3.

Design Criteria for UL and C-UL

The Models N252 EC Pendent and Recessed Pendent

Sprinklers are cULus Listed standard response control-

mode, extended coverage density/area sprinklers for

installation in accordance with the extended coverage

pendent spray sprinkler criteria of NFPA 13, or other ap-

plicable NFPA standards, when used in combination with

the following guidelines:

• Protection for extra hazard and high-piled stor-

age occupancies using NFPA 13 density/area

criteria.

• Suitable for use in wet pipe systems, and in dry-

pipe and preaction systems as specifically al-

lowed for pendent sprinklers in NFPA 13.

• cULus Listed for “unobstructed” or non-combus-

tible “obstructed” construction. Given that the

Model N252 EC sprinklers are specifically listed

for noncombustible obstructed construction, they

may be installed within trusses or bar joists hav-

ing noncombustible web members greater than

1 inch (25.4 mm) when applying the “Four Times

Rule” as defined in NFPA 13 under “Obstructions

to Sprinkler Discharge Pattern Development.”

• Maximum area of coverage per sprinklers is 196

ft2(18.2 m2); minimum area of coverage is 100 ft2

(9.3 m2). Maximum spacing between sprinklers

is 14 ft (4.3 m); minimum spacing between sprin-

klers is 10 ft (3.1 m).

• Minimum flow requirement is based on the de-

sign density applied over the actual area of cov-

erage per sprinkler. Example 1, a design density

of 0.43 gpm/ft2(17.5 mm/min) applied over 14 ft

x 14 ft (4.3 m x 4.3 m) spacing, or 196 ft2(18.2

m2), would require a minimum sprinkler design

flow rate and pressure of 84.3 gpm (319.2 L/min)

at 11.2 psi (0.77 bar). Example 2, a design den-

sity of 0.43 gpm/ft2(17.5 mm/min) applied over

14 ft x 12 ft (4.3 m x 3.7 m) spacing, or 168 ft2

(15.6 m2), would require a minimum sprinkler de-

sign flow rate and pressure of 72.2 gpm (273.3

L/min) at 8.2 psi (0.57 bar).

• Maximum working pressure - 175 psi (12.1 bar).

• Minimum end head pressure - 7 psi (0.5 bar).

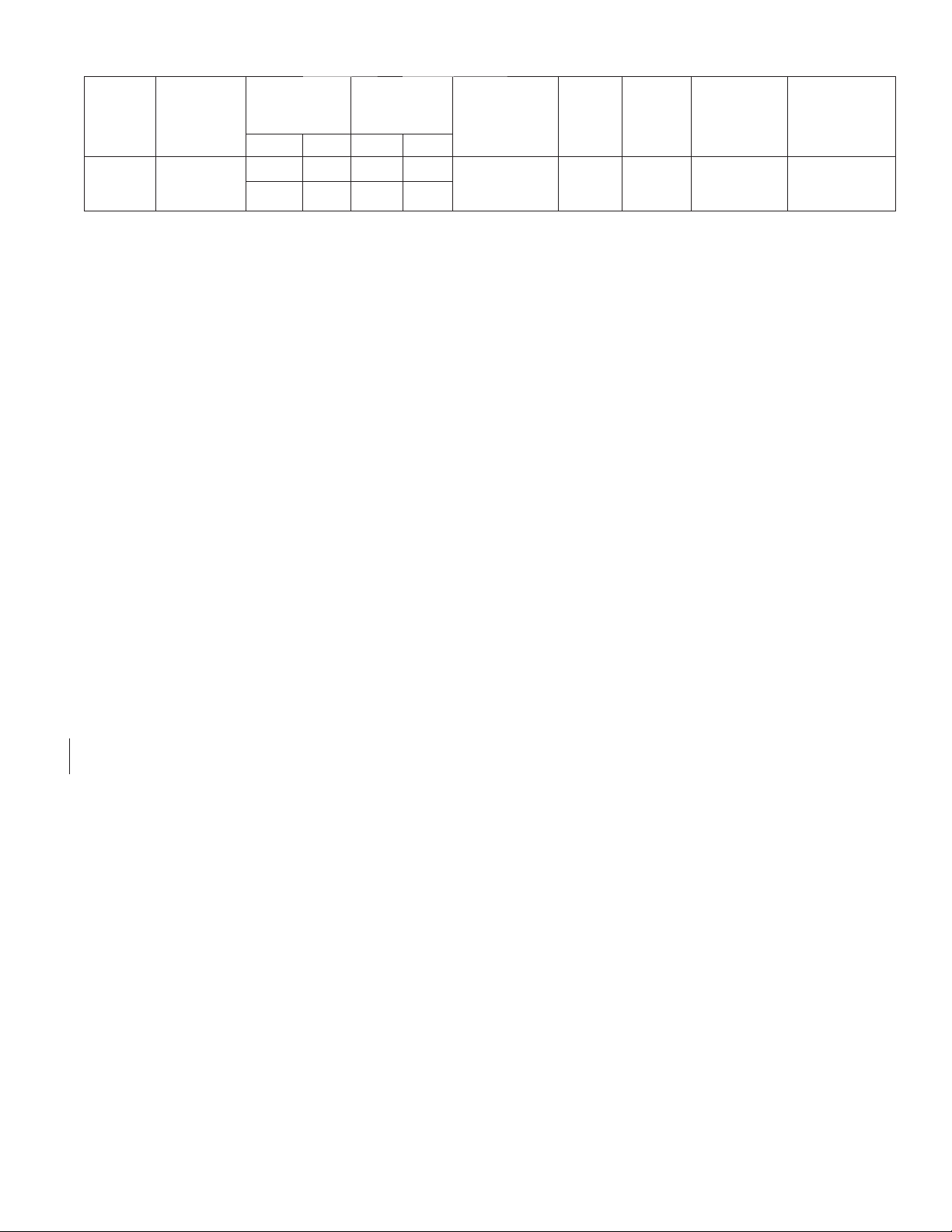

Technical Data

Sprinkler

Model Type

Temperature

Rating

Maximum

Ambient

Ceiling Temp.

Nominal K-

Factor

GPM/psi

(LPM/bar)½

Orifice

Size

Thread

Size

Sprinkler Ht.

Inch (mm)

Sprinkler

Identification

Number (SIN)

°F °C °F °C

N252 EC

Pendent/

Recessed

Pendent

165 74 100 38 25.2

(363) 1 inch 1” NPT

(R1)

3.6

(91,5) RA0842

212 100 150 66

• The minimum clearance between the deflec-

tor and the top of storage is 3 ft. (0,92m). For

clearances of 3 ft. (0,92m) up to 4 ft. (1,21m), the

minimum design pressure is 22 psi (1,52 bar).

For clearances of 4 ft. (1,21m) and greater, the

minimum design pressure is established by the

minimum flow requirement (however, the pres-

sure can never be less than 7 psi (0,48 bar)).

• Available temperature ratings are Ordinary, 165

°F (74 °C) and Intermediate, 212 °F (100 °C).

Selection of temperature rating is based on the

expected maximum ambient temperature expo-

sure, or in accordance with the high-piled stor-

age density/area curve requirements specified

in Chapter 12 of the 2002 edition of NFPA 13. In

accordance with the listing of the sprinkler, the

density curves normally associated with high

temperature rated sprinklers [286°F (141°C)] may

be used with either the ordinary or intermediate

temperature rating of the N252 EC sprinklers.

• The obstruction criteria in NFPA 13 for Extend-

ed Coverage Pendent Sprinklers shall be used

for the locating and positioning Model N252 EC

sprinklers relative to obstructions.

Design Criteria for FM

The Model N252 EC Pendent Sprinklers are FM approved to

be utilized in accordance with the following guidelines:

• FM approved for installations governed by data

sheets 2-0 and 8-9.

• FM Global considers this a “Quick Response”

extended coverage storage sprinkler.

Maintenance

The Models N252 EC Pendent and Recessed Pendent

Sprinklers should be inspected and the sprinkler system main-

tained in accordance with NFPA 25, and local jurisdictional

requirements. Do not clean sprinklers with soap and water,

ammonia, or any other cleaning fluids or solvents. Remove

dust by using a soft brush or gentle vacuuming. Remove any

sprinkler that has been painted (other than factory-applied) or

otherwise altered after leaving the factory. A stock of spare

sprinklers should be maintained to allow quick replacement

of damaged or operated sprinklers. Prior to installation, sprin-

klers should be maintained in the original cartons and packag-

ing until used to minimize the potential for damage to sprinkler

that would cause improper operation or non-operation.