HESA HFA-2000 User manual

Modugno (BA) S.S.

Tel. +39 080 5057 044 Fax +39 080 5057 054

96, km 119.874

•

Via B.Cellini 178

Tel. +39 055 8070 303 Fax +39 055 8070 505

TavarnelleV. P. (FI) •

Roma Via Val Grana 14

Tel. +39 06 8861 415 Fax +39 06 8861 391•

Via Triboniano 25 - 20156 Milano - Italy

Tel.+39 02 38036 1 Fax +39 02 38036 701

•

www.hesa.com e-mail:[email protected]

Operating Instructions

DT01192

Analogue Addressable

Fire Control Panel

HFA-2000

Software release v 9.6

DRAFT COPY

12/12/2003

i

Table of contents

HFA 2000 Fire Panel ..............................................................................................................................................4

Features found in this release.............................................................................................................................4

Power supply inputs............................................................................................................................................4

Sensors ...............................................................................................................................................................5

Connections to the sensors.............................................................................................................................5

Assigning addresses to the sensors................................................................................................................5

Automatically assigning sensors to zones...................................................................................................5

Manually assigning sensors to zones..........................................................................................................6

Sounding devices................................................................................................................................................6

Connections to the loop powered sounders....................................................................................................6

Assigning addresses to the sounders..............................................................................................................6

Supervision ..................................................................................................................................................6

Automatically programing the sounder addresses.......................................................................................6

Manually assign the sounders .....................................................................................................................6

Buttons.............................................................................................................................................................6

LCD display .....................................................................................................................................................7

Alarm display................................................................................................................................................7

Fault display.................................................................................................................................................8

LEDs................................................................................................................................................................8

Outputs................................................................................................................................................................8

Fixed functions.................................................................................................................................................8

Programmable outputs ....................................................................................................................................8

System Controls..................................................................................................................................................8

Access Codes..................................................................................................................................................8

To enter an access code:.............................................................................................................................8

To silence the sounding devices .....................................................................................................................8

System test......................................................................................................................................................9

To reset the system.........................................................................................................................................9

Entering text characters...................................................................................................................................9

Using menus....................................................................................................................................................9

Turning the system on for the first time...............................................................................................................9

Assign addresses to the sensors...............................................................................................................10

Assign loop powered sounders..................................................................................................................10

Turning the system on after addresses have been assigned ...........................................................................10

If it did not pass the tests, one or more of the following faults could be the cause: ..................................10

Programming the System, access level 3.........................................................................................................10

Programming Menu.......................................................................................................................................11

Event History .................................................................................................................................................11

Time...............................................................................................................................................................12

Date ...............................................................................................................................................................12

Delays............................................................................................................................................................12

Walk Test.......................................................................................................................................................12

To walk test one zone in a loop, for example, zone 7 in loop 2:................................................................13

To walk test all zones in a loop, for example, all zones in loop 1:.............................................................13

To walk test the entire system, all zones in both loops:.............................................................................13

Sensor Addressing ........................................................................................................................................13

Auto-Address .............................................................................................................................................13

Manual-Address.........................................................................................................................................14

If the sensor is on a t-tap........................................................................................................................15

Locate.........................................................................................................................................................15

LED Flashing sequence .........................................................................................................................15

Sounder Addressing......................................................................................................................................15

Auto-Address .............................................................................................................................................15

Manual-Address.........................................................................................................................................16

Add sounder...........................................................................................................................................16

Add all.....................................................................................................................................................16

REMOVE sounder..................................................................................................................................16

Remove all..............................................................................................................................................16

Activation Options...................................................................................................................................17

System Label.................................................................................................................................................17

Sensor Label..................................................................................................................................................17

Zone Label.....................................................................................................................................................17

ii

Codes.............................................................................................................................................................18

Language.......................................................................................................................................................18

Sensor Data...................................................................................................................................................18

Schedule........................................................................................................................................................19

CBE Timers ...................................................................................................................................................19

To program the delay and duration times for an output:............................................................................19

CBE Equations ..............................................................................................................................................20

To erase an equation.................................................................................................................................20

Important note about CBE timers...............................................................................................................20

Load Defaults.................................................................................................................................................20

Erase options.................................................................................................................................................21

Baud Rate......................................................................................................................................................21

Print options...................................................................................................................................................21

Print the Event History ...............................................................................................................................22

Select the Event Option..........................................................................................................................22

Option to print the selected type of event that occurred on a specific date: ..........................................23

Print the Programmed Data .......................................................................................................................23

Print the labels ...........................................................................................................................................23

Print the CBE Equations ............................................................................................................................24

Print the Sensor Data.................................................................................................................................24

Print the events as they occur, in real time................................................................................................25

Status Menu, access level 1..............................................................................................................................25

To access the status menu at access level 1................................................................................................25

Display a zone in alarm .................................................................................................................................26

Display a sensor in alarm ..............................................................................................................................26

Display a zone fault .......................................................................................................................................26

Display a sensor fault ....................................................................................................................................26

Display a loop fault ........................................................................................................................................27

Display a system fault....................................................................................................................................27

Display a sounder fault..................................................................................................................................27

Display a disabled zone.................................................................................................................................27

Display a disabled sensor..............................................................................................................................28

Status and Control Menu, access level 2..........................................................................................................28

Enable / Disable Zones..................................................................................................................................28

Enable / Disable Sensors ..............................................................................................................................28

Access via the serial port ..................................................................................................................................29

Interactive mode.........................................................................................................................................29

Data transfer mode ....................................................................................................................................29

Lockout.......................................................................................................................................................29

Appendix A............................................................................................................................................................30

Control-By-Event (CBE) Equations...................................................................................................................30

Overview............................................................................................................................................................30

Definitions ..................................................................................................................................................30

General structure of the equations.............................................................................................................30

Syntax and Symbols used in the equations......................................................................................................31

Directives...........................................................................................................................................................31

Lloop.........................................................................................................................................................31

Eevent type...............................................................................................................................................31

Variables............................................................................................................................................................31

Ssensor.....................................................................................................................................................31

Zzone........................................................................................................................................................31

Ggroup ......................................................................................................................................................32

Pproduct type............................................................................................................................................32

EV power supply fault...............................................................................................................................32

EB break in a loop wire.............................................................................................................................32

EN sensors not programmed....................................................................................................................32

EK communication fault............................................................................................................................32

Logic Operators.................................................................................................................................................32

+Logical OR..............................................................................................................................................33

&logical AND.............................................................................................................................................33

Logic Modifiers..................................................................................................................................................33

!NOT........................................................................................................................................................33

X.....................................................................................................................................................................33

Normal use, logic modifier .........................................................................................................................33

iii

Special use if the timer statement is not included in the equation.............................................................34

Special use if the timer statement is included in the equation...................................................................34

Y.....................................................................................................................................................................34

( ) parentheses........................................................................................................................................34

Timer Control.....................................................................................................................................................35

Ttimer statement.......................................................................................................................................35

Important note about CBE timers..................................................................................................................35

Syntax Summary...............................................................................................................................................35

Summary of the characters used in the equations and the syntax ...............................................................35

Error messages .............................................................................................................................................36

HFA 2000 Fire Panel.........................................................................................................................................37

ACK button ....................................................................................................................................................37

Silence button................................................................................................................................................37

Reset..............................................................................................................................................................37

Message telling the user that access level 1 is required when certain keys are pressed.............................37

Operation of loop powered sounders ............................................................................................................37

The global option is selected for a loop .....................................................................................................37

The "by zone" option is selected for a loop................................................................................................37

Polling stops when voltage becomes too low for the sensors to operate properly........................................38

Real time alarm display .................................................................................................................................38

The display of zone and sensor disablements are coordinated....................................................................38

Constant display of the number of zones in alarm and number of zones with faults....................................38

Alarm verification...........................................................................................................................................38

Key switch functions......................................................................................................................................39

Center.........................................................................................................................................................39

Left .............................................................................................................................................................39

Right...........................................................................................................................................................39

Additional erase function ...............................................................................................................................40

Cold start........................................................................................................................................................40

New display when resetting...........................................................................................................................40

Power supply failure display..........................................................................................................................40

A CBE equation can now turn on all the sounders........................................................................................40

The LEDs turn on in the sensors that are in alarm........................................................................................41

Access level indication was added................................................................................................................41

System Test:..................................................................................................................................................41

Navigation symbols were placed for all menu selections..............................................................................41

Menu Position and request indicators ...........................................................................................................42

Walk test ....................................................................................................................................................42

Time and Date............................................................................................................................................42

Manual addressing of loop powered sounders..........................................................................................42

Codes.........................................................................................................................................................42

CBE timers.................................................................................................................................................42

Delays, Erase, and Print ............................................................................................................................43

The types of sensor faults are now displayed ...............................................................................................43

Option to allow sensor labels to be associated with the hard addresses......................................................43

The labels should be adjusted under the following conditions:..................................................................44

The labels should NOT be adjusted under the following conditions:.........................................................44

_Toc58983606

Text string removed.......................................................................................................................................44

HESA S.p.A - Analogue Addressable Fire Control Panel HFA-2000 - Operating Instructions

DT01192HE1203R02

4

HFA 2000 Fire Panel

Instructions for operating release 9 of the software

Features found in this release

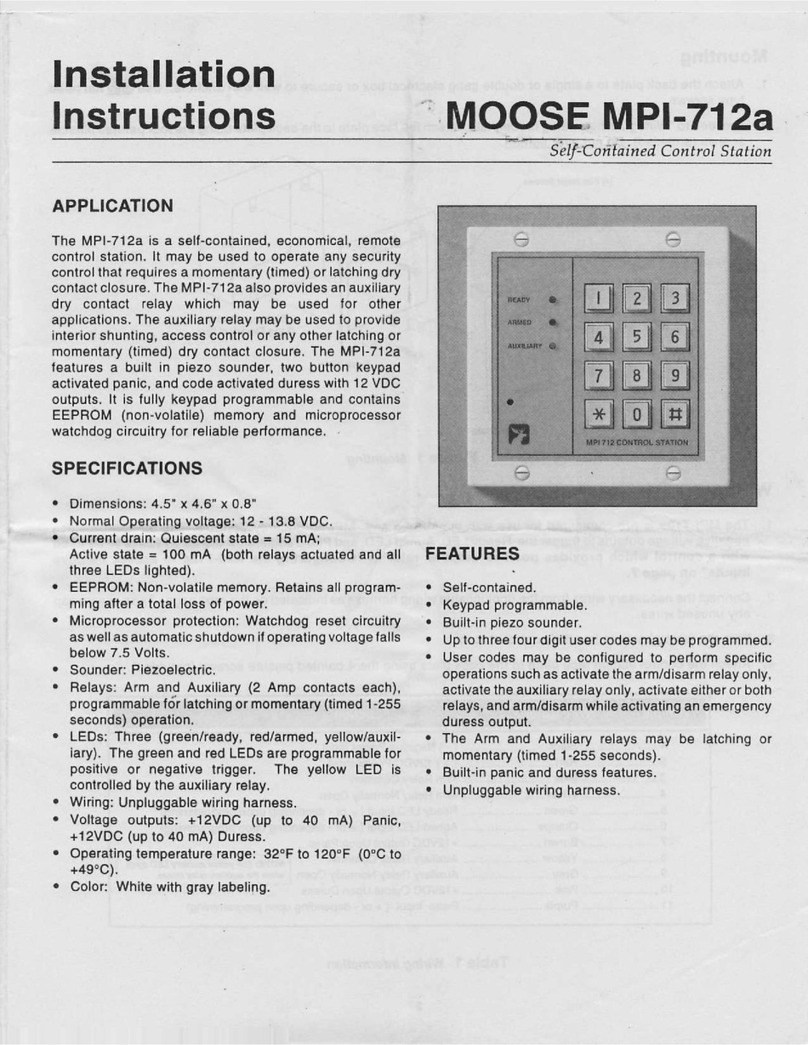

• Number of loops: 2

• Number of sensors per loop: 64 for a total of 128. T-taps are supported.

• Sensors are assigned addresses automatically.

• Zone numbers are assigned automatically. Sensors can then be assigned to other zones manually if

needed.

• Sensors can be located by having their LEDs display the addresses using coded flashes.

• Display: back lighted LCD, 2 lines, 40 characters on each line. It displays details about alarms and faults as

they occur. It is used for displaying the menus when checking the status of the system and when

programming the system.

• LEDs: 6 to indicate the status of the system.

• Controls: 6 control buttons. 12 number / character buttons for alphanumeric entries.

• Certain system functions can be controlled by a key switch.

• 5 outputs on the main circuit board: Alarm (relay), general fault (open collector), and 3 programmable

outputs (1 relay, 2 open collectors).

• Up to 32 additional programmable outputs using 4 relay expander modules, 8 outputs each.

• Control-by-event (CBE) equations are used to define the combinations of events that drive each

programmable output.

• Names, up to 24 characters long, can be programmed for the system, each zone, and each sensor

• Zones and sensors can be individually disabled.

• The real time clock automatically adjusts for daylight savings time.

• A system test can be activated. This causes all smoke and heat sensors to alarm.

• The system can be walk tested without creating an alarm.

• The silence function turns off the sounder, if it is on. It can be used to turn it back on if necessary. New

activations cancel the silence function.

• Event history memory can hold up to 400 events. It is circular. New events eventually overwrite the oldest.

• A serial port is available for printing or gaining access to the system via a personal computer.

• The event history can be displayed on the LCD or printed out via the printer port; events can be printed as

they occur.

• Data programmed into the system can be printed.

• Default values can be loaded.

• Entire sections of the memory can be erased that holds the events and information programmed by the

installer.

• 4 languages can be supported (although English and Italian are the only ones completed at this time).

• Sensors can be read to determine the signal level and the alarm threshold.

• A day night schedule can be established, a different smoke sensor sensitivity for day and night.

• Critical parts of the system are continuously monitored: Power supply, program memory, site-specific data,

and correct operation of the system.

• Loop powered sounders may be connected to each of the loops. They are supervised and can be

programmed to operate globally so they all sound when the internal sounder activates, or by zone so only

the sounder in a zone activates when there is an alarm, fault, or walk test in that zone.

Power supply inputs

A nominally 24 Vdc power supply is connected to the power inputs.

• If a monitored power supply is used, the normally closed monitoring contacts are connected to the fault

monitoring inputs. These contacts open if a power supply fault occurs, such as the loss of AC power. A

delay can be programmed to prevent power supply warnings during brief power outages.

• If a monitored power supply is not used, a jumper must be connected between the fault monitoring inputs.

• As a backup, the system monitors the internal 24 volt supply voltage. If it drops below 19 Vdc, a power

supply fault occurs even if the monitoring contacts remain closed.

5

Sensors

The panel is designed to operate with the ECO2000 family of analog addressable fire detectors manufactured

by System Sensor ®. They are as follows:

ECO2000M Micro module. Contains supervised input for a

contact

ECO2001 Call point

ECO2003 Photoelectric smoke detector

ECO2005 Thermal detector

Connections to the sensors

The sensors are connected sequentially along each loop. The positive wire connects to the +IN/OUT terminal on

each sensor. The negative wire nearest the LOOP DRIVE terminals on the panel connects to the -IN terminal of

the sensor; the

-OUT terminal connects to the -IN terminal on the next sensor along the loop.

T-taps may be connected to the loop. A T-tap is a branch from a node on the loop. A node is the

common connection between two adjacent sensors on the loop. There are some restrictions when using T-taps,

which are listed below:

• There must be one continuous loop from the loop drive terminals to the loop end terminals.

• Multiple loops are not allowed, which would be multiple paths from the loop drive terminals to the loop end

terminals.

• There can only be one T-tap connected to a node. Multiple branches from the same node are not allowed.

• There is no limit to the number of T-taps providing that each T-tap is the only branch on a node.

• A maximum of 32 sensors can be connected on a tap. This limit is in accordance with EN-54.

• Taps cannot have taps. Taps can only be connected to a node on the loop.

• 64 is the maximum number of sensors that can be connected on a loop including those on T-taps.

For small installations where only one loop is used, connect the LOOP DRIVE terminals to the LOOP END terminals

of the unused loop, positive to positive and negative to negative.

Assigning addresses to the sensors

This is done automatically while in the AUTO-ADDRESS mode for sensors. There is no provision for manually

assigning addresses to the sensors. The addresses are numbered in a predictable sequence from the first

sensor on the loop to the last. When a T-tap is found, the addressing sequence proceeds along the tap until it

finds the end. It then resumes the numbering sequence along the loop. The following illustrates the addressing

sequence when T-taps are used:

Automatically assigning sensors to zones

Zone markers are connected to the first sensor in each zone. The zone numbers are then assigned during the

AUTO-ADDRESS mode. Those sensors nearest the LOOP DRIVE terminals and before the first zone marker are

in zone 1. The sensor with the first zone marker is in zone 2. Sensors between that and the next zone marker

are also in zone 2. There can be up to 15 zones on a loop. A switch is used for setting the zone marker on the

ECO2000M and the ECO2001. Other sensors use a 10K resistor connected between the +RA terminal and the -IN

terminal. For further details, refer to the instructions supplied with each sensor.

To comply with EN-54 standards, zone markers that are connected to sensors on a tap are ignored.

This prevents sensors on the same tap from being in different zones.

Fire

Pane

1234

7101112

Loop

drive

Loop

end

5 6

8 9

Loop wiring using

multiple ‘T’ taps

6

Manually assigning sensors to zones

First, the sensor addresses must be assigned automatically. Next the sensors can be manually assigned to

zones. Only the sensors on the main loop can only be reassigned to other zones. To comply with the EN-54

standards sensors on taps cannot be reassigned to other zones because all sensors on a tap must be in the

same zone.

Sounding devices

The panel has an internal sounder. Loop powered sounders can be added to each of the loops. Depending on

the option programmed, they can operate globally so all sounders duplicate the action of the internal sounder,

or individually as events occur in the zone where they are assigned. The loop powered sounders are

supervised so if any fail or are removed, a warning occurs. The loop powered sounders are from the 500 series

of devices by System Sensor ®: EMA24ALR Wall mounted

sounder

DBS24ALW Detector base

sounder

Connections to the loop powered sounders

They are connected across the loop. There are two sets of (+) and (-) terminals on each sounder. Each pair of

terminals is connected together internally. This provides a convenient means to connect them to the loop.

• No more than 7 sounders should be installed between ECO2000 sensors.

• They should be located between sensors, not between the panel and a sensor.

• The maximum number of these sounders on a loop has not been determined yet. It will be a function of

cable resistance and the volume settings on the sounders.

Assigning addresses to the sounders

The address switches on the sounders should be set to the zone number where they are located. There are as

many available sounder addresses as there are zones on a loop, 1 to 15. The addresses of the sounders that

are installed should be programmed into the panel so they can be supervised. They can be assigned

automatically or manually.

Supervision

The panel routinely polls the sounders. It expects a response from all sounder addresses that have been

programmed into the panel. If it does not get a response, it issues a warning. Whether the sounders are

programmed to operate globally or by zone they can be supervised as long as they have different addresses. If

there are 2 or more sounders in a zone, and each has the same address, it will only detect a supervision fault if

all sounders having that address fail to respond. Supervision cannot detect the loss of a single sounder if its

address is not unique.

Automatically programing the sounder addresses

Unlike auto-addressing for sensors, this does not assign the addresses to the sounders; they are assigned by

the settings of the address switches. This process automatically finds the sensors that are connected to the

system and stores those numbers so they can be included in the supervisory polling operation.

Manually assign the sounders

Individual sounders can be manually assigned or removed from the panel's memory. Also, all the sounder

addresses can be assigned to a loop (1 to 15), or all can be removed.

Buttons

Numbers and characters can be entered during some of the programming functions. This is explained later. The

number keys are shared with the characters as follows:

Key Characters Key Characters Key Characters/contr

ol

1 ( . : / 5 JKL 9 WXYZ

2 ABC 6 MNO 0 ) + - !

3 DEF

(space) 7 PQRS * Back (control)

4 GHI 8 TUV # Enter (control)

7

Control buttons:

Control key Function

ACK After an alarm, this key can be pressed while at any access level. This acknowledgment is

entered into the event history memory along with the access level.

LIST After an access code is entered, this key displays the menu available to that access level.

Also, during an alarm display, this key can be used to display the most recent sensor to

alarm.

SYSTEM RESET When pressed while at access level 2, it clears alarms, faults, and any active programmable

outputs.

SYSTEM TEST When pressed while at access level 3, it causes ECO 2003 and 2005 sensors to report an

alarm (the other sensors can be manually activated.

LAMP TEST Turns on all LEDs when pressed

SILENCE on/off If the sounder or the alarm relay is active, pressing this key while at any access level turns it

off. Pressing it again while at any access level turns it on. New alarms or faults cancel the

silence function. The Silence Inhibit timer prevents it from being silenced immediately after

an event turns it on. This delay is a programmable item. If the delay is programmed to 0,

there is no delay.

Key switch:

Switch position Function

NORMAL The system operates normally. Control is via the keypad and control buttons.

SILENCE All sounding devices are silent while in this position. The silence inhibit timer has no effect.

RESET Clears alarms, and faults. This occurs when this position is first entered. After that, the

system continues to operate normally.

TEST This activates the walk test function for the entire system. The walk test mode continues

while the switch is in this position. It is not governed by the walk test timer.

Maintenance switch:

When on, all polling to the sensors stop and voltage is removed from the loops. This allows sensors to be safely

removed or added to the system while keeping the processor powered. This allows the real time clock to keep

time. While the maintenance switch is on, the system fault LED is on as a warning so it will not be forgotten.

The following operations can be done only while the maintenance switch is on:

• The special access code 987654 can be entered to get to access level 3. This would be used if the normal

access code were forgotten. While at access level 3, the access codes can be displayed and

reprogrammed if necessary.

• The default programming values can be loaded and sections of the EEPROM can be erased.

• Programming steps requiring communication to the sensors are not available while the maintenance switch

is on.

When the maintenance switch is turned off, a system reset is initiated then the system returns to normal

operation. This is similar to a normal system reset with the addition that any disabled zones and sensors are

enabled.

LCD display

It has 2 lines, 40 characters on each line. The backlighting turns on when any key is pressed and remains on

for 15 seconds after the last key was pressed. During standby, the system name is displayed on the top line;

the time and date is displayed on the bottom line. If a system name has not been programmed, HESA HFA-

2000 is displayed on the top line.

Alarm display

When there is an alarm, the zone where the first alarm occurred is displayed on the top line. The zone where

the most recent alarm occurred is displayed on the bottom line along with the number of zones currently in

alarm. The LIST button can be used to display the most recent sensor to alarm on the top line temporarily

replacing the display of the first zone to alarm. The display reverts back to normal when BACK (*) is pressed or

15 seconds after the last key press.

8

Fault display

When a fault occurs, it is displayed on the top line if there are no alarms being displayed.

LEDs

LED . Indicates the following:

ALARM When there is an alarm

DISABLED DETECTORS/ZONES If any zones or sensors are disabled

ZONE FAULT Faults in any sensor in a zone or general fault in a loop

SYSTEM FAULT Faults relating to the system, not limited to any particular loop or zone

POWER When the power supply is functioning correctly (see note below)

SILENCE The feature to silence the sounder is active

Note: The power supply monitoring contacts are closed when the power supply is operating normally; they open

when a fault is sensed such as the loss of AC. As a backup, the system monitors the internal 24 volt supply

voltage. When the connection between the monitoring inputs is closed, and the power supply voltage is greater

than +19Vdc, the green power LED is on. When the contacts open, a power fault warning is issued after the

programmed delay time; the green LED turns off, and the system fault LED turns on. If a power supply is not

available with monitoring, the monitoring inputs should be connected together with a jumper.

Outputs

Outputs are provided to connect to other equipment. Some use relays, others use open collectors. They are

described below:

Fixed functions

• Alarm relay: Activated when an alarm occurs.

• General fault, open collector: Normally on, turns off when any fault occurs in the system.

Programmable outputs

A maximum of 35 outputs are available. They are controlled by the control-by-event (CBE) equations:

• The programmable relay that is located on the main circuit board is output 0.

• The 2 programmable outputs that are located on the main circuit board are outputs 1 and 2.

• Up to 32 more outputs can be provided by installing relay expansion modules. Up to 4 modules can be

added. Each has 8 outputs for a total of 32. These are outputs 3 to 34.

System Controls

Access Codes

The default access codes are as follows. They can be changed while at access level 3.

• 1111 for access level 1

• 22222 for access level 2

• 333333 for access level 3

• Additional access code for access level 3, while the maintenance switch is on: 987654

To enter an access code:

• Enter the access code. The top line of the display blanks, and stars (*) appear for each digit entered.

• Press ENTER (#) to confirm.

• If an error is made, press BACK (*) to start over.

• After a valid access code is entered, ACCESS LEVEL n is displayed in the top line (n = 1, 2, or 3)

• If nothing further is done after 15 seconds, the access level is canceled.

To silence the sounding devices

Devices sound when an alarm or fault occurs. The SILENCE key toggles the silence feature. If the silence

feature is active, new faults or alarms turn it off causing the alarm to sound again.

• Enter the access code for level 1 or 2 then press ENTER (#). The access level is displayed on the top line.

• Press the SILENCE key; the Silence LED turns on enabling the silence feature. This can only can happen

after the silence inhibit time has expired, which is a programmable item.

o Access at level 1: Only the sounders are silenced.

9

o Access at level 2: Both the alarm relay is turned off and the sounders are silenced.

• To turn off the silence feature, press the SILENCE key after entering the access code. Certain conditions

apply: o Access at level 1: The silence feature is turned off only if it was enabled at access level 1.

o Access at level 2: The silence feature is turned off unconditionally.

• Another alternative: Move the key switch to the SILENCE position. It is not affected by the silence inhibit

timer.

Note: The loop powered sounders are updated at the start of each polling sequence to the sensors. Because of

this there will be a slight delay between the time an internal sounder is activated or deactivated until the loop

powered sounders react.

System test

This causes all ECO 2003 smoke detectors and ECO 2005 heat sensors to report an alarm. The ECO 2000M

and ECO 2001 can be manually activated.

• Enter the access code for level 3 then press ENTER (#). The access level is displayed on the top line.

• Press the SYSTEM TEST button to start the test. The Alarm LED turns on, the alarm relay is activated, and

the alarm is displayed on the LCD. All alarms are entered into the event history so their activation can be

checked later.

• A walk test is also available so each sensor can be individually tested without activating the alarm relay. It

can be entered via the menu at access levels 2 or 3 or by use of the key switch. This will be explained later.

To reset the system

This clears all alarms and fault indications. If the alarm or fault condition still occurs, the indication will return

after the reset. After the system is reset, any disabled zones and sensors remain disabled. They must be

individually enabled.

• Enter the access code for level 2 then press ENTER (#) .The access level is displayed on the top line.

• Press the SYSTEM RESET button to start the system reset operation.

• Another alternative: Move the key switch to the RESET position. Reset starts when that switch position is

first reached. It has no effect after that.

Entering text characters

Some programming modes require a text entry such as the characters for naming sensors, zones or entering

the control-by-event (CBE) equations. While in one of those modes, a cursor becomes visible. Enter a character

by pressing the number key that contains that character repeatedly until that character is displayed. Wait 2

seconds and the cursor moves right to the next location. Then the next character can be entered. To cancel an

entry, press BACK (*). It erases the previous character. To erase the entire entry, press BACK (*) repeatedly

until all characters have been erased. Then Press BACK (*) until the menu item is displayed again.

As an example, to enter "K", press 5; "5" is displayed. Press 5 again; "J" is displayed. Press 5 again; "K" is

displayed. After 2 seconds, "K" remains in the display and the cursor advances so the next character can be

entered.

Important note: The 3, D, E, F key also includes a space character. To select the space, keep pressing the 3

key until no character is displayed above the cursor. Wait 2 seconds for the cursor to move then resume

entering characters.

When not in a programming mode requiring character entry, only number entries can be made.

Using menus

While a menu is being accessed, the 2 and 8 keys function as up and down arrow keys respectively for scrolling

through a menu. The # key functions as ENTER for confirming a selection from a menu or an entry. The * key

functions as a BACK key for canceling an entry or going back to the previous menu.

Turning the system on for the first time

SYSTEM FAULT may be displayed on the top line if the EEPROM is blank. The System Fault or Zone Fault

LED, and the internal sounder turn on. No addresses have been assigned to the sensors yet and no hard

addresses (serial numbers) for those sensors are stored. The default time and date are displayed on the bottom

line: 00.00 SAT 01-01-00.

The sounder will be on. To turn it off, refer to the section To silence the internal sounder for instructions.

10

Assign addresses to the sensors

Before the system can operate properly, addresses must be assigned to the sensors. This is done automatically

in the AUTO-ADDRESS mode, which is one of the programming modes. Please refer the to the section entitled

Programming the System, access level 3 for instructions.

Assign loop powered sounders

After the sensors have their addresses assigned, the system polls normally. It also polls the sounders so it is

possible that a sounder fault may occur. Sounders may be assigned that are not installed in the system. After

sensor addressing, the sounders should be assigned to make sure that all the installed sounders, and no

others, will be polled.

Turning the system on after addresses have been assigned

The system is initialized by automatically polling the sensors and testing the following:

• It downloads the serial number from each sensor and compares it to the stored number for each sensor.

• It tests the type of each sensor (ECO2000M, ECO2001, etc.) and compares it to the stored type for that

sensor.

• If it passes all tests, it proceeds to routinely poll the sensors to detect alarms and faults as they occur.

If it did not pass the tests, one or more of the following faults could be the cause:

• One or more sensor had been removed:

The Zone Fault LED turns on and the internal sounder sounds.

Polling continues to monitor the remaining sensors.

• One or both of the loop wires is broken between sensors:

The zone fault LED turns on.

LOOP FAULT is displayed on the top line.

It automatically starts driving the loop from both ends. If there is one break between sensors, all

sensors can be reached by driving the loop from both ends. Polling resumes to monitor the sensors.

• There is more than one break in the loop:

The zone fault LEDs turns on.

LOOP FAULT is displayed on the top line.

It automatically starts driving the loop from both ends. Some sensors will not be able to be reached

after it starts driving the loop from both ends. A zone fault and loop fault result. The remaining sensors

are polled.

• There is a short circuit on a loop:

The zone fault LED turns on.

The isolators in the sensors open the circuit to disconnect the short circuit.

The isolators close again except for those sensors surrounding the short circuit.

If the short circuit is between sensors, the loop is driven from both ends. If the short circuit is between

the panel and the first sensor, or between the last sensor and the panel, the loop is only driven from the

end that is not shorted.

Turn on the maintenance switch to remove power from the loops then make the corrections. Then turn the

maintenance switch back off again.

Programming the System, access level 3

To get into the programming mode proceed as follows:

• Enter the code for access level 3, then press ENTER (#). ACCESS LEVEL 3 is displayed on the top line.

• Press LIST. The first item on the programming menu is EVENT HISTORY and is displayed on the top line. If

there are no alarms being displayed, ACCESS LEVEL 3 is displayed on the bottom line.

• Use the up (2) and down (8) arrow keys to display another menu item.

• Press ENTER (#) to the select the programming item.

Note: If no button has been pressed for 3 minutes while in any of the programming modes at this access level, it

exits and returns to normal operation.

11

Programming Menu

The following programming menu is available while at access level 3:

ZONE LABEL Enter a text label to describe the location of zone.

CODES Displays and programs codes for all 3 access levels.

LANGUAGE Displays current language, allows new language to be selected: English,

Italiano, Deutsch, Francais

SENSOR DATA Displays the current alarm signal level and the threshold of the selected

sensor

SCHEDULE Displays and programs the current schedule. The time for night sensitivity to

start and end, and the levels for night/day sensitivity

CBE TIMERS Displays and programs the timers used in the CBE equations

CBE EQUATIONS Displays and programs the control-by-event, CBE, equations

LOAD DEFAULTS Only available when the maintenance switch is on.

ERASE Erases sections of the EEPROM. Only available when the maintenance

switch is on

BAUD RATE Displays and programs the baud rate for the serial port

PRINT Prints the event history starting with the most recent event.

The following describes the programming steps for each menu item:

Event History

This displays the history of the last 400 events that occurred. New events overwrite the oldest. The most recent

event is displayed first.

• While the programming menu displays EVENT HISTORY, press ENTER (#) to display the most recent event.

If there are no events, NONE is displayed. This would only occur when the system is first put into service.

• If there are events, the time and date of the event is displayed on the bottom line; the type of event is

displayed on the top line. Some events have different levels of display. If it is an alarm, the first display is

like the following example: An alarm on loop 1, zone 2, sensor 14: ALARM L1 Z02 SOUTH ENTRANCE HALL

To see which sensor caused the alarm press ENTER (#) again: ALARM L1 S14 MAIN ENTRANCE

Press * to exit the second level display.

• Select another event by using the up (2) or down (8) arrow key. The up arrow key displays the previous

event. If not displaying the most recent alarm, the down arrow key displays the next event. Moving ahead in

time is like moving down a list of events with the most recent at the bottom. That is why the down arrow is

used for moving forward in time, down the list. To go back in time, the up arrow is used for moving up the

list.

• To move through the event history faster, press 5 then the up or down arrow key. It moves 10 events

forward or backward each time this is done. The next time the up or down arrow key is pressed, it moves in

the normal way, by one event.

Note: If less than 400 events have occurred, when moving back in time using the up arrow key, eventually blank

areas of the memory will be found. When that happens, NONE is displayed. When moving forward in time using

the down arrow key, it stops when it reaches the most recent event.

Menu Item Description

EVENT HISTORY Displays the time, day of week, and date the event occurred and a detailed

description of the event.

TIME Displays and sets the time, 24 hour clock: hh.mm: 00.00 to 23.59

DATE Displays and sets the date: dd-mm-yy

DELAYS Set delays: Silence Inhibit, maximum walk test duration, and power failure

warning.

WALK TEST Selects walk test options and turns the walk test feature on and off.

SENSOR ADDRESSING Automatically assigns addresses to the sensors then sensors to zones.

Sensors can be manually assigned to zones if needed. Sensors can be

located by having their LEDs display the addesses using coded flashes.

SOUNDER

ADDRESSING Assigns sounder addressed, automatically or manually. Also global / by zone

selection

SYSTEM LABEL Enter a text label for the name of the system, displayed during standby mode.

SENSOR LABEL Enter a text label to describe the location of a sensor.

12

Time

This is used to set the time using the 24 hour format: hh:mm ranging from 00.00 to 23.59.

• While the programming menu displays TIME, press ENTER (#) to select it.

• The current time, day of week, and date are displayed on the top line.

• Enter the first digit of the hour. TIME followed by this first digit is displayed.

• Enter the second digit of the hour.

• Press ENTER (#). The "." between the hour and the minute is displayed.

• Enter the digits for the minute.

• Press ENTER (#) to confirm the time. It returns to the programming menu where TIME is displayed again.

To cancel the time entry after the first digit is entered, press BACK (*). The time and date is displayed again.

Then to return to the programming menu, press BACK (*) again.

Date

This is used to set the date using the format: dd-mm-yy. The day of the week is set automatically.

• While the programming menu displays DATE, press ENTER (#) to select it.

• The current time, day of week, and date are displayed on the top line.

• Enter the first digit of the day of the month. DATE followed by this first digit is displayed.

• Enter the second digit of the day of the month.

• Press ENTER (#). The "-" between the day of the month and the month is displayed.

• Enter the digits for the month.

• Press ENTER (#). The "-" between the month and year is displayed

• Enter the digits for the year. If too many days for the month had been entered, it will not accept the year.

Press BACK (*) to clear the entry and start over.

• Press ENTER (#) to confirm the date. It returns to the programming menu where DATE is displayed again. If

the year is not a leap year, and if 29 days had been entered for February, ENTER (#) will not be accepted.

Press BACK (*) to clear the entry and start over.

To cancel the date entry after the first digit is entered, press BACK (*). The time and date is displayed again.

Then to return to the programming menu, press BACK (*) again.

Delays

Press ENTER (#) while DELAYS is displayed. The first item on the menu is displayed: SILENCE INHIBIT. Use

the up or down arrow keys to select the delay that is to be displayed and programmed. Select one of the

following to display:

Display Description

SILENCE INHIBIT After an event turns on the sounding devices, this is the time interval while the silence

function is inhibited. Range: 0 to 200 seconds. Default: 0

WALK TEST Walk testing will end after this time. Range 0 to 60 minutes. Default 0. When 0, walk

testing is disabled. This timer only has effect when walk testing is controlled from the

programming menu at access level 3. It has no effect when the key switch is used.

POWER WARNING This is the time after the power supply contacts open, usually due to a loss of AC, until

the power fault warning occurs. Range 0 to 10 minutes. Default: 0

• While the currently programmed delay is displayed, enter the new value.

• Press ENTER (#) to confirm the entry. It returns to the programming menu where DELAYS is displayed

again. Or, press BACK (*) to clear the entry and start over.

• Or, to keep the currently programmed delay time press BACK (*) to return to the programming menu where

DELAYS is displayed.

Walk Test

There are 3 options:

• One zone in a loop can be walk tested.

• All zones in a loop can be walk tested.

• The entire system can be walk tested, all zones in both loops.

13

To walk test one zone in a loop, for example, zone 7 in loop 2:

• Press ENTER (#) while WALK TEST is displayed from the programming menu.

• LOOP is displayed. Enter the loop number where the zone is located: 2

• Press ENTER (#). LOOP 2 ZONE is displayed.

• Enter the zone number, 7, followed by pressing ENTER (#).

• The following is displayed: LOOP 2 ZONE 07 WALK TEST OFF

• To turn on the walk test press ENTER (#). The display changes to: LOOP 2 ZONE 07 WALK TEST ON

• Walk test the zone. When a sensor is activated, only the sounders sound.

• After the walk test time has expired, which was set when it was programmed in DELAYS, it returns to

normal polling.

• To end the walk test before it times out, press the BACK (*) key while LOOP 2 ZONE 07 WALK TEST ON is

displayed. The display then changes to LOOP 2 ZONE 07 WALK TEST OFF.

• To exit and return to the programming menu, press the BACK (*) key while LOOP 2 ZONE 07 WALK TEST

OFF is displayed.

To walk test all zones in a loop, for example, all zones in loop 1:

• Press ENTER (#) while WALK TEST is displayed from the programming menu.

• LOOP is displayed. Enter the loop number where the zone is located: 1

• Press ENTER (#). LOOP 1 ZONE is displayed.

• Instead of a zone number, press 0.

• The following is displayed: LOOP 1 ALL ZONES WALK TEST OFF

• To turn on the walk test press ENTER (#). The display changes to: LOOP 1 ALL ZONES WALK TEST ON

• Walk test all the zones in the loop. When a sensor is activated, only the sounders sound.

• After the walk test time has expired, which was set when it was programmed in DELAYS, it returns to

normal polling.

• To end the walk test before it times out, press the BACK (*) key while LOOP 1 ALL ZONES WALK TEST ON is

displayed. The display then changes to LOOP 1 ALL ZONES WALK TEST OFF.

• To exit and return to the programming menu, press the BACK (*) key while LOOP 1 ALL ZONES WALK TEST

OFF is displayed.

To walk test the entire system, all zones in both loops:

• Press ENTER (#) while WALK TEST is displayed from the programming menu.

• LOOP is displayed. Instead of a loop number, press 0.

• The following is displayed: SYSTEM WALK TEST OFF

• To turn on the walk test press ENTER (#). The display changes to: SYSTEM WALK TEST ON

• Walk test all the zones in both loops. When a sensor is activated, only the sounders sound.

• After the walk test time has expired, which was set when DELAYS were programmed, it returns to normal

polling.

• To end the walk test before it times out, press the BACK (*) key while SYSTEM WALK TEST ON is displayed.

The display then changes to SYSTEM WALK TEST OFF.

• To exit and return to the programming menu, press the BACK (*) key while SYSTEM WALK TEST OFF is

displayed.

Sensor Addressing

When this is selected, the first item on the sensor addressing menu is displayed: AUTO-ADDRESS

The sensor addressing menu is as follows:

AUTO-ADDRESS It finds all the sounder addresses connected to a

loop

MANUAL-ADDRESS Sounder addresses on a loop are manually

assigned

LOCATE The LEDs on the sensors in the specified zone

display their addesses by using coded flashes.

Use the up (2) and down (8) arrow keys to display a menu item.

Auto-Address

This programming step is used to automatically assign addresses to the sensors in each loop and to assign

zone numbers. The sensor nearest the LOOP DRIVE terminals is assigned address 1, the next is 2, etc. When

it finds a T-tap, it continues the numbering sequence along the tap until it finds the end. It then resumes the

sequence along the loop. The sequence continues until all addresses have been assigned. The maximum is 64.

14

When all the sensors have been assigned addresses, it searches for zone markers along the loop then

automatically assigns the sensors to zones. It ignores sensors on taps. This is because the standards require

all sensors on a tap to be in the same zone.

• While the sensor addressing menu displays AUTO-ADDRESS, press ENTER (#) to select it.

• After ENTER (#) is pressed, LOOP is displayed.

• Press 1 or 2 then press ENTER (#) to select the loop.

Auto-addressing proceeds if no breaks were detected in the loop during initialization.

o WORKING is displayed as auto-addressing proceeds.

o When finished without errors, it returns to the programming menu where SENSOR ADDRESSING is

displayed.

If the loop wire has a break, BREAK followed by +and/or - is displayed indicating which wires are

broken.

o The display remains until BACK (*) is pressed. It then returns to the sensor addressing menu.

o Press BACK (*) again; it returns to the standby mode with the time and date displayed on the

bottom line.

o Remove power to the system, or to the loops by turning on the maintenance switch, then correct

the wiring.

o Turn the power on and repeat the auto-addressing process.

If there there is an error in the installation, FAULT n is displayed where n is the fault code. The fault

codes are listed below:

o The fault display remains until BACK (*) is pressed. It then returns to the sensor addressing menu.

o Press BACK (*) again; it returns to the standby mode with the time and date displayed on the

bottom line.

o Remove power to the system, or to the loops by turning on the maintenance switch, then correct

the wiring.

o Turn the power on and repeat the auto-addressing process.

Auto-addressing fault codes:

Fault

code n

Fault description:

1 More than 64 sensors are connected on the loop

2 Too many taps are connected to a node, only 1 tap is allowed

per node

3 A tap is connected on a tap. Taps are not allowed to have taps

4 More than 32 sensors are connected to a tap

Note: If a loop is not used, connect the LOOP DRIVE terminals to the LOOP END terminals of the same

polarity. Then proceed with auto addressing for that loop even though no sensors are connected. The system

determines that no sensors are connected so it will not expect responses from non-existent sensors during

normal operation.

Manual-Address

This is used to reassign sensors to other zones. It can only be done after all the sensor addresses have been

assigned using auto-addressing. Only the sensors on the main loop can be reassigned to other zones. To

comply with the EN-54 standards sensors on taps cannot be reassigned to other zones because all sensors on

a tap must be in the same zone.

• While the sensor addressing menu displays MANUAL-ADDRESS, press ENTER (#) to select it.

• After ENTER (#) is pressed, LOOP is displayed.

• Press 1 or 2 then press ENTER (#) to select the loop. SENSOR is then displayed.

• Enter the sensor number that is to be reassigned to another zone then press ENTER (#)

• The loop number, sensor number, sensor type, and the zone number where it is currently assigned are

displayed:

For example: LOOP 2 SENSOR 34 ECO2003 ZONE 05

• Enter the new zone number for this sensor. The display blanks and the new zone number appears as it is

entered.

• Press ENTER (#) to confirm the entry. LOOP n SENSOR is displayed so another sensor can be reassigned

on that loop.

• If no more sensors are to be reassigned on that loop press * again to return to the sensor addressing menu.

15

IF THE SENSOR IS ON A T-TAP

• After the sensor number is displayed, "TAP" is displayed after the zone number. Using the previous

example:

LOOP 2 SENSOR 34 ECO2003 ZONE 05 TAP

• It then ignores any attempt to enter a new zone number.

• Press BACK (*) to go back to where it asks for a sensor number.

• Enter a sensor that is not on a T-tap then proceed with the zone assignment.

This programming step can be used to determine the type and zone number for a sensor without reassigning it.

After the loop, sensor, type and zone are displayed, press BACK (*) to quit without changing the zone number.

Locate

Using the LED in each sensor, this feature is used to locate the sensors in the specified zone. It is also used to

verify the addresses of those sensors.

• While the sensor addressing menu displays LOCATE, press ENTER (#) to select it.

• After ENTER (#) is pressed, LOOP is displayed.

• Press 1 or 2 then press ENTER (#) to select the loop. ZONE is then displayed.

• Enter the zone number where the sensors are to be located then press ENTER (#).

• After a couple of seconds, WORKING is displayed and the sensors in that zone flash their addresses using

the format described below. The programming timer starts for 255 seconds (4 minutes 15 seconds) to give

the installer extra time before having to restart it. Normally a key press restarts the programming timer for

180 seconds (3 minutes).

• The programming timer can be restarted for 255 seconds by pressing ENTER (#). Pressing any other

button restarts the timer for the normal 180 seconds.

• To locate another zone on that loop, press BACK (*). The loop number is displayed followed by ZONE.

• Enter the new zone number then press ENTER (#). The LEDs may continue to flash in the previous zone

for several seconds until their flash sequence ends. They do not stop until the flash sequence is completed.

• To locate a zone in the other loop, it is necessary to return to the programming menu where SENSOR

ADDRESSING is displayed, then select LOCATE again to start from the beginning by entering the loop and

zone numbers.

• To exit and return to the programming menu, press the BACK (*) key while it requests a new zone. It will

take about 30 seconds before normal polling resumes on that loop.

LED FLASHING SEQUENCE

A short flutter of the LED is used to indicate the first (most significant) digit followed by a 1.5 second pause.

The LED then pulses the number of the address (2 = 2 pulses). A long pulse (1 second) is used to indicate a

zero digit (instead of no pulse). A 1.5 second pause follows the last pulse of the first digit. Two flutters of the

LED are used to indicate the second digit. The second digit follows in the same fashion as the first. The

process is repeated until blink mode is exited.

Sounder Addressing

The sounder addresses are set by the address switches on each sounder to the zone number where they are

installed. This programming step is used to store the sounder addresses so they can be supervised by polling

them. Sounders can be automatically or manually assigned. They can also be set to operate globally or by

zone. When sounder addressing is selected, the first item on the sounder addressing menu is displayed: AUTO-

ADDRESS.

The sounder addressing menu is as follows:

AUTO-ADDRESS It finds all the sounder addresses connected to a loop

MANUAL-ADDRESS Sounder addresses on a loop are manually assigned

ACTIVATION OPTIONS Selects between global activation or activation by

zone

Use the up (2) and down (8) arrow keys to display a menu item.

Auto-Address

• While the sensor addressing menu displays AUTO-ADDRESS, press ENTER (#) to select it.

• After ENTER (#) is pressed, LOOP is displayed.

• Press 1 or 2 then press ENTER (#) to select the loop.

• WORKING is displayed as auto-addressing proceeds.

• When finished, it returns to the sounder addressing menu where AUTO-ADDRESS is displayed.

16

• Press BACK (*) to return to the programming menu where SOUNDER ADDRESSING is displayed.

Manual-Address

• While the sounder addressing menu displays MANUAL-ADDRESS, press ENTER (#) to select it.

• After ENTER (#) is pressed, LOOP is displayed.

• Press 1 or 2 then press ENTER (#) to select the loop.

• The list of all sounders currently assigned to that loop is displayed. For example, if all are assigned:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

If no sounders are assigned, NONE is displayed.

• Press ENTER (#) while the list is displayed to proceed to the menu for manual addressing or BACK (*) to

exit.

• The first item on the manual addressing menu is displayed: SAVE

Normally, after displaying the currently programmed list of sounders, SAVE would not be used. Use the up

(2) and down (8) arrow keys to display another menu item.

The manual addressing menu is as follows:

SAVE Saves the displayed list of sounders

ADD SOUNDER The sounder number entered is added to the list

ADD ALL Assigns all 15 sounders to the loop

REMOVE SOUNDER The sounder number entered is removed from

the list

REMOVE ALL Deletes all sounders from the loop

ADD SOUNDER

• While the manual addressing menu displays ADD SOUNDER, press ENTER (#) to select it. The display

blanks.

• Enter a sounder address that is to be added to the list of sounders.

• Press ENTER (#) to confirm the entry. The display blanks again.

• Continue to add sounder addresses in any order. Follow each entry by pressing ENTER (#).

• When finished adding sounder addresses, press BACK (*)

• The revised list of sounders is displayed.

• If more sounders are to be added, press ENTER (#) and select ADD SOUNDER again then enter those

sounders.

• When the list of sounders in the display is correct, press ENTER (#), or press BACK (*) to quit without

saving the changes.

• After ENTER (#) is pressed, the menu item SAVE is then displayed. Press ENTER (#) again to save the

revised list.

• It then returns to the sounder addressing menu where MANUAL-ADDRESS is displayed.

Important note! To save the list be sure to press ENTER (#) to display SAVE then press ENTER (#) again to

complete the saving process.

ADD ALL

This adds all available sounder addresses to the list, 1 to 15.

• While the manual addressing menu displays ADD ALL, press ENTER (#) to select it.

• The list of all sounders is displayed: 1 to 15.

• To save the list, press ENTER (#), or press BACK (*) to quit without saving the changes.

• After ENTER (#) is pressed, the menu item SAVE is then displayed. Press ENTER (#) again to save the

revised list.

• It then returns to the sounder addressing menu where MANUAL-ADDRESS is displayed.

Note: This can be used if most sensor addresses are installed. All sensors addresses can be added to the list

then the few that are not used can be removed (explained next).

REMOVE SOUNDER

This process is identical to that for adding individual sounders except the sounder addresses that are entered

are removed from the list.

REMOVE ALL

17

This process is identical to that for adding all sounder addresses except all the sounder addresses are removed

from the list. After ENTER (#) is pressed while REMOVE ALL is displayed, NONE is displayed. Indicating that

there are no sounders on the list. Be sure to use the save operation next.

ACTIVATION OPTIONS

There are 2 choices for each loop:

GLOBAL All loop powered sounders follow the action of the internal

sounder.

BY ZONE An alarm, fault, or walk test in a zone will cause only the loop

powered sounder in that zone to sound.

In both cases, the sounder addresses should be set to the zone where they are installed then their addresses

should be programmed using one of the addressing procedures. This allows the sounders to be supervised. To

select the option:

• While the sounder addressing menu displays ACTIVATION OPTIONS, press ENTER (#) to select it.

• After ENTER (#) is pressed, LOOP is displayed.

• Press 1 or 2 then press ENTER (#) to select the loop.

• The option currently programmed is displayed.

• Use the up (2) and down (8) arrow keys to toggle between GLOBAL and BY ZONE.

• Press ENTER (#) to select the item. It also saves it.

• It then returns to the sounder addressing menu where ACTIVATION OPTIONS is displayed.

System Label

This label describes the installation. It can be anything. For example, it can be the name of the building, or the

business. During the standby mode, the system label is displayed on the top line. The time and date is

displayed on the bottom line. If no system label had been programmed, HESA 2000 is displayed instead.

When entering this programming mode, the currently programmed label, if any, is displayed on the top

line. To keep this label, press BACK (*) and it returns to the programming menu. To change it, refer to the

section at the beginning of this document entitled Entering text characters then proceed as follows:

• While the programming menu displays SYSTEM LABEL, press ENTER (#).

• The current label, if any, is displayed on the top line.