Important Safety Information

• Please read these instructions thoroughly and retain for future use.

• All products manufactured and supplied by Heritage are safe provided they are

installed, used correctly and receive regular maintenance in accordance with these

instructions.

• If you are in any doubt about your ability to install this product safely you

must employ the services of an experienced qualied plumber.

• This tting needs to be installed in accordance with, and meet the requirements of

the Water Supply (Water Fittings) Regulations 1999 and Scottish Byelaws 2004.

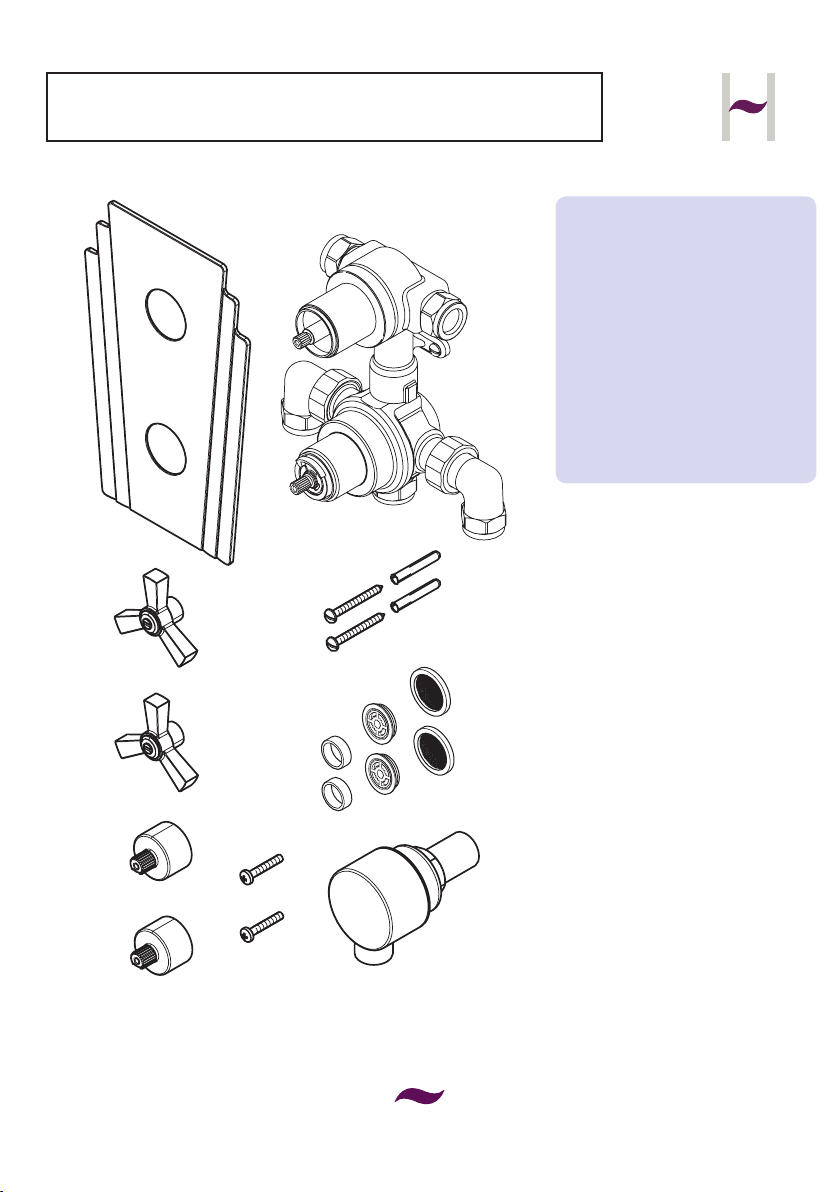

• Remove all packaging and check there are no missing or damaged parts.

• Before starting any installation please consider the following:

• Before drilling into walls, check that there are no hidden electrical wires, cables or

water supply pipes.This can be checked with the aid of an electronic detector.

• If power tools are used do not forget to: - Wear eye protection

- Unplug equipment after use

• Warning: Before installing the new shower valve it is essential that you

thoroughly ush through the pipework in order to remove any

remaining swarf, solder, etc. Failure to carry out this procedure

could cause problems or damage to the workings of the shower

valve.

• Fitting isolation valves to the inlet feeds is required for ease of maintenance.

• Access must be made available to the shower valve / mixer body for maintenance /

servicing purposes.

• Warning: Do not operate this product if you suspect it is frozen. Do not site

the Mixing Valve where it might be subjected to freezing conditions.

• These shower valves must not be modied in any way as this will invalidate the

guarantee.

Need help? Give us a call on 0844 701 8503 and speak to one of our trained advisers. 3