4

HETRONIC SYSTEM COMPONENTS

The Hetronic radio remote control system consists of a

receiver and transmitter with belt, battery charger, and

two rechargeable batteries.

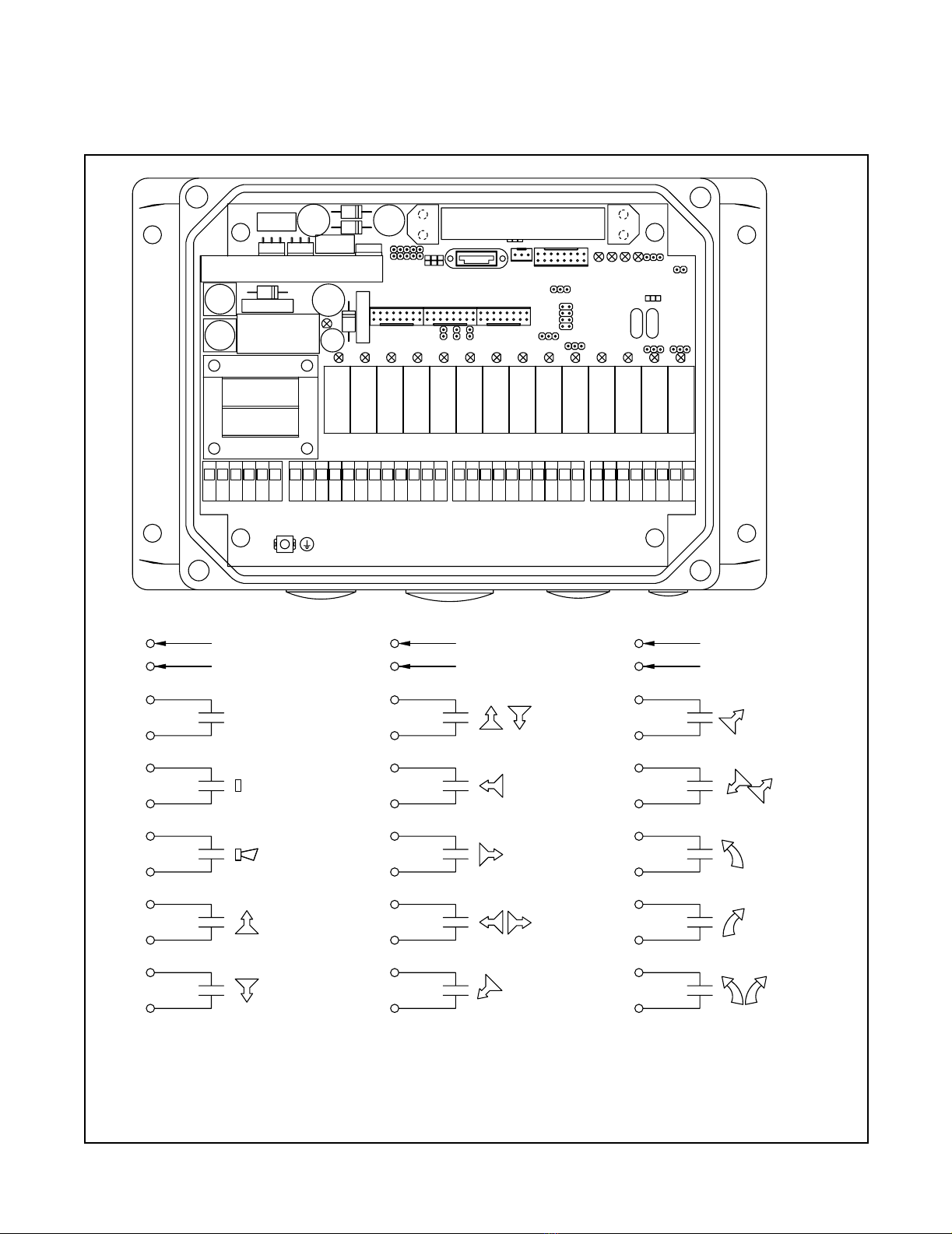

RX 14-0004 Receiver Standard Features

Start relay, horn relay, E-Stop relay

• Up to 14 digital outputs

• Self-diagnostics

• 48 V, 115 V or 230 V for AC cranes/machines

• 12VDC or 24VDC for DC cranes/machines

RX 20 Receiver Standard Features

Start relay, horn relay, E-Stop relay, and two option

relays

• Up to 20 digital outputs

• Self-diagnostics

• 48 V, 115 V or 230 V for AC cranes/machines

• 12VDC or 24VDC for DC cranes/machines

TG Dig-V1 Transmitter Standard Features

• Removable key power switch

• E-stop switch

• 1 2-detent start pushbutton

• 1 2-detent horn pushbutton

• 8 2-speed motion pushbuttons

• 2 2-detent latching/momentary option pushbuttons

•Sleepmode

• 100 m (300 ft.) range

• Internal antenna

• Shoulder strap

SYSTEM OVERVIEW

Theory of Operation

The Hetronic radio remote control system includes a

transmitter and a receiver. These systems operate over

the 400-470 MHz radio band range (70 cm band) and

are FCC approved.

The transmitter generates the electronic signal that

communicates with the receiver. The transmitter and

receiver are set with identical address codes and

frequency channels. This allows operation of multiple

systems within the same area without signal

interference.

The receiver only accepts commands from the

transmitter with the same address code.

NOTE: The receiver and transmitter have the address

code set at the factory.

E-Stop Function

The most important feature of the radio remote control

system is the E-Stop. The transmitter sends the E-stop

status signal along with the specified crane/machine

function. This method confirms that ongoing operations

are safe. If the E-stop pushbutton is pressed, the E-stop

relay in the receiver causes all crane/machine motions

to stop. The receiver goes into Safe mode.

To restart the system, disengage the E-stop button and

press the Start button.

The E-Stop responds faster than any other function.

When E-Stop is engaged, the system ignores any other

signal that is transmitted. The problem must be

corrected before the system will respond to any other

signal.

The E-Stop is self-monitoring and redundant in the

transmitter and receiver. The system performs a

self-test to ensure the E-Stop circuit is working properly.

If an error is detected, the system automatically goes

into Safe mode.

When the transmitter is turned on, it performs a self-test

to be sure that communications are within designated

parameters. If an error is detected, the transmitter will

not transmit any signals.

Transmitter Sleep Mode

The transmitter sleep mode is designed to prevent

accidental operation. The transmitter can be set for the

following sleep modes:

• 30 seconds

• 2 minutes

• 5 minutes

If the transmitter is not used for the set sleep mode

period, it turns itself off. The controls are not operational

while the transmitter is in sleep mode. To restart the

transmitter, turn the key switch off and then back on, and

press the Start button.

IMPORTANT: If the transmitter has a latching

pushbutton that is engaged, sleep mode will not occur.

Receiver Safe Mode

The following conditions cause the receiver to go into

Safe mode:

• The transmitter goes into Sleep Mode

• Radio signal interference

• Transmitter out of operating range

• E-Stop button is activated

• E-Stop circuit failure

• Low battery sends E-stop after time out

When the transmitter signal is no longer sensed by the

receiver, the Time Out process begins. The Time Out

period is set to 450 msec at the factory. If the receiver

does not establish contact with the transmitter within

that time period, it goes into the Safe Mode.

In Safe Mode, the receiver shuts off activation power to

the output relays and activates the E-stop function.To

restart the system, be sure the transmitter signal is

active and sensed by the receiver. Then press the Start

pushbutton.