Hi-Tech Diamond 31-000 User manual

10" Slab Saw

EST. 1984

HI TECH

INSTRUCTION MANUAL

EST. 19 84

HI TECH

2

SAFETY INSTRUCTIONS

IMPORTANT! READ FIRST

For your own safety be sure to read, understand and follow all warnings, safety rules and

instructions in this instruction manual before using this machine. Failure to do so can

result in serious personal injury. This instruction manual is intended for the following

machine models: 31-000, 31-001, 31-004 and 31-006.

Save these instructions

SETUP

• Intended for indoor use only.

• Avoid dangerous environments. Do not use

this machine near gasoline or other flammable

liquids.

• Make sure machine is securely placed on a

sturdy, level surface with ample working area

and away from open electrical outlets.

• Check for damaged parts. Before use of this

machine, always check for any damaged parts

to determine that it will operate properly and

perform its intended function. Check for proper

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may aect its operation. A

part that is damaged must be properly replaced

through the manufacturer of this machine to

avoid risk of injury.

• Use only identical 10" Slab saw parts for

replacement parts. Use of any other parts not

originally intended for the 10" Slab saw machine

may create a hazard or cause product damage.

• Know your power tool. Read this instruction

manual carefully. Learn the correct applications

and limitations as well as specific warnings and

hazards related to this machine.

USAGE

• Always wear proper apparel. Do not wear any

loose clothing, gloves, neckties or jewelry that

can get caught in the machine’s moving parts.

Secure long hair with a rubber band or hair tie.

• Always wear proper eye protection to protect

you from any debris that may fly out while

sawing. We recommend wearing safety goggles or

safety glasses with side shields. Everyday glasses

3

SAFETY INSTRUCTIONS

are not safety glasses. If anyone is around the

machine while it’s in use, they must also wear

safety glasses.

• Keep work area well lit and clean. Make sure

your work area is not cluttered.

• Do not operate unattended. Adult supervision

is required at all times. Never leave the machine

running unattended.

• Do not operate this machine while under the

influence of drugs, alcohol or any medication.

• Never run saw blades dry. Saw blades are

designed to be used with a lubricant, such as oil

or water, and will be ruined immediately if used

dry. Always make sure you are using adequate

oil or water while sawing so that rock dust

doesn’t form. This dust contains chemicals that

can be hazardous to your lungs if inhaled and

is known to cause cancer, birth defects or other

reproductive harm. To reduce your exposure

to these chemicals, work in a well ventilated

area and wear a face or dust mask if the sawing

operation is dusty.

• Never attempt to cut curves with the saw

blade. Saw blades are designed to cut straight

lines only. Ignoring this warning may result in a

damaged saw blade and possible injury.

• Never cut more than one workpiece at a time.

• Some rocks contain poisonous elements.

Avoid sawing rocks that contain uranium,

mercury, lead, arsenic, etc. Make sure you know

the material you are sawing.

• Allow your trim saw to cool. By ignoring this

warning, the 10" Slab saw can overheat and deform

the saw housing. We recommend cutting on the 10"

Slab saw for 30 minutes on, then allow 30 minutes

o so the machine can cool down.

• Do not force the tool or attachment to do a job

it is not designed to do.

• Saw blades continue to spin aer turn o,

eventually slowing to a stop.

• Avoid awkward operations and hand

positions. Make sure you have good balance

while working on this machine. A sudden slip

could cause your hand to move into the disc.

• Always stay alert. You must be focused while

working on this machine. Stones can catch on the

saw blade and eject out of the sawing area.

MAINTENANCE

• Always disconnect from power before

servicing. Disconnect machine from power

source before making any adjustments and when

not in use.

• Do not abuse the power cord. Never carry

the machine by the cord or yank it to disconnect

from receptacle. Keep cord away from heat, oil

and sharp edges.

• Do not open the saw housing. There are no

user serviceable parts inside.

• Clean and dry machine aer use.

4

TABLE OF CONTENTS

SAFETY INSTRUCTIONS 2

WARRANTY INFORMATION 5

MACHINE DETAILS 6

OPERATING INSTRUCTIONS 7

CUTTING TIPS 9

MAINTENANCE 10

SAW BLADE ADJUSTMENTS 11

ACCESSORIES 12

FAQS 14

TROUBLESHOOTING 15

REGISTER YOUR PRODUCT

Register your Hi-Tech Diamond 10" Slab saw at

hitechdiamond.com/register to help facilitate

any warranty related requests. You can also

register your 10" Slab saw by completing and

mailing us the enclosed registration form.

Complimentary mailing envelope is included for

your convenience.

5

ONE-YEAR LIMITED WARRANTY

What does this warranty cover?

This warranty covers all structural and electrical

parts of the Hi-Tech Diamond 10" Slab saw such

as the motor, rectifier, etc.

What does this warranty not cover?

This warranty does not cover any consumable

goods such as saw blades, diamond abrasives

and/or polishing products. This warranty also

does not cover any abuse, misuse, intentional

damage, incorrect usage, failure to adequately

take care of the machine, improperly following

the instructions, servicing by someone other than

Hi-Tech Diamond personnel, the or loss and/or

any act of nature.

Who is covered under this warranty?

This warranty only covers the original purchaser

of the equipment. It is non-transferable.

What is the warranty period?

This warranty service is in force for one full year

from the date of your purchase. Please retain

the original invoice of your machine for proof

of warranty or register your 10" Slab saw.

Need our warranty service?

Contact us directly by phone at (630) 596-9909

or by email at sales@hitechdiamond.com and

we will assist you. You must prove that you

are under warranty by providing us with

the original invoice of your machine or by

registering your 10" Slab saw to receive our

warranty service.

This 10" Slab saw is warranted by the manufacturer to be free from

defect for the period of one full year from the date of purchase.

Extended warranty program

You’ve made a smart investment by purchasing

this Hi-Tech Diamond 10" Slab saw so protect

it by extending this manufacturer’s warranty

another 1-2 years! For purchase and more details,

visit hitechdiamond.com or call (630) 596-9909.

Important note: You have up to 45 days from the

purchase date of this Hi-Tech Diamond machine to

add this extended warranty.

6

MACHINE DETAILS

This image shows parts and accessories included with your 10" Slab saw machine.

1

2

3

4

5

1. 10" Slab saw base

unit (1/3 hp, 1,740 rpm

motor)

2. On/o power switch

3. Slab saw blade guard

4. Slab saw table

5. Drain plug

6. 10" thick notched

diamond saw blade

7. 10" thick sintered

diamond saw blade

8. 3/32" Allen wrench

(included with

instruction manual)

9. Slab saw spray

shield (included with

instruction manual)

6

8

9

7

7

7

OPERATING INSTRUCTIONS

1Carefully unpack the slab saw from the box

and remove all loose foam and accessories.

Set the packaging aside should you need it in the

future. Check to make sure all parts are present

on both the machine and in the instruction

manual. If you find any missing or damaged

parts, call us immediately at 1 (630) 596-9909

Place the slab saw on a table or flat surface in a

well lit location. The machine must sit level.

2

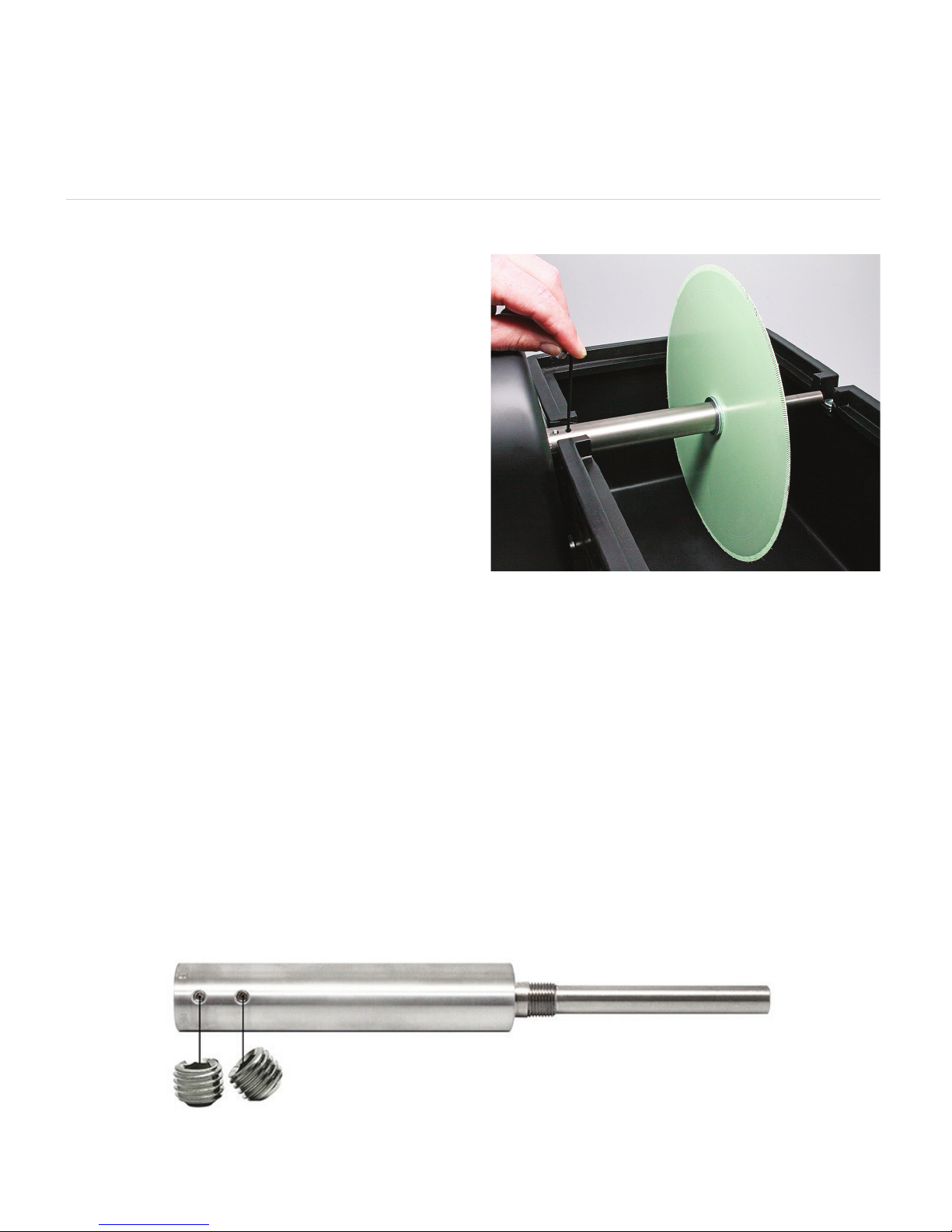

Remove the black saw table from the machine.

The saw table sits above the water reservoir.

Inside the water reservoir, there is a stainless

steel arbor (Fig. A). On the stainless steel arbor,

there are four washers, one nut and a brass bar

(Fig. A). To attach the saw blade, unscrew the

brass bar with a Phillips #2 screwdriver (not

included). Once loosened, slide the brass bar to

the right and completely remove from the arbor.

Next, manually remove the nut from the arbor,

turning counter-clockwise. Also remove two

washers, leaving the remaining two on the arbor.

At this point, the brass bar, nut and two washers

should be completely removed from the arbor.

Slide one of the two included saw blades onto the

arbor. Replace the two washers, knob (turning

clockwise to tighten) and brass bar. Screw the

brass bar back into the housing. Notes: Only use

10" saw blades with 5/8" arbor holes on this trim

saw machine. Do not over tighten the nut, it should

only be slightly tighter than finger tight.

Fig. A

Fig. B

Stainless steel arbor

Washer (4) Nut

Brass bar

3

The slab saw is designed to operate with oil or

water. What you use is your preference. Never

run the saw blade dry. Fill the reservoir with oil

or water until the bottom of the saw blade is 1/8"

deep (Fig. B). Do not overfill the reservoir or there

will be excessive oil or water spraying from the saw

blade while you cut.

8

OPERATING INSTRUCTIONS

7There should be a fine mist coming from your

saw blade while it spins. If there isn’t, pour

additional water over the blade until there is a

mist. Note: In use, always make sure the saw blade

is properly lubricated. Never run dry.

8Aer each use, turn o the machine, then

unplug your slab saw from its power source.

Drain the water reservoir be removing the drain

plug. Dry the machine and saw blade with paper

towels or a cloth. You may also spin dry the saw

blade by running it on the slab saw until it is

completely dry. Notes: Always dry your saw blade

aer each use to prevent rusting. Keep out of reach

of children.

4

Replace the saw table. Insert the black spray

shield (part #8) into the two slots located at

the front of the saw table (Fig. C). The spray shield

can be inserted in either direction.

5Before turning your slab saw on, manually

spin the saw blade towards you to make sure

the blade is not in contact with the saw table.

If there is contact, see page 11 for instructions

on how to position the saw blade for clearance.

Note: Some saw blades tend to wave side to side as

you spin them. They typically straighten out aer

turning the machine on.

6

Put on safety goggles (not included), then

turn on the machine by turning the power

switch to the on position. Note: Cutting speed

depends on the type of saw blade you are using.

Never exceed the saw blade’s maximum rpm.

Fig. C

9

CUTTING TIPS

1Before you make the first cut, line up your

rock or glass properly with the saw blade.

Lightly slide the material into the saw blade until

a groove forms, then push the material firmly

through the saw blade. Do not attempt to cut

curves with the trim saw, it is designed to cut

straight lines only. As you near the end of the

cut, reduce pressure to avoid a sudden “break-

through”. Reducing pressure also gives you a

cleaner cut. Note: Never force a saw blade, let the

blade do the work.

2

This slab saw is to be used for slabbing larger

material. The rocks and glass you are sawing

should never exceed more than 2/3 the size of

the visible cutting area of the saw blade. The

blade height of the 10" slab saw is 3-3/4". This

measurement is taken from the saw table to the

top of the saw blade (Fig. D).

3

The red saw blade included with your saw

has a sintered diamond rim that may require

“sharpening” or “dressing” over long, continuous

use. Simply put, the diamonds embedded into

the sintered matrix of the blade are wearing

down, and the metal sintered matrix surrounding

the diamonds are deforming over them. This

metal matrix needs to be abraded away to

expose the diamond surface. Dress and sharpen

sintered saw blades with aluminum oxide, silicon

carbide stone, dressing stick or brick. Run 3-4

times through the saw blade for a quick fix. Note:

Always abide by your saw blade instructions. Not

all saw blades should be sharpened or dressed, as

it can ruin the saw blade.

Fig. D

10

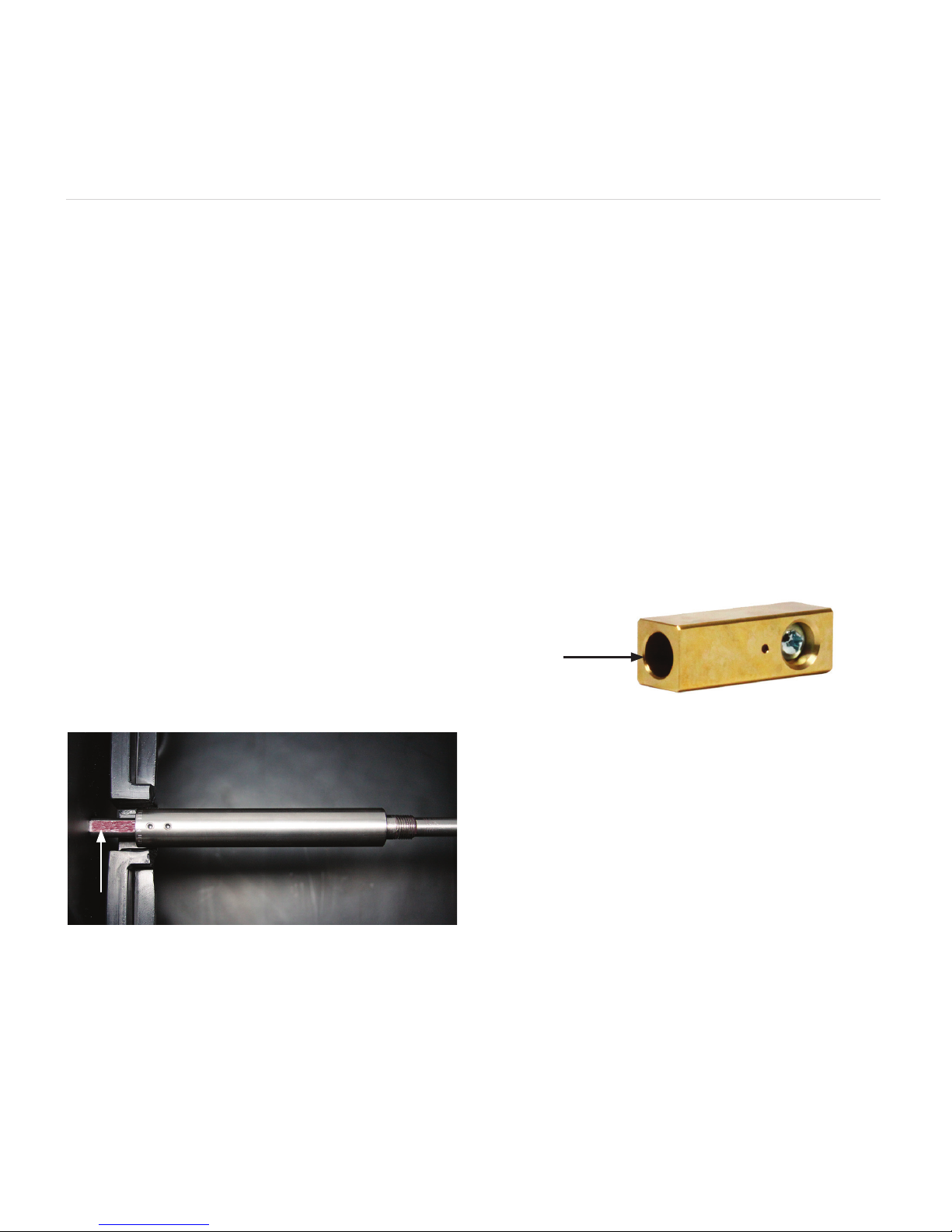

ARBOR & BRASS BAR

Greasing the inside of the brass bar where the

arbor fits into is required because the arbor and

brass bar are made of dierent materials. Over

time, they can seize together, making it impos-

sible to separate from each other. Insert lithium

grease or marine grease inside the brass bar

(Fig. E) every time you change the saw blade. We

suggest greasing this part more frequently than

when you oil (or grease) the arbor and motor sha

because these parts create more friction. Note:

Only use lithium grease or marine grease. Using

dierent oils may cause the arbor to lock-up into

the brass bar, making it impossible to remove.

CLEANING

Aer each use, drain the water reservoir by re-

moving the drain plug. Any used water must not

be disposed down a sink, as rock sediment can

harden like cement, closing o the drain. Dry the

machine and saw blade with paper towels or a

cloth. You may also spin dry the saw blade by run-

ning it on the trim saw until it is completely dry.

Notes: Always dry your saw blade aer each use to

prevent rusting. Keep out of reach of children.

MOTOR DETAILS

For questions regarding the motor, please refer to

the instructions provided by the motor manufac-

turer (included with this instruction manual).

MAINTENANCE

ARBOR & MOTOR SHAFT

Oiling (or greasing) the inside of the stainless

steel arbor and the motor sha is required

because the arbor and motor sha are made of

dierent materials. Over time, they can seize to-

gether, making it impossible to remove the arbor

from the sha. Every two months or so, remove

the arbor from the motor sha by loosening the

two set screws using the included Allen wrench,

turning counter-clockwise. Once loosened, slide

the arbor o the motor sha. Apply a few drops of

motor oil, way oil, lithium or water pump grease

inside the arbor where it fits onto the sha. Also

apply a few drops of oil or grease onto the motor

sha, rubbing to coat the sha lightly. Make sure

there is no excess oil so that oil doesn’t drip down

the motor sha and get into the motor. This will

cause an instant motor burn-out. Replace the

arbor onto the sha, using the Allen wrench to

tighten the two set screws.

Fig. E

Insert grease

here

Arbor

Motor sha with grease

11

SAW BLADE ADJUSTMENTS

BLADE POSITIONING &

CLEARANCE ADJUSTMENTS

Follow these four steps to adjust the position of

the saw arbor and saw blade so that the blade

does not make contact with the saw table. This

process may require trial and error.

1Remove the saw table, then remove the brass

bar. Loosen the two set screws located in

the saw arbor using the Allen wrench, turning

counter-clockwise (Fig. F). Once loosened, the

saw arbor can slide side to side.

2

Replace the saw table and position the saw

blade so that it is not in contact with the saw

table. Your blade should spin freely.

3

Remove the saw table to tighten the two

set screws using the Allen wrench, turning

clockwise, and replace the brass bar.

4Replace the saw table and manually rotate

the saw blade, making sure the blade is not

making contact with the saw table one last time

before turning the slab saw on.

Fig. F

NEED A REPLACEMENT SET SCREW?

The two set screws located in the saw arbor are available at your local hardware store. The size of the

set screws are 18-8 stainless steel, cup point, 10-32 thread, 3/16" long.

12

ACCESSORIES

Saw fence

The saw fence accessory aligns your material

for precise, accurate cuts. It securely fits onto

the 10" slab saw table and is adjustable to

accommodate the size of the material you are

cutting. If you have trouble cutting your stones

or glass in perfect, straight lines, then this

helpful accessory is for you.

Saw vise

The saw vise accessory secures your material

while you cut so you can be hands-free. It

secures onto the 10" slab saw housing and

is an adjustable guide that allows for precise

cuts. The carriage advances slowly to feed your

material evenly into the saw blade. Installation

is fast and easy. If you don’t want your hands

near the saw blade while you cut, then this

helpful accessory is for you.

The accessories featured on this page are compatible with the Hi-Tech Diamond 10" slab

saw machine. For a listing of all Hi-Tech Diamond products, visit hitechdiamond.com.

13

ACCESSORIES

The saw blades featured on this page are compatible with the Hi-Tech Diamond 10" slab

saw machine. For a listing of all Hi-Tech Diamond products, visit hitechdiamond.com.

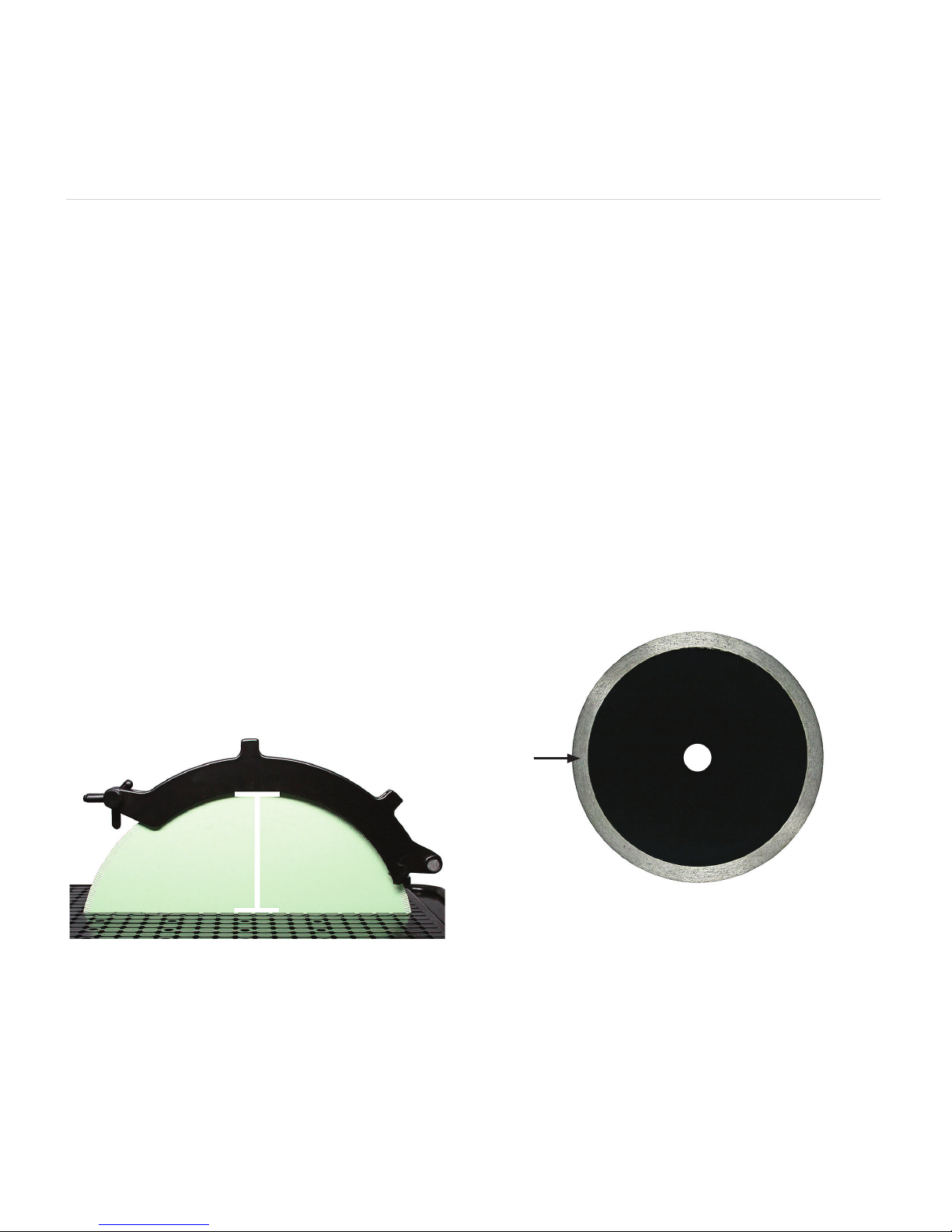

Thick notched diamond saw blades

Our green, thick notched diamond saw blades are

designed for cutting and slabbing material such

as agates, jades and geodes.

Available sizes for this trim saw

10" diameter X .031" core X .044" kerf

Note: This saw blade is included with this slab saw

machine.

Thin sintered diamond saw blades

Our red, thin sintered diamond saw blades are

designed for cutting and slabbing material such

as quartz, topaz, glass and fine agates.

Available sizes for this trim saw

10" diameter X .031" core X .038" kerf

Note: This saw blade is included with this slab saw

machine.

Thick sintered diamond saw blades

Our black, thick sintered diamond saw blades are

designed for cutting and slabbing material such

as agates, geodes, tile and ceramic.

Available sizes for this trim saw

10" diameter X .062" core X .078" kerf

14

Kerf

FAQS

What lubricants can I use with this

slab saw?

This slab saw machine is designed to be

operated with oil or water. We recommend

water because it is less messy to work with than

oil. If you are using water as a lubricant, we

suggest adding a coolant to reduce heat buildup

between the saw blade and stone. Some stones,

such as tourmaline for example, fracture with

too much heat. No one likes a fractured stone!

How large should the material be

that I’m cutting?

This slab saw is to be used for slabbing larger

material. The rocks and glass you are cutting

should never exceed more than 2/3 the size of

the visible cutting area of the saw blade. The

blade height of the 10" slab saw is 3-3/4". This

measurement is taken from the saw table to the

top of the saw blade (see below).

What size saw blades can I use on

this slab saw?

Only use 10" diameter saw blades on this slab saw

machine. Please note that only saw blades with

5/8" arbor holes fit onto the saw arbor.

In regards to saw blades, what do

“core” and “kerf” mean?

Core is the thickness of the inside of the saw

blade (the core), while kerf is the thickness of the

saw blade’s rim. When purchasing a saw blade,

the dimension of the kerf is what matters most

because the kerf determines how thick of a cut you

will get. FYI - the kerf gets thinner over time as the

saw blade wears away with continuous cutting.

What is the recommended RPM for

this slab saw?

The RPM speed depends on the type of saw blade

you are using and the saw blade’s maximum

RPM. Remember to never exceed the maximum

RPM of your saw blade.

Core

15

Why is there excessive oil or water

spraying from the saw blade?

If there is excessive oil or water spraying from

the saw blade while you’re cutting, this means

you have over-filled the water reservoir. Fill

the reservoir with water (or oil) so that just the

bottom of the saw blade is sitting in it, about 1/8"

deep (see below).

My saw blades keep rusting. How

can I prevent this?

Rusting occurs when the saw blade is not

properly dried o aer each use or if the saw

blade is le sitting in the saw machine’s water

reservoir when not in use. The best solution to

prevent rusting is to remove the saw blade from

your trim saw aer each use and dry with a paper

towel or cloth. Remember to always keep saw

blades away from children.

TROUBLESHOOTING

What happens if my saw machine

overheats?

The housing that the slab saw is made out of is

polyethylene, which can deform if the machine

is run too long, causing the machine to overheat.

To prevent this from happening, you must take time

to cool your machine. We suggest running your

slab saw for 30 minutes on, 30 minutes o to cool.

Alternatively, you can use an external fan to blow air

through the vent located on the side of the motor

housing. This will help prolong usage time.

I can’t remove the arbor from the

motor shaft.

If you can’t remove the arbor from the motor

sha using the Allen wrench, it is most likely

because the arbor and motor sha seized

together. This is a result from not oiling the inside

of the arbor according to the oiling instructions

on page 10. If it impossible to remove, please

contact Hi-Tech Diamond at 1 (630) 596-9909 and

one of our specialized technicians will help you

over the phone for correct removal.

Do you sell electrical spare

parts for my slab saw? Whom

do I contact if I need a repair or

replacement for my slab saw?

Due to the technical nature of our machines,

we do not oer electrical spare parts for you to

install yourself such as motors, speed controllers,

rectifiers, etc. Instead, we oer a repair

service that is done in-house by our qualified

technicians. For more information about our

repair service, visit hitechdiamond.com/repairs.

MANUFACTURED BY

Reentel International Inc.

808 Burr Oak Drive

Westmont, IL 60559

U.S.A.

PHONE

1 (630) 596-9909

EMAIL

WEBSITE

hitechdiamond.com

FACEBOOK

facebook.com/hitechdiamond

TWITTER

twitter.com/hitechdiamond

EST. 1984

HI TECH

Rev 12/28/17

EST. 19 84

HI TECH

This manual suits for next models

3

Table of contents