Hexagon VERIPOS LD900 User manual

AB-V-MA-650 1 February 2021

JF/RR 1

LD900 and INS Commissioning Guide

Introduction

This commissioning guide will provide the information required to install the VERIPOS LD900 unit withINS, by

detailing howan LD900 should be configured and how an IMU should be mounted, interfaced and configured.

Contents

Introduction

Prerequisites

INS Authorisation

GNSS Heading Antenna Installation

Reference Frames

IMU Placement

IMU Interfacing

Alignment / Calibration

Rotational Offset Adjustment

Configuration

Operation

Troubleshooting

Appendix A –Equipment Required

Appendix B - IMUPerformance

The VERIPOS INS systemconsists ofan LD900 (LD900 or LD900M model) receiver, authorised forINS use

and operating in PPP mode with active GNSS heading. The LD900 presently supports integration with two

Novatel IMU models, the IMU-ISA-100C and IMU-µIMU-IC:

Novatel IMU-ISA-100C (left) and Novatel IMU-µIMU-IC (right)

INS operations can be configured and monitored using the LD900 MMI, or an interfaced Quantum software

system. This guide will provide details for both options.

AB-V-MA-00650 01 February 2021

JF/RR 2

LD900 and INS

Commissioning Guide

Prerequisites

Prior to starting LD900 and INS commissioning the system must:

1. Have a high-quality antenna installation.

2. Have an AUTH code for INS (which includes Heading)

3. Be activated and receiving VERIPOS PPPcorrection services.

Appendix-A provides a comprehensive equipment listing including part numbers. Alsorefer to the LD900 and

Quantum documentation section in VOSSifrequired.

INS Authorisation

The LD900 must be correctly authorised before it can be used for INS operations. If required obtain an INS

authorisation code by contacting yourVERIPOSproject manager,or by email

(support.veripos@hexagon.com). The Auth Code will be supplied witha guide explaining how the codes can

be applied to the LD900. Note the INS authorisation code includesthe GNSSheading functionality.

A simple way to check if the LD900 is authorised for INS operations is tocheck if INS is presenton the LD900

status screen, asshown in the above image. If there is no INS status iconvisible, then the LD900 is notyet

authorised forINS use.

GNSS Heading Antenna Installation

Consideration for the placement ofthe primary and secondary antennasis required to ensure reliable and

accurate LD900 GNSS reception and heading calculation. Please also consider the INS installation

requirements detailed in sectionIMU Placement.

AntennaSeparation

The GNSS heading accuracy is largely determined by the distance between the primary and secondary

antennas. The larger the antenna separation, the better the heading accuracy will be.VERIPOSrecommend a

minimum antenna separation of2m.

Antenna Separation

Accuracy

2m

0.08°

4m

0.05°

10m

0.02°

AB-V-MA-00650 01 February 2021

JF/RR 3

LD900 and INS

Commissioning Guide

Antenna Installation

Optimum results will be easier to achieve with an along ship installation. The heading orientation is computed

from the GNSS1 antenna toGNSS2 antenna as illustrated below. In this configuration,the GNSSheading

closely reflects the actual vessel heading.A smalloffset (or C-O)must be applied to the LD900.

Along ship antenna installation

Where along ship installation isnot possible, GNSS1 and GNSS2 can be installed across-ship.The offset

would need to align the GNSS heading to the alignment ofthe actualvessel heading. In the example below,

this will typically be around 90° offfrom the true vessel heading:

Across-shipantenna installation

When the LD900 is authorised for INS operations there will be no dedicated Heading icon, asthiswill have

been replaced by the INS icon. However, the GNSS heading status can be checked byselecting the INS icon

and pressing tick.The heading calculation will always be shown irrespective ofthe INS status and

measurements.

LD900 Status page (left) and Status > INS page (right)

GNSS1

GNSS2

Vessel

Heading

GNSS1

GNSS2

Vessel

Heading

AB-V-MA-00650 01 February 2021

JF/RR 4

LD900 and INS

Commissioning Guide

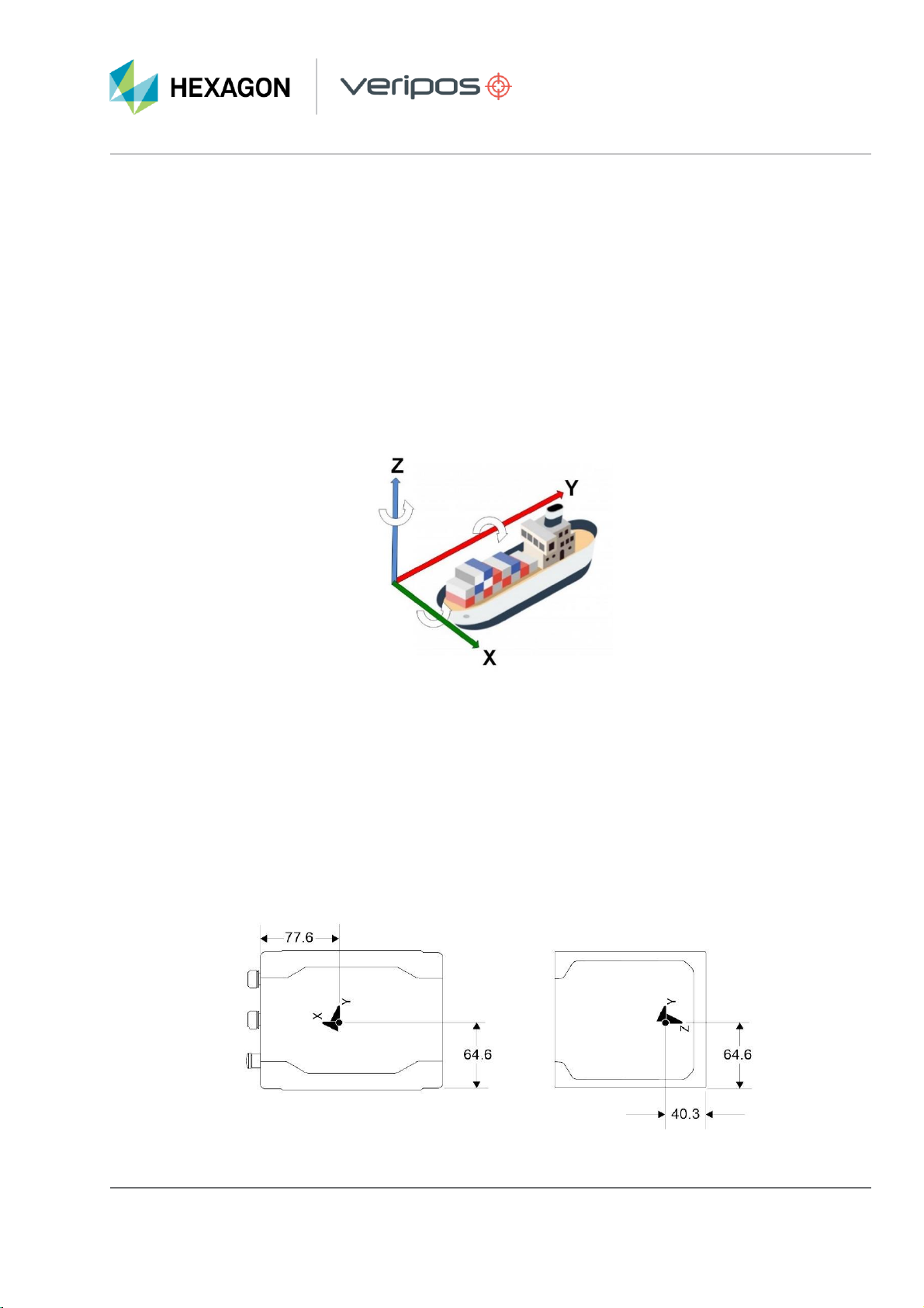

Reference Frames

It is important to have a basic understanding ofreference frames when dealing with INS. Reference frames are

especially important when configuring the systems rotational offsets.Two types ofreference frames will be

considered, the VesselReference Frame and the IMU Body Frame.

VesselReferenceFrame

The definition of the Vessel Frame is as follows:

X-axis –points out the starboard side ofthe vessel

Y-axis –points out the front ofthe vessel in the direction oftravel

Z-axis –points up vertically on the vessel

Vessel Reference Frame

IMU Body Frame

The definition of the IMU Body frame is given by the physical axesofthe IMU and represents how the sensors

are mounted inside the IMU. Both the IMU Body frame axes and Centre ofNavigation markers are on two of

the IMU enclosure sides

The Centre of Navigation markers highlight the centre ofthe Rotational axesofthe IMU, the actualcentre of

navigation lies internally in the IMU where the XYZ rotational axes intersect. Therefore, If the user measures all

translational offsets to a single Centre ofNavigation marker then twoofthe translational offsetsmust be

adjusted to be aligned with the Centre ofNavigation. The figure below illustrates the position of the Centre of

Navigation markers and the dimensions in millimetres.

IMU-ISA-100C Centre of Navigation Markers

AB-V-MA-00650 01 February 2021

JF/RR 5

LD900 and INS

Commissioning Guide

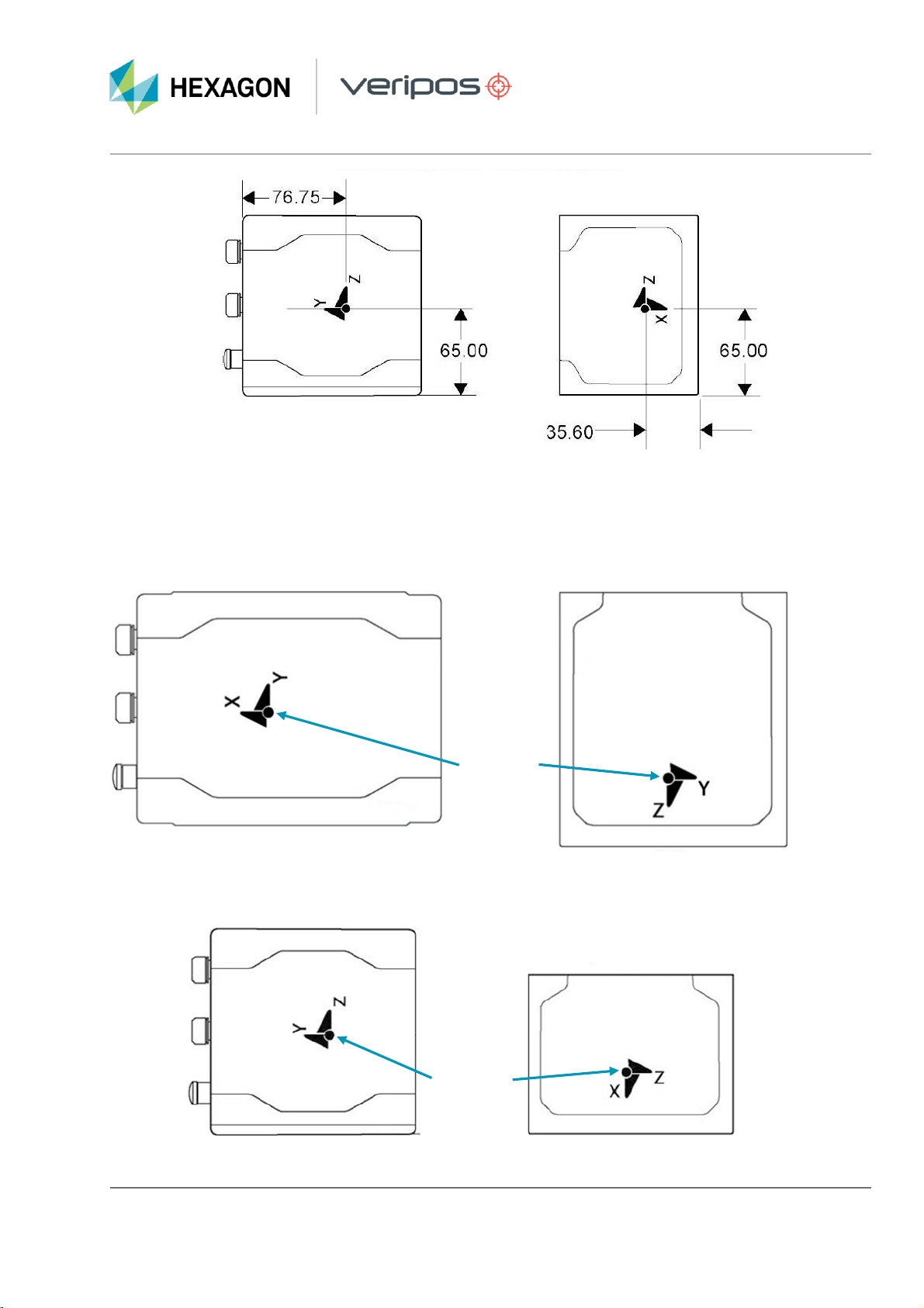

IMU-µIMU-IC Centre of Navigation Markers

IMU-µIMU-IC Centre of Navigation Markers

The two figures following show the IMU Body Frame for both supported IMU models. Thesediagrams highlight

the centre ofnavigation differences between the IMU-ISA-100Cand IMU-µIMU-IC models. The different IMU

frameworks have pre-configured rotational offsets applied by the system configuration when selected, with the

premise ofthe IMU being mounted with the connectorsfacing forward along the vessel frame Y-axis.

PLAN VIEW

REAR VIEW

PLAN VIEW

REAR VIEW

IMU-ISA-100C IMU Body Frame

CENTRE OF

NAVIGATION

CENTRE OF

NAVIGATION

IMU-µIMU-IC Body Frame

AB-V-MA-00650 01 February 2021

JF/RR 6

LD900 and INS

Commissioning Guide

IMU Placement

The following factors need to be considered when installing the IMU.

•Mount as close as possible to the vessel centre point ofgravity

•Mounted on a fabricated plate secured to a flat level surface within the vessel frame.

•Mounted with connectors facing forward

•The IMU base plate must have clearance to allow IMU to be securelybolted.

•Mount in a secure location where it will not be damaged

•Avoid locations thathave a strong vibration.

•The installation engineer should endeavourto align the IMU axes as closely as possible with the

vessel frame using a general arrangement diagram, or by referencing available surfaces such as walls

or floor welds. Referto the below figure, following the arrows to orientate the IMU with the vessel

frame:

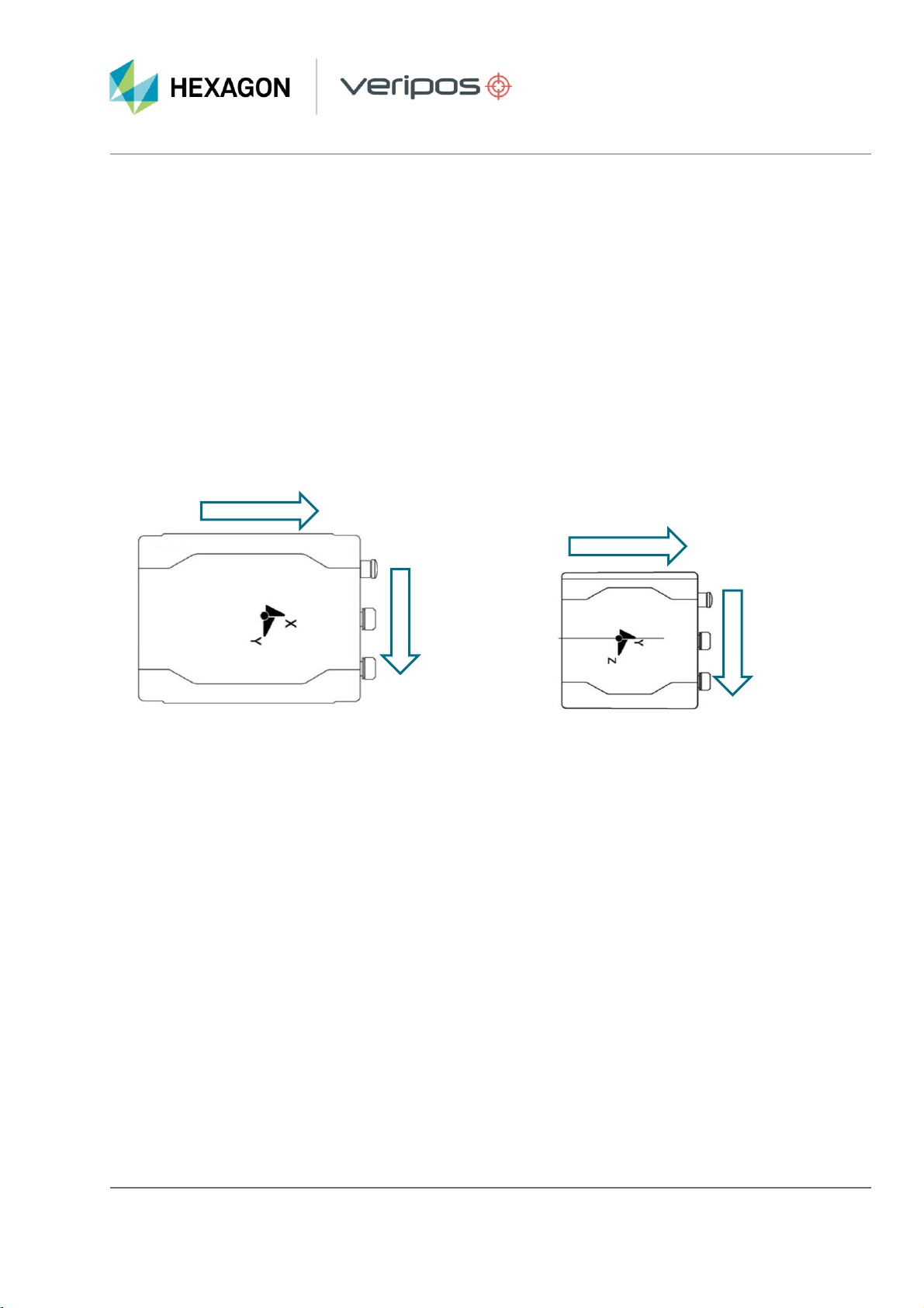

IMU-ISA-100C –Plan View IMU-µIMU-IC - Plan View

As shown below, the IMU baseplates feature four mounting holes, threaded for M6 bolts. The IMU must be

securely bolted to the IMU baseplate on a level surface, with the connectorsfacing forward to the vessel

bow. By mounting the IMU in a fixed position a constant distance and orientation between the IMU to the

GNSS antenna can be maintained.

FORWARD

STARBOARD

FORWARD

STARBOARD

AB-V-MA-00650 01 February 2021

JF/RR 7

LD900 and INS

Commissioning Guide

When the IMU has been mounted in the correct orientation, pre-setrotational offsets willbe automatically

applied (when the IMU is selected within the LD900 or Quantum),aligning the IMU Frame with the Vessel

Frame. Any computed offsets should be added or subtracted from these pre-set values. The pre-set rotational

offsets forthe two models are shown in the table below:

IMU

X Rotation

Y Rotation

Z Rotation

IMU-ISA -100C

+180

0

+90

IMU-µIMU-IC

0

-90

0

IMU-ISA-100C Base Plate

IMU-µIMU-IC Base Plate

AB-V-MA-00650 01 February 2021

JF/RR 8

LD900 and INS

Commissioning Guide

IMU Interfacing

Cabling

The LD900 will be interfaced to the IMU using RS422 serial data-communications. This section details the

LD900 and IMU requirements forINS operations. The diagram below provides an overview of the principal

system component interconnections:

INS Schematic Example

IMU DC Power

A 2-metre long DC power supply cable is supplied with the IMU, this consistsofan M12 Male connectorto five

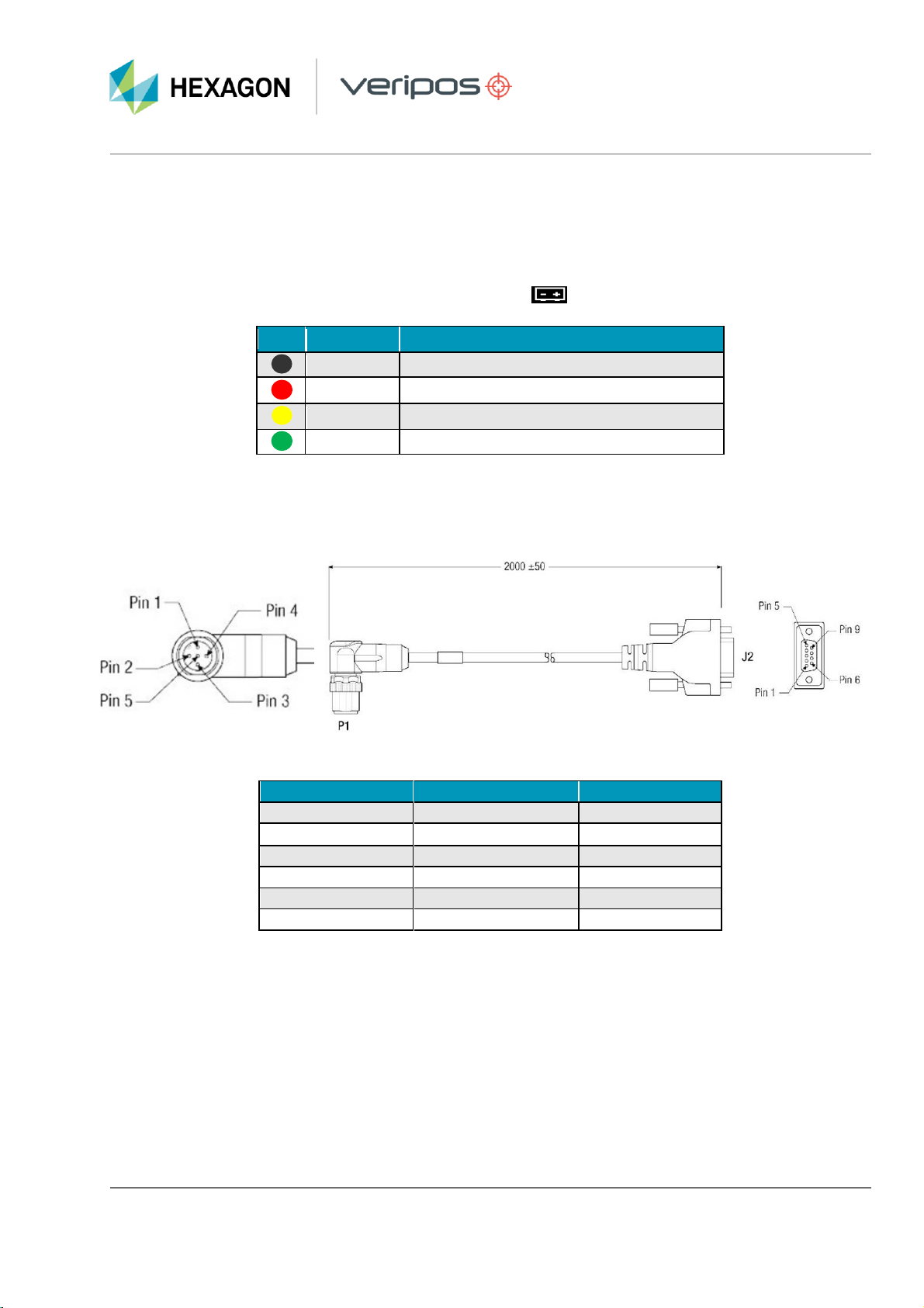

bare cable ends as shown below:

IMU port pinout

P1 Pinout (M12)

Function

Wire Colour

1

VIN-

Brown

2

VIN+

White

3

VIN+

Blue

4

VIN-

Black

5

Chassis

Grey

Power Cable Schematics (inmm)

AB-V-MA-00650 01 February 2021

JF/RR 9

LD900 and INS

Commissioning Guide

Two isolated DC powersources can be used to power the IMU. Alternatively, the two VIN- and two VIN+ pins

can be connected in parallel and connected to a single DCpower supply. Ensure thatthe positive is connected

to VIN+ and that negative is connected to VIN-. The supply voltage must be within the range of10 to 38 VDC.

Chassis can be connected to a common earthing point in an equipmentrack.

When checkingthe health ofthe IMU DCpower, the Power( ) LED on the IMU can be used as reference:

RS422 Interfacing

A 2-metre long interface cable is supplied with the IMU, this consists ofan M12 Male connector (IMU) to a DB9

Male connector (LD900):

Supplied INS RS422 Data Cable (dimensions in mm)

P1 Pinout (M12)

Function

J2 Pinout (DB9)

1

TX+

2

2

RX+

3

3

TX-

8

4

RX-

7

5

GND

5

Chasis

Shield

Shield

LED

State

Meaning

Off

No power to IMU

On

An error occurred during boot or initialisation

SlowFlash

Booting up / IMU initialisation

On

No error occurred during boot orinitialisation

IMU Power LED

RS422 cablepinouts

AB-V-MA-00650 01 February 2021

JF/RR 10

LD900 and INS

Commissioning Guide

With the use ofquality shielded data cable, theRS422 interface cable should not exceed 50 metres. Avoid

running the interface cable close to noisy power lines, or otherelectrical noise sources.

When checkingthe IMU health the COM ( ) LED on the IMU can be used as a reference:

LED

State

Meaning

Off

No communication between IMU and LD900

On

IMU is transmittingand receiving data without errors

SlowFlash

IMU is receiving data from the LD900 but not transmitting

Fast Flash

IMU is transmittingdata but not receiving data from the LD900

IMU COM LED

AB-V-MA-00650 01 February 2021

JF/RR 11

LD900 and INS

Commissioning Guide

Alignment / Calibration

The IMU and antenna placements must be aligned to the vessel frame. The system configuration requires the

following measurements;

•Lever arm (IMU to Antenna 1)

oX (Starboard Positive)

oY (Forward Positive)

oZ (Up Positive)

•Heading

oRotational offset from GNSS1 to GNSS2 antennas

•IMU Rotational Offsets

oX (Pitch)

oY (Roll)

oZ (Yaw)

Precise offsets can be determined by performing a dimensional controlsurvey ofthe vessel while alongside or

in dock. The dimensional survey measurements should be taken using an independentsystem, free of

installation or misalignment errors.

In addition to the IMU rotational offsets, the heading alignment offset should also be computedbetween the

two GNSS antennas and these results used to adjust the rotational offsets to precise values.

Note: If the rotational offsets are greaterthan +/- 1⁰accuracytheINS computationsmaystill initialise,but the

solution will be negatively impacted and not maintain a converged solution, once vessel motion occurs.

It is also important to accuratelymeasure the lever arm distance (XYZ) from the IMU centre ofnavigation to

the antenna reference point (ARP) ofthe GNSS1 antenna. These translational offsets can be measured as

part of the dimensional survey. Ensure the ARPto phase centre Zoffset is adjusted in the final application of

the offsets. The translational offset measurements must be accurate towithin +/- 1cm.

To fully calibrate and converge the systemforthe active PPP solution to use INS aiding vessel movement will

be required. Typical vessel movement during transit will be adequate for convergence, this calibration will take

several minutes up to 10 minutes. This calibration process is performed automatically by the system and does

not require any userinteraction. Where calibration istaking a prolonged period, the vessel should perform

figure of 8 movement.

AB-V-MA-00650 01 February 2021

JF/RR 12

LD900 and INS

Commissioning Guide

INS Translational Offsets

AB-V-MA-00650 01 February 2021

JF/RR 13

LD900 and INS

Commissioning Guide

Rotational Offset Adjustment

This section will illustrate how the measured rotational alignment offsets (precise offsets) should be adjusted to

the default course offset. The following illustratesthe adjustments methods for both supported IMU models.

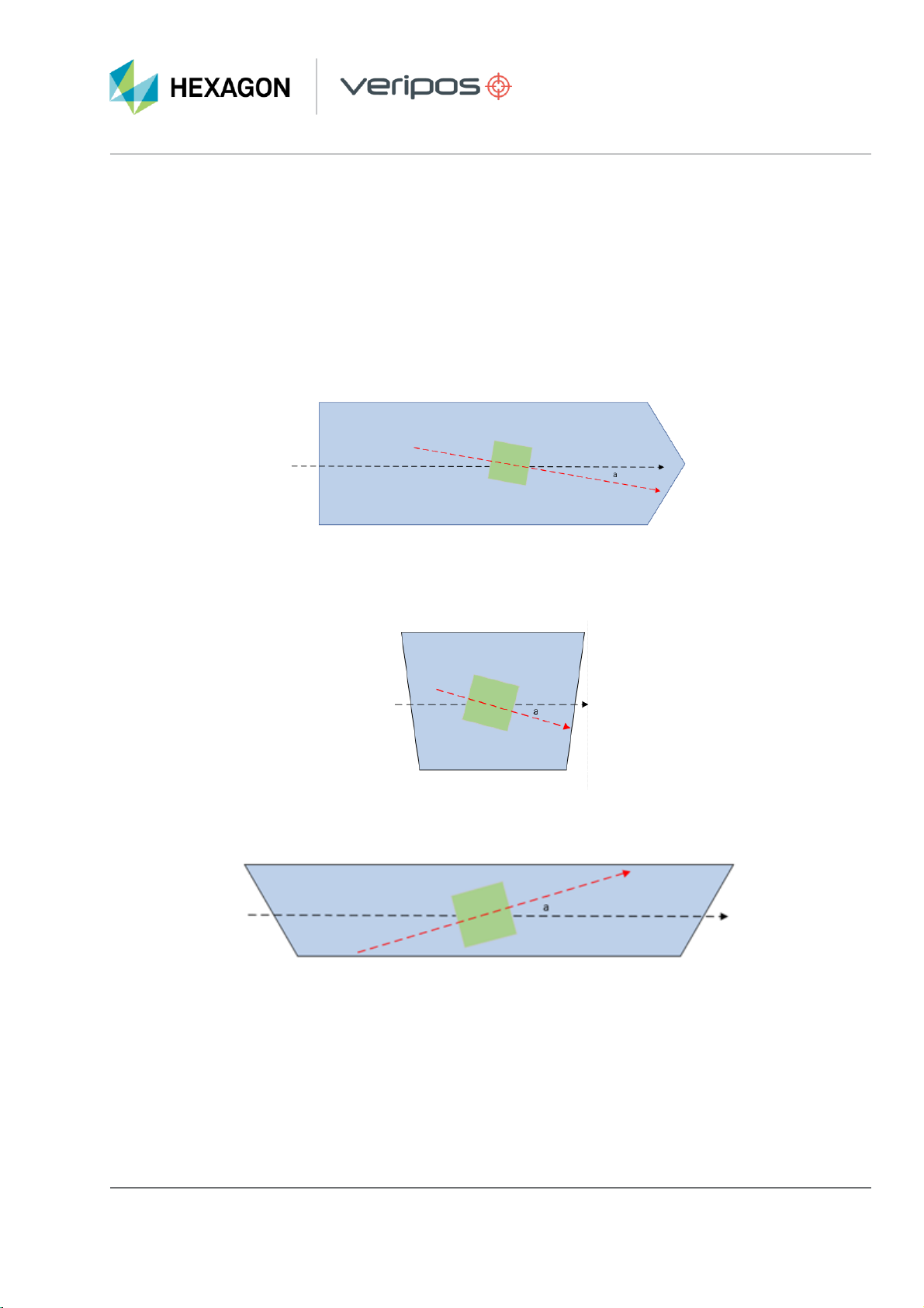

IMU-ISA-100C

When the Xaxis of the IMU is offset to starboard by angle “a”. The Installation Rotation Z +90 value is reduced

by the measured angle:

When the Y axis ofthe IMU is offset down to the starboard by angle “a”. The Installation Rotation X+180 value

is reduced by the measured angle:

When the Zaxis ofthe IMU is offset up to the bow by angle “a”. The Installation Rotation Y 0 value is reduced

by the measured angle:

INS Rotational Offsets –Side View (into Starboard Side)

INS Rotational Offsets –Vessel Plan View

INS Rotational Offsets –Forward View (from vessel Aft)

AB-V-MA-00650 01 February 2021

JF/RR 14

LD900 and INS

Commissioning Guide

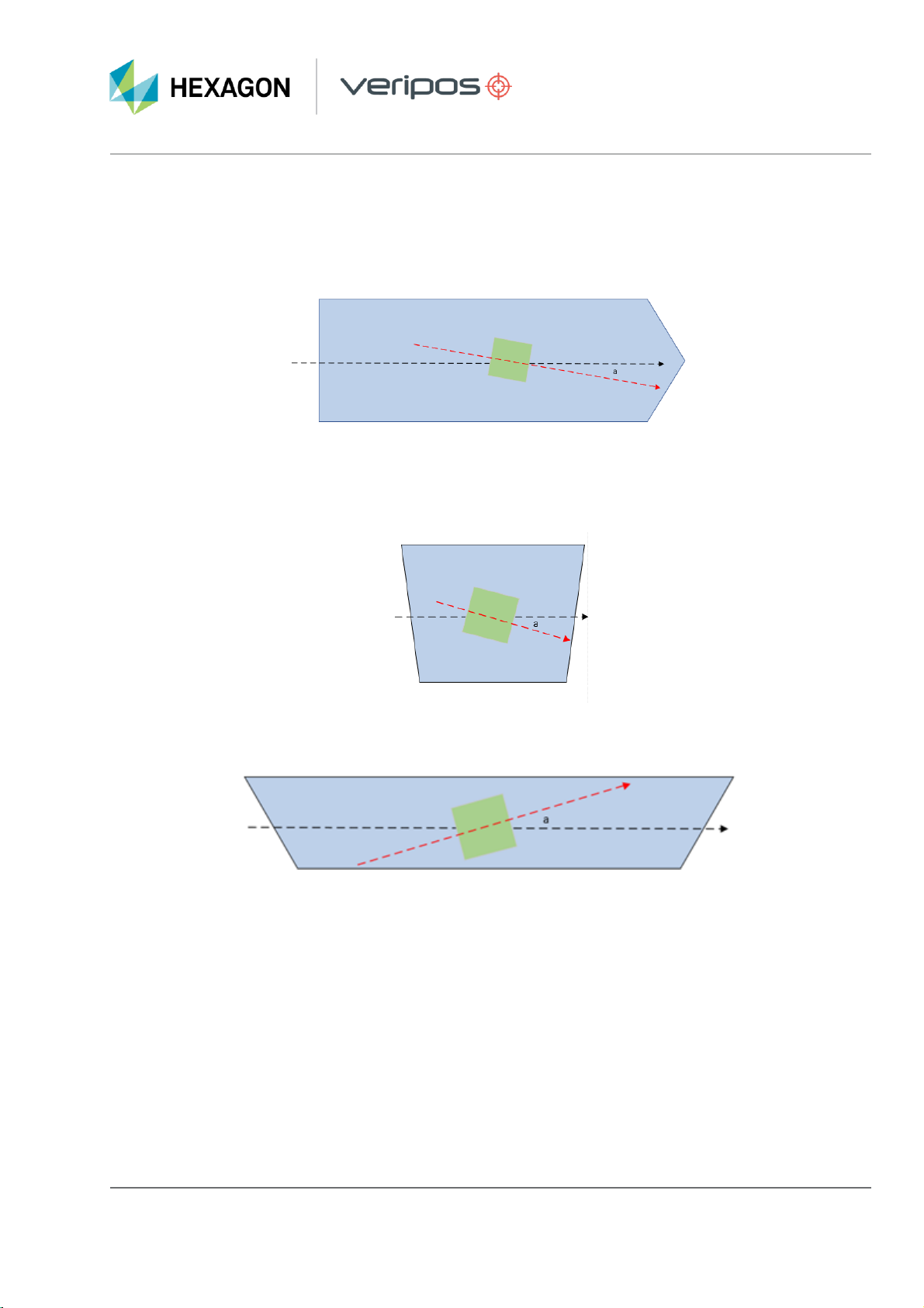

IMU-µIMU-IC

When the Y axis of the IMU is offset to starboard by angle “a”. The Installation Rotation X 0 value is reduced

by the measured angle.

INS Rotational Offsets –Vessel Plan View

When the Z axis oftheIMUis offset to starboard by angle “a”. The Installation Rotation Y -90 value is reduced

by the measured angle (Ifthe measured value for ‘a’was 10 degrees the value would reduce to -100)

When the X axis of the IMU is offset to starboard by angle “a”. The Installation Rotation Z0 value is reduced by

the measured angle.

INS Rotational Offsets –Side View (into Starboard Side)

INS Rotational Offsets –Forward View (into vessel Aft)

AB-V-MA-00650 01 February 2021

JF/RR 15

LD900 and INS

Commissioning Guide

Configuration

At this stage, the IMU is securely mounted with offsets determined, powered up and connected to a LD900

COM port. The LD900 has been activated for PPP solution, which is converged and stable and the LD900 is

ready for configuration. The LD900 can be configured via the MMI as detailed in the next section, or by using

Quantum.

LD900 Configuration

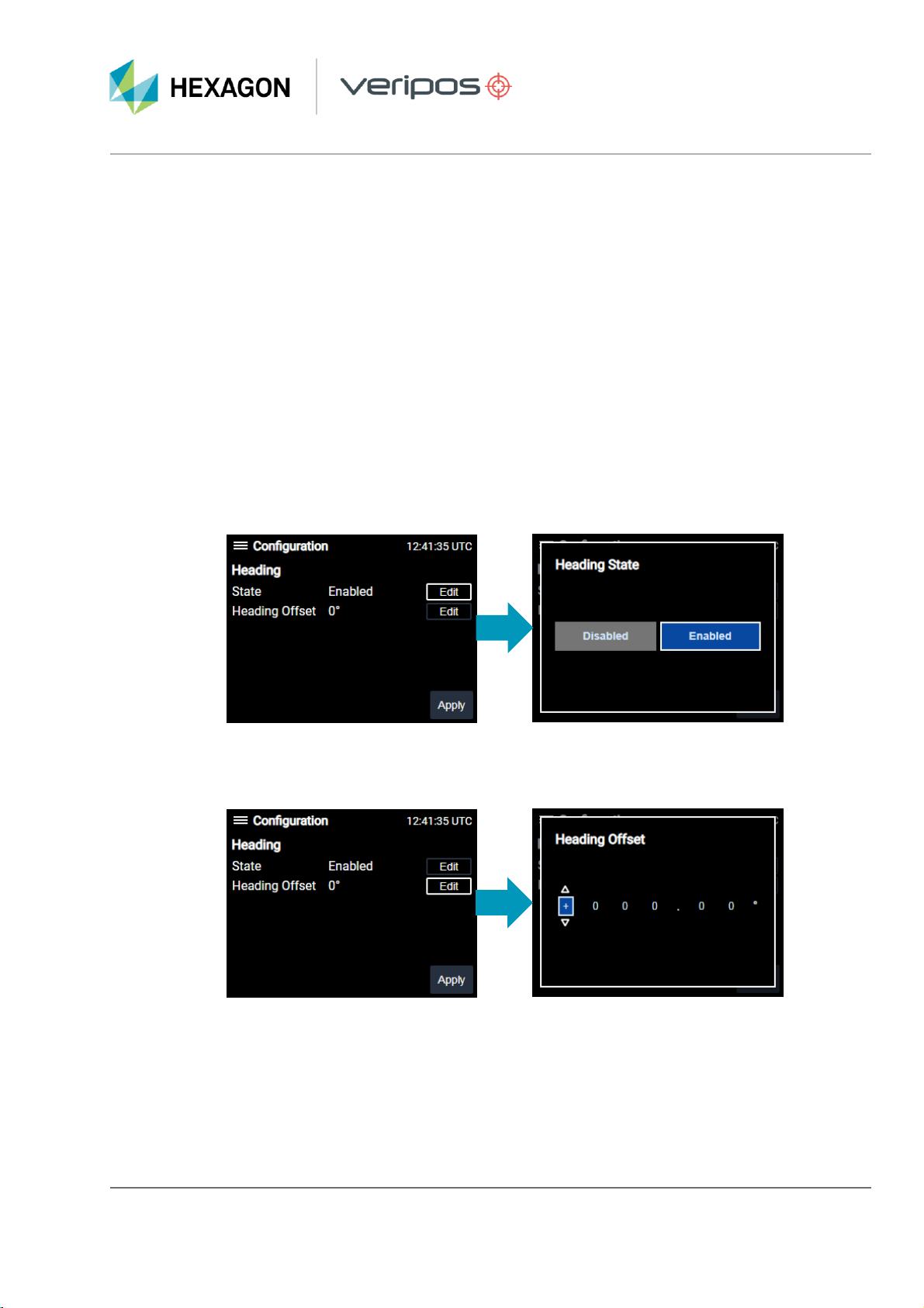

Heading

Accessing the menu Configuration > Heading within the LD900 MMI will allowfor the LD900 heading to be

set-up.

State controls ifheading is computed and available from the system. While Edit on the same row as State is

selected, use tick to bring up the Heading State and using the arrowkeys select Enabled, followed by tick.

Then use the arrowkeys to select Apply, rightto select Yesand tick to apply:

To configure the heading offset (C-O) select Editforthe Heading Offset row, followed by tick. Then use the

arrow buttons and tick to enter the GNSSheading offset. Use the arrow keys to select Apply, right to select

Yes and tick to apply the change:

AB-V-MA-00650 01 February 2021

JF/RR 16

LD900 and INS

Commissioning Guide

Return to the home screen and INS status will be unchanged (grey). The GNSS headingcan be observed

within the INS status. The reported GNSS heading should show alignment with the vesselheading, no other

values will be present at this stage.

IMU Type & Serial Port

Accessing the menu Configuration > INSwithinthe MMI will allow for the LD900 to be set-up forINS

Operations.

The IMU Type can be selected within the menu Configuration > INS.While Edit is selected on the IMU Type

row press tick and using the arrowkeys select IMU-ISA-100C orIMU-µIMU-IC as required, followed by tick.

Then use the arrowkeys and tick to select Apply, right to select Yesand tick to apply the change:

Once the IMU Type has been selected the IMU Port can be selected. While Edit is selected on the IMU Port

row press tick and using the arrowkeys and tick select COM1, COM2 orCOM3 (default)as required, followed

by tick. Then use the arrow keys to select Apply, tick to select Yesand tick to apply the change:

AB-V-MA-00650 01 February 2021

JF/RR 17

LD900 and INS

Commissioning Guide

Installation Rotation

The following details how the X (Pitch), Y (Roll) and Z(Yaw) rotational offsets are entered into the LD900.

While Installation Rotation isselected click on Edit, followed by tick and using the arrow buttonsand tick

enter an Xvalue within +/- 180.00. Use the arrow keys and tick to select Done, then use the arrow keys and

tick to select Apply,right to select Yesand tick to apply the change. Repeat for the same process for the Y

and Zoffsets.

Antenna 1 Offset (Lever-Arm)

When entering the lever arm offset (IMU to GNSS1 antenna) the following table can be used as reference:

While Antenna Offset 1 is highlighted clickon Edit, followed by tick. Then use the arrowbuttonsand tick to

enter an Xvalue within +/- 99.999 meters. Use the arrow and tick keys to select Done, then use the arrow and

tick keys to select Apply, rightto select Yesand tick to apply the change.

Vessel Axis

Positive

Negative

X

Starboard

Port

Y

Forward

Aft

Z

Up

Down

AB-V-MA-00650 01 February 2021

JF/RR 18

LD900 and INS

Commissioning Guide

QuantumConfiguration

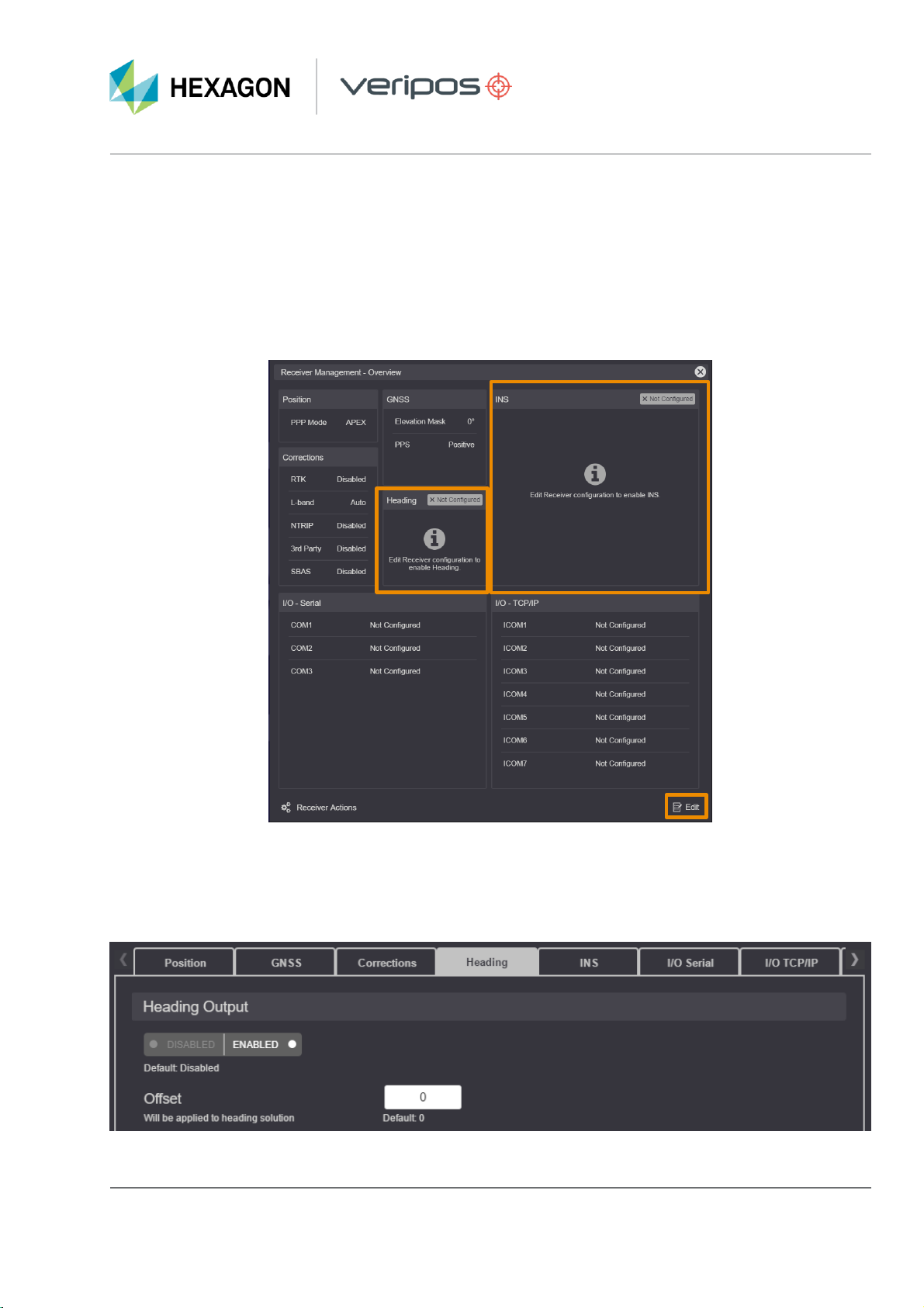

Receiver Management

When correctlyauthorised both Heading and INSareas will be displayed within SETTINGS> System

Configuration > Receiver Management showing XNot Configured. If no such areas are shown, then

request a Quantum Heading license from the VERIPOS Helpdesk. Click on Edit, foundat thebottom right-

hand corner of the screen:

SETTINGS > System Configuration > Receiver Management –Overview page

Enabling Heading

Within the Headingtab toggle Heading Output to ENABLED. Doing so will reveal the Offset setting where

the GNSS heading offset should be entered. Once heading has been configured click on Apply.

Quantum Heading configuration page

AB-V-MA-00650 01 February 2021

JF/RR 19

LD900 and INS

Commissioning Guide

Enabling INS

Within the INS tab initially, only one optionwill be available, allowing for INS to be DISABLED (or)ENABLED.

Toggle this to ENABLED to reveal additional options:

INS Tab within Quantum

Once all options are fully configured click Apply to confirm changesand apply configuration to the LD900 and

IMU.

Type

The two INS IMUs supported for use within

Quantum are the IMU-ISA-100C and the IMU-

μIMU-IC.

Port

The LD900 COM port which the IMU is being

interfaced on (COM1, COM2 orCOM3) should

be selected here.

IMU Installation> Rotational Offset

This field allows the user to enter Rotational

Offset X,Y and Z values within a -180.00° to

+180.00° range.

IMU to Antenna Offset > Primary Antenna

This field allows the user to enter Primary

Antenna Offset X,Y and Zvalues within a

range of -99.99 to +99.99 metres.

Once INS has been configured click on Apply.

AB-V-MA-00650 01 February 2021

JF/RR 20

LD900 and INS

Commissioning Guide

Operation

The successful configuration ofINS can be determined by checking the LD900 MMI Statuspage and, ifused,

within the Quantum main page.

INS Status (LD900 MMI)

The LD900 INS status can be viewed on the MMI by pressing the home button.

Before configuration, the INS Icon will be Grey and once configured this will change from Grey to Amber. Once

an INS solution is calculated the icon will turn Green and once there has been significantvessel motion an

‘INS Aided’ notification will appear, confirming a blended GNSS and INS solution. If there is a problem with

either the configuration orthe hardware, then the status of the INS Icon will be Red. The INS transition

sequence is illustrated below:

Authorised, not

configured

Configured

and aligning

Aligned

Fully converged and INS

solution active

Selecting the INS statuswith the cursor and presenting tick willreveal additional details. Once the INS solution

is operational the GNSS heading will closely match the INS heading.

INS Status details

Other manuals for VERIPOS LD900

2

This manual suits for next models

1

Table of contents

Other Hexagon Receiver manuals