HI-FOG 1900 Manual

18/09/2017

Document number 0003301084 Ver. A Page 1 of 18

HI-FOG® 1900 SPRINKLER

WITH

A1000 TYPE ASSEMBLY BODY WITH STOP VALVE

IDENTIFICATION AND CORRECTION PROCEDURE

The purpose of this document is to provide guidance and instructions for corrective

actions required to mitigate the risk of HI-FOG 1900 sprinkler installed in some

A1000 type assembly bodies with an internal stop valve as referred to in Safety

Bulletin 2017\004.

The information in this document is in the following order:

Introduction and General Work Instructions

1. Background information

2. Affected and other HI-FOG sprinkler types

3. Affected and other Assembly Bodies

4. Corrective Actions

5. Troubleshooting

Appendix A: Follow-Up form

Appendix B: Summary of Product Types Differences

CAUTION

HI-FOG Systems comprise mechanical components

and employ high-pressure for water pressurization.

System installation embraces high-pressure testing of discharge tubing.

Care must be taken to ensure that in the installation all relevant procedures are

followed to the satisfaction of the authority having jurisdiction

and that only competent personnel, appropriately trained, are

permitted to install, test, commission and service the system.

18/09/2017

Document number 0003301084 Ver. A Page 2 of 18

1. Background information

Installation of HI-FOG sprinklers consists of HI-FOG sprinkler inserted into a

specifically built Assembly Body, also known as ‘Mounting Adaptor’.

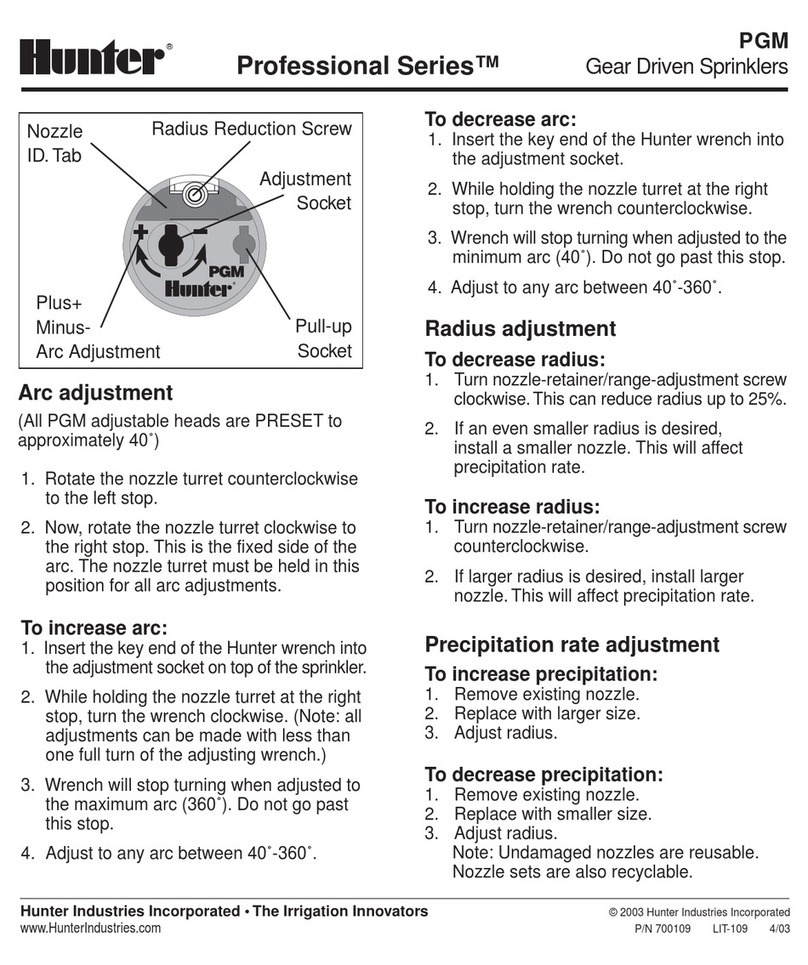

Figure 01 : HI-FOG sprinkler in Assembly Body

The A1000 Assembly Bodies were built to accommodate the HI-FOG 1000

sprinklers. Some types of this Assembly Body include an internal stop valve that

prevents the flow through the Assembly Body if the sprinkler is removed.

The HI-FOG 1900 sprinklers have been developed as replacement of HI-FOG

1000 sprinklers using some of the improvements presented in the HI-FOG 2000

sprinklers.

For some of the Assembly Body type A1000, there is a risk that a HI-FOG 1900

sprinkler will press the internal stop valve beyond the intended range and thus

may diminish or in the worst case prevent the water flow to the sprinkler in case of

discharge.

The risk is limited to the specific Assembly Body types, used in combination with

HI-FOG 1900 sprinklers.

The risk does not extend to other Assembly Body types, to Assembly Bodies

without internal stop valve or to any other HI-FOG sprinklers with any Assembly

Body.

See details in the following sections to identify the affected components.

18/09/2017

Document number 0003301084 Ver. A Page 3 of 18

2. Affected and other HI-FOG sprinkler types

The risk and the related corrective action required are relevant for HI-FOG 1900

sprinklers only.

Other HI-FOG sprinkler types require none of the actions referred to by this

document.

To differentiate the HI-FOG 1900 sprinkler from other HI-FOG sprinkler types

note the following features:

a. HI-FOG 1000 sprinkler have a similar conical shape as the HI-FOG 1900,

but the HI-FOG 1900 has a groove above the conical section while the

HI-FOG 1000 does not.

b. HI-FOG 2000 and HI-FOG 3000 sprinklers do not have a conical section

c. Other types, such as pop-up or machinery-space open spray-heads, that are

not included in the illustration below, do not have a glass bulb.

HI-FOG 1900

HI-FOG 1000

HI-FOG 2000

HI-FOG 3000

Appearance:

-Cone shape

-Groove above the

cone

Appearance:

-Cone shape

-No groove

Appearance:

-No cone

-No groove

Appearance:

-No cone

-No groove

Action Required No Action Required

Figure 02 : HI-FOG sprinkler types

18/09/2017

Document number 0003301084 Ver. A Page 4 of 18

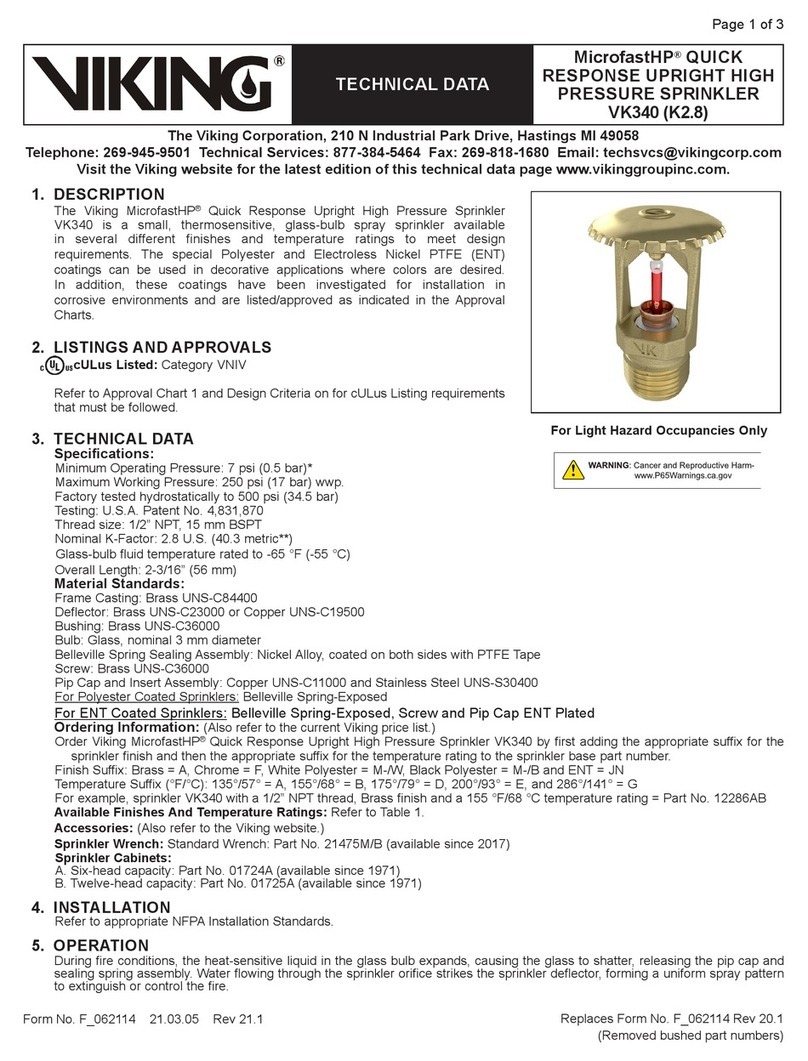

3. Affected and other Assembly Bodies

The risk and the related corrective action required are relevant only for HI-FOG

1900 sprinklers (see Chapter 2 to identify) when installed in some A1000 types

Assembly Body, which contain an internal stop valve.

HI-FOG sprinkler installed in other types of Assembly Body require none of the

actions referred to by this document.

To differentiate the A1000 Assembly Body from other Assembly Body types note

the following:

a. With the A1000 type Assembly body there is no gap between the HI-FOG

1900 sprinkler and the cover plate when the HI-FOG 1900 sprinkler is

installed (see Figure 01). The cover plate (see Figure 01) of A1000

Assembly body types is held in place by the sprinkler.

b. The A2000 Assembly body type is suitable only for HI-FOG 2000 sprinklers

(see Figure 02 for sprinkler types).

c. A HI-FOG 1900 sprinkler installed in an AB type Assembly body would either

leave a 2 – 3 mm gap between the top of the sprinkler and the cover plate,

or would have an adaptor ring filling the gap.

See Figure 03 for AB types below – left half without adaptor ring and right

half with adaptor ring. The cover plate of AB type is connected to the

Mounting Adaptor with a lock ring.

d. The Ctype the installation with HI-FOG 1900 sprinkler would leave a narrow

gap between the top of the sprinkler and the cover plate - The cover plate of

Ctype is snapped directly to the Assembly body.

A1000 types

A2000 types

AB types

C types

Notes:

-Cover plate

supported by the

sprinkler : no gap

Notes:

-Cover plate

supported by the

sprinkler : not

applicable for HF

1900

Notes:

-Cover plate

supported by lock

ring : gap or

adaptor ring

Notes:

-Cover plate

snapped to the

Assembly Body :

gap

Action Required

for HI-FOG 1900

No Action Required

Figure 03 : Assembly Body types

18/09/2017

Document number 0003301084 Ver. A Page 5 of 18

4. Corrective Actions

As corrective action the O-ring needs to be replaced and a spacer plate needs to

be added to each HI-FOG 1900 sprinkler installed in A1000 type assembly body

with an internal stop valve.

Note: These instructions are intended for HI-FOG systems with electric

powered pump units.

For GPU (Gas-driven Pump Units) please contact Marioff for system

specific instructions.

4.1. Required Documents and Tools

To assure all affected sprinklers are addressed, it is recommended to prepare a

work plan before starting the work.

The following documents are recommended to be used in the process:

•HI-FOG sprinkler layout drawing to provide the locations of all potentially

affected sprinklers, section valves and flushing valves which will be used

during the modification process.

Please note that even though the HI-FOG sprinkler layout drawings indicate

HI-FOG 1000 sprinklers they may have been replaced by HI-FOG 1900

sprinklers during testing or service.

•Appendix A of this document contains a follow-up table for the checking and

adjusting of sprinklers.

Required parts:

•Spacer Ring, Marioff item code 2000267114

•O-Ring 15x2,0, Marioff item code 2000297566

Spacer plate

O-Ring 15x2,0

Figure 04 : Required parts

Required tools (see Figure 05 for details):

•O-Ring assembly tool; item code 2000297565

•Sprinkler key; item code M11015 or Sprinkler dismounting tool; item code W-

0010888

•Flushing hose; item code M14510 or Section valve test hose; item code

D23050 or Section valve test hose; item code D23040

•Buckets and rags as some spillage is expected when removing and

reinstalling the sprinklers

18/09/2017

Document number 0003301084 Ver. A Page 6 of 18

•Ladder

•Scaffolding where needed

Sprinkler key

item code M11015 Sprinkler dismounting

tool item code W-

0010888

Flushing hose

item code M14510

Section valve test hose item code

D23050 Section valve test

hose item code

D23040

O-Rings assembly

tool item code

2000297565

Figure 05 : Tools

4.2. Preparations

Note: HI-FOG 1900 sprinklers can also be found as spare parts in storage.

Make sure that also the spare HI-FOG 1900 sprinklers are included in the

work plan.

Identify and log the location of all installed HI-FOG 1900 sprinklers. Use the HI-

FOG sprinkler layout drawings as indication of potential locations of HI-FOG

1900 sprinklers (remember that HI-FOG 1900 sprinklers are replacements of HI-

FOG 1000 sprinklers) and confirm the type visually (see Chapter 2 for details).

Identify and log the type of assembly body whenever possible by visual

inspection (see Chapter 3 for details).

After mapping the location of all potentially affected HI-FOG 1900 sprinklers

which are mounted to A1000 type Assembly bodies, prepare a work plan that will

assure all affected sprinklers will be taken into account when performing the

corrective actions.

Before starting the work, inform the bridge and ECR that the HI-FOG system is

partly out of operation during corrective actions to avoid accidental alarms!

18/09/2017

Document number 0003301084 Ver. A Page 7 of 18

4.3. Performing corrective actions

4.3.1. Isolate the Accumulator Units

Before starting corrective actions, switch on the Nitrogen

blocking from the key switch on the control panel or disconnect

the nitrogen accumulator unit (if applicable) to avoid the

accidental release of nitrogen (see

Figure 06

and

Figure 07

).

Figure 06 : Disconnecting the solenoid plug from a Bürkert valve

Figure 07 : Disconnecting the solenoid plug from a release valve

4.3.2. Isolate and de-pressurize the section under work

Before removing the sprinklers it is advisable to isolate (see a below) and

depressurize the section where the HF1900 sprinklers will be modified to

minimize the risks of spillage and false starting of the pump unit.

Depressurizing the section can be done either from the Flushing Valve (see b

below) or from the Section Valve (see c below).

18/09/2017

Document number 0003301084 Ver. A Page 8 of 18

Figure 08 illustrates the schematic view of a typical section:

Figure 08 : Schematic view of a typical section

a. Before depressurizing the section, make sure the section where corrective

actions are being carried out is isolated by closing the section valve as

illustrated below. (see Figure 09 ).

Note: Use your hands only to manually open or close the valve. Excessive

force is not required and should not be used.

SBA section valve

SVA section valve

Figure 09 : Section valves

b. The section can be depressurized from the flushing valve with a flushing

hose (see Figure 05 ). The flushing valves of the sections should be marked

on the HI-FOG sprinkler layout drawings. Flushing valves are equipped with

a flushing valve sign (see Figure 10 ).

Minimess connection

point

18/09/2017

Document number 0003301084 Ver. A Page 9 of 18

Figure 10 : Flushing valve sign

-Connect the flushing hose to the flushing valve.

-Point the hose towards a sewer or a drain. Hold the hose firmly with

both hands.

-Open the flushing valve.

-Let the water flow through long enough for the section to de-

pressurize.

-Close the flushing valve.

-Disconnect the flushing hose from the flushing valve.

c. The section can also be depressurized by connecting a test hose (see

Figure 05 ) to the test valve of the section valve (see Figure 09 ). Hose item

code D23050 is suitable for SBA valves and D23040 fits to the ‘Minimes’

connection on SVA valves.

-Connect the test hose to the section valve’s test valve connection.

-Point the hose towards a bucket or drain.

-Slowly open the test valve connection.

-Let water flow through long enough for the pressure to fully release.

-Close the test valve.

-Disconnect the hose.

4.3.3. Inspect and retrofit potentially affected Sprinklers

a. Confirm that the Sprinkler is of type HI-FOG 1900 (see Chapter 2)

Log the type and location of sprinkler in the Follow-Up sheet (

Appendix A )

Figure 11 : Location and type of sprinkler

b. Inspect the Assembly Body. If it is visually identified as other type than

A1000 (see Chapter 3) then log the type in the follow up sheet (see Figure

18/09/2017

Document number 0003301084 Ver. A Page 10 of 18

12 ) and continue to the next sprinkler, there are no corrective actions

needed.

Figure 12 : Assembly Body type

c. In case the Assembly Body cannot be visually identified, or is identified as

A1000, remove the sprinkler by opening it with the correct sprinkler key or

with a sprinkler dismounting tool (see Figure 05 ).

-Do not use excessive force or you might damage the sprinkler cage.

-Use a rag or a bucket when removing the sprinkler to catch water

collected in the assembly body.

d. Inspect the Assembly Body. If it is NOT type A1000 (see Chapter 3) then log

the type in the follow up sheet (see Figure 12 ) and continue to the next

sprinkler.

If the type is A1000 then verify from the inside of the assembly body if

there is an internal stop valve (see Figure 13).

Pin type internal stop valve

Ball type internal stop valve (not in A1000 \

A2000 \ AB type Assembly Bodies)

Figure 13 : Internal stop valve

Log the type and existence \ absence of internal stop valve in the follow up

sheet (see Figure 12 ).

If there is NO internal stop valve, reinstall the sprinkler (go to step gbelow).

If the type is A1000 AND there IS an internal stop valve then continue:

e. Remove the 15x1,5 O-ring from the sprinkler (see Figure 14 ). Do not

damage or scratch the sprinkler’s sealing surface. Cut the removed O-Ring

to assure it does not mix with the new seals.

Note: to avoid damage to the sealing surface do not use any metal tools for

removing the O-Ring

f. Install the new 15x2,0 O-ring to the sprinkler by placing the O-ring

installation cone (see Figure 05 ) over the spindle and rolling the new O-ring

onto the sprinkler until you are sure the O-ring sits correctly in its groove

(see Figure 14 ).

g. Install the spacer to the sprinkler (see Figure 14 ).

18/09/2017

Document number 0003301084 Ver. A Page 11 of 18

15x2,0 O-ring to replace the 15x1,5 O-

ring supplied with sprinklers

Spacer plate to be assembled on the HI-

FOG 1900 sprinkler

Figure 14 : Replacement of O-Ring and installation of Spacer

h. Install the sprinkler and the cover plate back into place. Tighten it with the

sprinkler key. Do not use excessive force.

Log in the follow-up sheet:

-Is a cover plate (see Figure 15) present (yes/no)

-Date of changing the O-Ring \ installing the spacer plate

NOTE: Do not use excessive force when tightening the sprinkler to avoid

damaging the sprinkler.

Figure 15 : HI-FOG 1900 installed with (left) & without (right) a spacer

i. Remember to fill the record in the Follow-Up form before proceeding. Repeat

the steps above until all potentially affected sprinklers in the section are

corrected.

4.3.4. Pressurize and Flush the Section

After all sprinklers in the section have been addressed the section needs to be

engaged to the system and the functionality of the section valve should be

tested.

a. Man the testing positions:

-Person A: at the control panel or mimic panel where you can reset the

system

-Person B: in the protected compartment or holding the flushing hose

-Person C: at the flushing valve or section valve

b. Open the section valve. The pump unit may start. Wait for it to reach 130

bars and reset the system by pressing the ‘reset’ button for two seconds.

(Person A)

18/09/2017

Document number 0003301084 Ver. A Page 12 of 18

c. Check that the system stabilizes to stand-by pressure (25 bars if not

otherwise indicated). (Person A)

d. Check that there are no leaks from the installed sprinklers. (Person B and C)

e. Remove the plug from the flushing valve and connect the flushing hose to

the flushing valve. Make sure that you can hold the flushing hose firmly with

both hands during the system flushing and point it to a place where water

can be safely sprayed. (Person B and C)

NOTE: The water exits the hose with high pressure. Be sure that you can

hold the hose firmly with both hands!

f. Open the flushing valve to create flow in the system. (Person C)

g. The pump unit should activate within 1 minute.

h. Check from the control / mimic panel or the ship automation system that the

pump unit starts and verify that the correct section gives the correct alarm.

Reset the audio alarm from the buzzer reset/acknowledge button. (Person

A)

i. Let water flow from the hose for a couple of minutes to flush the section.

(Person B and C)

j. Close the flushing valve. (Person C)

k. Reset the system from the control panel after the flushing valve has been

closed and the system has reached 130 bars pressure. (Person A)

l. Check that the system stabilizes to stand-by pressure (25 bars if not

otherwise indicated). (Person A)

m.Disconnect the flushing hose from the flushing valve and install the plug

back into place. (Person C)

After competing these steps proceed to the next section in the work plan.

4.4. Post Actions

After finalizing the corrective actions in all sections, the system should be put

back into normal standby mode and the nitrogen accumulator unit should be

switched back on / reconnected. (see Figure 06 and Figure 07 ).

NOTE: Make sure that there is no activation demand on for the HI-FOG

system before reconnecting the nitrogen accumulator units!

-Inform the bridge and ECR that the work is completed and the system is

in normal stand-by mode.

Send the filled Follow-Up form to Marioff quality@marioff.fi

18/09/2017

Document number 0003301084 Ver. A Page 13 of 18

5. Troubleshooting

5.1. Leakage of retrofitted or reinstalled sprinkler

Leakage can be caused e.g. when the O-ring is not replaced and the Spacer

plate is used, when the O-ring is damaged or misplaced, or when the sealing

surface on the sprinkler or the Assembly Body is scratched or contaminated.

Corrective actions:

-Depressurise the system

-Remove the sprinkler and make sure that all the surfaces of the

sprinkler and the Assembly Body are clean and undamaged

-Replace the O-Ring and make sure it sits properly in its groove

5.2. Assembly Body type is not visibly like the listed types

The Safety Bulletin and this document focus on the relevant types, which are

connected to the ceiling by assembly plates, and to several similar models.

Other types, e.g. models that are wall mounted, or that are bolted directly to the

surface, do not require further action.

Exposed A1000 Assembly Bodies, with no cover plate, do require attention.

See Figure 16below for more examples.

A1000 Assembly body

without cover plate

Action as other A1000

Grooved Assembly body

type

No Action Required

Long Assembly body type

No Action Required

Welded Tube Assembly

body type

No Action Required

Wall Mounting Assembly

body type

No Action Required

Surface Assembly body

type

No Action Required

Figure 16 : more Assembly Bodies

18/09/2017

Document number 0003301084 Ver. A Page 14 of 18

5.3. Cover plate missing

Assembly Body type A1000 with or without cover plate (see Figure 01) needs to be

addressed in the same manner.

18/09/2017

Document number 0003301084 Ver. A Page 15 of 18

Appendix A : Follow-Up form

SITE DATA

Ship

IMO no.

Sprinkler

Location

Assembly body

Code*

Deck

Section

Type**

stop valve

[y/n]

Change

Date***

e.g.

C-0006881

Deck 5

S017

A1000

Y

21.Sep.17

e.g.

C-0009072

Spare part

stock

-

-

22.Sep.17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

* Item Code of a sprinkler is a series of letters and digits, starting with ‘C’, printed on the side of HI-

FOG 1000 \ 1900 sprinklers

** Type : A1000 \ A2000 \ AB \ C (see Figure 03 )

*** date of installing replacement O-Ring and Spacer OR ‘X’ if replacement not done

18/09/2017

Document number 0003301084 Ver. A Page 16 of 18

Sprinkler

Location

Assembly body

Code*

Deck

Section

Type**

stop valve

[y/n]

Change

Date***

e.g.

C-0006881

Deck 5

S017

A1000

Y

21.Sep.17

e.g.

C-0009072

Spare part

stock

-

-

22.Sep.17

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

…

18/09/2017

Document number 0003301084 Ver. A Page 17 of 18

Appendix B : Summary of Product Types Differences

HI-FOG 1900

HI-FOG 1000

HI-FOG 2000

HI-FOG 3000

Appearance:

-Cone shape

-Groove above the

cone

Appearance:

-Cone shape

-No groove

Appearance:

-No cone

-No groove

Appearance:

-No cone

-No groove

Action Required

No Action Required

Figure 02 : HI-FOG sprinkler types

A1000 types

A2000 types

AB types

C types

Notes:

-Cover plate supported by

the sprinkler : no gap

Notes:

-Cover plate supported by

the sprinkler : not

applicable for

HF1900

Notes:

-Plate supported by snap-ring

: gap or spacer

Notes:

-Cover plate snapped to

the Assembly Body with a

lock ring : gap

Action Required for HI-

FOG 1900

No Action Required

Figure 03 : Assembly Body types

18/09/2017

Document number 0003301084 Ver. A Page 18 of 18

15x2,0 O-ring to replace the 15x1,5 O-

ring supplied with sprinklers

Spacer plate to be assembled on the

HI-FOG 1900 sprinkler

Figure 14 : replacement of O-Ring and installation of Spacer plate

Figure 15 : HI-FOG 1900 installed with (left) & without (right) a Spacer

plate

A1000 Assembly body

without cover plate

Action as other A1000

Grooved Assembly body type

No Action Required Long Assembly body type

No Action Required

Welded Tube Assembly body

type:No Action Required

Wall Mounting Assembly body

type:No Action Required

Surface Assembly body type:

No Action Required

Figure 16 : more Assembly Bodies

Pin type internal stop valve

Ball type internal stop valve (not in A / AB

type Assembly Bodies)

Figure 13 : internal stop valve

Table of contents