Herz MD10 User manual

BA MD10MD14 V30 R12 03_2012 EU short 1

HERZ

Herz Mitteldruckgebläse – Betriebsanleitung

Herz medium-pressure blowers – Operating instructions

Ventilateurs moyenne

pression Herz – Notice d’utilisation

Herz Ventilatori a media pressione– struzioni per l’uso

Herz middendrukventilatoren – Bedieningshandleiding

Herz wentylatory średniociśnieniowe - nstrukcja obsługi

Herz középnyomású

légellátó – Használati útmutató

Herz Високо налягане вентилатор - инструкции за работа

HERZ

GmbH

Biberweg 1, D-5 5 Neuwied

Telefon +49 (0)2 22 / 8 10 8

Telefax +49 (0)2 22 / 8 10 80

Internet http://www.herz-gmbh.com

E-mail: info@herz-gmbh.com

BA MD10MD14 V30 R12 03_2012 EU short 7

1. CONTENTS

1. MACHINE SPECIFICATIONS

2. INFORMATION ON TRANSPORTATION AND

HANDLING

3. INFORMATION ON PUTTING INTO SERVICE

4. INSTRUCTIONS FOR OPERATION AND USE

5. INSTRUCTIONS FOR MAINTENANCE

. SAFETY RELATED INFORMATION ON TAKING OUT

OF OPERATION AND REMOVAL

7. LIABILITY AND EXCLUSION OF LIABILITY

8. TECHNICAL SPECIFICATIONS

APPEND X A: EXPLOSION DRAWING

APPEND X B: GENERAL SPARE PARTS

APPEND X C: DECLARATION OF CONFORMITY

These Operating Instructions must be available to operating

personnel at all times. Read these Operating and Assembly

Instructions carefully before installing and putting the blower into

service.

Subject to change without prior notice. If in any doubt, the

manufacturer should be consulted. This document is protected

by copyright. It must not be disclosed to third parties without our

express written consent. Any form of duplication or recording

and storage in electronic equipment is forbidden.

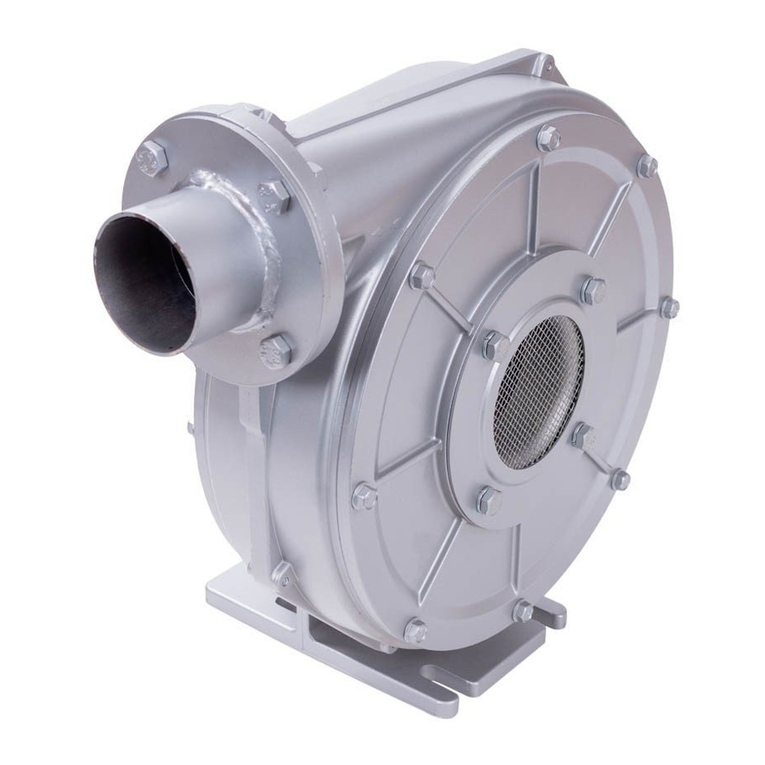

1. MACH NE SPEC F CAT ONS

Please refer to the cover sheet for our address.

For the area of validity of these Operating and Assembly

Instructions, please refer to the Declaration of Installation

Conformity contained in Annex C.

The technical specifications on page 11 apply to the standard

version. Your blower’s specifications may differ from these

specifications (refer to nameplate). If this is the case, please

refer to the enclosed, additionally applicable documents or your

own applicable Operating and Assembly Instructions.

Nameplate

The data on the rating plate is applicable to connection,

maintenance and ordering of spare parts.

Also refer to the nameplate for the serial number of the

appliance and its year of manufacture.

1.1 Designated use

The blowers are designed for delivering clean air only.

Use of the blowers for

• aggressive,

• abrasive,

• sticky,

• toxic,

• potentially explosive or

• very moist

media is not permissible.

The maximum temperature of the conveyed medium must not

exceed -20°C to +80°C in the standard version and 180°C in

special versions fi tted with a thermal barrier. Solid particles or

contaminants must be removed by a fi lter unit before entering

the blower.

The maximum ambient temperature must not exceed + 0° C in

the standard version.

The blower is not suitable for open-air installation or

switchedmode operation. The standard version of the blower is

not suitable for use in explosive atmospheres.

Special versions

for applications not mentioned above are available on request.

Remodelling and modifi cation of the blower are not permitted. In

the case of special equipment, the enclosed supplementary

Operating and Assembly Instructions must be observed and

adhered to. The supplementary instructions differ in certain

respects from these Operating and Assembly Instructions.

Elektror blowers offer a high level of operational reliability.

As the blowers are high-powered machines, the safety

instructions must be strictly observed in order to avoid injuries,

damage to objects and to the machine itself.

1.2 Mechanical hazards

The mechanical hazards in HERZ blowers have been minimised

in accordance with the current state of the art, as well as the

requirements for safety and health protection. To eliminate any

further risk on the part of the operator, we recommend that

suitable protective gear be used and worn during all lifecycle

phases of the appliance (please refer to the instructions below).

1.3 Danger of hand injury

The rotating parts inside the appliance pose a high risk of injury

during operation. Before opening, reaching in or inserting tools

into the appliance, always shut it down and wait until all moving

parts come to a standstill. Make sure the appliance is reliably

protected against restarting while work is in progress.

Also make sure that no hazardous situation can occur as a

consequence of restarting after shutdown, e.g. as a result of a

power cut or blockage.

1.4 Weight and stability

Beware of falling hazards during transportation and installation in

particular. Refer to 2.1 – Transportation and handling, as well as

3.1 – Installation and assembly.

1.5 Suction effect

The blowers produce a powerful suction effect.

Warning!

Objects, items of clothing and also hair can be

sucked into the intake port. Risk of injury!

Do not stand near the intake opening during

operation.

The blower must not be operated with an open

intake opening. The intake opening must be

covered with protective grating according to DIN

EN ISO 13857.

Never place your hands in the intake opening.

1.6 Blowing effect

Warning!

The blowing effect is very powerful on the exhaust

side. Sucked in objects may be ejected at very

high speed (danger of injury).

The blowers are designed for delivery of clean air

only. To reliably prevent the sucking-in of foreign

objects or contaminants, which might be

discharged, these objects have to be removed

before entering into the blower by installing a

filter. Do not reach into the exhaust.

8 BA MD10MD14 V30 R12 03_2012 EU short

1.7 Temperature

Warning!

The blower housing assumes the temperature of

the conveyed medium during operation. If this is

above +50° C, the blower must be protected

against direct contact by the operator (risk of burn

injury).

In the case of high-power models in particular, the temperature

of the conveyed medium can increase as it fl ows from the intake

side to the exhaust side. The temperature difference can be in

the region of up to +20°C, depending on the operating

conditions. This varies from one model to another.

1.8 Motor circuit breaker

Before putting the blower into operation, be sure to safeguard

the drive motor with a motor circuit-breaker (this does not apply

to frequency-converter-operated appliances).

Where appliances are frequency-converter-operated, the

existing temperature sensor (PTC resistor sensor) must be

connected to the converter and evaluated.

1.9 Noise emission

The noise generated by a blower is not constant throughout the

performance range. For details of radiated noise level, please

refer to the table on page 11.

In some cases, sound insulation may be necessary (it is

recommended that emission levels be measured by the

operator). Sound insulation must be provided by the operator to

avoid exceeding the statutory maximum levels at the workplace

and in the immediate vicinity of the blower.

No sound insulation of any kind whatsoever should cause the

ambient temperature to exceed +40°C at the drive motor (this is

not permissible).

1.10 Electrical hazards

Before carrying out electrical work, the appliance must always be

switched off and protected against accidental restarting.

Check that no voltage is present.

2. NFORMAT ON ON TRANSPORTAT ON

AND

HANDL NG OF THE MACH NE

2.1 Transportation and handling

• Before installation and putting into service, check all

parts for transit damage. A damaged blower is a

potential safety hazard and, therefore, should not be

put into service.

• Do not leave the blower unprotected in the open

(protect against ingress of moisture).

• Attach hoist securely. Only use hoists and load

suspension devices with suffi cient load-carrying

capacity. Secure the route of transportation.

3.

NFORMAT ON ON COMM SS ON NG

THE MACH NE

3.1 nstallation and assembly

• Install the blower so it is protected against weather

and sun exposure. Refer also to the information on

installation under 1.1, Designated use .

• Do not expose to vibrations or shocks. Permissible

vibrational load on blower: refer to ISO 14 94, BV-3.

• Standard blowers with base: Bolt securely to a level

and fi rm surface at the place of use, making sure that

the surface has adequate load-bearing capacity and

avoiding vibration transmission or vibrational load.

• Cover open intakes or outlets with protective grating

according to DIN EN ISO 13857.

Warning!

Putting into operation of the incomplete machine

is prohibited until it has been ascertained that the

machine into which the incomplete machine is to

be installed complies with the provisions of the

Machinery Directive (2006/42/EC).

• Ensure adequate motor ventilation. Permissible

ambient temperatures:

Series version with a rated voltage (max. +/-10% voltage

tolerance) and a rated frequency of 50 Hz or 0 Hz:

• Ambient temperature -20°C to + 0°C

Special voltages, multi-voltage motors, FU compatible versions,

FUK versions, UL certifi ed appliances, appliances with

Aircontrol :

• Ambient temperature -20°C to +40°C

• The performance of the drive motor’s ventilation

system must not be impaired by the installation

situation.

3.2 Electrical connection

∗

∗∗

∗

Note!

The work described in this section may only be

performed by a qualifi ed electrician. Connect the

appliance to the power supply in the terminal box

as per the wiring diagram and in compliance with

the applicable local regulations.

Three-phase or a.c. motors can be used as drive motors.

In the appliance designation, the letter D stands for threephase

a.c. and the letter E for single-phase a.c.

• The drive motor must be protected using a motor

overload switch (this does not apply to frequency

converter operated appliances). Where appliances are

frequencyconverter- operated, the existing

temperature sensor (PTC resistor sensor) or

temperature switch (normally closed contact) must be

connected to the converter and evaluated.

• Check that the mains voltage matches the ratings on

the nameplate.

• The safety earth terminal can be found in the terminal

box.

∗

∗∗

∗

Note!

• For operation of the drive motor with a

frequency converter, the following points

should also be noted:

• Motors may only be operated on a

frequency converter if they have “/FU”

(which denotes “frequency converter

compatible”) marked on the nameplate,

or if they have been ordered as

“frequency converter compatible”

motors and confirmed.

• The maximum supply voltage of the

frequency converter is 400 V without a

motor filter. If longer wires and higher

converter supply voltages are used

and/or the max. pulse voltage (1300 Vpp)

at the motor terminals is exceeded,

suitable precautions, e.g. a motor filter,

must be taken to protect the motor.

Please consult the converter supplier in

this matter. If the motor filter is supplied

with the blower, it must be installed

between the converter and the motor.

Please make sure that there is sufficient

reserve space in the switch cabinet and

adhere to the guidelines for installation

and assembly in the operating

instructions issued by the frequency

converter/motor filter manufacturer.

BA MD10MD14 V30 R12 03_2012 EU short 9

∗

∗∗

∗

•

The wire running between the motor and

the frequency converter must not exceed

a length of 20 m, configured as a

suitable, shielded cable and laid by as

direct a route as possible, without any

additional plug/clamp connections.

• The braided screen in the connecting

cable must cover the full length of the

cable on both sides, i.e. be connected to

the earthing system at the frequency

converter and to the motor using a low

electrical resistance. For this purpose,

suitable EMC cable couplings must be

used on the motor side. They must

contact the cable shield around its full

circumference and have a low

resistance.

For further information about EMC compliant installation and

assembly, refer to the Operating and Assembly Instructions

issued by the frequency converter manufacturer.

3.2.1 Confi guration for three-phase current blowers

Checking the direction of rotation

Switch on the blower. The running direction of the impeller

should correspond to the direction arrow on the housing. If the

impeller rotates in the wrong direction, then interchange L1 and

L3.

3.2.2 Configuration for single-phase a.c. blowers

3.3 Special configurations and additional clamps

Terminal diagrams can be found in the motor terminal box for

voltage interchangeable motors, pole-changeable motors, FU

motors and other special configurations of threephase a.c. and

a.c. motors. This also applies to the optional thermal winding

protection and the space heater.

4. NSTRUCT ONS FOR OPERAT ON

AND USE

4.1 Basic information

Please observe the notes on designated use in section 1.1, as

well as the safety guidelines in sections 1.2 to 1.10.

If electrical current drops below the rated current of the drive

motor during operation, check to see if the mains voltage and

frequency match the appliance ratings (nameplate).

After protective shutdowns, e.g. tripping of the motor

circuitbreaker, activation of the PTC evaluation unit by motors

with a PTC resistor sensor, or after a protective shutdown of the

frequency converter during FU applications, the appliance must

not be restarted until the problem has been identified and

eliminated.

If the blower cannot be operated over the whole range of the

characteristic curve, the motor may overload if the system

resistance is too low (excessive current consumption). The

volumetric air fl ow should be reduced in this case by means of a

throttle valve fi tted on the intake or discharge side.

The blower must not be subjected to vibration or impact loads.

4.2 Frequency converter operation

A frequency converter is used, allowing a wide range of speed

adjustments. There is only a small, load-related difference in rpm

between idle state and the max. load of the blowers.

To ensure trouble-free operation of the blowers, it is

important that the converter meet the following

requirements:

• Converter output equal to or greater than motor power

output *)

• Converter current equal to or greater than motor

current *)

• Converter output voltage equal to rated motor voltage

• The pulse frequency of the converter should be 8 kHz,

since a lower pulse frequency can cause very noisy

motor operation.

• The converter should have a connection for a

temperature sensor (PTC resistor sensor) or a

temperature switch (normally-closed contact)

*) Refer to the rating plate for data

The motor can be operated in a delta or star-point configuration,

depending on the input voltage of the converter.

The following U/f assignments must be confi gured at the

converter.

If this is ignored, the motor current will increase

disproportionately and the drive motor will fail to achieve its rated

speed.

∗

∗∗

∗

Note!

Do not set the converter to a higher frequency

(rpm) than the frequency (f ) specified on the

nameplate, because this can overload the motor or

irreparably damage the blower due to

overspeeding. Similarly, a so-called “boost“ must

never be set at the converter because this would

result in excessive heating of the drive motor. The

temperature sensors must be connected to the

relevant converter inputs in order to protect the

drive motor. Single-phase a.c. motors are

unsuitable for converter operation.

To ensure safe and trouble-free operation, the

installation and safety instructions provided by

the frequency converter supplier in the operating

or application manuals must be strictly adhered

to.

Please note also that, in certain ambient

conditions, heavy soiling of the cooling fins can

occur in FUK-compliant appliances. If the cooling

capacity of the cooling fi ns is insufficient, the

frequency converter will shut down. Appliances

which are operated in these environments must be

inspected on a regular basis.

10 BA MD10MD14 V30 R12 03_2012 EU short

Protection by residual-current-operated circuit breaker

(F circuit-breaker):

IGBT frequency converters produce discharge currents of >=3.5

mA due to their design principle. These discharge currents can

lead to unwanted tripping in systems protected by a 30 mA-FI

circuit-breaker.

If a fault occurs, fault currents can also discharge through the PE

conductor as direct current. If protection is needed on the supply

side by means of an FI circuit-breaker, then an ACDC sensitive

(type B) FI circuit-breaker must be used. Use of an FI circuit-

breaker other than type B can cause death or serious injury if a

fault occurs.

To meet the EN 1800-5-1 standard, the PE conductor must be

duplexed and routed through separate terminals or have a cross-

section of at least 10 mm² Cu.

Operation and connection to public grids:

Most frequency converters are designed to operate on industrial

grids. If the converter is connected directly to and operated on a

public grid, then additional interference suppression measures,

such as a mains choke, must be built into the mains feeder. For

further information, refer to the converter manufacturer’s

specifications.

5. NSTRUCT ONS FOR MA NTENANCE

Wear parts are subject to the recommended maintenance

intervals (see 5.1 to 5.3). The service life of wearing parts (ball

bearings and filters) depends on the operating hours, the load

and other influences, such as temperature, etc.

Maintenance and servicing may only be performed by persons

with the necessary expertise and regular training. In addition to

the appliance’s operating instructions and the regulations and

recommendations for the system as a whole, the following points

should be observed:

nspection and maintenance intervals:

The operator must set the cleaning, inspection and maintenance

intervals himself according to operating hours, load and

operating conditions.

mmediate inspection and maintenance

The blower must be inspected immediately if vibrations or

reduced air fl ow are observed.

∗

∗∗

∗

Note!

Repairs must be carried out by the manufacturer.

We cannot accept any liability for modifi cations or

the replacement of components carried out by

third parties.

5.1 Ball bearings

The side channel is equipped with enclosed deep groove ball

bearings, which do not have be to re-greased and have a

minimum service life of approx. 22,000 hours. We recommend

exchanging the ball bearings before the end of their service life

(at least 22,000 hours).

A service period of 30 months must not be exceeded if the

blower runs continuously for 24 hours a day.

5.2 Seals and radial shaft sealing rings

Sealing elements and shaft sealing rings must, for safety

reasons, always be replaced after maintenance work involving

opening, removing or otherwise modifying sealing elements.

5.3 Micro-filters

The degree of clogging of the filter elements should be checked

at regular intervals, depending on the ambient conditions /

conditions of use. This means that the user is responsible for

ensuring that the filters are permeable.

5.4 Cleaning

Cleaning or maintenance must not damage or alter the appliance

and its component parts to the detriment of health and safety

protection, and must not, for instance, affect the balancing of the

impeller.

6. SAFETY RELATED NFORMAT ON

ON

TAK NG OUT OF OPERAT ON AND

REMOVAL

The disconnecting of all electrical connections and all other

electrical engineering work in connection with taking the blower

out of operation must be referred to a qualified electrician.

The blower may only be dismantled after all rotating parts have

come to a standstill and a safeguard has been provided to

prevent restarting. Dismantling and removal must be performed

in accordance with the guidelines set out in section 2.1,

Transportation and handling. Dispose of in the appropriate

manner.

7. L AB L TY AND EXCLUS

ON OF

L AB L TY

The owner bears responsibility for the designated use of the unit.

HERZ GmbH shall not be liable in any case of damage resulting

from non-designated use of its units and components.

This also applies, in particular, to special usages and application

conditions, which have not been expressly co-ordinated with

HERZ GmbH.

Furthermore, HERZ GmbH shall not be liable for damage

resulting from modifications or conversions to the delivered

equipment or accessories, in particular, if such changes can

impair the explosion protection.

Similarly, HERZ GmbH shall assume no liability for maintenance

work and repairs, and the possible consequences thereof, that

have been performed incorrectly, with delay, by technicians not

qualified by HERZ GmbH, or which have not been carried out at

all.

BA MD10MD14 V30 R12 03_2012 EU short 11

8. TECHN CAL SPEZ F CAT ONS

Type:

Blower type MD10

Volumetric

flow rate

Total

pressure-

difference

Voltage

Frequency

Power-

consumption

m³/min Pa V Hz A

4,9 1000 200 - 277

345 - 480 50 0,45 – 0,48

0,2 – 0,28

5,9 1 00 200 - 277

345 - 480 0 0,55 – 0,59

0,32 – 0,34

Max. perm.

Blower

speed

Motor

output

Sound

pressure

level

Weight

rpm KW LpA(db) KG

2750 0,075 73 8,5

3120 0,140 7 8,5

Suction opening

:

Ø 70 mm

Outlet opening

:

Ø 0 mm (aussen)

Dimens

ion

(lxbxh)

:

231 x 35 ,5 x 344,5

Ambient temperature

.

:

-20°C bis + 0°C

Protection type

:

IP 54

Optional 1 x 230V

:

Kondensator 230 V; 8 µF / V

Type MD14

Volumetric

flow rate

Total

pressure-

difference

Voltage

Frequency

Power-

consumption

m³/min Pa V Hz A

1 ,5 1400 200 - 277

345 - 480 50 1,55 – 2, 0

0,90 – 1,50

19,5 2000 200 - 277

345 - 480 0 2,00 – 2,25

1,15 – 1,30

Max. perm.

Blower

speed

Motor

output

Sound

pressure

level

Weight

rpm KW LpA(db) KG

2825 0,37 7 17,0

3340 0,55 77 17,0

Suction opening

:

Ø 125 mm

Outlet opening

:

Ø 90 mm (aussen)

Dimension

(lxbxh)

:

345 x 485 x 485,5

Ambient temperature

.

:

-20°C bis + 0°C

Protection type

:

IP 54

Optional 1 x 230V

:

Kondensator 230 V; 30 µF / V

Other manuals for MD10

1

This manual suits for next models

1

Other Herz Blower manuals