A Master Breeder

Console provides automated loss-in-weight batching of a programmed amount for the hen feeding. There is an

auto/manual override feature for each auger via an external switch.

Operation Manual

Version 2.0 7 Part Number MAN-000009

System Settings

The SETUP mode is used to configure the different settings and parameters of the BinTrac

Breeder Control.

Note: If there is no activity for a period of time while in SETUP mode, the system will exit

SETUP mode and return to Weight Display mode.

Accessing the Setup mode

1. Press and hold the SELECT button down until is displayed.

Segmented display:

Navigating Setup mode

To navigate through the options in SETUP mode, use the and keys to cycle through the

options/parameters. Refer to the SETUP menu flow chart to the right.

Selecting an Option in Setup mode

To select an option/parameter to edit in SETUP mode, you must navigate to the option

you wish to edit using the and keys. Press the SELECT key when you reach the desired

option.

Options in Setup Mode

In the SETUP Mode, the four LEDs indicate configuration options as being enabled

(solid on) or disabled (flashing).

GROSS WEIGHT - Configures a BinTrac or Breeder Indicator as a Remote

Display automatically when connected to a Master Breeder

Control with Peripheral Devices enabled.

BATCH AMT - NOT USED

LED (left of RUN) - NOT USED

RUN - Enable communications to Peripheral devices.

Must be enabled when Breeder Control is connected to a

Remote Display device (REMOTE BinTrac or Breeder Control

console).

SETUP Menu

Flow Chart

Operation Manual

Version 2.0 8 Part Number MAN-000009

Batch

Enables you to set the batch option to LoAd or u.LoAd (unload). LoAd is used when you want material batched into

a bin. Based on the gross weight of the bin, material is batched into the bin until the batched amount equals the gross

amount. u.LoAd is used when you want material batched out of a bin. In this case, the bin is holding a bulk amount of

feed and will batch out the programmed batch amount.

1. Press the SELECT key to enter menu.

2. Use the or keys to select or ..

Segmented display:

Rated Value

The average rated output in millivolt/volt (mV/V) of the load cells. If using load cells other than the HerdStar load

cells, you may need adjust this value appropriately.

*IMPORTANT –DO NOT change this setting from the default of 3.000 if you are using HerdStar load cells.

1. Press the BIN key to select the desired bin.

2. Use the UPPER key to increase the rated output by 0.001.

3. Use the LOWER key to decrease the rated output by 0.001.

Segmented display:

Load Cell Capacity Value

Sets the total capacity of each bin. The total capacity is the sum of all the load cells rated capacity. This can be

calculated by multiplying the capacity of individual load cells by the number of legs on the bin. Example: A four-

legged bin using 10k load cells would result in an L.C.CAP setting of 40000.

Note: When setting up for kilograms, convert the total capacity to kilograms.

1. Press the BIN key to select the desired bin.

2. Use the UPPER key to increase the value by 1 lb.

3. Use the LOWER key to decrease the value by 1 lb.

Segmented Display:

Operation Manual

Version 2.0 9 Part Number MAN-000009

Increment Value

Sets the increment that the bin weight will be rounded to. The reading from a bin

is rounded to the nearest multiple of the increment, using standard rounding rules.

The possible values are: 1, 2, 5, 10, 20, 50, 100, 200, 500, 1., 2.,5.,10.,20., and 50..

Example: If an increment of 10 is selected and the net value of a bin’s weight is

11,314 lbs., the segmented display will read 11310. Refer to Figure 1 for more

examples based on a net weight of 11,314 pounds.

Note: When the increment value is followed by a “.”,the displayed weight

value is then scaled by 10. For example, an increment value of 1. would cause

120462 pounds to show as 12046. on the display. This is required when the

displayed weight will exceed the 5 available digits on the BTB200.

1. Press the BIN key to select the desired bin.

2. Use the UPPER key to increase the increment value.

3. Use the LOWER key to decrease the increment value.

Segmented display:

Full Value

Sets the weight of a full bin. This is for calibration of the LED bar graph level. The

value dictates at what net weight the bar graph will display completely full (all 16 LEDs lit).

1. Press the BIN key to select the desired bin.

2. Use the UPPER key to increase the value by 1 lb.

3. Use the LOWER key to decrease the value by 1 lb.

Segmented display:

Zero Value

Sets the weight of the empty bin. This value can also be set in the Operation Settings. This is used to compensate for

the empty weight of the bin to give an accurate value for the net weight of the material inside the bin.

Example: A bin weighs 1,200 lbs. empty. By setting the zero value to 1200, the BinTrac indicator calculates the

material weight as the total weight less the zero-weight value.

Note: If the bin was zeroed on the Indicator by pressing and holding the UPPER and LOWER keys (see Page

16 –Startup step 5), this field will display the automatically calculated amount.

1. Press the BIN key to select the desired bin.

2. Use the UPPER key to increase the value by 1.

3. Use the LOWER key to decrease the value by 1.

Segmented display:

incr

Display

1

11314

2

11314

5

11315

10

11310

20

11320

50

11300

100

11300

200

11400

500

11500

1.

1131.

2.

1132.

5.

1130.

10.

1130.

20.

1140.

50.

1150.

Figure 1

Operation Manual

Version 2.0 10 Part Number MAN-000009

Year

Sets the current year.

Segmented display:

Month

Sets the current month.

Segmented display:

Date

Sets the current date.

Segmented display:

Hour

Sets the current hour in 24-hour format.

Segmented display:

Minute

Sets the current minute

Segmented display:

Station ID Value

Sets the Station ID of the device. When interfacing the device to a Communication Hub (CH100), set this value from

1 to 127. Each BinTrac device must have a unique Station ID.

1. Press the BIN key to select the desired bin.

2. Use the UPPER key to increase the value by 1.

3. Use the LOWER key to decrease the value by 1.

Segmented display:

Software Version

Displays the Breeder Control programmed software version number.

1. Press the BIN key to see the software version number.

Segmented display:

Operation Manual

Version 2.0 11 Part Number MAN-000009

Smart Summing Box Software Version (Version 3.0 and higher)

Displays the software version number of each of the connected Smart Summing Boxes. This number may be

required if technical help is needed.

1. Press the BIN key to see the software version for each enabled bin.

Segmented display:

End

Allows the user to exit SETUP mode.

1. Press the BIN button to exit SETUP mode.

Segmented display:

Operation Manual

Version 2.0 12 Part Number MAN-000009

Setup and Operation

Gain-In-Weight (Load Batch Method)

Overview

The BinTrac Breeder Control allows the user to select the amount of feed required for the day.

The control activates a fill system to deliver feed from the Inventory Bin to the Weigh Bin. The

Weigh Bin is equipped with load cells to weigh the incoming feed. Once the total amount of

feed (Gross Weight) is loaded into the Weigh Bin, the Breeder Control shuts down the

incoming fill line.

Operation Manual

Version 2.0 13 Part Number MAN-000009

Setup Parameters

Follow the system wiring diagram (Page 18) to aid in the installation process, including supplied relays and switches.

Once installation is completed, the BinTrac Breeder Control unit must be programmed as summarized below:

1. The BinTrac Breeder Control console controls the batching from the inventory bin into the weigh bin (steps 1

through 19).

Access SETUP mode and configure the following:

•Set the Batch type to Load Batching

•Set an L.C.CAP value that matches the total capacity of all load cells

•Set a FuLL value that matches the maximum capacity of the weigh bin

•Set the Hour time parameter (default is CST Zone)

System Settings in Setup Mode

The SETUP mode is used to configure the one-time system setup settings for the appropriate

configuration. The following SETUP parameters MUST be correctly configured to ensure proper

operation and weighing:

•BATCH

•L.C.CAP

•FULL

•ZERO

•HOUR

NOTE: When first powering on the unit, .will be displayed. This is simply a reminder that

the load cell capacity for the system must be entered in the SETUP menu to ensure proper weighing

calibration.

NOTE: If there is no activity for a period of time while in SETUP mode, the system will exit and return

to the Weight Display mode.

Navigating Setup Mode

To navigate through the options in SETUP mode, use the and keys to cycle through the

options/parameters. See the SETUP menu flow chart to the right.

Accessing the Setup Mode

1. Press and hold the SELECT button down until is displayed.

Segmented display:

2. Press the key and will be displayed.

SETUP Menu

Flow Chart

Operation Manual

Version 2.0 14 Part Number MAN-000009

Batch

Enables you to set the batch option to LoAd or u.LoAd. In this configuration, the parameter MUST be set for LoAd

to batch from the inventory bin into the weigh bin.

Segmented display:

3. Press the SELECT key to enter BATCH menu, and .should be displayed. Press to set to .

4. Press the SELECT key and then is shown.

5. Press and . . is displayed.

Capacity (L.C.CAP)

The load cell system capacity is the sum of all the load cells rated capacity in either pounds or kilograms. This

parameter sets the calibration of the system. To determine this value, multiply the number of load cells by their

capacity.

Example: A four leg bin with 5k load cells would require an L.C.CAP setting of 20000 pounds.

Segmented display:

6. Press the SELECT key. The display will show the current setting (default is 30000).

7. Use the and keys to increase or decrease the value. Hold the key down to increase/decrease quickly.

8. Upon setting the appropriate value, press SELECT and the display will show .

9. Press the key and is displayed.

Full Value

This value is the maximum weight of a full bin in either pounds or kilograms as is for calibration of the LED bar graph

level. The value determines at what weight the bar graph will display completely full (all 16 LEDs lit). Set this to the

maximum amount of feed that you would consider the bin to be full.

Segmented display:

10. Press the SELECT key.

11. Use the and keys to increase or decrease the value. Hold the key down to increase/decrease quickly.

12. Upon setting the appropriate value, press SELECT and the display will show .

Operation Manual

Version 2.0 15 Part Number MAN-000009

Zero Value

Sets the weight of the empty bin in either pounds or kilograms. Convenient when wanting to calibrate a system when

a small amount of feed is already in the bin. The zero value is used to compensate for the empty weight of the bin to

give an accurate value for the net weight of the material inside the bin. The Breeder Control calculates the material

weight as the total weight less the zero (empty) weight value.

Example: A bin weighs 1200 pounds empty. In standard operation mode, simply press and hold on both the

and keys until displays. This would then set the zero value in the SETUP mode to 1200.

Segmented display:

13. Press the SELECT key. The current zero value is shown. If zeroed in standard operation mode, simply record

this value for future reference. If you need to adjust this value, use the and keys until the desired value

for an empty bin is shown.

14. Press the SELECT key and is displayed.

15. Press the key three times until is displayed.

Hour

Sets the current hour in 24-hour (military) format. The default hour is set to CST and should be adjusted, if necessary,

for your time zone.

Segmented display:

16. Press the SELECT key and the current hour is displayed. Use the and keys to enter the proper hour in

24-hour format.

17. Once the proper value is displayed, press SELECT and is displayed.

18. Press the key four times until is displayed.

End

Allows the user to exit SETUP mode.

19. Press the SELECT button while is displayed to exit SETUP mode.

Segmented display:

Operation Manual

Version 2.0 16 Part Number MAN-000009

Startup

1. Inspect BinTrac installation on weigh bin and verify legs are evenly lifted and not binding.

2. Verify area under bin legs is free and clear of any material.

3. Check weighing accuracy

a. Have someone with known weight sit on bin cross-bar support as close to leg as possible to verify

bracket assembly is accurately measuring weight.

b. Repeat on each cross-bar support.

4. Important - Manually fill weigh bin with approximately 100 lbs. of feed to allow for overshoot and

ensure flowability of feed during unload process.

5. Zero Inventory Bin.

a. Make sure weigh bin is empty and in the Gross weight mode on the Breeder Console. Hold on both

the and keys until the display shows .

b. Record Zero __________ (empty weight of bin) by viewing in SETUP Menu

(Used for resetting the zero point of the scale if it is ever zeroed out with weight on the bin in the

future).

Note: The batch filling of Weigh Bin must be completed one hour prior to starting the batching of the

programmed feeding.

Operation

Press the SELECT key to select between Gross Weight and Batch Amount. The Gross Weight is the total material

remaining in the bin. The bar graph indicates the approximate level of the bin. The Batch Amount is remaining weight

left to batch to reach the Batch Target. Note: Batch Weight always starts at the Batch Target and counts down to “0”

weight. This provides the best means to display the amount left to batch.

Manual Batch Run

1. Press the key until is displayed.

2. Press SELECT to view the Batch Target Weight value.

3. Use the key to increase the value by 1.

4. Use the key to decrease the value by 1.

5. Press SELECT to display the batch run control status ( or ).

6. Use the or keys to enable or disable batch run control.

7. Press SELECT to start Batching if run was selected. The batch run will begin immediately.

Scheduled Batch Run

1. Press key until is displayed.

2. Use the key to select .

3. Press SELECT to view the hour and minute schedule.

4. Use the key to select hour and minute to schedule batch.

Note: This is a 24-hour clock (i.e. 13:00 = 1:00pm).

5. Press SELECT to view the Batch Target Weight value.

6. Use the key to increase the value by 1.

7. Use the key to decrease the value by 1.

8. Press SELECT to display the batch run control status ( or ).

Operation Manual

Version 2.0 17 Part Number MAN-000009

9. Use the or keys to enable or disable batch run control.

10. Press SELECT with displayed. The Indicator will then display the batch amount and a countdown to the

next batch run.

11. To stop a scheduled batch run, use the key and will be displayed. Press the SELECT key once to

stop and again on the batch amount. The Indicator will then return to display the gross amount in the bin.

Pause Batch Run

1. To pause a batch in mid run, press the key twice and is displayed. Press SELECT key to pause

the batch run.

2. When paused, the indicator will alternate between and the remaining batch amount on the screen.

3. To restart the batch, press the key until is displayed, then press the SELECT key. The batch will

then continue until completed.

Display Fill Events

This procedure allows you to view the last four recorded fill events.

1. Press the key until is displayed.

2. Press SELECT to view the last recorded fill event.

3. Press the key to view other prior recorded fill events.

4. Press SELECT to return to Weight Display mode or unit will return to Weight Display mode after a period of

time with no activity (no keystrokes).

Display 24 Hour Usage

This procedure allows you to view the last four 24-hour usage amounts.

1. Press the key twice until is displayed.

2. Press SELECT to view the last recorded 24-hour usage amount.

3. Press key to view other prior recorded usage amounts.

4. Press SELECT to return to Weight Display mode or unit will return to Weight Display mode after a period of

time with no activity (no keystrokes).

Operation Manual

Version 2.0 18 Part Number MAN-000009

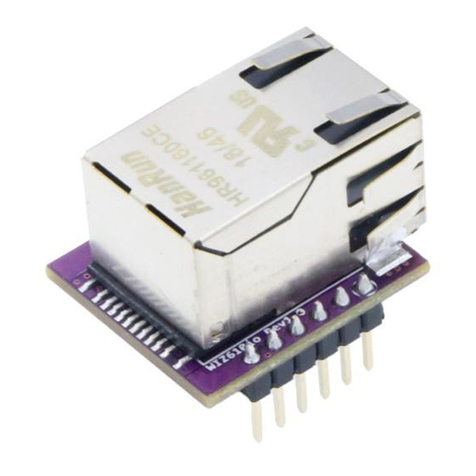

Wiring Diagram

Operation Manual

Version 2.0 19 Part Number MAN-000009

Loss-In-Weight (Unload Batch Method)

Overview

In a single bin system, the BinTrac Breeder Control allows the user to select the amount of feed

required for the day. The Breeder Control enables the hopper/feed line fill system to draw feed

directly from the bin until the required amount of feed has been delivered into the house. When

the total amount of feed has been delivered, the Breeder Control shuts down the feed delivery

system.

Operation Manual

Version 2.0 20 Part Number MAN-000009

Setup Parameters

Follow the system wiring diagram (Page 25) to aid in the installation process, including supplied relays and switches.

Once installation is completed, the BinTrac Breeder Control unit must be programmed as summarized below:

1. The BinTrac Breeder Control console controls the unload batching withdrawal auger (steps 1 through 19).

Access SETUP mode and configure the following:

•Set the Batch type to Unload Batching

•Set an L.C.CAP value that matches the total capacity of all load cells

•Set a FuLL value that matches the maximum capacity of the weigh bin

•Set the Hour time parameter (default is CST Zone)

System Settings in Setup Mode

The SETUP mode is used to configure the one-time system setup settings for the appropriate

configuration. The following SETUP parameters MUST be correctly configured to ensure proper

operation and weighing:

•BATCH

•L.C.CAP

•FULL

•ZERO

•HOUR

NOTE: When first powering on the unit .will be displayed, simply as a reminder that the

load cell capacity for the system must be entered in the SETUP menu to ensure proper weighing

calibration.

NOTE: If there is no activity for a period of time while in SETUP mode, the system will exit and

return to the Weight Display mode.

Navigating Setup Mode

To navigate through the options in Setup mode, use the and keys to cycle through the

options/parameters. See the SETUP menu flow chart to the right.

Accessing the Setup Mode

1. Press and hold the SELECT button down until is displayed.

Segmented display:

2. Press the and will be displayed.

SETUP Menu

Flow Chart

Other manuals for BinTrac Breeder Control

1

Table of contents

Other herdstar Control Unit manuals

Popular Control Unit manuals by other brands

Franke

Franke AQUALINE AQRM558 Installation and operating instructions

Avnet

Avnet AES-ACC-U96-ONCAM-MEZ Getting started guide

Bose

Bose FreeSpace 1B manual

YASKAWA

YASKAWA CANopen SI-S3/V installation manual

BFT

BFT SIRIO FR-TMA Installation and user manual

Fike

Fike FIK-M500M Installation and maintenance instructions