Herrmidifier Herrtronic RDU-D Owner's manual

Engineered Humidification Systems

Herrmidifier®| www.herrmidifier-hvac.com

Herrtronic®RDU-D

Supplemental Manual

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

2www.herrmidifier-hvac.com

TABLE OF CONTENTS

I. Warranty Information................................................................................................................................3

II. General Description..................................................................................................................................3

Mounting Option ..................................................................................................................................3

Accessory Bag Contents .....................................................................................................................4

RDU-D Dimensions .............................................................................................................................4

III. Installation Preparation.............................................................................................................................4

Unit Clearances...................................................................................................................................4

IV. Direct Mount Option ..................................................................................................................................5

MDS with Direct Mount RDU...............................................................................................................5

MDD with Direct Mount RDU...............................................................................................................5

V. Remote Mount Option ................................................................................................................................6

MDS with Remote RDU.......................................................................................................................6

MDD with Remote RDU.......................................................................................................................7

VI. RDU Operation..........................................................................................................................................7

Steam Plume Chart .............................................................................................................................7

VII. Troubleshooting Chart...............................................................................................................................8

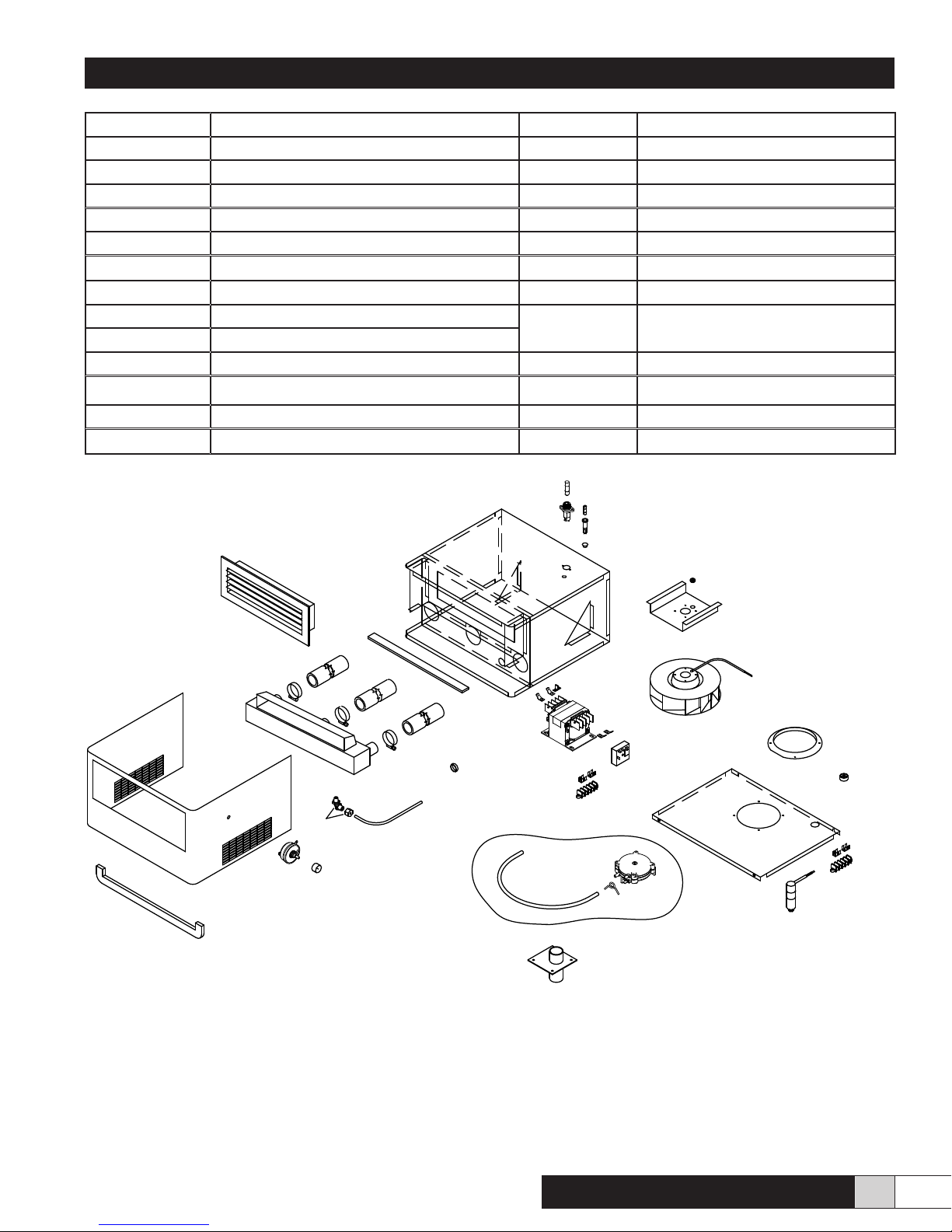

VIII. Parts List...................................................................................................................................................9

Exploded View.......................................................................................................................................9

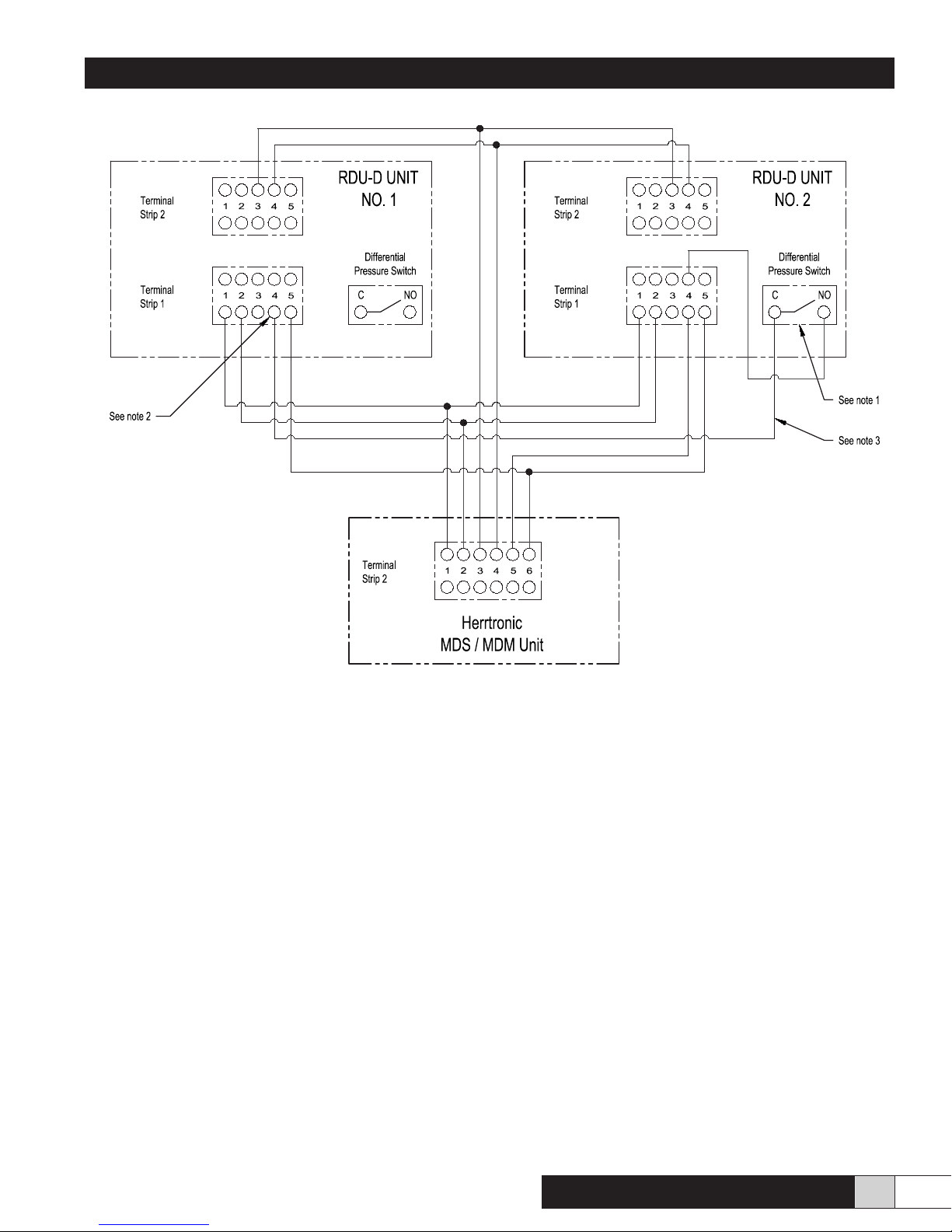

IX. Wiring Diagrams........................................................................................................................................10

RDU-D with Transformer 460/600V. ....................................................................................................10

RDU-D with Transformer 380V. ...........................................................................................................11

RDU-D without Transformer ................................................................................................................12

MDS/MDM Control to (2) RDU-D Units ...............................................................................................13

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

3

www.herrmidifier-hvac.com

I. LIMITED WARRANTY

Seller warrants the equipment of its manufacturing to

be free from defects in workmanship and material for a

period of 24 months after shipment. This warranty is

limited, however, to the repair or replacement of defective

equipment, which is returned, freight prepaid, to Seller’s

factory.

This limited warranty does not apply to any part or

component that is damaged in transit or when handling,

has been subject to misuse, negligence or accident, has

not been installed, operated or serviced according to

Seller’s instructions, or has been operated beyond the

factory-rated capacity or has been altered in any way.

Seller’s liability is limited to replacement of defective parts

or components and does not include any cost of labor

(including, but not limited to, labor required to remove and/

or reinstall any defective part) other than Trion/Herrmidier

factory labor.

Trion/Herrmidier shall not be responsible for loss of use

of any product, loss of time, inconvenience, or damage

to other equipment, or any other indirect or consequential

damage with respect to property whether as a result of

breach of warranty, neglect, or otherwise.

THE WARRANTIES AND LIABILITIES SET FORTH ARE

IN LIEU OF ALL OTHER WARRANTIES AND

LIABILITIES, EXPRESSED OR IMPLIED, IN LAW OR

IN FACT, INCLUDING IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FORPARTICULAR

PURPOSE.

The foregoing shall constitute the total liability of seller

in the case of defective performance of all or any of the

equipment or services provided to Buyer. Buyer agrees

to accept and hereby accepts the foregoing as the sole

and exclusive remedy for any breach or alleged breach of

warranty by Seller.

II. GENERAL DESCRIPTION

The RDU-D Series Room Distribution Units are designed

as a companion module for all MD Series Herrtronic

humidiers.

The RDU may be directly mounted on top of the Herrtronic

cabinet or mounted remotely. The RDU consists of a fan,

controls, & steam hose to distribute the steam directly into

the space. RDU-D must he remotely mounted when used

with an MDM series humidier.

Figure 1 - Mounting Options

Model No Electrical

Characteristics Capacity

RDU-D-1 208-240-1-50/60 5-50 lbs/hr.

RDU-D-1T 480-600-1-50/60

RDU-D-2 208-240-1-50/60 60-100 lbs/hr.

RDU-D-2T 480-600-1-50/60

RDU-D-2R 208-240-1-50/60

110-250 lbs/hr.

RDU-D-2L 208-240-1-50/60

RDU-D-2TR 480-600-1-50/60

RDU-D-2TL 480-600-1-50/60

Note: 1T & 2T models include a transformer to provide

208/230 single phase power to the RDU.

Note: MDD Units require two RDU units. For Direct

Mount you must use a specic right and left mount unit.

For remote mount, two Identical units may be used.

For remote mounting applications, the plumbing and

electrical connections may be routed through the bottom

or back of the RDU. There are two electrical knockouts,

two steam supply knockouts and one condensate return

knockout on both the bottom and back to facilitate

installation.

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

4www.herrmidifier-hvac.com

As shipped, the RDU is set up for direct unit mounting.

Longer wiring and condensate return tubing (supplied) will

be required for remote mounting. Be sure to use 18 gauge

(minimum) copper conductor wire with insulation rated for

600 VAC. Supply power may originate from the Herrtronic

humidier or a separate supply. If a separate source is

used, be sure to install a dedicated power disconnect.

All hardware and accessory components required for

installation are included as listed below:

Accessory Bag Contents

Item Quantity

¾” I.D. Plastic bushing 2

3” Diameter plastic hole plug 2

5/16” I.D. Plastic bushing 1

Steam inlet union 1*

2 ½” Stainless steel hose clamp 1*

¼” x 2” Lag screw 2

#8–32 x 3/8” Stainless steel machine screw 4

Wiring Kit 1

¼” O.D. Condensate return tubing 10’

*-Double quantity for RDU-D-2 series units

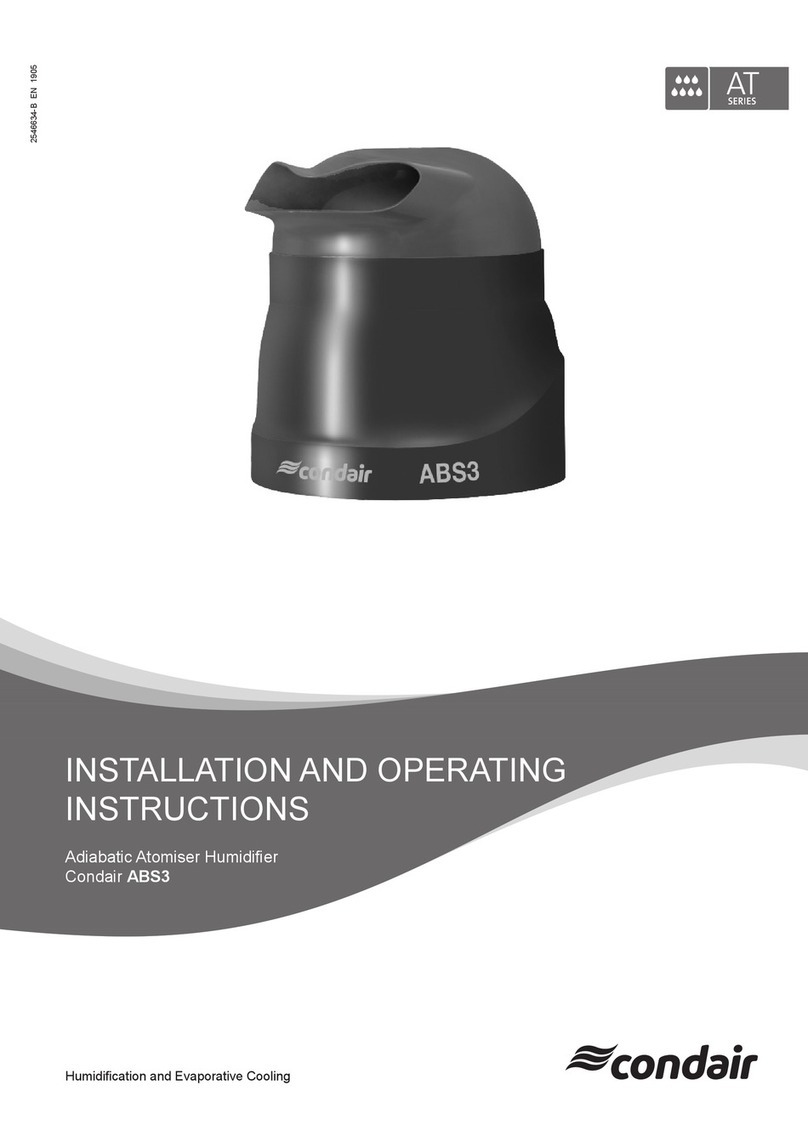

Figure 2 - Overall Dimensions

III. INSTALLATION PREPARATION

! WARNING !

Disconnect power to the humidier while

installing RDU.

The RDU unit must either be placed higher than the

Herrtronic unit or provisions for handling the condensate

via an external drain must be made. The following chart

details the physical clearances around the cabinet for

servicing the unit. Figure 13 details the clearances required

due to the steam plume.

MINIMUM CLEARANCES AROUND CABINET

LEFT - 15”

RIGHT - 15”

TOP* - 2”

BOTTOM - 0”

* Subject to output, fan speed and room conditions

NOTE:

The steam plume should not impinge on walls,

ceilings or other objects. Supply air registers, if

present, must be directed away from RDU.

Figure 3 - Bottom View Dimensions

Figure 4 - Back View Dimensions

10.05"

16.91" 15.40"

Figure 3 Top View Dimensions

.99"

4.99"

7.13" 4.00"

7.70"

1.20"

3.00"

.56"

(4) 7/8" Holes

Power Access

(2) 7/8" Holes

Optional Condensate Drain

(2) 3" Holes

Steam Hose Inlet

Figure 4 - Bottom View

Front of Unit

2.45"

12.00"

2.45"

2.30"

(4) 7/8" Knockouts

Power Access

3.00"

1.00"

.99"

5.77"

.50"

2.50"

(2) 2 1/2" Holes

Optional Steam Inlets

(2) 5/16 X 5/8 Dia.

Keyhole Mounting Slots

Figure 5 - Back View

4.14"

12.76"

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

5

www.herrmidifier-hvac.com

REMOVE THE COVER FROM THE RDU

1. Loosen the two hex socket head set screws on the fan

speed control knob and remove knob (Figure 5).

2. Remove the phillips head screws which fasten the

cover to the housing.

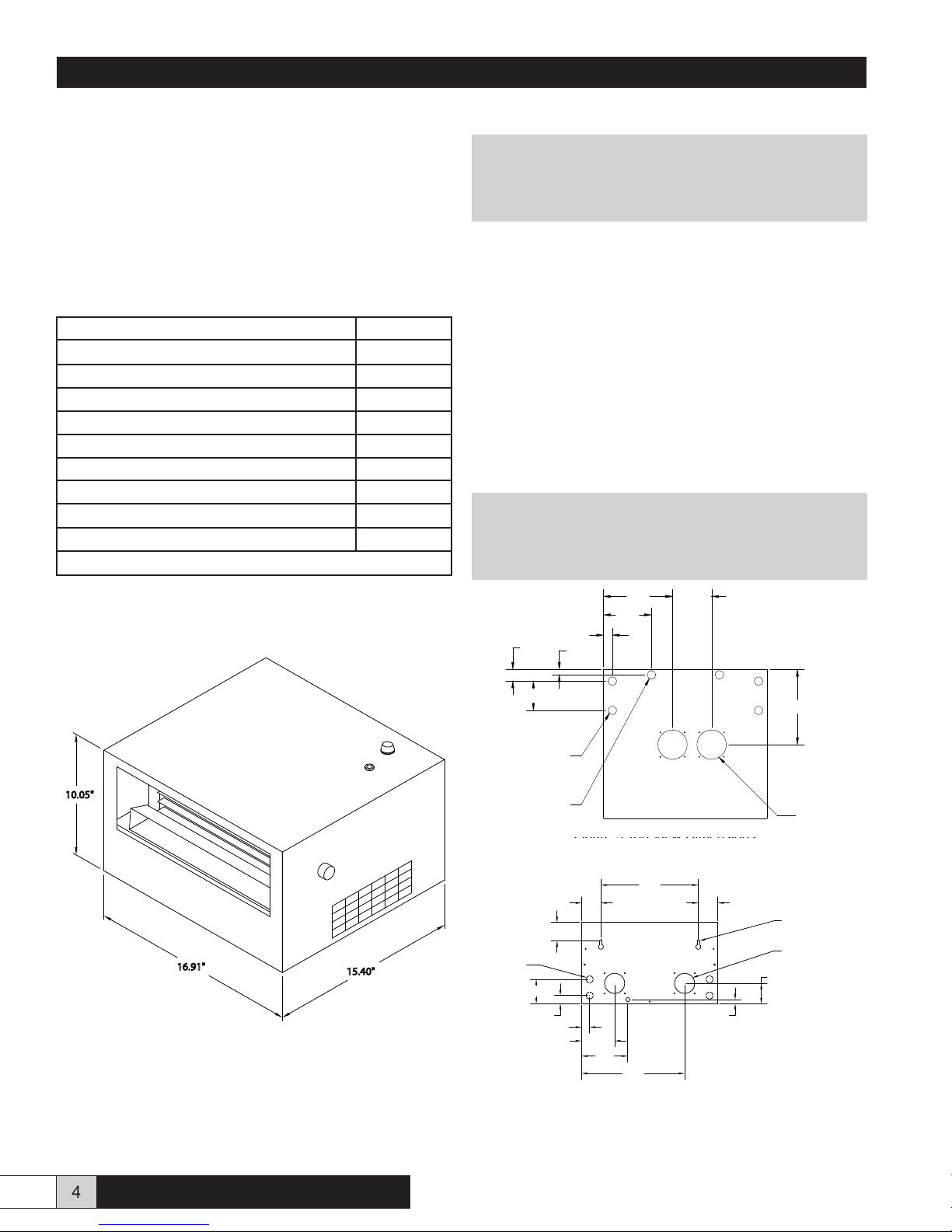

IV. DIRECT MOUNT OPTION (MDS, MDD)(Figure 6 & 7)

! WARNING!

Be sure to disconnect power to the Herrtronic

Humidier before beginning installation.

1. Assure that the mounting for the Herrtronic unit will

support the additional 40 pound load of each RDU

unit.

2. Remove the knock-out from the top of the Herrtronic

cabinet and install the 5/16” I.D. plastic bushing for the

condensate return.

3. Remove the rearmost 7/8” knockout from the top of

the Herrtronic cabinet.

4. Install one 3/4” plasitc bushing from the inside into the

rearmost 7/8” hole in the bottom of the RDU.

5. Place the RDU on the Herrtronic cabinet, guiding the

steam hose(s) into the tank compartment.

6. Feed the wires (total of seven) through the 3/4” bushing

and condensate tubing through the 5/16” bushing into

the Herrtronic unit.

7. Fasten the RDU in place using four #8-32 self-tapping

screws installed from inside the Herrtronic cabinet.

8. Replace the RDU cover & fan speed control knob.

9. Insert the condensate return tubing into the grey

plastic ll tee. It will extend I” into the tee.

10. Connect wires # 1 -6 to the 6 pole RDU terminal strip

located near the top of the Herrtronic high voltage

electrical compartment. Connect the ground wire #24

to the Herrtronic ground terminal located near the

bottom of the high voltage compartment.

NOTE

See Figure 15, 16 & 17 for standard electrical hookup

for MDM and MDS.

11. Remove jumper wire #39 from the Herrtronic 12

pole controls terminal strip located in the low voltage

electrical compartment between poles #1 and #2.

Installation is now complete. Proceed to the RDU Operation

section of this manual then to the Start-Up section of the

Herrtronic Installation and Operation Manual OM-93.

Figure 6 - MDS Direct Mount

Figure 7 - MDD Direct Mount

ENTERFAULTS

HERRTRONIC MD

ON/OFF

CYL FULL

BACK

FAULTPOWER

HERRMIDIFIER

HERRMIDIFIER

HERRMIDIFIER

HERRMIDIFIER

HERRMIDIFIER

SLAVE

FAULTPOWER

BACK

ENTER

FAULTS

ON/OFF

CYL FULL

MASTER

FAULTPOWER

BACK

ENTER

ON/OFF

FAULTS

CYL FULL

HERRTRONIC MD

PHILLIPS HEAD SCREWS

(6) PER SIDE

(1) ON FRONT

SIDE

Fan Speed Control Knob

Figure 5

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

6www.herrmidifier-hvac.com

V. REMOTE MOUNT OPTION (MDM, MDS, MDD)

1. The RDU may hang directly on a wall using the two

1/4” x 2” lag screws included. There are two key-hole

slots on the back of the cabinet which engage these

screws. Be certain that: 1) the screws are fastened

securely enough to the wall to support the 40 lbs.

weight of each RDU unit, and 2) the screws are level.

Turn the screws in until the heads are 1/8” away from

the mounting surface.

2. Hang the unit on the wall and tighten the two lag

screws.

3. The steam hose(s) is to be connected using the steam

inlet union(s) (Figure 8).

4. Trim the steam hose(s) which is connected to the RDU

manifold so that it ts properly onto the union(s) and

secure connections with a hose clamp(s).

5. Fasten steam inlet union(s) to bottom or back of RDU

cabinet with screws.

6. Remove the knockout from the top of the Herrtronic

cabinet and install the 5/16” I.D. plastic bushing

(included).

7. Remove the 18” piece of condensate return tubing

connected to the manifold elbow.

8. Uncoil the 10’ piece of condensate return tubing (drain

line), feed into the RDU cabinet, from the bottom or

back, and connect to the manifold elbow.

9. Run the condensate return tubing down into the

Herrtronic cabinet through the 5/16” I.D. plastic

bushing.

10. The condensate tubing can be attached to the steam

hose or electrical conduit interconnecting the RDU

and Herrtronic with cable ties or equivalent.

11. After the condensate tubing is secured, insuring that

there are no kinks or low spots, the length should be

trimmed so that it can extend 1” into the grey plastic ll

tee in the Herrtronic unit.

12. National, state or local electrical codes may require

the use of two separate conduits - one for high voltage

supply power and one for control wiring.

13. There are a total of seven wires which are to be

connected between the RDU and the Herrtronic unit.

The RDU receives all of its power and control from the

Herrtronic unit. Use the two 7/8” holes or knockouts

on the bottom or back of the RDU cabinet and the two

7/8” knockouts on the top of the Herrtronic cabinet for

wiring conduit.

14. Wires #3 and #4 are the high voltage power supply

and should be run in one conduit.

15. Along with the ground wire #24, wires #1, #2, #5, and

#6 should be run in the second conduit.

16. Connect wires # 1-6 to the 6 pole RDU terminal strip

located near the top of the Herrtronic high voltage

electrical compartment. Connect the ground wire #24

to the Herrtronic ground terminal located near the

bottom of the high voltage compartment.

NOTE

See Figure 15, 16 & 17 for standard electrical hookup

for MDM and MDS.

17. Remove jumper wire #39 from the Herrtronic 12

pole controls terminal strip located in the low voltage

electrical compartment between poles #1 and #2.

18. Replace the RDU cover and the fan speed control

knob.

Installation is now complete. Proceed to the RDU operation

section then to the start-up section of the Herrtronic

Installation, Operations and Service Manual OM-93.

Figure 8 - Steam Connections (Side View)

Figure 9 - Drain Line (Front View)

Figure 10 - MDS Remote Mount

BLOWER

DRAIN

LINE

STEAM HOSE

STEAM INLET UNION

(REMOTE MOUNT)

STEAM INLET UNION

(ALTERNATE LOCATION)

DRAIN

LINE

GRILL

>50 lb/hr requires second hose

CYLFULL POWER FAULT

BACK

ON/OFF

FAULTS ENTER

HERRTRONIC MD

Figure 10 - Front View

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

7

www.herrmidifier-hvac.com

Figure 11 - MDD Remote Mount

VI. RDU OPERATION

Upon starting the Herrtronic unit, the RDU fan will be

energized. If airow is not sensed within ten seconds, the

Herrtronic unit will shutdown and a fault will be registered.

Depress ‘”Fault” button to conrm fault condition and clear

fault by pressing “Enter” and then “Back” button to return

to Menu 1.

Once operating, the fan speed can be adjusted continuously

from 1—5 (slow—fast) by turning the fan speed control

knob. Refer to the chart below for the optimum fan speed

setting for your application.

When the Herrtronic unit is turned “off”, either by switch

or controller, the RDU fan will continue to operate for 15

minutes to prevent the formation of condensate inside the

cabinet. The steam plume direction can be controlled both

horizontally and vertically by adjusting the louvers on the

air discharge grille.Louvers adjusted as shown in Figure

12 produce the most consistent and shortest evaporation

distance.

Figure 12 - Louver Details

Figure 11 - MDD Remote Mount

HERRTRONIC MD

STEAM INLET UNION

(REMOTE MOUNT)

STEAM HOSE

DRAIN

LINE

BLOWER

OPTIMUM LOUVER

DIRECTION, DOWN 30°

Figure 14 - Optimum Louver Placement

Figure 13 - Steam Plume Characteristics

! WARNING!

To avoid potential contact with steam, be certain to shut off the Herrtronic unit BEFORE

adjusting the louvers.

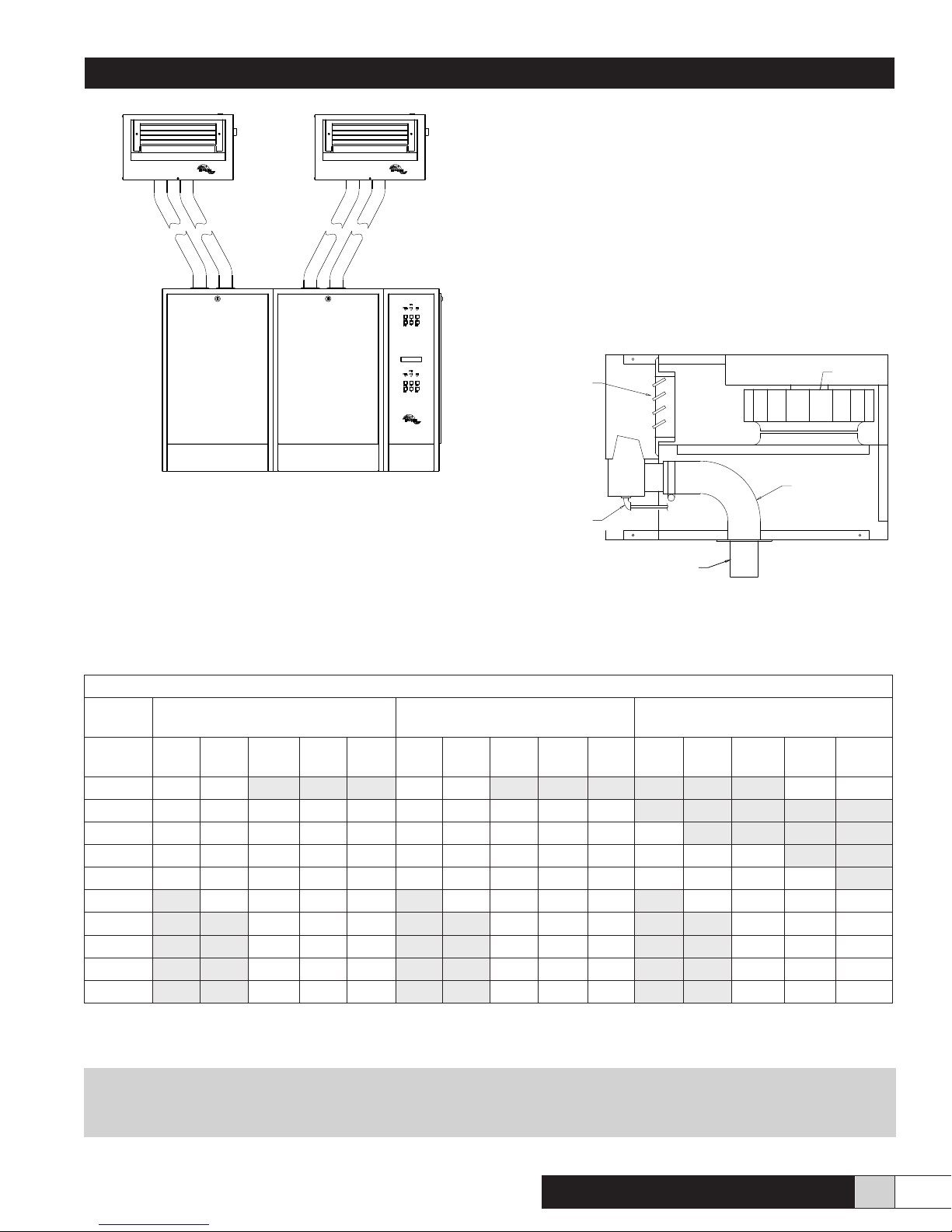

STEAM PLUME (@75° F, 55% R.H.)

Output

lbs./Hr

Throw (in.)

Blower Speed (CFM)

Breadth (in.)

Blower Speed (CFM)

Rise (in.)

Blower Speed (CFM)

1

(210)

2

(240)

3

(280)

4

(320)

5

(365)

1

(210)

2

(240)

3

(280)

4

(320)

5

(365)

1

(210)

2

(240)

3

(280)

4

(320)

5

(365)

10 20 15 15 15

20 50 35 30 35 35 20 20 18 18 18

30 90 80 75 70 60 28 26 24 24 24 10

40 98 92 90 94 100 36 36 36 32 26 18 12 6

50 112 112 116 120 120 40 36 36 36 30 36 22 12 6

60 120 126 130 134 36 34 28 28 58 30 14 6

70 126 132 138 42 40 36 36 20 12

80 130 138 156 48 42 40 52 24 16

90 136 144 156 58 52 46 72 36 20

100 126 138 156 60 60 48 120 50 25

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

8www.herrmidifier-hvac.com

VII. TROUBLESHOOTING

Problem/Symptom Reason / Correction

Steam Condensing on RDU sheetmetal or other objects. 1. Adjust louvers per gure 12

2. Fan not running. Check pressure switch for fail closed

condition. Herrtronic unit should not operate if fan is not

running.

3. Too little airow. Increase fan speed.

4. Room is very cold, very humid, or objects are cold.

Decrease humidity setpoint at Herrtronic unit or humidity

controller.

Fan not energizing 1. Check that the fan rotates freely.

2. Check fuses in RDU.

3. Check wiring to fan.

4. Check voltage to fan - should be 220 VAC +/- 10%.

5. Replace fan and capacitor.

Fan speed adjustment not working. 1. Replace rheostat.

Water spitting out of manifold 1. Check condensate drain hose. If it is clogged, clean.

2. Make sure condensate drain hose is sloped properly

and there are no low spots or kinks.

Fan does not continue to operate for 15 minutes after

Herrtronic unit shuts down.

1. Check wiring to relay/timer.

2. Check that the 24 VAC is present between terminal #2

and #3 on relay timer. If so, replace timer.

Air pressure switch not closing. 1. Fan speed setting too low. Increase fan speed.

2. Check tubing on switch for clogging or out of position.

3. Faulty air pressure switch. Replace.

Blown fuses in RDU 1. Check fan for short circuit.

2. Check RDU wiring for short circuit.

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

9

www.herrmidifier-hvac.com

1847C Quick Connects EST-1404 Rheostat

120096-006 Hole Plug EST-1405 Relay Timer

165475-001 Dierential Pressure Switch Kit EST-1407 Blower Speed Control Knob

165538-001 Fuse, 8/10 A EST-1408 Capacitor

265544-001 Fuseholder EST-1409 Bushing

265561-001 Transformer (RDU-D-1T & 2T) for 480/600 EST-1415 1/4” Tubing

265561-002 Transformer (RDU-D-1T & 2T) for 380 EST-1416 Fuseholder

DH-052 Foam Tape EST-1417 Fuse, 1 A

EST-230 Steam Hose EST-1447-1

EST-1447-2

Manifold Assembly (Specify Unit

Model Number)

EST-353 Bushing

EST-531 5-Pole Terminal Rail EST-1458 Steam Inlet Union

EST-1401 Distribution Grille EST-1538 Rubber Grommet

EST-1402 Blower EST-1563 Stainless Steel Hose Clamp

EST-1403 Blower Inlet Ring GT-20-20 Elbow

EST-1409

EST-353

EST-1402

EST-1403

EST-1408

EST-531

1847C

165475-001

EST-1405

EST-531

1847C

EST-1416

EST-1417

120096-006

EST-1401

DH-052

EST-1407

EST-1415

GT-20-20

EST-230

EST-1563

EST-1447

DH-052

165538-001

265544-001

265561

EST-1404

EST-1538

EST-1458

Figure 14 - Exploded View

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

10 www.herrmidifier-hvac.com

H2 FOR 460V INPUT

H3 FOR 600V INPUT

Figure 15 - RDU-D with 460/600V Transformer

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

11

www.herrmidifier-hvac.com

Figure 16 - RDU-D with 380V Transformer

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

12 www.herrmidifier-hvac.com

Figure 17 - RDU-D w/o Transformer

Herrtronic®RDU-D Supplement

Installation, Operation, & Maintenance Manual

13

www.herrmidifier-hvac.com

Figure 18 - MDS/MDM Control to (2) RDU-D Units

Notes:

1. Disconnect wire number (16) from the common terminal of the differential pressure switch in the RDU-D unit

number (2). Remove the spade connector and cap with a wire nut.

2. Disconnect Blue wire number (5) from terminal strip number (1) on RDU-D unit number (1) remove the spade

connector and cap with a wire nut.

3. This wire is connected to RDU-D unit number (1) at terminal strip number (1). Position number (4) to the

RDU-D number (2) common terminal of the differential pressure switch.

Engineered Humidification Systems

Form No. OM-102 09/13 ©Herrmidier 2013. All Rights Reserved.

Herrmidifier®

101 McNeill Rd. | Sanford, NC 27330

Table of contents

Other Herrmidifier Humidifier manuals

Herrmidifier

Herrmidifier 6000 Series User manual

Herrmidifier

Herrmidifier G-200/300 Owner's manual

Herrmidifier

Herrmidifier 465-C1 Manual

Herrmidifier

Herrmidifier Herrmidisteam-SS User manual

Herrmidifier

Herrmidifier Herrtronic AD User manual

Herrmidifier

Herrmidifier 2000 User manual

Herrmidifier

Herrmidifier G-100ES Owner's manual

Herrmidifier

Herrmidifier 707U Manual

Herrmidifier

Herrmidifier Herrdraulic User manual

Herrmidifier

Herrmidifier Herrtronic 6500 Series User manual