Hi-Force BC18X User manual

TDS1343

1010

BATTERY OPERATED HYDRAULIC CRIMPING TOOLS

MODEL NUMBERS BC18X, BC30, BC40, BC63

OPERATING INSTRUCTIONS

INTRODUCTION

The BC self-contained battery operated hydraulic cable crimping tools are fitted with

an automatic pressure relief valve and are supplied complete with standard die sets

and carrying case. With 180° rotating head they are designed for easy access into

confined spaces.

SAFETY NOTES

Always wear suitable personal protection when operating hydraulic equipment.

DANGER: Keep all body parts away from Crimper and work piece during operation.

IMPORTANT: Ensure that the correct size tool and die is selected for the job.

IMPORTANT: Minimum age of operator must be 18 years. The operator must have

read and understood all instructions, safety issues, cautions and warnings before

starting to operate this equipment.

WARNING: Risk of finger trapping. Only hold the tool by means of the handle.

WARNING: Do not overload equipment. Overloading causes equipment failure and

possible personal injury.

CAUTION: Make sure that all system components are protected from external

sources of damage, such as excessive heat, flame, moving machine parts, sharp

edges and corrosive chemicals.

WARNING: Immediately replace worn or damaged parts with genuine Hi-Force

parts.

WARNING: Always wear safety glasses and other appropriate personal protection

equipment. The operator must take precautions against injury due to failure of the

tool or work piece.

DANGER: Do not attempt to crimp on a live cable. The tool is not insulated.

SELECTION AND INSERTION OF DIE SETS

All Hi- Force hydraulic crimpers are supplied complete with Die sets to suit the

applicable range of the Crimper. All Die sets are marked with their applicable size

capacity to avoid accidental mixing of different sizes. Standard die sets are suitable

for use with copper cable connectors ONLY. When aluminium cable connectors are

used

The fitting of dies is a simple process that requires no tools, but the method varies

depending on the crimper in use.

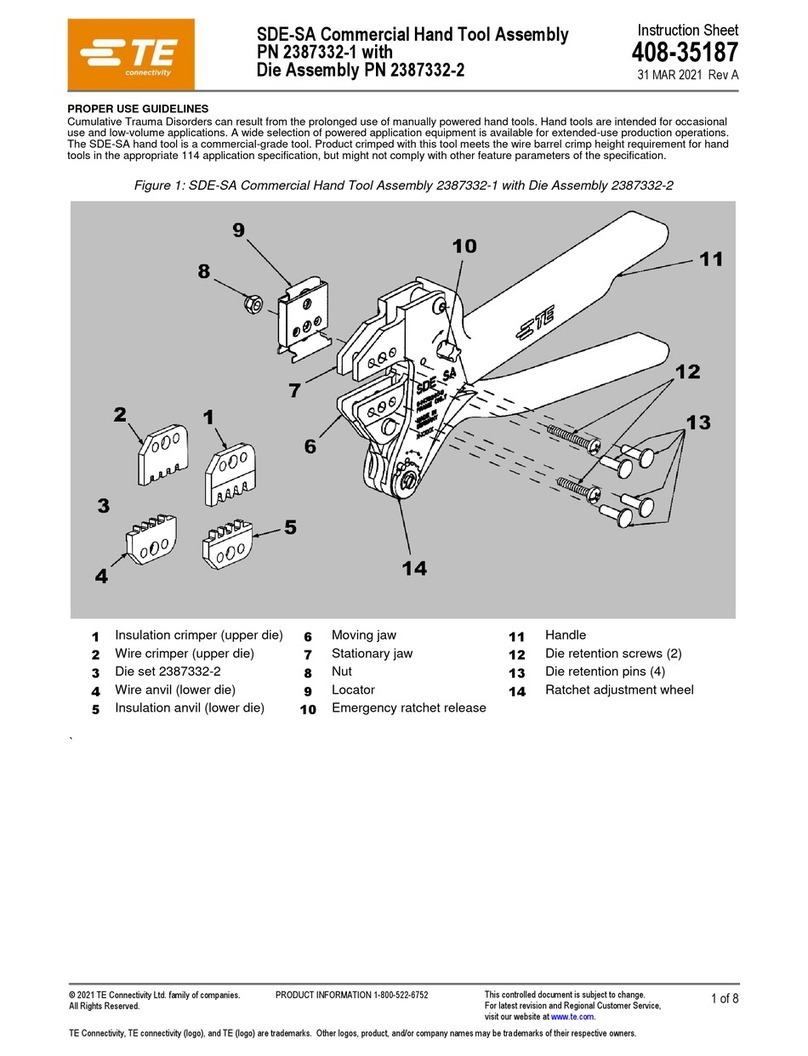

BC18X

Open the Jaws by pushing the end of the jaw in the direction of the arrow in the

diagram below. Select the appropriate die pair, checking that the two halves match in

size. Take care as some of the smaller dies contain two sizes of crimp. Slide the dies

into the recesses in the jaw until they latch into place by means of the ball mounted in

the side of the die. Close the jaw by squeezing the two halves together until they

latch into each other.

TDS1343

1010

BC30 and BC40

To insert the Dies pull the locating button plunger on the end of the head assembly to

retract the locating plunger. Slide one half of the die into position. Release locating

plunger to ‘Lock’ in to the groove in the rear of the die. Slide the other half of the die

into the opposing jaw. If required advance piston to expose Die release plunger to

assist with location. (see instructions below) Check the Die is correctly located by

trying to slide the Die out. It should not move! Check that a matching pair of die

halves has been used.

TDS1343

1010

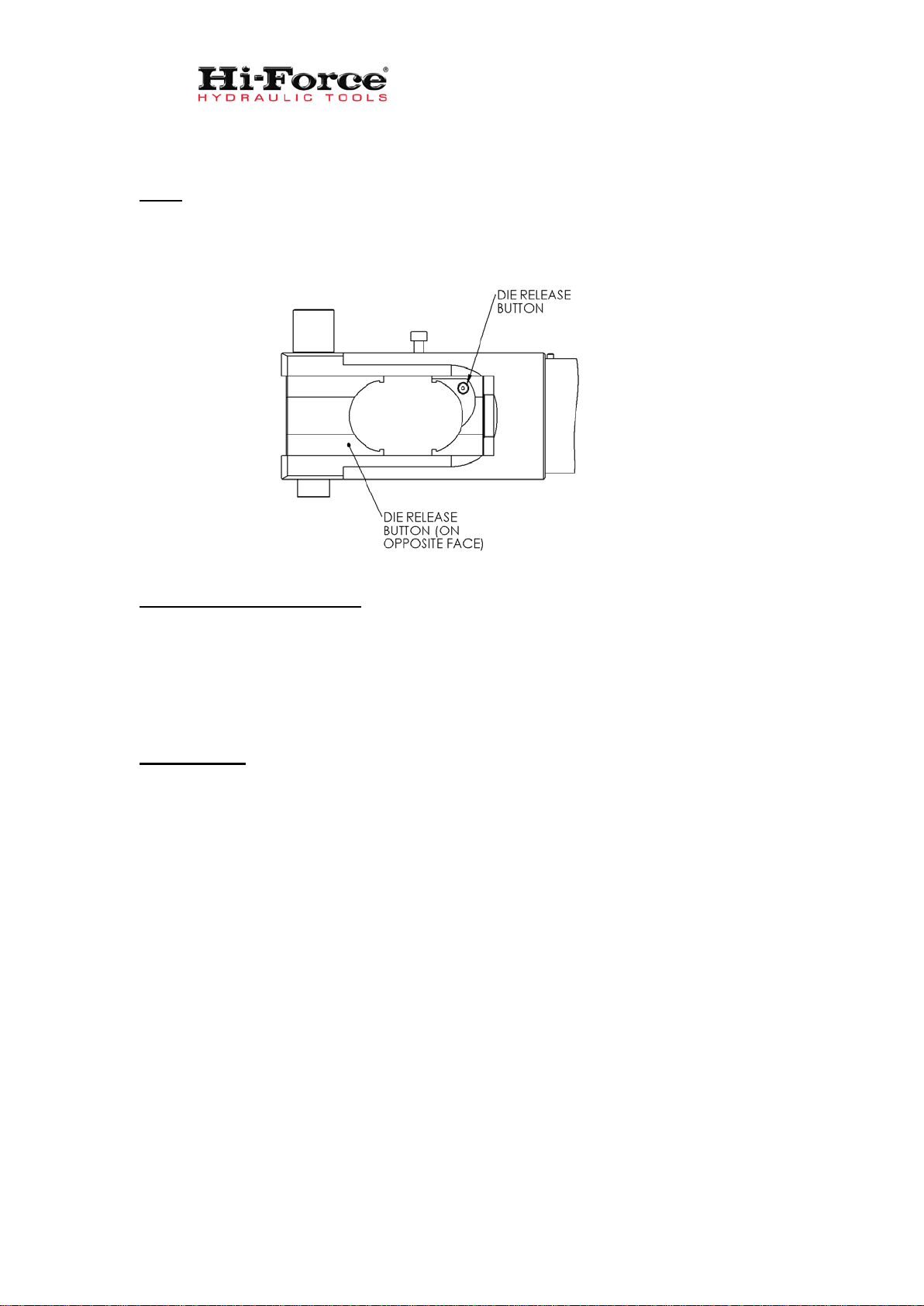

BC63

Press the die release buttons situated on opposite sides of the tool and slide each

die half into place ensuring that a matching pair is used.

FITTING A BATTERY PACK

To fit the battery, Remove the protective cover from the terminals (retain for future

use) push firmly into the housing on the base of the tool handle until it clicks into

place. To remove battery depress battery latch button and pull battery away from the

handle as shown in the diagrams. Charge the battery before use by means of

charger CU110, CU220 or CU1114. Spare battery packs are available from HI-

Force. Order part number BP144.

OPERATION.

Pressing the trigger will advance the piston and close the dies. Pressing the release

button will retract the piston and open the dies.

Correctly position the crimper over the connector to be crimped. Press and hold the

trigger and the dies will close and crimp the connector to the cable.

When the connector is fully crimped to the cable the dies will be fully closed and no

further movement takes place. The pressure relief valve on the tool will then operate

and the motor will be heard to speed up. Release the trigger. Press the release

button and the dies will retract ready for next use. Note, keep the release button

depressed until the dies have fully retracted.

The LED battery indicator gives the status of the battery and shows when it is

necessary to recharge the battery.

Red yellow and green light – battery condition good.

Red and yellow lights – battery running low

Red – Battery exhausted – Recharge required. Or replace with spare battery

TDS1343

1010

BATTERY CHARGING

Batteries should be charged using HI-Force charger supplied (or a HI-Force charging

accessory supplied separately)

Connect charger to the mains. Select the correct voltage (14.4 volt) by pressing the

“select voltage” button until the appropriate LED lights up. Insert battery and charge

for 2-3 hours.

To prolong battery life, discharge fully, using the “discharge” button. Do not carry out

this operation on a fully charged battery.

MAINTENANCE

•Keep your Hi-Force crimper set free from dirt, sand and grease at all times.

Any contamination will greatly reduce the Crimper effectiveness. Crimpers

come complete with either storage boxes or bags. Always store your Hi-Force

Crimper Set properly.

•Regularly check all fastenings to ensure they have not worked loose.

•Always fully retract the Crimper Head Piston between operations and while

stored. Leaving the Piston extended will weaken the Retraction Spring and

also leave the piston exposed to damage/ corrosion.

•For major overhauls/ repairs contact HI-Force or your nearest Hi-Force

service centre.

TDS1343

1010

•After storage for long periods the battery will need to be charged fully before

next use.

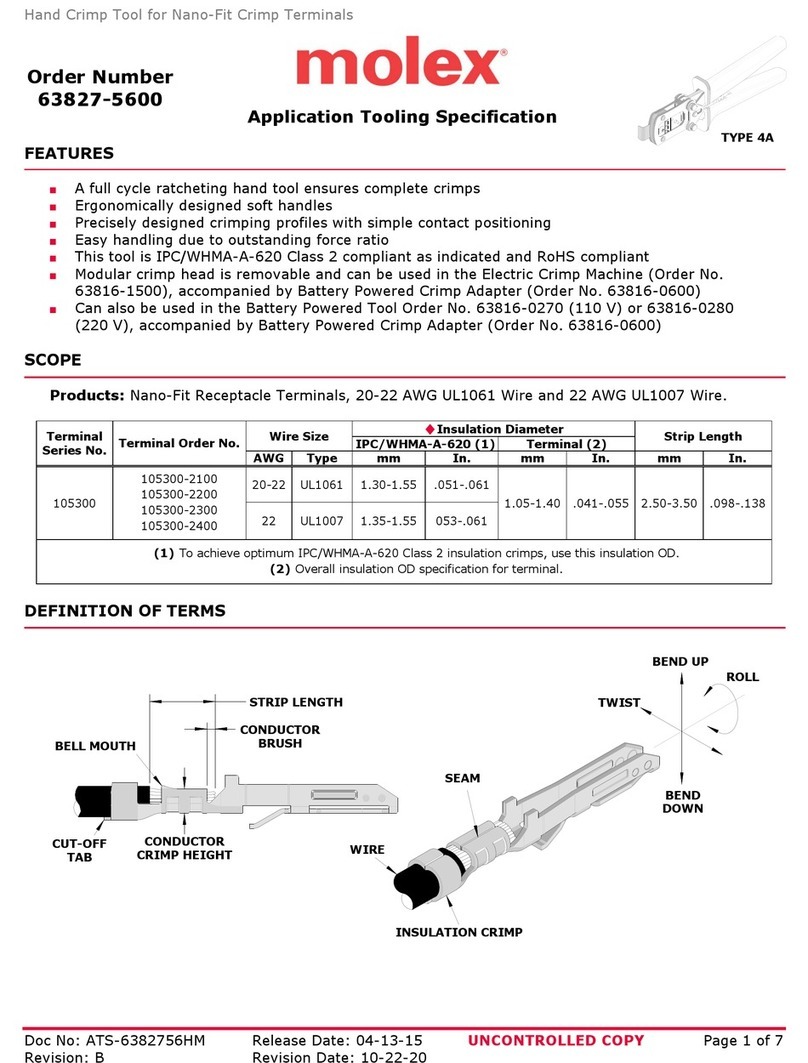

•Changing the oil: Remove the two screws on the rear of the unit (see pictures

below) Remove the oil filler cover. Pull out the reservoir plug. Tip out the old

oil and dispose of with respect for the environment. Re-fill with clean hydraulic

oil to ISO viscosity grade 15.

•If storing for long periods spray exposed metal parts with rust preventative

oil.

Oil filling procedure

This manual suits for next models

3

Table of contents