Herz HD 240 User manual

HERZ

Herz Hochdruckgebläse - Betriebsanleitung

Herz high-pressure blowers – Operating instructions

Ventilateurs haute pression Herz – Notice d’utilisation

Ventilatori ad alta pressione Herz – Instrizioni per l’uso

Herz Oldalcsatornás légellátó - Használati útmutató

HERZ

Herz GmbH

Biberweg 1, D-56566 Neuwied

Telefon +49 (0)26 22 / 8 10 86

Telefax +49 (0)26 22 / 8 10 80

Internet http://www.herz-gmbh.com

E-mail: [email protected]

HERZ GmbH

BA HD240 02/2010 V.3.0 Rev. 2.0 9

INDEX

1. GENERAL INSTRUCTIONS 10

1.1 CONDITIONS OF USE 10

1.2 STORAGE AND SHIPPING 10

1.3 INSTALLATION 10

1.3.1 FJET BLOWER - EXHAUSTER 10

1.3.2 ELECTRIC MOTOR 11

1.3.2.1 CURRENT MEASUREMENT 11

1.4 COMMISSIONING 11

1.5 OPERATING ADJUSTMENTS 11

1.6 MAINTENANCE 11

2. INSTALLATION SKETCHES 12

2.1 PRESSURE SERVICE 12

2.2 PARALLEL PRESSURE SERVICE 12

2.3 SERIES PRESSURE SERVICE 12

2.4 VACUUM SERVICE 12

2.5 PARALLEL VACUUM SERVICE 12

2.6 GAS TRANSFER 12

2.7 LIST ACCESSORIES 12

3. INTERNAL CLEANING INSTRUCTIONS 13

3.1 CLEANING INSTRUCTIONS 13

3.2 REPLACEMENT SOUND-ABSORBING PANELS 13

4. SILENCER HOUSING MOUNTING INSTRUCTIONS 14

4.1 USING THE 90° MANIFOLD KIT TYPE CK 14

HERZ GmbH

10 BA HD240 02/2010 V.3.0 Rev. 2.0

1. GENERAL INSTRUCTIONS

CAUTION

The ‘FJET’ blowers - exhausters have been

designed and manufactured for use in an

industrial environment, operated by qualified

personnel and as a unit to be incorporated in a

machine, which conforms to the CE Machinery

Directive.

The ‘FJET’ blowers - exhausters, like all

machinery and equipment with live and moving

parts, can be a source of serious hazards unless

properly used and protected.

The user is committed to ensure that:

All handling, assembly, installation, connection,

maintenance and repair operations are

undertaken by qualified personnel. Such people

who by their background, training and experience

as well as through their knowledge of statutory

regulations, legislation, safety measures and

operating conditions are able to carry out any

necessary steps avoiding all possible risks to

health and damage.

Such personnel should have received all the instructions

and information, including any local legislation, and will

follow them during the performance of any operation.

It shall be forbidden for unqualified personnel to carry out

any operation, even indirectly, on the machines and

equipment.

During the installation, all the prescribed working

conditions, including any possible local requirements, shall

be observed. Additionally it is forbidden to put the unit in

service before the machines of which they are a part are

declared to conform to the CE Machinery Directive.

The user must be aware that in operation:

• • the surface temperatures can reach 160°C;

• • the unit cannot contain high internal pressures, no

greater than Ps referred to in SN 1867;

• • there is small loss of the fluid handled;

• • the level of noise may be unacceptable in certain

applications.

1.1 CONDITIONS OF USE

The ‘FJET’ blowers - exhausters are designed for the continuous

movement of air or non-explosive, non-hazardous and

nonflammable gases and for service in non-explosive

environments.

Solid particles, however small, including dirt can cause serious

damage; therefore it is essential that such substances should be

removed from the gas by suitable filters upstream of the inlet.

(Units which do not have an adequate filter ARE NOT

COVERED BY THE GUARANTEE).

The maximum driving pressure must never be exceeded (∆pmax

of SN 1867).

UNDER NO CIRCUMSTANCES OPERATE THE UNIT WITH

THE GAS INLET OR OUTLET CLOSED. IN PARTICULAR

THIS APPLIES TO THE UNITS WITH THE CAPACITY FOR

HIGHER DRIVING PRESSURES.

Protect the units with an appropriate safety valve.

The performance characteristics are liable to variations due to

the following factors:

• • Differences of the suction or discharge pressures from the

reference conditions (1013 mbar);

• • Operation in a system with both a low suction pressure

and a high back pressure;

• • Operation with a gas at a different temperature or of a

different specific gravity from the reference data (1.23

kg/m3; 15 °C);

• • Variations in the rotational velocity of the fan with respect

to the reference value.

Both the gas inlet temperature and the ambient temperature

must be in the range of -15°C to +40°C.

At the same time, ensure that the unit has good ambient

ventilation, especially when subjected to severe operating

conditions. A unit subjected to frequent starting or to high

ambient temperatures may be prone to overheating and in such

cases further information should be requested. Similarly, where

flammable gases may be present, information must be

requested for alternative models certified for the Ex.

environment.

1.2 STORAGE AND SHIPPING

Store the unit in a dry place, preferably in original packaging.

Do not remove the protection plugs from the ports. Avoid

stacking anything on top of the packaging.

To move the packed boxes, use the largest pallet or support

base possible to obtain the maximum stability.

On all occasions handle the units with care and avoid sudden

impacts. Lifting eyes are provided to unpack units weighting

more than 25 kg. (The weight of the unit is M in SN 1867).

1.3.1.1 INSTALLATION

1.3.2 ‘FJET’ BLOWER – EXHAUSTER

It is important that the unit is installed in a well-ventilated

environment where the temperature does not exceed 40°C.

If outside, protect the unit from direct sunlight and avoid the

possibility of water collecting in the external crevices especially

when installed with the axis vertical.

IMPORTANT!

Ingress of foreign matter, however small, will cause serious

damage.

Such matter includes dust, sand, masonry debris, impurities in

the tubes, cutting burrs or filings, welding or soldering slag and

splatter, metal burrs and any residues from sealing and making

the tube connections.

The unit can be mounted with the axis in any position. As

supplied, the unit is balanced and will not transmit vibrations,

however it is recommended that it be mounted on vibration

damping supports. To connect the accessories, remove the

flanges from the unit and then seal and tighten.

Do not over tighten remembering that the operating pressures

are low.

Tube connections must be made with flexible couplings.

Avoid using rigid couplings, which will induce stress and cause

harmful vibrations.

Remember to protect the inlet with suitable filters.

If it is necessary to regulate the flow, install a bypass valve (refer

to section 1.5).

Only remove the plugs on the ports when making the final

connections.

HERZ GmbH

BA HD240 02/2010 V.3.0 Rev. 2.0 11

Select the tube size and the couplings to minimize the pressure

drop, in particular:

• Do not use tubing of a smaller diameter than the ports of the

unit; When installing units in parallel, size the manifold and

main conduit accordingly;

• Utilise large radius bends and avoid using elbows;

• Avoid using valves which have a reduced orifice relative to

the general system; Use swing check valves (utilising

lightweight discs) which have the lowest pressure drop,

rather than spring loaded check valves;

• For oxygenation select low loss diffusers (lowest pressure

drop) and note that the pressure drop across plugs and

porous membranes will increase over time due to

progressive clogging.

A safety relief valve should be installed to avoid overloading the

unit as a result of pressure differential variations.

Make the electrical connections to the motor and check the

direction of rotation before connecting the conduit.

The ‘FJET’ blowers - exhausters are already supplied as

standard with silencers in the suction and exhaust ports (the

noise levels Lp and Lw, with piped inlet and outlet flow, are

detailed in SN 1867).

For operation into free air (either suction or discharge) the free

flow noise can be muffled with additional silencers.

In every situation avoid installing the unit on a structure, which

can transmit or amplify any noise (tanks, sheet metal etc.).

Installation sketches - please refer to next page.

Further information should be requested regarding additional

noise reduction by installing the unit in soundproof enclosures.

1.3.2 ELECTRIC MOTOR

WARNING

BEFORE UNDERTAKING ANY OPERATION ENSURE THAT

THE UNIT IS DISCONNECTED FROM THE ELECTRICITY

SUPPLY.

The electric motor has been selected for service in an ambient

temperature between -15°C and +40°C at an altitude no higher

than 1000 m. Ensure that the information on the nameplate is

consistent with the supply voltage and frequency.

Variations in the supply voltage up to ± 10% are acceptable.

Outside the normal operating conditions the motor cannot deliver

full power and problems can arise with starting, especially for

single-phase motors.

Make the electrical connections referring to the wiring diagram in

the terminal box, connecting an earth cable of adequate capacity

to the earth terminal.

The fuses are designed only for short circuit protection and not

to safeguard the motor. Therefore overload cut-outs

(temperature or current) are essential to guard against the risk of

overloads on the motor --- for example failure of one line in a

three phase supply, an excessively high start up frequency,

unacceptable variations in the supply voltage, stalled rotor, etc..

Set the overload cutouts at the nominal current specified on the

nameplate.

The fuses should be rated for the peak currents or use “slow

blow” fuses especially in applications of direct starting.

THE ENTIRE GUARANTEE SHALL CEASE TO APPLY WHEN

INADEQUATE PROTECTION IS PROVIDED.

1.3.2.1 CURRENT MEASUREMENT

The current drawn refers to normal operating conditions.

Departures from the nominal operating conditions can result in

variations of 10%.

There can be small differences in the measured value of each

phase. These are tolerable up to a maximum deviation of 9%

(ref. IEC 34-1).

1.4 COMMISSIONING

To commission the unit:

• Set the operating pressure or vacuum using a suitable

gauge.

• Check the relieving pressure of the safety valve.

• Measure the current drawn by the motor and verify that it is

within the limit stated on the name plate (refer to Para.

1.3.2.1).

• Adjust the overload cutouts accordingly.

• After one hour's operation, repeat the current

measurements and verify that they are still within the stated

limits.

1.5 OPERATING ADJUSTMENTS

The ‘FJET’ blowers - exhausters will automatically generate the

driving pressure required at the point of use.

Since the power absorbed and the operating temperature is

primarily a function of the driving pressure, it is possible that

these can exceed the permitted operating conditions for the unit.

Frequently the pressure losses of the tubing are overlooked as

the major factor determining the driving pressure.

The driving pressure can be reduced by eliminating all possible

obstructions and restrictions in the flow path. If it is still too high,

the flow can be reduced by installing a bypass valve.

Never choke the flow by throttling the suction or the discharge.

1.6 MAINTENANCE

After every 10-15 days of use clean the cartridge filter. Replace

the cartridge frequently in dusty environments.

A dirty filter will create a strong suction resistance and

consequently a higher driving pressure, a higher operating

temperature and an increase in the absorbed power.

Check that the driving pressure does not change over time.

It is important that a unit in service is subjected to periodic

inspections by qualified personnel to insure against failures,

which, directly or indirectly, could cause damage.

Departures from the normal operating conditions (e.g. a rise in

the absorbed power, unusual operating noises, vibrations, etc.)

are a sign of abnormal operation, which can lead to failure.

In the event of difficulties please contact CBI or the relevant

sales agent.

Please note that repairs undertaken by a third party will

invalidate the guarantee.

Periodically remove any surface deposits which otherwise can

cause the operating temperature to rise.

Commitments, agreements or legal relationships are

governed by the corresponding sales contract. The above

items are in no way limited by the contents of this manual.

The quality of the materials and of the workmanship is

guaranteed as set out by the standard conditions of sales.

The guarantee is not valid for the following: damage

incurred during transport; inadequate storage; faulty

installation; incorrect use; exceeding performance limits;

electrical or mechanical miss-use.

Store the packaging for possible future use.

HERZ GmbH

12 BA HD240 02/2010 V.3.0 Rev. 2.0

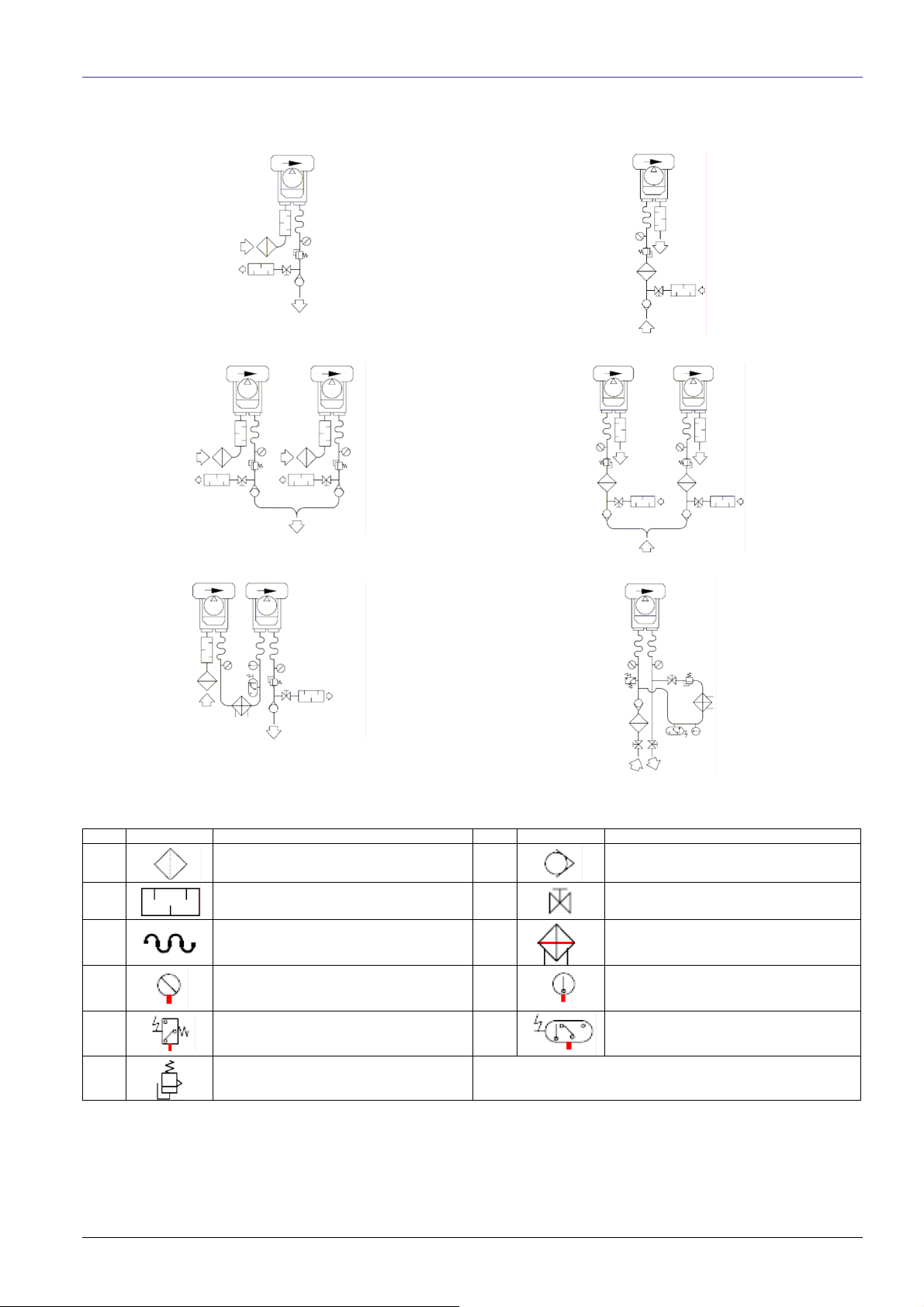

2. INSTALLATION SKETCHES

2.1 PRESSURE SERVICE 2.4 VACUUM SERVICE

2.2 PARALLEL PRESSURE SERVICE 2.5 PARALLEL VACUUM SERVICE

2.3 SERIES PRESSURE SERVICE 2.6 GAS TRANSFER

2.7 LIST ACCESSORIES

Item Denomination Item Denomination

1 Filter – Inline filter 7

Check valve

(2) Silencer 8

Valve

3 Flexible coupling (9)

Cooler

4 Pressure – Vacuum gauge (10)

Thermometer

5 Pressure – Vacuum switch (11)

Temperature switch

6

Relief valve (x) IF NECESSARY

Other manuals for HD 240

1

Table of contents

Other Herz Blower manuals

Popular Blower manuals by other brands

Lithium Earthwise

Lithium Earthwise LB20024 Operator's manual

EINHELL

EINHELL GE-CL 36 Li E Original operating instructions

EINHELL

EINHELL VENTURRO 18/210 operating instructions

Troy-Bilt

Troy-Bilt 657 Operator's manual

Weed Eater

Weed Eater VS2000BV instruction manual

KRAUSMANN

KRAUSMANN U37020-00 Operation manual