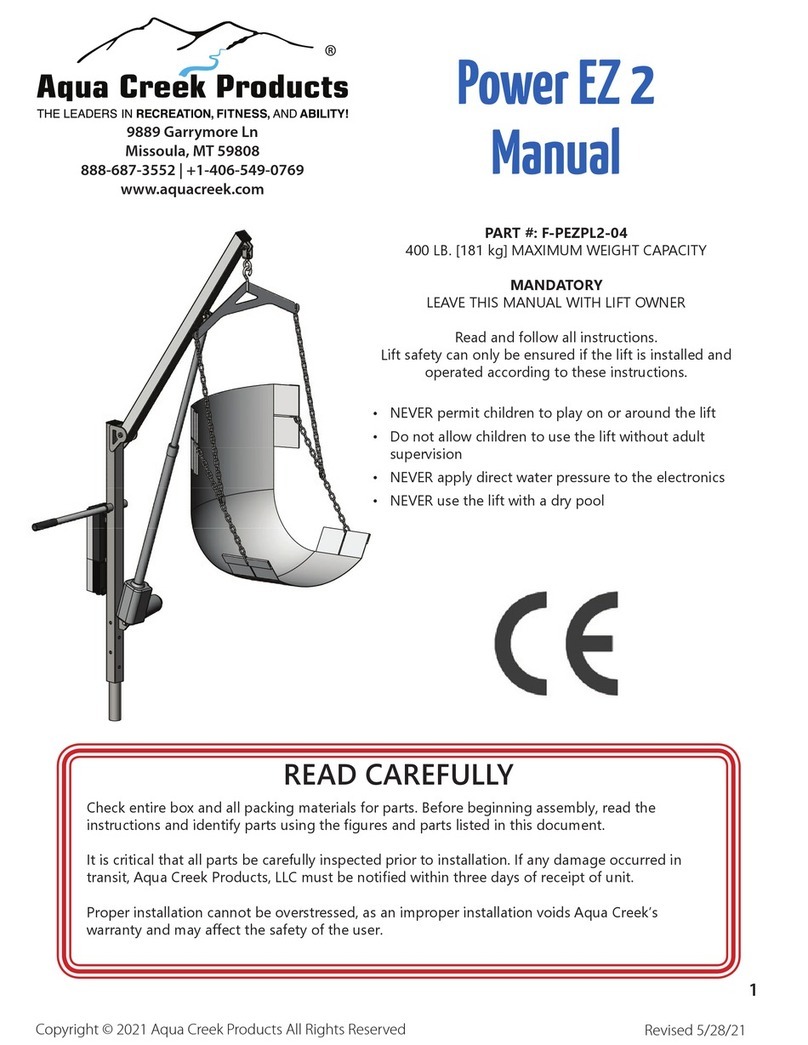

HERKULES K900S User manual

Part# 1002861-04

11/30/2016

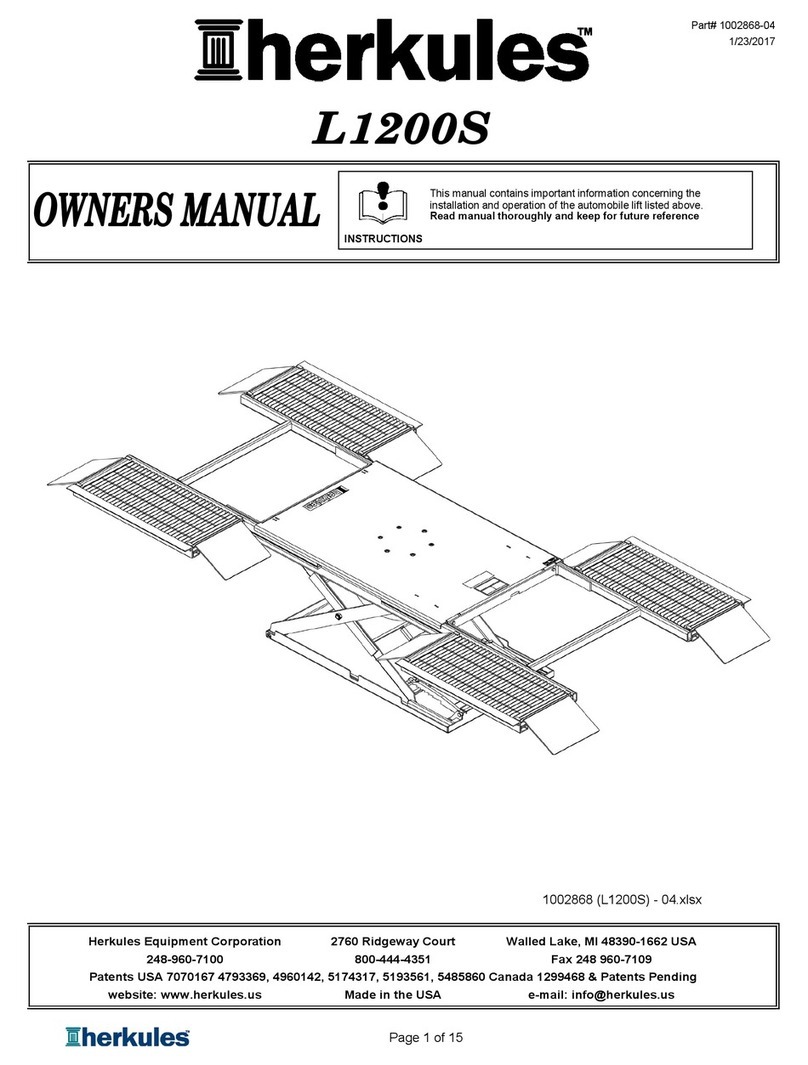

This manual contains important information concerning the

installation and operation of the automobile lift listed above.

Read manual thoroughly and keep for future reference

INSTRUCTIONS

Herkules Equipment Corporation 2760 Ridgeway Court Walled Lake, MI 48390-1662 USA

248-960-7100 800-444-4351 Fax 248 960-7109

Patents USA 7070167 4793369, 4960142, 5174317, 5193561, 5485860 Canada 1299468 & Patents Pending

website: www.herkules.us Made in the USA e-mail: info@herkules.us

Page 1 of 16

Warnings ……………………………………………………………………………………………………………………… 2 - 5

Installation ………………………………………………………………………………………………………………….. 6

Duty Cycle ………………………………………………………………………………………………………………….. 7

Operation ……………………………………………………………………………………………………………………. 7 - 8

Maintenance Instructions ……………………………………………………………………………………………………….8

Troubleshooting ……………………………………………………………………………………………………………… 9

Optional Accessories …………………………………………………………………………………………………… 10

Parts List ……………………………………………………………………………………………………………… 11

Controller Layout ……………………………………………………………………………………………………………… 12

Internal Valve Layout ……………………………………………………………………………………………………………… 13

Installation of Suspension Kit ……………………………………………………………………………………………………… 14

Model Information & Schematic ……………………………………………………………………………………………………………… 15 - 16

Serial Number

Model Number

Purchase Date

Distributor

The limited liability warranty applies to the pneumatic chambers of our Herkules lifts and to the initial user against defective

materials for a period of five years from the proof of purchase date. The limited liability warranty applies to other

components of our Herkules lifts to the initial user against defective materials for a period of one year from the proof of

purchase date.

This warranty does not apply to equipment damaged from accident, abuse, overload, misuse, negligence, improper

installation, abrasive or corrosive materials, or shipping damage.

In the event of failure, the defective item must be returned, freight prepaid, to the Herkules manufacturing plant for repair

or replacement. If repairs are required Herkules will not be liable for these repairs to take place in the field regardless

of the application. Proof of purchase and date of purchase must be confirmed. An RGA number (Return Goods

Authorization) and written approval from Herkules must be obtained before any goods can be shipped to Herkules. Herkules

reserves the right to determine whether the cause of failure is due to defective material, normal wear, and/or other causes.

There are no warranties which extend be

y

ond the description on the face hereof. Herkules disclaims an

y

warranty of merchantability or fitness for a particular purpose in connection with the Buyer’s purchase

of any Product under this agreement. Damages are limited to the sales price of the Herkules system.

The terms and conditions herein represent the entire agreement between Herkules and the Buyer.

Any prior / future representations do not apply.

Table of Contents

Warning Symbol Caution Symbol

Limited Liability Warranty

CAUTIONWARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

This symbol alerts you to the possibility of damage to or

destruction of equipment if you do not follow the

instructions.

This product has patent protection under

one or more of the following patent numbers:

7070167, 5485860, 5193561, 5174317

4960142, 4793369, 1299468

and Patents Pending

website: www.herkules.us

1002742

PATENT NUMBERS

Page 2 of 16

THIS MANUAL CONTAINS IMPORTANT INFORMATION CONCERNING THE INSTALLATION AND

OPERATION OF VEHICLE LIFTS.

WE OFFER TWO SUGGESTIONS:

• READ ALL MANUALS THOROUGHLY BEFORE INSTALLATION.

• KEEP ALL MANUALS FOR FUTURE REFERENCE.

1 Do not exceed the rated load capacity of the lift.

2 Do not continue to push the control lever after lift is fully raised, even though safety valve will prevent

over-inflation of air bag.

3 Use lift only on level surfaces.

4 Keep clear of lift while it is in motion.

5 Do not use air supply exceeding 120 PSI.

6 Do not leave a vehicle raised on the lift overnight.

7 Do not operate lift with defective Control assembly.

8 Never for any reason put arm or any other body part inside lift.

1 Herkules will not be held responsible for any personal injury and/or property damage due to

owner/operator failure to follow the warnings and cautions listed in this manual.

2 Read and understand all warnings, cautions, instructions and manuals before operating this equipment.

3 It is the owner/operators responsibility to maintain the legibility of all warning and instruction labels.

4 DO NOT alter or modify any part of this equipment.

5 DO NOT attempt to bypass the safety lock system.

6 DO NOT tamper with pressure relief valve system inside the lift.

7 DO NOT operate lift while person(s) are in the vehicle

8 ALWAYS check equipment regularly for proper operation and repair or replace worn or damaged parts

immediately.

9 ALWAYS remove damaged lifts from service until repairs are made to the unit. Use only manufacturer's

approved parts and accessories.

Warnings

WARNING

CAUTION

WARNING

CAUTION

WARNING

CAUTION

Page 3 of 16

Tags - Operating Instructions

Warning:

This symbol alerts you to the possibility of serious injury or death if you do not follow

the instructions

Caution:

This symbol alerts you to the possibility of damage to or destruction of equipment if

you do not follow the instructions.

I. Tag - Operating Instructions (P/N 1006355) Front

Page 4 of 16

I. Tag - Operating Instructions (P/N 1006355) Back

II. Tag - Operating Instructions - Air (P/N 1006356)

Page 5 of 16

Locate lift on a level surface in a position most convenient for the loading and unloading of vehicles.

Obtain hose clamps

ID Part # Description Qty.

1 1000166 CLAMP HOSE WIDE BAND #8 SS/Z 1

2 720-122 CLAMP HOSE # 4 SS/Z 1

Using the hose clamp (1000166), clamp the 3/8" ID air line from the lift to 3/8" hose barb on the hand control

assembly (see fig.1).

Using hose clamp (720-122), clamp the 1/4" ID air line from the lift to hose barb (1004805) on the hand

control assembly (see fig.1).

NOTE: Check these connections periodically to prevent leakage.

Obtain 1/4 NPT connector compatible with the quick disconnect on your shop air line.

NOTE: Connector not supplied with lift.

Install 1/4 NPT connector into open port (Port 1) on hand control valve (see fig.2).

Connect your shop air line to connector and test for proper operation.

NOTE: Must use clean, dry air only. Herkules recommends using a filter/regulator (see Optional Accessories).

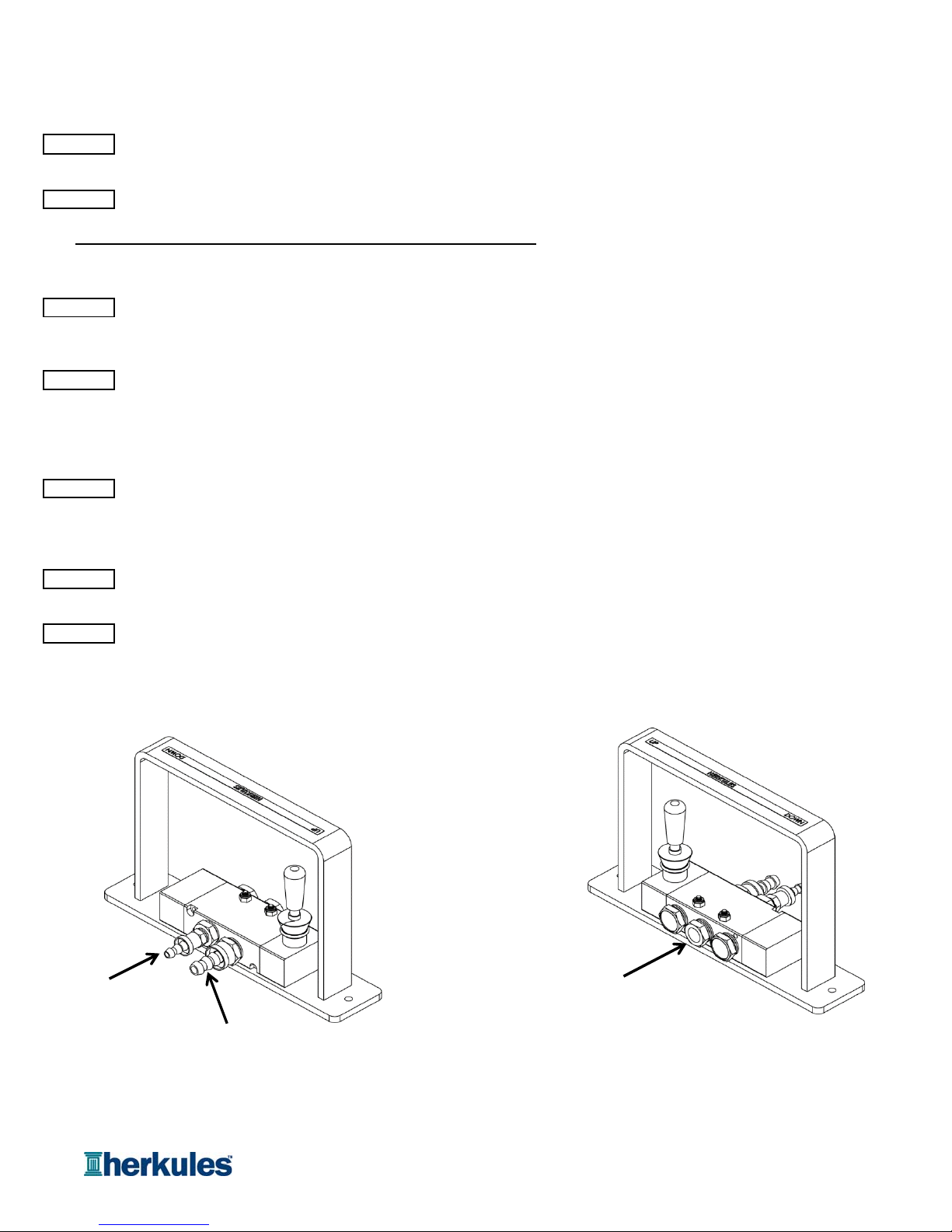

fig 1 fig 2

STEP 7

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

Installation

3/8" Hose barb

Port 1

1/4" Hose barb

Page 6 of 16

I. Lift Cycle Rating:

This lift is rated for 1 - 5 cycles per day maximum. For high cycle usage warranty does not apply.

II. Duty Cycle:

This lift is rated for approximately 7,000 - 10,000 cycles between repairs (MTBF). This lift is not rated for high duty cycles.

Items that will need repair may include: 1) air bag, 2) safety ratchet, 3) scissors, 4) pivots, and 5) valves.

For heavy duty scissor lift systems that requires little maintenance Herkules recommends our Herkules Ball Screw or Belt

Drive Scissor Lift Systems. These lift systems are designed and manufactured for high duty cycles and long life.

Herkules recommends our electric Ball Screw or Belt Drive lift system for high cycle applications.

Check the weight of the vehicle to be sure that it does not exceed the rated load capacity of the lift: 5,000 lbs.

Drive the vehicle over the first set of ramps and onto the second set of ramps so that all four tires are on the lift, and position the

vehicle so that the vehicle is centered by weight over the center of the lift. Once the vehicle is in the desired position,

set the parking brake of the vehicle.

To raise the lift, move the lever of the hand controller assembly into the UP position. Hold the lever in the UP position

until vehicle has reached the desired working height, then release. The mechanical safety arms will automatically

fall into position as the lift rises.

Do not continue to push the control lever after lift is fully raised, even though safety valve will prevent

over-inflation of air bag.

NOTE: Check the stability of the vehicle during the lifting process, and when vehicle is at desired working height.

If vehicle is unstable, immediately stop the lifting process, slowly lower the lift and reposition vehicle.

To lower the lift, move the lever of the hand controller assembly into the DOWN position. Hold the lever in the DOWN

position until the lift is completely lowered and the wheel platforms are resting on the ground. The mechanical safety arms

will swing up during descent.

NOTE: Check the stability of the vehicle during the lowering process. If vehicle is unstable, immediately stop and

diagnose the issue before continuing to lower the lift.

Operation

STEP 1

STEP 2

STEP 3

STEP 4

Duty Cycle

Page 7 of 16

Once the lift is completely lowered, drive the vehicle off of the lift.

Check clamps and hose connections periodically for tightness to prevent air leakage.

Make sure all moving parts are clean and unobstructed by foreign objects.

Clean filter element every 3 months if applicable.

Grease and oil pivot points once every 3 months.

Lubricate daily if lift is in high cycle application.

Use 90-weight gear lube (SAE 85W 140 EP) to lubricate the pivots and shafts once every 3 months or as needed.

Grease the upper and lower wheel channels every 3 months or as needed.

Lubricate lock mechanism pivot points every 3 months or as needed.

Use overhead rigging when any maintenance beyond external lubrication is required.

STEP 7

STEP 8

STEP 2

STEP 3

STEP 4

STEP 5

STEP 5

Maintenance Instructions

STEP 6

STEP 1

fig.3

Page 8 of 16

Problem Possible Solution

Lift will not go up 1Check that air inlet is connected to the controller.

2 Check to ensure lockout is not engaged (if purchased as option).

3 Check air hoses to ensure no kinks or cuts in the line.

4Check to ensure no debris is preventing wheels from rolling in track.

5 Check regulator gauge is set to minimum of 80 psi (if purchased as option).

Lift is making a hissing noise 1 Check all air lines to ensure they are properly connected and

no leaks are occurring.

2 Check pressure relief valve.

If pressure relief valve is "leaking" lower lift immediately. The air bag

is in a state of over pressurization.

3 Check air bag for cuts or holes.

Lift is making a squeaking noise 1 Lubricate center joints and wheel tracks.

Troubleshooting

Page 9 of 16

ID Part # Description Qty Units

1 12848 Control Valve Assembly - Hand - Lift Only - 2 x Muffler 1 EA

2 12849 Control Assembly - Hand - Lift Only - Wall Mount 1 EA

3 12850 Control Assembly - Hand - Lift Only - Pedestal Mount 1 EA

4 12851 Filter / Regulator Assembly 1 EA

5 12852 Filter / Regulator / Lock Out Assembly 1 EA

6 1002450 Lock Out Valve 1 EA

- 12368 Set of (4) Rubber Blocks - 3-7/8 x 5 x 1-1/2 1 EA

- 12369 Set of (4) Rubber Blocks - 3-7/8 x 8 x 1-1/2 1 EA

Optional K900S Accessories

3

2

1

4

5

6

Page 10 of 16

Part # Quantity Units

17047 1 EA.

16929 2 EA.

16930 2 EA.

16925 2 EA.

16928 2 EA.

17043 1 EA.

15244 1 EA.

10253 1 EA.

693-103 8 EA.

009-126 8 EA.

1000498 8 EA.

009-131B 4 EA.

009-131A 4 EA.

009-137B 2 EA.

009-124 6 EA.

008-113A 4 EA.

10377 2 EA.

720-122 1 EA.

1000166 1 EA.

300-001 1 EA.

10037 1 EA.

M00 1 EA.

009-151 4 IN.

17048 1 EA.

1000505 2 EA.

100-334 225 IN.

100-333 228 IN.

1002968 2 EA.

009-125 1 EA.

009-153 1 EA.

1006323 2 EA.

1006222 1 EA.

1000082 1 EA.

1002860 1 EA.

BOLT HEX 9/16-12 X 2 GD 5 Z

WASHER 9/16 SAE F/W ZINC

NUT JAM 9/16-12 Z

NUT LOCK 9/16-12 Z

SCISSOR ARM WLDMNT C 2-1/2 X 39-3/4

SCISSOR ARM WLDMNT G 2-1/2 X 35-3/4

SCISSOR ARM WLDMNT A 2-1/2 X 39-3/4

SCISSOR ARM WLDMNT E 2-1/2 X 35-3/4

TOP PAN WELDMENT 38-1/4 X 58-1/4

KIT SUSPENSION K900 & K900P

SAFETY CYLINDER ASSY FOR LIFT

WHEEL 40 MM PLASTIC

BOTTOM PAN WELDMENT 37 X 49-1/16

Parts Layout

STICKER BOX LIFT MODEL & SERIAL

ACCELERATOR VALVE ASSEMBLY

MUFFLER 3/8 AIR EXHAUST

TUBE 1-1/4 CLEAR

LIFT CONTROLLER ASSY KIT

CAP 1.0 ID PE BLACK

Description

DECAL MAXIMUM CAPACITY 6000 LBS

DECAL HERKULES LIFT 5.25 X 14.5

OWNERS MANUAL K900

HOSE 3/8" PUSH TO LOK

HOSE 1/4" PUSH TO LOK

TUBE COILED 5/32 OD X 6 NYLON

HERKULES LIFT SERIAL TAGS

BOLT FHSC 5/8-11 X 5 CUT 3.25 BLACK

WASHER FLAT 5/8 SAE Z

NUT LOCK 5/8-11 Z

BOLT ASSEMBLY - CUT AT 3.125

INSTRUCTION LABEL FOR LIFT

CLAMP HOSE # 4 SS/Z

CLAMP HOSE # 8 SS/Z

AIR BAG - K-900

Page 11 of 16

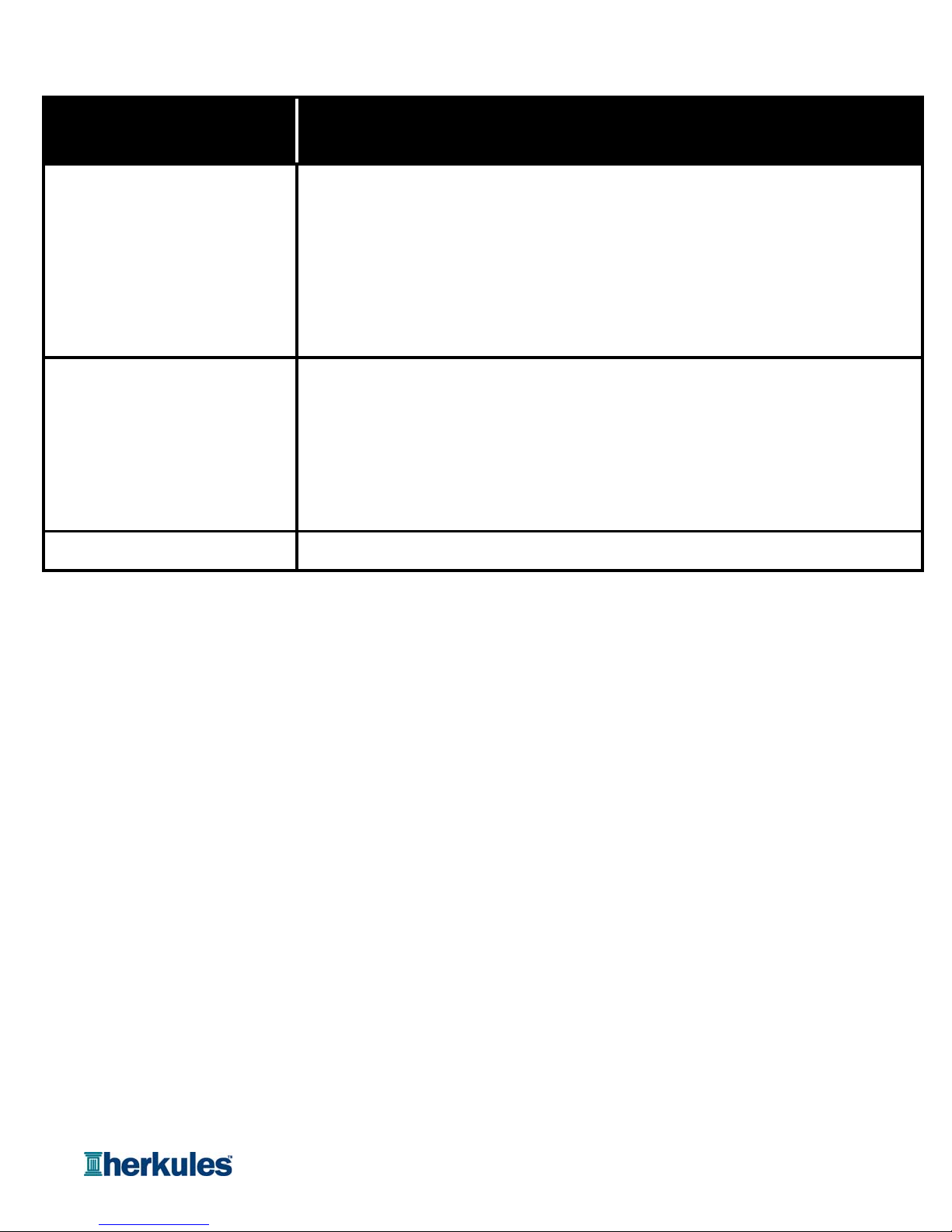

ID Part # Qty Units

1 1002449 1 EA.

2 17049 1 EA.

3 1000078 1 EA.

4 1003585 1 EA.

5 002-172 2 EA.

6 1004805 1 EA.

7 66B 2 EA.

8 1004798 2 EA.

9 1001602 2 EA.

NOTE: Entire controller assembly is part number 14857.

HOSE BARB PTL 3/8 X 1/2 NPT

NUT NYLOCK 8-32 Z

Controller Layout

SCREW FHSC 8-32 X 1-3/4 BLACK

VENT BREATHER 1/2 FOR LIFT CONTROLS

VALVE HAND P5 POS 3 SC OC 1/2 NPT

HAND CONTROL WELDMENT

STICKER UP HERK DOWN .625 X 7

Description

HOSE BARB PTL 1/4 X 1/4 NPT BRASS

RED BUSHING 1/2 NPT X 1/4 NPT BRASS

4

1

2

3

5

6

7

9

8

Page 12 of 16

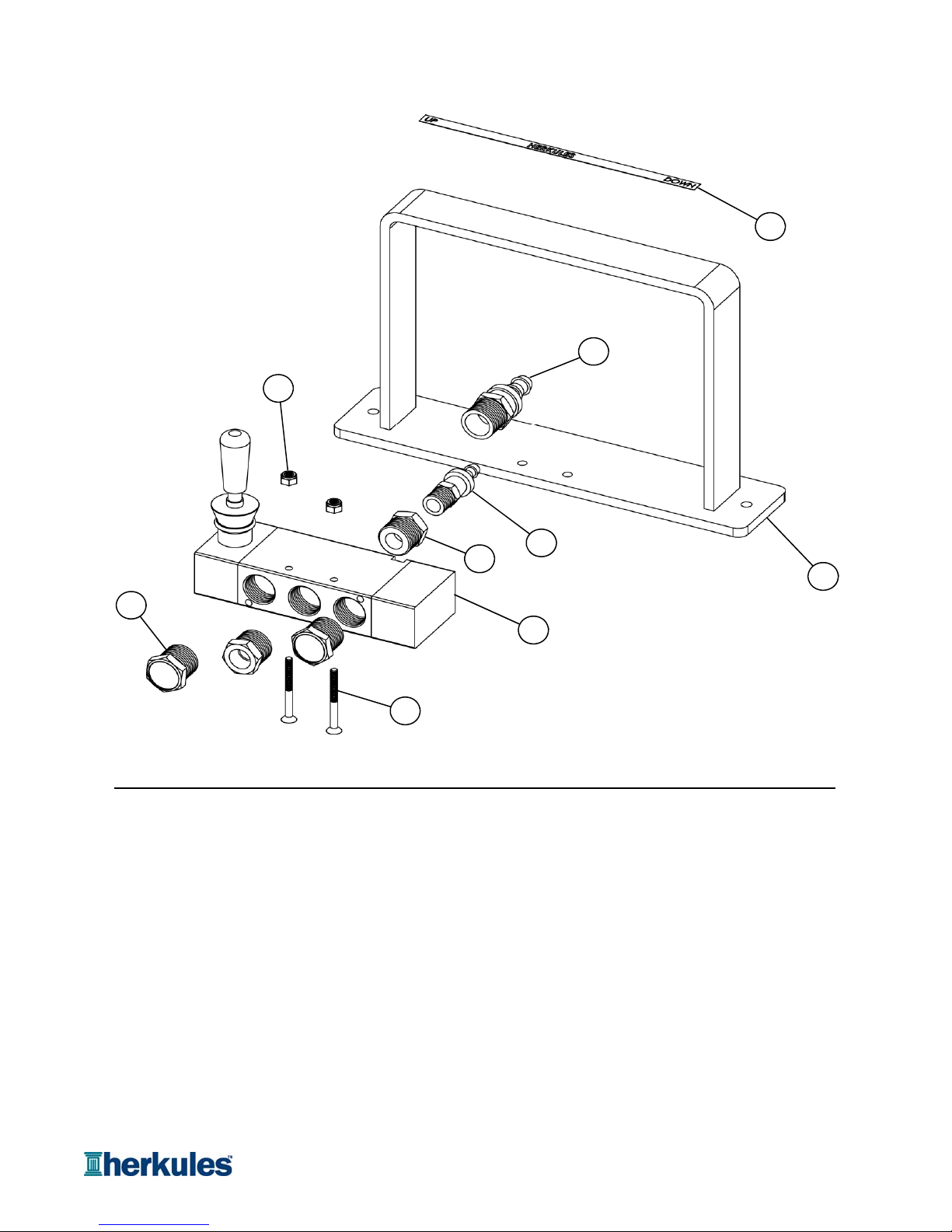

ID Part # Qty Units

1 009-141 1 EA.

2 M00 1 EA.

3 009-151 4 IN

4 1000166 1 EA.

5 720-122 1 EA.

6 700-112 1 EA.

7 1007872 1 EA.

8 T4 2 EA.

9 1003288 1 EA

10 M6 1 EA.

11 61A 1 EA.

12 M25C 1 EA.

13 1006006 1 EA.

14 C12D 1 EA

NOTE: Entire internal valve assembly is part number 10037.

VALVE 4-WAY PILOT 3/8 NPT BLACK

TEE STREET 1/8 NPT BRASS

Internal Valve Layout

MANIFOLD BLOCK 2 X 2 X 1-1/2 ALUM

Description

FITTING PTC 5/32 X 1/8 NPT

HOSE BARB PTL 1/4 X 1/8 NPT

ELBOW STREET 1/8 NPT BRASS

PLUG SOCKET 3/8 NPT BRASS

NIPPLE HEX 3/8 NPT BRASS

HOSE BARB PTL 3/8 X 1/8 NPT BRASS

MUFFLER 3/8 AIR EXHAUST

TUBE 1-1/4 CLEAR

CLAMP HOSE # 8 SS/Z

CLAMP HOSE # 4 SS

VALVE PRESSURE RELIEF 1/2 NPT 3.5 BAR

1

2

3

5

4

6

7

8

9

14

10

11

13

12

Page 13 of 16

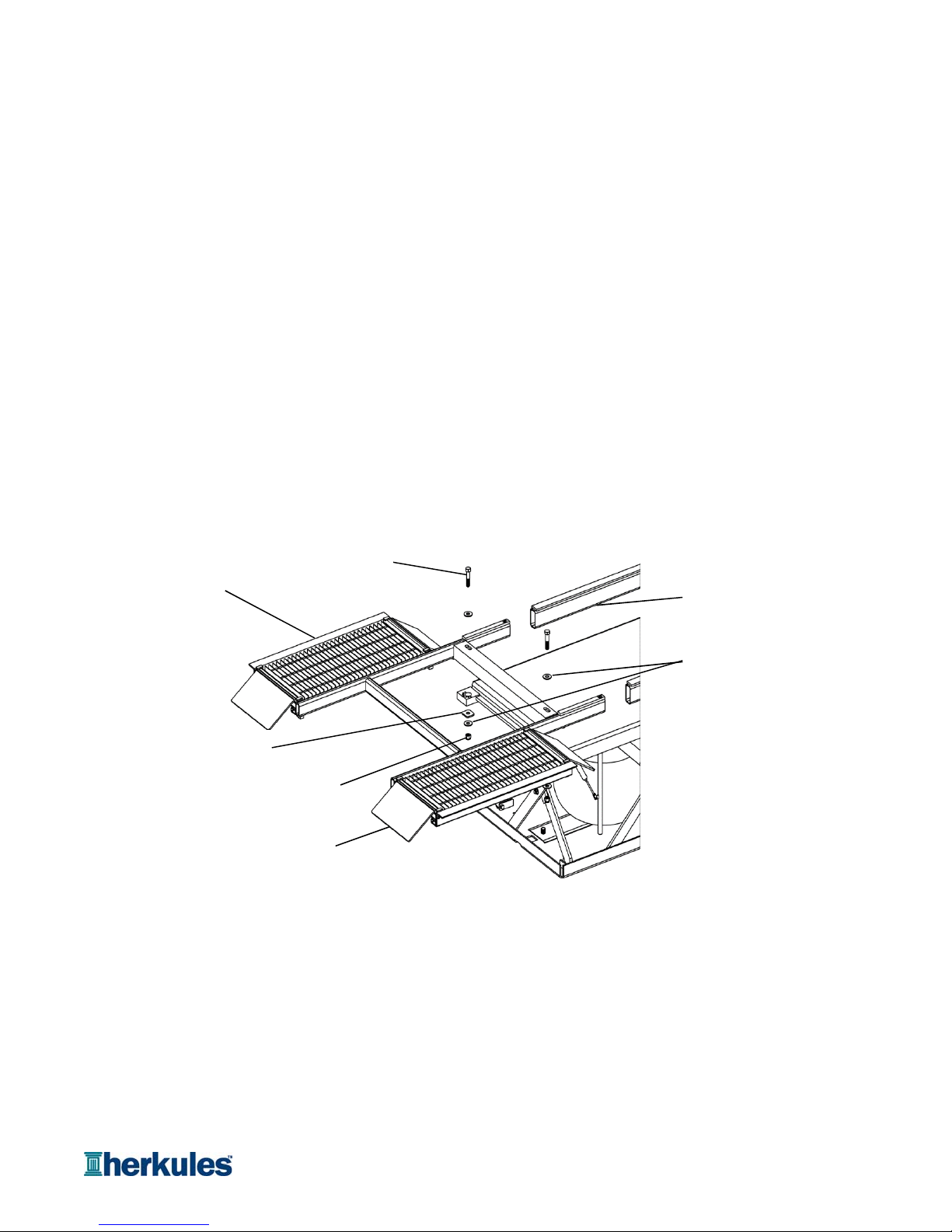

1. Layout the components of the 15244 KIT around the lift.

3. Position one side of the wing brackets over the appropriate lift blocks (see fig. 1).

4. Bolt the wing brackets to the lift as shown in fig. 1.

5. Slide the two tubes (#15247) into position on each side of the wing.

6. Slide the other wing into the tubes and line the mounting bracket over the lift blocks as shown in fig. 1.

8. Bolt the second set of wing brackets to the lift as shown in fig. 1.

9. Replace the old maximum capacity sticker with the new sticker. A stationary lift has 5000 lb. lifting capacity

after the 15244 KIT is installed.

10. Attach two ramps (10148) to each wing assembly (see fig. 1).

Installation of Suspension Kit

Wing 15244 Kit

(P/N 15245) Tube

Assembly

(P/N 15247)

Flat Washer

(P/N 009-125)

Hex Bolt

(P/N 1006319)

Ramp

Assembly

(P/N 10148)

Hex Nut

(P/N 1000241)

Flat Washer

(P/N 15260)

Page 14 of 16

Model Information

Page 15 of 16

Page 16 of 16

Table of contents

Other HERKULES Lifting System manuals

Popular Lifting System manuals by other brands

Discount Equipment

Discount Equipment SKYJACK SJ3013 Operation manual

Tractel

Tractel AH10-40 manual

twin busch

twin busch TW236M Installation, operation and maintenance manual

Sunex Tools

Sunex Tools 6616 owner's manual

Braun

Braun CENTURY NCL 02 Series Service manual

Haklift

Haklift LYKA1006 Translation of the original instructions

WMH Tool Group

WMH Tool Group JET TSLT-770 Operating instructions and parts manual

BorMann

BorMann BWR5218 user manual

Vestil

Vestil LLW Use and maintenance manual

Ravaglioli

Ravaglioli RAV232 NL manual

MAC TOOLS

MAC TOOLS LFMR6 Installation, operation and maintenance manual

RITE-HITE

RITE-HITE RHH owner's manual